Professional Documents

Culture Documents

SPC-332530-U

SPC-332530-U

Uploaded by

kkkhattabbbCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SPC-332530-U

SPC-332530-U

Uploaded by

kkkhattabbbCopyright:

Available Formats

COSMOS – E Engineers & Consultants

SIEMENS PS TOOLING PROJECT

AIN SOKHNA, EGYPT

SECTION 332530

SANITARY SEWERAGE

PART 1 - GENERAL

1.1 RELATED DOCUMENTS

A. Drawings and general provisions of the Contract, including Conditions of Contract and

Division 1 Specification Sections, apply to this Section.

1.2 SUMMARY

A. This Section includes sanitary sewerage outside the building.

B. Related Sections include the following:

1. Division 31 Section "Earthwork" for excavating, trenching and backfilling.

2. Division 3 Section "Cast-in-Place Concrete" for concrete structures.

1.3 DEFINITIONS

A. The following are abbreviations for materials:

1. UPVC: Un-plasticized polyvinyl chloride plastic.

2. GRP: Glass-Fiber Reinforced Plastic.

3. VC: Vitrified clay.

1.4 PERFORMANCE REQUIREMENTS

A. Gravity-Flow, Nonpressure-Piping Pressure Ratings: At least equal to system test pressure.

1.5 SUBMITTALS

A. Product Data: Submit manufacturer's technical product data and installation instructions

for system materials and products.

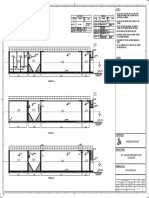

B. Include plans, elevations, details, and attachments for the following:

1. Sewage pipe network, including pipe diameters and gradients

2. Manholes and other structures, including invert levels, frames, covers, and grates.

C. Coordination Drawings: Show manholes and other structures, pipe sizes, locations, and

elevations. Include details of underground structures and connections. Show other piping

SANITARY SEWERAGE 332530 - Page 1 of 12

COSMOS – E Engineers & Consultants

SIEMENS PS TOOLING PROJECT

AIN SOKHNA, EGYPT

in same trench and clearances from sewerage system piping. Indicate interface and spatial

relationship between piping and proximate structures.

D. Coordination Profile Drawings: Show system piping in elevation. Draw profiles at

horizontal scale of not less than 1:500 and vertical scale of not less than 1:50. Indicate

underground structures and pipe. Show types, sizes, materials, and elevations of other

utilities crossing system piping.

E. As-Built Drawings: At project close-out, submit record drawings of installed pipework and

products, in accordance with requirements of the Specification, Division 1.

F. Maintenance Data: Submit maintenance data and parts lists for system materials and

products. Include this data, product data, Shop Drawings, and submit drawings in

maintenance manual; in accordance with requirements of the Specification, Division 1.

G. Certificate of Compliance.

H. Field Test Reports: Indicate and interpret test results for compliance with performance

requirements.

1.6 DELIVERY, STORAGE, AND HANDLING

A. Do not store plastic structures, pipe, and fittings in direct sunlight.

B. Protect pipe, pipe fittings, and seals from dirt and damage.

C. Handle pipes, precast concrete manholes and other structures according to the

manufacturer's written instructions.

D. Manufacturer's recommendations on handling, repairing, laying, jointing, anchoring,

cutting and other works for pipes and fittings are to be strictly followed.

1.7 PROJECT CONDITIONS

A. Site Information: Perform site survey, research public utility records, and verify existing

utility locations.

B. Locate existing structures and piping, if any, to be closed and abandoned.

C. Existing Utilities: Do not interrupt or interfere with utilities serving facilities on the Project

site or on adjoining property unless permitted by the Engineer under the following

conditions and then only after arranging to provide temporary utility services according to

requirements indicated or directed:

1. Notify the Engineer not less than 72 hours' in advance of proposed utility

interruptions.

2. Do not proceed with utility interruptions without the Engineer's written permission.

1.8 QUALITY ASSURANCE TESTING

SANITARY SEWERAGE 332530 - Page 2 of 12

COSMOS – E Engineers & Consultants

SIEMENS PS TOOLING PROJECT

AIN SOKHNA, EGYPT

A. Testing on GRP Pipes: The following tests shall be carried out on manufactured pipes.

Details of the testing program to be submitted to the Engineer for review and approval

prior to commencement of pipe manufacture. The manufacturer quality control scheme

shall be to BS 5750 or ISO 9002. Guidance on quality control and sampling shall be BS 5480

Appendix Q. At least the following tests shall be carried out and reported for approval:

1. Longitudinal strength to ASTM D3262.

2. Hydraulic test to ASTM D 3517.

3. Stiffness to ASTM Method D 2412 or BS 5480.

4. Wall thickness to BS 5480.

5. Diameter to BS 5480.

6. Hardness to ASTM 2583.

7. Loss of ignition to ASTM D 2584.

8. Hoop tensile to ASTM D 3517.

SANITARY SEWERAGE 332530 - Page 3 of 12

COSMOS – E Engineers & Consultants

SIEMENS PS TOOLING PROJECT

AIN SOKHNA, EGYPT

PART 2 - PRODUCTS

2.1 PIPING MATERIALS

A. Refer to Part 3 article for piping applications.

2.2 PIPES AND FITTINGS

A. UPVC Sewer Pipe and Fittings:

1. PIPE: to BS 4460 and BS 54481 or DIN 19534 Parts 1 and 2, with standard dimension

ratio (SDR) of 41. Pipes of larger diameters than those included in BS 4660 and BS

5481 are to be DIN 19534 Parts 1 and 2.

2. UPVC FITTINGS: to be injection moulded and to same standard as UPVC pipes.

3. JOINTS: to be sealing ring type.

4. SOLVENT CEMENT: to BS 4346 Part 3.

B. GRP Sewer Pipes and Fittings:

1. Pipes and fittings to BS 5480, or AWWA C950-88.

2. Pipe and fittings shall include a corrosion resistant liner, a structural wall and a resin

rich exterior surface.

3. The liner shall have a nominal thickness of 1.0 mm. The liner surface shall be

reinforced with "C" glass. The remainder of the liner thickness shall be reinforced

with an acid resistant chopper "E" glass strand or mat.

4. The pipe structural wall shall consist of glass reinforcement, and fine silica sand, all

impregnated with resin. The fine silica sand shall be added to the structural layer to

achieve the design thickness for the required stiffness specified such that the overall

hoop flexural modulus (E) for pipe is not less than 24 GN/M2. Silica sand and filler

content shall not exceed 50%.

5. Pipes shall be provided with a resin rich outer layer reinforced with one layer of "C"

glass veil. The exterior layer shall have a minimum thickness of 0.2 mm. The resin

layer shall be rich and reinforced with one layer of C glass.

6. The resin used for the corrosion resistant liner of the pipe and fittings shall be high

grade polyester resin (isophthalic or better) type. For the structural wall and exterior

layer of the pipe a high grade isophthalic polyester resin shall be used. No dark

pigments shall be used in the pipe or fittings.

7. All glass reinforcements except for the inner and outer surfaces of the pipe and

fittings shall be of the "E" type. Surface reinforcement shall be of the "C" glass type.

8. Pipes shall be designed for a life of not less than 50 years. Contractor shall submit

calculations for initial and long term deflection with Truck loads, Buckling, Vacuum,

Pressure Class, and Strain in accordance with Appendix "A" of AWWA, C-950-88 or

equivalent. The maximum calculated long term deflection should not exceed 3%.

Copies of the design calculations shall be submitted to the Engineer for approval.

SANITARY SEWERAGE 332530 - Page 4 of 12

COSMOS – E Engineers & Consultants

SIEMENS PS TOOLING PROJECT

AIN SOKHNA, EGYPT

a. Stiffness: Minimum 10,000 N/m2. Suitability of stiffness shall be verified for

the various trench and pipe laying conditions and as recommended by the

manufacturer.

b. Longitudinal Strength: To BS 5480 table 2 or ASTM D 3262 - 88 table 7.

c. Hoop Strength: To ASTM D 3517 Table 8.

d. Strain Corrosion Resistance: Tests are to be carried out as per ASTM D 3681 or

BS 5480 strain corrosion value at 50 years to equal or exceed 0.7%.

e. Markings: To BS 5480 clause 11.

f. Joints: GRP double socket couplings with rubber rings to BS EN 681: Parts 1

and 2, BS EN 682 and BS 7874. Allowable angular deflection to BS 5480 Table

3.

C. Vitrified Clay pipes shall conform to the requirements specified in:

1. PIPE AND FITTINGS: to BS 65 glazed on inside with ceramic or salt glaze of extra

strength.

2. JOINTS: to be of flexible sleeve type.

2.3 MANHOLES AND CHAMBERS

A. Normal-Traffic Precast Concrete Manholes: ASTM C 478M, precast, reinforced concrete, of

depth indicated, with provision for rubber gasketed joints.

1. Diameter: 1200 mm minimum, unless otherwise indicated.

2. Ballast: Increase thickness of precast concrete sections or add concrete to base

section, as required to prevent flotation.

3. Base Section: 150 mm minimum thickness for floor slab and 100-mm minimum

thickness for walls and base riser section, and having separate base slab or base

section with integral floor.

4. Riser Sections: 100 mm minimum thickness, and lengths to provide depth indicated.

5. Top Section: Eccentric-cone type. Top of cone of size that matches grade rings.

6. Gaskets: ASTM C 443M rubber.

7. Grade Rings: Include two or three brick or reinforced-concrete rings, of 150 to 225

mm total thickness, that match 610 mm diameter frame and cover.

8. Pipe Connectors: ASTM C 923M, resilient, of size required, for each pipe connecting

to base section.

B. Heavy-Traffic Precast Concrete Manholes: ASTM C 913; designed according to

ASTM C 890 for A-16, heavy-traffic, structural loading; of depth, shape, and dimensions

indicated, with provision for rubber gasketed joints.

1. Ballast: Increase thickness of one or more precast concrete sections or add concrete

to structure, as required to prevent flotation.

2. Gaskets: Rubber.

3. Grade Rings: Include two or three brick or reinforced-concrete rings, of 150 to 225

mm total thickness, that match 610 mm diameter frame and cover.

4. Pipe Connectors: ASTM C 923M, resilient, of size required, for each pipe connecting

to base section.

SANITARY SEWERAGE 332530 - Page 5 of 12

COSMOS – E Engineers & Consultants

SIEMENS PS TOOLING PROJECT

AIN SOKHNA, EGYPT

C. Cast-in-Place Concrete chambers: Construct of reinforced-concrete bottom, walls, and top;

designed according to ASTM C 890 for A-16, heavy-traffic, structural loading; of depth,

shape, dimensions, and appurtenances indicated.

1. Ballast: Increase thickness of concrete, as required to prevent flotation.

2. Grade Rings: Include two or three brick or reinforced-concrete rings, of 150 to 225

mm total thickness, that match 610 mm diameter frame and cover.

D. Manhole and chamber Frames and Covers: Ductile iron to BS EN 124 or equivalent, epoxy

coated, ventilated top. Suitable lifting device for covers to be provided at a rate of one for

every 10 covers. Frames to be bolted to manhole to ensure proper fixity. Wording on

cover is to be as approved on Site. Types to be as follows:

1. For roadways: Class D400 heavy duty non-rock type for wheel loads up to 11.5 tons.

Minimum test load 400KN.

2. For sidewalks: Class B125, light duty. Minimum test load 125 KN.

3. Size: As indicated on the Drawings.

E. Manhole Cover Inserts: Manufactured, GRP form, of size to fit between manhole frame

and cover and designed to prevent stormwater inflow. Include handle for removal and

gasket for gastight sealing.

F. Step Irons shall be to BS 1247: PT1

2.4 CONCRETE

A. General: Reinforced cast-in-place concrete according to Division 3 Section "Cast-in-Place

Concrete", and the following:

1. Cement: ASTM C 150.

2. Design Mix: 30 MPa minimum, with 0.45 maximum water-cementitious materials

ratio.

3. Channels and Benches: Field formed from concrete 30 MPa minimum, with 0.45

maximum water-cementitious materials ratio. Include channels and benches in

manholes.

2.5 PROTECTIVE COATINGS

A. Internal faces of manholes and chambers shall be coated with four coats of coal tar epoxy

paint, 70% epoxy and 30% coal tar. The coating shall be applied by brush in accordance

with manufacturer's instructions. Minimum thickness shall be 1000 microns.

B. Waterproofing for external surfaces:

1. Structures above groundwater level: Waterproofing for external surfaces shall be

bituminous damp-proofing as specified in Division 7.

2. Structures below groundwater level: Waterproofing for external surfaces shall be

app-modified bituminous sheet waterproofing as specified in Division 7.

SANITARY SEWERAGE 332530 - Page 6 of 12

COSMOS – E Engineers & Consultants

SIEMENS PS TOOLING PROJECT

AIN SOKHNA, EGYPT

C. Backwater Valves

1. PVC Backwater Valves: Similar to ASME A112.14.1, horizontal type; with PVC body,

PVC removable cover, and PVC swing check valve.

D. Cleanouts

1. PVC Cleanouts: PVC body with PVC threaded plug. Include PVC sewer pipe fitting

and riser to clean out of same material as sewer piping.

PART 3 - EXECUTION

3.1 EARTHWORK

A. Excavating, trenching, and backfilling are specified in Division 31 Section "Earthwork."

3.2 IDENTIFICATION

A. Materials and their installation are specified in Division 31 Section "Earthwork." Arrange

for installing green warning tapes directly over piping and at outside edges of underground

structures.

1. Use warning tape or detectable warning tape over ferrous piping.

2. Use detectable warning tape over nonferrous piping and over edges of underground

structures.

3.3 PIPING APPLICATIONS

A. General: Include watertight joints.

B. Refer to Part 2 of this Section for detailed specifications for pipe and fitting products listed

below. Use pipe, fittings, and joining methods according to applications indicated.

C. Gravity-Flow, Non-pressure Sewer Piping: Use the following pipe materials for each size

range:

1. Up to DN 500: UPVC sewer pipe and fittings; gaskets; and gasketed joints.

2. Greater than DN 500: GRP sewer pipe and fittings, gaskets; and gasketed joints.

3.4 INSTALLATION, GENERAL

A. General Locations and Arrangements: Drawing plans and details indicate general location

and arrangement of underground sanitary sewerage piping. Location and arrangement of

piping layout take design considerations into account. Install piping as indicated, to extent

practical.

SANITARY SEWERAGE 332530 - Page 7 of 12

COSMOS – E Engineers & Consultants

SIEMENS PS TOOLING PROJECT

AIN SOKHNA, EGYPT

B. Install piping beginning at low point, true to grades and alignment indicated with unbroken

continuity of invert. Place bell ends of piping facing upstream. Install gaskets, seals,

sleeves, and couplings according to the manufacturer's written instructions for using

lubricants, cements, and other installation requirements. Maintain swab or drag in line,

and pull past each joint as it is completed.

C. Use manholes for changes in direction, unless fittings are indicated. Use fittings for branch

connections, unless direct tap into existing sewer is indicated.

D. Install two flexible joints: the first at 1 diameter distance maximum from outside face of

manhole and the second at not more than 1.0m away from the first joint.

E. Install piping and connect to building's sanitary drains, of sizes and in locations indicated.

Terminate piping as indicated.

1. Install gravity-flow piping pitched down in direction of flow, at minimum slope of 2

percent, unless otherwise indicated.

F. Tunneling: Install pipe under streets or other obstructions that cannot be disturbed by

tunneling, jacking, or a combination of both.

3.5 PIPE JOINT CONSTRUCTION AND INSTALLATION

A. General: Join and install pipe and fittings according to installations indicated.

B. Refer to Division 33 Section "Piped Utilities - Basic Materials and Methods" for basic piping

joint construction and installation.

C. System Piping Joints: Make joints using system manufacturer's couplings, unless otherwise

indicated.

D. Install with top surfaces of components, except piping, flush with finished surface.

E. Follow manufacturer's instructions regarding placement of bedding and backfilling,

cleanliness of joint surfaces, lubricant used, correct location of components, provision of

correct gaps between end of spigot and back of socket, maximum permissible deflection of

joints for detachable couplings and flexible joints, provision of flexible joints for

connections to pipes built into structures.

F. uPVC Sewer Pipe and Fittings: As follows:

1. Join pipe and gasketed fittings with gaskets according to ASTM D 2321.

2. Join profile sewer pipe fittings with gaskets according to ASTM D 2321 and the

manufacturer's written instructions.

3. Install according to ASTM D 2321.

G. GRP Pipe and Fittings: Install according to AWWA C950 and to the manufacturer’s

recommendations.

3.6 MANHOLE INSTALLATION

SANITARY SEWERAGE 332530 - Page 8 of 12

COSMOS – E Engineers & Consultants

SIEMENS PS TOOLING PROJECT

AIN SOKHNA, EGYPT

A. General: Install manholes, complete with appurtenances and accessories indicated.

B. Set tops of frames and covers flush with finished surface of manholes that occur in

pavements. Set tops 75 mm above finished surface elsewhere, unless otherwise indicated.

C. Precast Units: The Contractor shall cast in steel watertight forms at least 3 weeks before

sections are used. The Contractor shall bed lowest unit on in situ concrete base and bed

and haunch in cement mortar. The Contractor shall liberally coat joints of units with

approved bituminous material of trowelling grade prior to fixing. The Contractor shall

ensure joints are filled solid and neatly strike off surplus compound. The Contractor shall

not disturb work for 7 days thereafter. Alternatively, the Contractor shall seal joints with

approved preformed jointing strip in accordance with manufacturer's instructions and shall

bed precast concrete cover slab on top unit in cement mortar.

D. Channels in bottom of manhole shall be smooth, semi-circular and size equal to diameter

of adjacent sewers. For straight through manholes, the Contractor shall construct channels

of half pipe sections. The Contractor shall make changes in direction of flow with smooth

curves as large as manholes permit. Changes in size and grade of channels shall be gradual

and even.

E. Benching: The Contractor shall form in sulphate resisting concrete Class 250/20 to rise

vertically from top of channels to a height not less than soffit of outlet pipe, then slope

upwards 1 in 10 to walls. Within 3 hours, the Contractor shall float with coat of sulphate

resisting cement-sand mortar 1:2 and finish smooth with steel trowel.

F. External Coating: Refer to Part 2 "Protective Coatings" for related specifications.

G. Internal Coating: Refer to Part 2 "Protective Coatings" for related specifications.

H. Step Irons: The Contractor shall cast into precast units or grout into preformed mortices.

The Contractor shall not use step irons as lifting eyes. Devices for lifting and handling shall

be provided on exterior faces.

I. Adjustment for Level: The Contractor shall build top courses of brickwork or concrete rings

after completion of surrounding levels and adjust as necessary to give accurate and even

final levels.

J. Covers and Gratings: The Contractor shall bed frame solidly in mortar and fix firmly using

fixing bolts and set cover in position to prevent twisting. The Contractor shall position

centrally over opening and level and square with surrounding finishes.

3.7 CAST IN PLACE CONCRETE

A. Refer to Division 3 Section "Cast-in-Place Concrete" for formwork, reinforcement, and

concrete.

3.8 FIELD QUALITY CONTROL

SANITARY SEWERAGE 332530 - Page 9 of 12

COSMOS – E Engineers & Consultants

SIEMENS PS TOOLING PROJECT

AIN SOKHNA, EGYPT

A. Clear interior of piping and structures of dirt and superfluous material as work progresses.

Maintain swab or drag in piping, and pull past each joint as it is completed.

1. In large, accessible piping, brushes and brooms may be used for cleaning.

2. Place plug in end of incomplete piping at the end of the day and when work stops.

3. Flush piping between manholes and other structures to remove collected debris, if

required by the Engineer, or authorities having jurisdiction.

B. Inspect the interior of piping to determine whether line displacement or other damage has

occurred. Inspect after approximately 600 mm of backfill is in place, and again

immediately prior to Substantial Completion. Submit separate reports for each system

inspection.

C. Alignment: Tolerances are to be 6 mm in level and 25 mm in line between manholes or

access points unless otherwise specified. Where pipe is to be constructed in straight lines

between manholes or lampholes, the length will not be accepted if a light at each manhole

or lamphole cannot be seen from adjacent manholes.

D. Test new piping systems, and parts of existing systems that have been altered, extended,

or repaired, for leaks and defects as follows:

1. Field testing: Generally

a. Provision of test equipment: All items for test have to be provided on site

before the test, i.e. pressure gauges, instruments, water etc.

b. Carry out tests in the presence of the Engineer's Representative.

c. Fittings and joints: Permanently anchor fittings before testing and leave all

joints exposed for checking.

d. Test sections: Test gravity sewers in sections between manholes.

e. Test sections: Limit test sections in pressure lines to not more than 500 m.

f. Test sections: Test pressure lines between valve chambers whenever possible.

g. Test plug: Secure end of main and test plug by struts.

h. Closed valve: Do not test against a closed valve unless there is no acceptable

alternative.

i. Apply pressure by manually operated test pump or, in the case of large

diameter mains, by power driven test pump, if approved.

j. Examine exposed joints and repair visible leaks.

k. Failure: Should a test fail, locate leak and replace or make good defective pipe

or replace and make good faulty joint. Retest main.

l. Records: Keep test records in an approved form. Hand original copy to the

Engineer immediately after completion of test.

m. Non-pressure lines not exceeding 1000 mm diameter are to be air tested

before backfilling and hydrostatic tested after backfilling.

n. Non-pressure lines over 1000 mm diameter are to be visually inspected from

the inside and tested at joints by hydraulic individual joint test.

o. Non-pressure lines: Carry out infiltration tests where crown of pipe at high

part of length under test is more than 1.2 m below water table.

2. Hydrostatic Testing of Non-pressure Pipelines

a. Procedure is to be as described for pressure pipelines.

SANITARY SEWERAGE 332530 - Page 10 of 12

COSMOS – E Engineers & Consultants

SIEMENS PS TOOLING PROJECT

AIN SOKHNA, EGYPT

b. Test pressure: 1.0 m head of water above pipe soffit at highest point and not

greater than 6 m head of water at lowest point of section under test. If

maximum head is exceeded, test section in stages.

c. Test period: 30 minutes.

d. Allowable leakage: 0.02 litres/linear metre/metre diameter/30 minutes.

3. Air Testing of Pipelines

a. Test procedure to BS EN 752: Parts 2-4.

b. Plug effectively length under test.

c. Apply pressure by approved method (i.e. hand pump) until a pressure 120 mm

head of water is indicated on a U-tube connected to the system.

d. Pressure drop: Without further pumping, pressure is not to fall by more than

25 mm in a period of 5 minutes.

e. Failure to pass the air test is not conclusive and if no leakage can be traced by

external application of soapy water to all sealing areas, then a hydrostatic test

is to be carried out before final rejection.

4. Infiltration Test for Gravity Pipes

a. Timing: Carry out test after total backfilling of length under test.

b. Plug effectively all inlets to system as directed.

c. Measure residual flow by approved method i.e. weir or other.

d. Infiltration limits: The following limits are not to be exceeded:

1) Pipelines not exceeding 700 mm: 0.02 litres/hour/100 linear

metres/mm diameter,

2) Pipelines over 700 mm: 0.03 litres/hour/100 linear metres/mm

diameter.

e. Failure: Test will be deemed to have failed if allowable infiltration water is

exceeded. Locate source of excessive infiltration by approved means i.e.

traversing light and mirrors or inflated rubber plug etc. and make good.

Repeat test until successful.

5. Visual Inspection Test

a. Timing: Carry out test after total backfilling of length under test.

b. Limit of length to be tested at one time is three full length pipes unless

otherwise approved.

c. Apparatus: Use rubber tyred bogies which do not damage lining of pipe and

an adequate supply of electric lamps.

d. Check joints by means of feelers to ensure rubber rings are correctly located.

e. Check pipe barrel for visible cracks.

6. Hydraulic Individual Joint Test for Pipes Exceeding 1000 mm:

a. Procedure: Carry out to BS 5886, Type 2 testing after backfilling, or equivalent.

Pressurize joint to 2 bars. Wait for 10 minutes at the end of which repressure

to 2 bars. Wait for 5 minutes. No pressure drop shall be observed at the end

of the latter period.

SANITARY SEWERAGE 332530 - Page 11 of 12

COSMOS – E Engineers & Consultants

SIEMENS PS TOOLING PROJECT

AIN SOKHNA, EGYPT

b. Test pressure: 2 bar.

c. Test period: 5 minutes.

d. Allowable leakage or pressure drop: None.

7. Deflection Tests for GRP Pipes:

a. Conduct: Deflection tests for GRP pipes as required by the Engineer at 3

stages. Deflection shall be measured at the spigot end at mid point and at

socket end.

b. Stage 1: At completion of primary backfill (deflection at this stage should be

below 0.5%).

c. Stage 2: At final backfill (maximum allowable deflection 2.5%).

d. Stage 3: Six months after final backfill (maximum allowable deflection 4.0%).

e. Pipes not passing the deflection tests at stage 2 or stage 3 will be removed

and replaced.

8. Cleaning and Inspection of sewers:

a. Cleaning: Clean pipeline of silt and debris after backfilling pipe trenches and

completing manholes, hatch boxes etc. but before surfaces are permanently

reinstated and make ready for inspection by the Engineer's Representative.

b. Inspection: Pipelines of 700 mm diameter and over are, where practicable, to

be inspected from the inside and when necessary a suitable trolley is to be

provided for this purpose.

c. Inspection: Pipelines less than 700 mm diameter and larger pipelines which

cannot be inspected from the inside, are to be inspected by passing a cylinder

of diameter 25 mm less than the internal diameter of the pipe and length not

less than the internal diameter of the pipe through each pipeline.

E. Testing of manholes: Plug manhole inlets and outlets, fill manhole with water and allow to

stand for at least 24 hours or such longer period to allow for complete absorption. Re-top

with water. Allowable leakage over 24 hours is not to exceed 1% of total volume of

manhole, otherwise make good and retest.

END OF SECTION 332530

SANITARY SEWERAGE 332530 - Page 12 of 12

You might also like

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- AWWA C 204 Mortar Lined MS PipeDocument19 pagesAWWA C 204 Mortar Lined MS PipeAnonymous D66WHl100% (1)

- Precast Post Tentioned TanksDocument20 pagesPrecast Post Tentioned TanksMarcel SteoleaNo ratings yet

- Crushers PDFDocument28 pagesCrushers PDFKhana Rizki MaulanaNo ratings yet

- SPC-332630-UDocument12 pagesSPC-332630-UkkkhattabbbNo ratings yet

- Strom DrainageDocument16 pagesStrom DrainageammarrafeiNo ratings yet

- P 1-11 Storm Drainage PDFDocument11 pagesP 1-11 Storm Drainage PDFMahmoud GwailyNo ratings yet

- 22 14 00 - Facility Storm Drainage PDFDocument6 pages22 14 00 - Facility Storm Drainage PDFsyed0% (1)

- GRP PipeDocument9 pagesGRP Pipesethu1091No ratings yet

- Drain PipeDocument4 pagesDrain PipeNur HaryatiNo ratings yet

- Tieback Anchors - 1.24.11Document7 pagesTieback Anchors - 1.24.11xcvNo ratings yet

- High Density Polyethylene - HDPE - Pipe and FittingsDocument8 pagesHigh Density Polyethylene - HDPE - Pipe and Fittingsnilesh_erusNo ratings yet

- Section 02717 - Concrete Sewer Rehabilitation by Machine-Wound PVC PipeDocument6 pagesSection 02717 - Concrete Sewer Rehabilitation by Machine-Wound PVC Pipefahren_de2015No ratings yet

- Facility Sanitary SewersDocument14 pagesFacility Sanitary SewerssamNo ratings yet

- SPC Occ 221423 MeDocument4 pagesSPC Occ 221423 Metarekhisham1234No ratings yet

- BMMM SectionDocument9 pagesBMMM SectionObaidAliKhanNo ratings yet

- 232113-HYDRONIC PIPINGDocument39 pages232113-HYDRONIC PIPINGMohamed SokarNo ratings yet

- 27-0543-underground-duct-and-raceways-08.2023Document9 pages27-0543-underground-duct-and-raceways-08.2023Chimban ChappuNo ratings yet

- 33 05 13 Manholes and Structures 10Document4 pages33 05 13 Manholes and Structures 10Mohammed AlkhateebNo ratings yet

- 4635-5-SPC-102 - 000 250 50130 Rev0 (Installation and Fusi 9D9Document9 pages4635-5-SPC-102 - 000 250 50130 Rev0 (Installation and Fusi 9D9Anonymous NupAudbjjNo ratings yet

- 13 31 00 - Fabric Structures PDFDocument7 pages13 31 00 - Fabric Structures PDFmasoodaeNo ratings yet

- Busbar Trunking System (Busways)Document6 pagesBusbar Trunking System (Busways)saravana3kumar3ravic100% (1)

- ITEM 615.01090003 - WATER FEATURE Scope of WorkDocument13 pagesITEM 615.01090003 - WATER FEATURE Scope of Workemiediray03No ratings yet

- SPC Occ 221316 MeDocument9 pagesSPC Occ 221316 Metarekhisham1234No ratings yet

- Metal Duct WorkDocument9 pagesMetal Duct WorkSyed Waqas HussainNo ratings yet

- SECTION 02800 Cured in Place (Cip) Sewer Lining Part 1 - General 1.1Document10 pagesSECTION 02800 Cured in Place (Cip) Sewer Lining Part 1 - General 1.1cloantafNo ratings yet

- 10-2010 Basic Mtrls Methods HVAC Design Guide CleanDocument10 pages10-2010 Basic Mtrls Methods HVAC Design Guide CleanzeliteNo ratings yet

- AnnexuresDocument29 pagesAnnexuresammarashraf91No ratings yet

- 33 11 00.13 - High Density Polyethylene (HDPE) PipeDocument7 pages33 11 00.13 - High Density Polyethylene (HDPE) PipeGerryNo ratings yet

- 334100Document5 pages334100jia wangNo ratings yet

- Sanitory Works SpecDocument10 pagesSanitory Works SpecCyril J PadiyathNo ratings yet

- SECTION 02605 Manholes: Part 1. GeneralDocument11 pagesSECTION 02605 Manholes: Part 1. GeneralDaniel KariukiNo ratings yet

- Solar Car Park CanopyDocument6 pagesSolar Car Park CanopyAnish BabuNo ratings yet

- MECHANICAL PADS - CIVIL - Construction - Division 23Document23 pagesMECHANICAL PADS - CIVIL - Construction - Division 23JomyJoseNo ratings yet

- Central Business District CBD EAST - Phase 1 of The New Administrative CapitalDocument20 pagesCentral Business District CBD EAST - Phase 1 of The New Administrative CapitalLi LiuNo ratings yet

- Section 334110 - Storm Drainage: TA1056 MBI Sampang Agung Brewery ExtensionDocument3 pagesSection 334110 - Storm Drainage: TA1056 MBI Sampang Agung Brewery Extensionery achjariNo ratings yet

- Cable Trays For Electrical Systems-Rev05Document8 pagesCable Trays For Electrical Systems-Rev05Mohamed Hamed100% (1)

- Technical Specification For Micropile ConstructionDocument9 pagesTechnical Specification For Micropile ConstructionFFerideKochanNo ratings yet

- Polyurethane Lining and Coating Specification Penstock Welded Joints 20120327Document12 pagesPolyurethane Lining and Coating Specification Penstock Welded Joints 20120327anbilselvamNo ratings yet

- 02720Document9 pages02720uddinnadeemNo ratings yet

- Calcium BoardDocument9 pagesCalcium BoardKurnianda Dian WulandariNo ratings yet

- Spec 2Document637 pagesSpec 2Waqar KhanNo ratings yet

- Wms Acmv Duct WorksDocument8 pagesWms Acmv Duct Worksfahmi_majid_2No ratings yet

- Steel Pipe, CMLC - Rev 3-17Document18 pagesSteel Pipe, CMLC - Rev 3-17A T AlhershNo ratings yet

- 33 05 13 Manholes and Structures 10Document4 pages33 05 13 Manholes and Structures 10salamNo ratings yet

- 031100Document5 pages031100Janus AntonioNo ratings yet

- Manholes - MSTDocument8 pagesManholes - MSTwafikmh4No ratings yet

- Division 22 - Plumbing Section 22 13 16 - Sanitary Waste and Vent PipingDocument8 pagesDivision 22 - Plumbing Section 22 13 16 - Sanitary Waste and Vent PipingAlexander MasongsongNo ratings yet

- Electrical Spec.'S Wiring Devices & Methods of Installation 16130-1Document9 pagesElectrical Spec.'S Wiring Devices & Methods of Installation 16130-1Waleed Abd El-HamiedNo ratings yet

- Flexible Conduit SpecsDocument10 pagesFlexible Conduit Specsafraz_xecNo ratings yet

- Section 08630 Metal-Framed SkylightDocument4 pagesSection 08630 Metal-Framed SkylightMØhãmmed ØwięsNo ratings yet

- SECTION 26 05 41 Underground Electrical ConstructionDocument11 pagesSECTION 26 05 41 Underground Electrical ConstructionEzana EzanaNo ratings yet

- 04200Document9 pages04200uddinnadeemNo ratings yet

- QT-09-2008 ConcreteDocument25 pagesQT-09-2008 ConcreteRichard WriteNo ratings yet

- Architectural SpecificationsDocument20 pagesArchitectural SpecificationsJulius Noe San PedroNo ratings yet

- PCI Hollow Core Specifications 4-8-11Document7 pagesPCI Hollow Core Specifications 4-8-11Ako BogdaNo ratings yet

- Keystone 133elite PDocument8 pagesKeystone 133elite PTAHER AMMARNo ratings yet

- Section 20 Horizontal Directional Drilling (HDD) /hdpe Pipe: 20.01 Scope: A. GeneralDocument6 pagesSection 20 Horizontal Directional Drilling (HDD) /hdpe Pipe: 20.01 Scope: A. GeneralRon CylNo ratings yet

- Concrete ReinforcingDocument7 pagesConcrete ReinforcingZul StudiozNo ratings yet

- (0018) 2.3 - SteelWaterPipe - Aug2011Document14 pages(0018) 2.3 - SteelWaterPipe - Aug2011Sixto GerardoNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Div 15Document111 pagesDiv 15kkkhattabbbNo ratings yet

- Sign Family Dec. 2018 (DT) (Global)Document20 pagesSign Family Dec. 2018 (DT) (Global)kkkhattabbbNo ratings yet

- Lobby Concept Narrative - Dec. 2022 (DT) (EMEA)Document24 pagesLobby Concept Narrative - Dec. 2022 (DT) (EMEA)kkkhattabbbNo ratings yet

- SDCC Water Specification Aug 2008-Dublin Pressure TestDocument15 pagesSDCC Water Specification Aug 2008-Dublin Pressure TestkkkhattabbbNo ratings yet

- SCADA RTU Panel SubmittalDocument67 pagesSCADA RTU Panel SubmittalkkkhattabbbNo ratings yet

- 021 Fuel TanksDocument6 pages021 Fuel TankskkkhattabbbNo ratings yet

- DoorsNXT Software Installation GuideDocument4 pagesDoorsNXT Software Installation GuidekkkhattabbbNo ratings yet

- HID EntryproxDocument2 pagesHID EntryproxkkkhattabbbNo ratings yet

- StdSpec15044 02-01-08 2Document3 pagesStdSpec15044 02-01-08 2kkkhattabbbNo ratings yet

- Doors For Windows Data SheetDocument2 pagesDoors For Windows Data SheetkkkhattabbbNo ratings yet

- STD 15144Document4 pagesSTD 15144kkkhattabbbNo ratings yet

- Enhanced Pre-Qualification Doc Vol 1Document83 pagesEnhanced Pre-Qualification Doc Vol 1kkkhattabbbNo ratings yet

- Civil Sheet3Document1 pageCivil Sheet3kkkhattabbbNo ratings yet

- Product guide-MITSUBISHIDocument13 pagesProduct guide-MITSUBISHIkkkhattabbbNo ratings yet

- 002-RTK-A-005-03-XX-002 - BOH Plan - RoofDocument1 page002-RTK-A-005-03-XX-002 - BOH Plan - RoofkkkhattabbbNo ratings yet

- What Is The Difference BW KWH and KWDocument4 pagesWhat Is The Difference BW KWH and KWkkkhattabbbNo ratings yet

- VolumeTwo CompleteDocument234 pagesVolumeTwo CompletekkkhattabbbNo ratings yet

- 72 A2015 SIG-IDS FD FRStatementsDocument20 pages72 A2015 SIG-IDS FD FRStatementskkkhattabbbNo ratings yet

- 002-RTK-A-005-03-XX-001 - Leasing Plan - RoofDocument1 page002-RTK-A-005-03-XX-001 - Leasing Plan - RoofkkkhattabbbNo ratings yet

- Process Calculation-Rev0Document15 pagesProcess Calculation-Rev0kkkhattabbbNo ratings yet

- Comatrol Distributor Letter 2020Document1 pageComatrol Distributor Letter 2020kkkhattabbbNo ratings yet

- Hydraulic & Pumps Calculation-Rev00Document12 pagesHydraulic & Pumps Calculation-Rev00kkkhattabbbNo ratings yet

- Infinova Comatrol AuthDocument1 pageInfinova Comatrol AuthkkkhattabbbNo ratings yet

- 002-RTK-A-005-01-XX-002 - BOH Plan - Level 01Document1 page002-RTK-A-005-01-XX-002 - BOH Plan - Level 01kkkhattabbbNo ratings yet

- BP Comatrol-137oct2020Document1 pageBP Comatrol-137oct2020kkkhattabbbNo ratings yet

- Ziton Comatrol-2020Document1 pageZiton Comatrol-2020kkkhattabbbNo ratings yet

- COO-Advance Commu - SHA0044-s2Document2 pagesCOO-Advance Commu - SHA0044-s2kkkhattabbbNo ratings yet

- POWER CONSUMPTION Young1991Document9 pagesPOWER CONSUMPTION Young1991kkkhattabbbNo ratings yet

- Types of CCTV Cameras - The Complete Guide - BusinessWatchDocument12 pagesTypes of CCTV Cameras - The Complete Guide - BusinessWatchkkkhattabbbNo ratings yet

- مشروع حريق لفرع الاسمرات عام 2022Document5 pagesمشروع حريق لفرع الاسمرات عام 2022kkkhattabbbNo ratings yet

- Experimental Investigation On Self-Healing Performance of Cementitious Composite Incorporating Fly Ash and Ground Granulated Blast Furnace SlagDocument126 pagesExperimental Investigation On Self-Healing Performance of Cementitious Composite Incorporating Fly Ash and Ground Granulated Blast Furnace SlagDesak Nyoman Deasi TrianiNo ratings yet

- TDS Ardrox 9881 09 25 2013Document3 pagesTDS Ardrox 9881 09 25 2013PP043No ratings yet

- Load Testing Bridges - 3.6MBDocument43 pagesLoad Testing Bridges - 3.6MBscribbey123No ratings yet

- Standard Pressure GaugesDocument2 pagesStandard Pressure GaugesRaj ChavanNo ratings yet

- A CrossarmsDocument42 pagesA Crossarmsosvald97No ratings yet

- BS4449/1997 & BS 4449/2005/ASTM A 615/A 615/M: Reinforcement Steel SpecificationsDocument1 pageBS4449/1997 & BS 4449/2005/ASTM A 615/A 615/M: Reinforcement Steel Specificationsgreat_triskelionNo ratings yet

- Product Catalogue: Welding ConsumablesDocument44 pagesProduct Catalogue: Welding ConsumablesSerhan AysanNo ratings yet

- Chapter 2 - Axial Loading (Part A)Document22 pagesChapter 2 - Axial Loading (Part A)Nafis SprataNo ratings yet

- Design Hydrothermal Carbonization of Biomass Waste by Using A Stirred Reactor UndipDocument6 pagesDesign Hydrothermal Carbonization of Biomass Waste by Using A Stirred Reactor Undipraymond tambunanNo ratings yet

- United States Patent (191: Schaper Et A1Document3 pagesUnited States Patent (191: Schaper Et A1Juan Pablo EspinosaNo ratings yet

- Self-Healing Concrete: University of Anbar College of Engineering Civil DepartmentDocument11 pagesSelf-Healing Concrete: University of Anbar College of Engineering Civil Departmentحميد مجيدNo ratings yet

- Aluminum Door Skin Full ReplacementDocument1 pageAluminum Door Skin Full ReplacementAntonio da LuzNo ratings yet

- Effect of Aggregate Size Distribution On Concrete Compressive StrengthDocument5 pagesEffect of Aggregate Size Distribution On Concrete Compressive StrengthPrakash Kumar KumarNo ratings yet

- Condensation Unit: ObjectiveDocument5 pagesCondensation Unit: ObjectiveAnas UmerNo ratings yet

- Dimension StoneDocument12 pagesDimension Stoneyrdgcgf5664100% (1)

- BDA 30803 Notes (Student Version - Printable) Sem 2 2012 - 2013 PDFDocument203 pagesBDA 30803 Notes (Student Version - Printable) Sem 2 2012 - 2013 PDFIlenggeswaran Murugesu100% (1)

- 2011 Enthalpy Tutorial (With Ans)Document11 pages2011 Enthalpy Tutorial (With Ans)kahwahcheong100% (1)

- Proconnect H05 - H07-BQ-FDocument1 pageProconnect H05 - H07-BQ-FPaul ScottNo ratings yet

- WPS - 017Document12 pagesWPS - 017MAT-LIONNo ratings yet

- CLMD4A ScieG7Document40 pagesCLMD4A ScieG7Ronan Thaddeus Delos SantosNo ratings yet

- 1 CH 3Document29 pages1 CH 3mohammed yasharNo ratings yet

- CHEMISTRY TOPIC 3 TrendsDocument3 pagesCHEMISTRY TOPIC 3 TrendsAisy BalalaNo ratings yet

- Adsorption Isotherm Models - Classification, PhysicalDocument79 pagesAdsorption Isotherm Models - Classification, PhysicalAnis SuffiNo ratings yet

- Biodeterioration of Crude Oil and Oil Derived ProductsDocument23 pagesBiodeterioration of Crude Oil and Oil Derived Productsdiegovillegas1966100% (1)

- Kalmetall W Kalpraxis GBDocument12 pagesKalmetall W Kalpraxis GBkaniappan sakthivelNo ratings yet

- Physical and Chemical Changes - MCQDocument9 pagesPhysical and Chemical Changes - MCQMinuteBrain LearningNo ratings yet

- SFBM BTechDocument59 pagesSFBM BTechSaurav PaulNo ratings yet

- Kingspan Kooltherm k106 90mm Standard Details Brochure en GB v04Document80 pagesKingspan Kooltherm k106 90mm Standard Details Brochure en GB v04Alexandru VasileNo ratings yet

- 36 Bio Adsorbent Potential of Coconut Cocos Nucifera L. Husk in Treating Simulated Lead Contaminated Soil SUPER FINALDocument61 pages36 Bio Adsorbent Potential of Coconut Cocos Nucifera L. Husk in Treating Simulated Lead Contaminated Soil SUPER FINALyxly imperialNo ratings yet