Professional Documents

Culture Documents

Erection & dismantling of scaffold structures

Erection & dismantling of scaffold structures

Uploaded by

Safety ExpertCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Erection & dismantling of scaffold structures

Erection & dismantling of scaffold structures

Uploaded by

Safety ExpertCopyright:

Available Formats

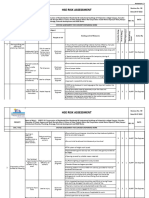

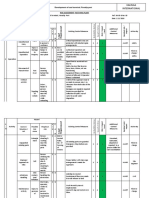

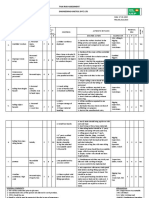

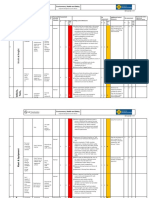

LARSEN & TOUBRO LIMITED

INFRASTRUCTURE INDEPENDENT COMPANY

Ref: IM-08-B Rev 00

EHS RISK ASSESSMENT

Name of the Project : WDFC, Phase-II, EMP-16 Business Unit: RBU

Activity considered : Erection and dismantling of scalffolds Date: 06-01-2017

Severity Rating

Hazard / Environment Aspect

Probability

Risk / Residual

Rating

Sl. Peo Additional Control

Activity Source / Existing Control Measures Impact Risk / Action By

No Possible ple Measures

Situation Level Impact

Outcome at

/ Act

risk

Wor Site

Material ker/ Engineer

1.maintaining good

handling Improper Slip –trip help

1. housekeeping 1 4 L L

(loading / Access and fall

er 2. proper material stacking

unloading)

Wor 1. Emergency lighting Site

ker/ arrangements must be Engineer

Poor

Slip –trip help provided. /

illuminati 1 4 L . L

and fall 2. proper supervision must be P&M

on er

ensured that workers do not

work in poor illumination.

Wor Site Engg

kers 1.All sharp edges must be /

Sharp Wear & tear checked Safety engg.

/ 1 3 L

edges 2 PPe’s like gloves and safety L

help boots must be used.

ers

WRULD’s Wor 1. Manual handling must be

Manual kers reduced.

/ 1 3 L L

handling 2. Weight must be lifted closer

Back pain / Site engg.

to the body.

help 3.Training must be imparted to /

ers workmen Safety engg

Wor Site

kers engineer

Uneven 1.Not exceeding the Loading

Transportation Toppling of /

2. ramp/ro / limit 1 3 L L

of material vehicle P&M

ad help 2.Adequate supervision

Engineer

ers

1.Collision Site

with object engineer

/

2. Collision

1.Competentcy and Fitness of Traffic

with man 1.Separate walkway for

the driver Engineer

Rash 3. Rash Wor pedestrian and vehicle

2. Driving within the speed limit /

driving driving kers movement

3. PUC certificate and NOC of SHE

/ / 2 3 H 2.Bank’s men or helper L

4.Fall of TM the vehicle Engineer

over Help while reversing

in the pit 4. Driver having valid driving

speeding ers 3.Use of Reverse horn

5. Soil license

while reversing

Collapse 5 Reverse horns

1.Toppling Site

Wor

Preparing the of scaffold engineer

kers 1.Soil testing is done prior to

base and Loose Using scheme drawing for /

3. 2.settlement / erection of scaffold 1 4 M L

ground for soil erecting scaffolds. Safety

of scaffold Help 2.Use of base plate is done

scaffold Engineer

ers

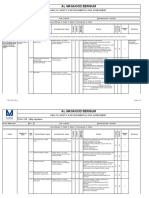

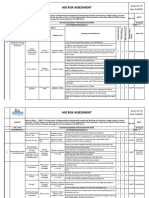

1.loose 1. Engaging competent 1. PTW must be Site

material at workmen only. strictly followed engineer

the edge 2. Training and pep talks 2. Area must be /

Wor 3. Strict supervision barricaded. Safety

2. slip of

Erecting and kers 4. Check on weather 3. Use of toe board Engineer

Material material

4. dismantling of / conditions and wind 1 4 at leading edges L

handling from the M

scaffold Help speed. 4. Securing all the

hand of the

ers 5. Using proper PPE’s hand tools by

worker.

Safety harness, gloves , tying with line

3.slip of safety shoes yards

hand tool 6. Good illumination

7. No worker shall be

allowed to work under

the scaffold while

erection and

dismantling is in

progress.

1.Use of safety harness while Site

working at height engineer

1.Fall of Wor

2. Use of toe board at leading /

material kers

edges Safety

Slip trip / 1 3 L L

2, fall of 3.Securing all the hand tools by Engineer

Help

workmen tying with line yards

ers

___________________

PM / CM / Section In-charge EHSO

You might also like

- PM Schedule Interior Fit Out Works For DIB Baniyas Branch Abu Dhabi UAE PDFDocument5 pagesPM Schedule Interior Fit Out Works For DIB Baniyas Branch Abu Dhabi UAE PDFXozan100% (1)

- ShutteringDocument2 pagesShutteringRohit Singh92% (13)

- 002 11KV Switchgear JHA Work SheetDocument4 pages002 11KV Switchgear JHA Work SheetWaseem Ahmad100% (2)

- Risk Assessment For Installation of Automatic Revolving Door InstallationDocument7 pagesRisk Assessment For Installation of Automatic Revolving Door InstallationTECHCOM100% (1)

- shuttering of column,beam, slabDocument3 pagesshuttering of column,beam, slabSafety ExpertNo ratings yet

- shuttering of foundationDocument3 pagesshuttering of foundationSafety ExpertNo ratings yet

- Rebar cuttingDocument3 pagesRebar cuttingSafety ExpertNo ratings yet

- Placing of concreteDocument2 pagesPlacing of concreteSafety ExpertNo ratings yet

- IM-08-B EHS Risk Assessment DC WorkDocument4 pagesIM-08-B EHS Risk Assessment DC WorkAndrés PacompíaNo ratings yet

- IM-08-B EHS Risk Assessment AC WorkDocument5 pagesIM-08-B EHS Risk Assessment AC WorkAndrés PacompíaNo ratings yet

- OFFICE RISK ASSESSMENTDocument7 pagesOFFICE RISK ASSESSMENTSafety ExpertNo ratings yet

- Risk Assessment For Concrete Repair WorkDocument3 pagesRisk Assessment For Concrete Repair Workkeshav chaturvediNo ratings yet

- Task /activity: Installation of Abseil HooksDocument10 pagesTask /activity: Installation of Abseil HooksfrancisbautistaNo ratings yet

- Civil EHS Risk Assessment - 1. ExcavationDocument2 pagesCivil EHS Risk Assessment - 1. Excavationshamshu123No ratings yet

- 2 RA - Storm Water Drainage Works (Revised)Document19 pages2 RA - Storm Water Drainage Works (Revised)Muhammad Shahid Iqbal100% (3)

- AMB 172-016 LiftingDocument3 pagesAMB 172-016 LiftingRues AgNo ratings yet

- HEMP/JHA/RA/HITRA - Pneumatic TestingDocument7 pagesHEMP/JHA/RA/HITRA - Pneumatic TestingSidhanath SinghNo ratings yet

- RA Cable PullingDocument3 pagesRA Cable PullingRandy Adisyah0% (1)

- Batching Plant ActivityDocument5 pagesBatching Plant ActivityPrabu LingamNo ratings yet

- Hira For DemolitionDocument3 pagesHira For DemolitionMokka SamaiyalNo ratings yet

- Risk Assessment For Excavation & BackfillingDocument4 pagesRisk Assessment For Excavation & Backfillingkeshav chaturvediNo ratings yet

- IM-08-B EHS Risk Assessment Welding & Gas CuttingDocument4 pagesIM-08-B EHS Risk Assessment Welding & Gas CuttingGyanendra Narayan Nayak100% (3)

- RISK/IMPACT ASSESSMENT (To Be Used Both Occupation Health, Safety & Environment)Document1 pageRISK/IMPACT ASSESSMENT (To Be Used Both Occupation Health, Safety & Environment)Sijo Rajan100% (1)

- Risk Assesment - MobilisationDocument7 pagesRisk Assesment - Mobilisationشاز إياسNo ratings yet

- RA - A - 86 - Usage - of - MEWP (Boom Lift) @micronDocument3 pagesRA - A - 86 - Usage - of - MEWP (Boom Lift) @micronKalesha Vali ShaikNo ratings yet

- Risk AssessmentDocument13 pagesRisk Assessmentmohsin.meizaNo ratings yet

- Transition Duck Risk AnalysisDocument3 pagesTransition Duck Risk AnalysisAnıl AKÇANo ratings yet

- 30 - Turfing WorksDocument1 page30 - Turfing WorksRafee Pie100% (1)

- IM-08-B HSE Wall Grinding For Finishing WorkDocument2 pagesIM-08-B HSE Wall Grinding For Finishing WorkAnsari HarisNo ratings yet

- HIRA - CONSOLIDATED of EPCDocument29 pagesHIRA - CONSOLIDATED of EPCMd Nurul Islam100% (1)

- JRA 10-005 Insttalation of New Dodo GateDocument9 pagesJRA 10-005 Insttalation of New Dodo GateAijaz AhmedNo ratings yet

- IM-08-B EHS Risk Assessment of Stores & StackyardDocument3 pagesIM-08-B EHS Risk Assessment of Stores & StackyardGyanendra Narayan Nayak100% (1)

- JSA Gypsom WorkDocument5 pagesJSA Gypsom WorksoubhagyaNo ratings yet

- Risk Assessment For Installation of Light FittingsDocument11 pagesRisk Assessment For Installation of Light FittingsHerdhiska Pradhiarta AjiprayogaNo ratings yet

- TRA of Ladder & PlatformDocument2 pagesTRA of Ladder & PlatformASIF MUZAFFARNo ratings yet

- RA Underground Fire Pipe Installation Work R02Document15 pagesRA Underground Fire Pipe Installation Work R02vinayNo ratings yet

- Jsa-07 For Acb Breaker PMDocument2 pagesJsa-07 For Acb Breaker PMNavneetNo ratings yet

- Risk Assessment Form: Contracting W.L.LDocument7 pagesRisk Assessment Form: Contracting W.L.Lbelhareth seifeddineNo ratings yet

- CMI-TRCP (04.25) T.C MachineDocument2 pagesCMI-TRCP (04.25) T.C Machine김순혁No ratings yet

- Safety JSA Workin at HeightDocument1 pageSafety JSA Workin at HeightBHARAT TALPADANo ratings yet

- CMI-TRCP (04.28) T.C MachineDocument2 pagesCMI-TRCP (04.28) T.C Machine김순혁No ratings yet

- HIRA - StoresDocument3 pagesHIRA - StoresMMRDACA07 SAFETY100% (1)

- 1 RA Water Works (Revised)Document21 pages1 RA Water Works (Revised)Muhammad Shahid Iqbal0% (1)

- HSM 3 HIRA - RISK Assessment.Document7 pagesHSM 3 HIRA - RISK Assessment.Vikash Kumar RayNo ratings yet

- AVN-MAR-PIP-RA-003 - R0 - Installation of Drain Line Below HelipadDocument3 pagesAVN-MAR-PIP-RA-003 - R0 - Installation of Drain Line Below HelipadtaufikNo ratings yet

- Concrete Pouring (Top Slab & Wall) Risk Assessment (0075) - Rev-02Document19 pagesConcrete Pouring (Top Slab & Wall) Risk Assessment (0075) - Rev-02Muhammad OsamaNo ratings yet

- Demolisation AhaDocument3 pagesDemolisation AhaLawrence adeleke OmisakinNo ratings yet

- Al Qooz Contracting LLC: Hazard Identification and Risk AssesmentDocument8 pagesAl Qooz Contracting LLC: Hazard Identification and Risk Assesmentشاز إياس100% (1)

- RA of Chlorination & Disinfection of Domestic Water Supply SystemDocument12 pagesRA of Chlorination & Disinfection of Domestic Water Supply SystemAhmad Omar50% (2)

- Risk Assessment Ubderground Electric Power SupplyDocument4 pagesRisk Assessment Ubderground Electric Power SupplySameer Abdul RaufNo ratings yet

- Risk Assessment_Installation of Platform at FM1Document14 pagesRisk Assessment_Installation of Platform at FM1Fred Vincent BaldomeroNo ratings yet

- RA for Lifting & Installation of Ladder and PlatformDocument2 pagesRA for Lifting & Installation of Ladder and Platformferoz khanNo ratings yet

- Above Ground Chilled Water Pipe InsulationDocument3 pagesAbove Ground Chilled Water Pipe InsulationLawrence adeleke OmisakinNo ratings yet

- 1 (Hazard Analysis) For Earth Works Gurun Jsa G 001 Rev 002Document3 pages1 (Hazard Analysis) For Earth Works Gurun Jsa G 001 Rev 002nurul sarahNo ratings yet

- 005-JSA X-Ray & Gamma Ray RadiographyDocument7 pages005-JSA X-Ray & Gamma Ray RadiographyMoaatazz NouisriNo ratings yet

- JRA No 11-193 Hydro Testing On 28 Bar Pressure For (WP) Water Produce Lines at FEC AreaDocument8 pagesJRA No 11-193 Hydro Testing On 28 Bar Pressure For (WP) Water Produce Lines at FEC AreaAijaz AhmedNo ratings yet

- JRA 10-001 Devlopment of Barrow AreaDocument5 pagesJRA 10-001 Devlopment of Barrow AreaAijaz AhmedNo ratings yet

- Punjab General Industries Private Limited: Hazard Identification and Risk Assessment (HIRA)Document9 pagesPunjab General Industries Private Limited: Hazard Identification and Risk Assessment (HIRA)Rohit VishwakarmaNo ratings yet

- Risk Assesmennt For OutfallDocument9 pagesRisk Assesmennt For Outfallchinmay jagdeepNo ratings yet

- 140110 TSPR IS SpecificationsDocument5 pages140110 TSPR IS SpecificationsSafety ExpertNo ratings yet

- shuttering of foundationDocument3 pagesshuttering of foundationSafety ExpertNo ratings yet

- Rebar cuttingDocument3 pagesRebar cuttingSafety ExpertNo ratings yet

- Safety measures during dense fog conditionsDocument1 pageSafety measures during dense fog conditionsSafety ExpertNo ratings yet

- SENEPOL1Document36 pagesSENEPOL1JuanNo ratings yet

- Bajaj Electricals Limited Vs Metals & Allied Products and Anr. On 4 August, 1987Document8 pagesBajaj Electricals Limited Vs Metals & Allied Products and Anr. On 4 August, 1987RajesureshNo ratings yet

- D Claves - Examen A2Document1 pageD Claves - Examen A2Anyelin JaimesNo ratings yet

- B.SC Fashion Design R2018 C&SDocument85 pagesB.SC Fashion Design R2018 C&SvivekNo ratings yet

- Discourse Vs - TextDocument11 pagesDiscourse Vs - TextImmo Eagle JuniØrNo ratings yet

- Aeotec DSD37-ZWUS by Aeon Labs - Installation ManualDocument2 pagesAeotec DSD37-ZWUS by Aeon Labs - Installation ManualAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- Haytham Abd Allah Ezbawy ResumeDocument3 pagesHaytham Abd Allah Ezbawy Resumehayssam ezbawyNo ratings yet

- Jezza Mariz A. Alo Diane C. Dapitanon Atty. Debbie Love S. Pudpud Criselda Z. RamosDocument1 pageJezza Mariz A. Alo Diane C. Dapitanon Atty. Debbie Love S. Pudpud Criselda Z. RamosLeana ValenciaNo ratings yet

- Wild Amazon Cradle of Life Film TestDocument2 pagesWild Amazon Cradle of Life Film TestQuratulain MustafaNo ratings yet

- Lesson Material G2 - What Does He Do After School (REVISI)Document8 pagesLesson Material G2 - What Does He Do After School (REVISI)ivan stefanusNo ratings yet

- JCDecaux Gen Z IRL Opportunity ReportDocument28 pagesJCDecaux Gen Z IRL Opportunity ReportBlake Samson-ReißkyNo ratings yet

- Indian Income Tax Return Acknowledgement: Name of Premises/Building/VillageDocument1 pageIndian Income Tax Return Acknowledgement: Name of Premises/Building/Villagehealth with wealthNo ratings yet

- Labor Law 1996-2006 Bar Exams Q and Suggested AnswersDocument129 pagesLabor Law 1996-2006 Bar Exams Q and Suggested Answersmanol_salaNo ratings yet

- November 2019 (v3) QP - Paper 4 CIE Chemistry IGCSEDocument16 pagesNovember 2019 (v3) QP - Paper 4 CIE Chemistry IGCSEJeevith Soumya SuhasNo ratings yet

- Full Papers: Modular Simulation of Fluidized Bed ReactorsDocument7 pagesFull Papers: Modular Simulation of Fluidized Bed Reactorsmohsen ranjbarNo ratings yet

- Iron Powder MsdsDocument4 pagesIron Powder MsdsarzkpNo ratings yet

- Lecture 11 GearDocument96 pagesLecture 11 GearMohd Naim Bin KaramaNo ratings yet

- Bulacan MTC: Notifiable Diseases Law Can't Be Used Against People Without Quarantine Pass, ButDocument7 pagesBulacan MTC: Notifiable Diseases Law Can't Be Used Against People Without Quarantine Pass, ButYNNA DERAYNo ratings yet

- Physics Investigatory ProjectDocument18 pagesPhysics Investigatory ProjectMoghanNo ratings yet

- Specification For BMW POLYBAGSDocument3 pagesSpecification For BMW POLYBAGSDarpan BhattNo ratings yet

- CESPL - Profile1Document93 pagesCESPL - Profile1Satvinder Deep SinghNo ratings yet

- The Power of Faith Confession & WorshipDocument38 pagesThe Power of Faith Confession & WorshipLarryDelaCruz100% (1)

- Plaaf Trainng PhilosophyDocument46 pagesPlaaf Trainng Philosophyneetin vatsya100% (1)

- Trinity Core Custom ScriptDocument2 pagesTrinity Core Custom ScriptvalakiakarkiNo ratings yet

- Poker ThesisDocument8 pagesPoker Thesisfjn3d3mc100% (3)

- Case Study of Railway Bridge Over Chakri River in PathankotDocument6 pagesCase Study of Railway Bridge Over Chakri River in Pathankotsaurav rajNo ratings yet

- Simple Past Full ExercisesDocument6 pagesSimple Past Full Exercisespablo1130No ratings yet

- LCM105 LCM115 PDFDocument3 pagesLCM105 LCM115 PDFCABean1No ratings yet

- Accelerated MotionDocument205 pagesAccelerated MotionphysicspalanichamyNo ratings yet