Professional Documents

Culture Documents

Learning From Incident-9

Learning From Incident-9

Uploaded by

Omprakash DansenaCopyright:

Available Formats

You might also like

- 1720.3-2016 - Timber Structures - Residential BuildingsDocument121 pages1720.3-2016 - Timber Structures - Residential BuildingsMark Carroll-Chilts100% (1)

- Low Cost Housing PDFDocument26 pagesLow Cost Housing PDFJitendriya78% (40)

- Method Statement For Heat Exchanger Revise1Document19 pagesMethod Statement For Heat Exchanger Revise1DanielLeeNo ratings yet

- Restaurant Floor Plan (1st Floor)Document1 pageRestaurant Floor Plan (1st Floor)Ma. Isabel RodriguezNo ratings yet

- Unit 3Document133 pagesUnit 3Tamilvanan GovindanNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Hot Tap PipingDocument21 pagesHot Tap PipingRachel FloresNo ratings yet

- CCPS - Building Process Safety Culture - Tools To Enhance PS Performance - Flixborough Case HistoryDocument5 pagesCCPS - Building Process Safety Culture - Tools To Enhance PS Performance - Flixborough Case Historysl1828No ratings yet

- Hot Tap ProcedureDocument21 pagesHot Tap ProcedureImanuel Sitepu100% (1)

- What Went Wrong: TopicDocument35 pagesWhat Went Wrong: Topickara_25No ratings yet

- Formosa PVC ExplosionDocument11 pagesFormosa PVC ExplosionNatasha OliviaNo ratings yet

- Maintenance Craftsman Burned by Bitumen: Lessons LearnedDocument2 pagesMaintenance Craftsman Burned by Bitumen: Lessons Learnedkirandevi1981No ratings yet

- MBLalreportonJaipurFire MR RoyDocument82 pagesMBLalreportonJaipurFire MR Royeshwarvv100% (2)

- Collision Between TDS and Pipe Racker - Ver 6Document12 pagesCollision Between TDS and Pipe Racker - Ver 6vikrant911No ratings yet

- Case StudyDocument4 pagesCase StudyShubham ChauhanNo ratings yet

- Learnings From Fatal Accident at Refinery On 27.05.2023Document1 pageLearnings From Fatal Accident at Refinery On 27.05.202300083583rfNo ratings yet

- Fire Leak FinalDocument46 pagesFire Leak FinalRemington ManalotoNo ratings yet

- Compressed Air Working: Environment, Health and SafetyDocument3 pagesCompressed Air Working: Environment, Health and SafetyDinesh BadheNo ratings yet

- Preparation For MaintenanceDocument1 pagePreparation For Maintenancekara_25No ratings yet

- Texas City Refinery Explosion - WikipediaDocument18 pagesTexas City Refinery Explosion - WikipediaMOHAN RAVICHANDRANNo ratings yet

- Ultradeep-Field Study: Extreme-Underbalanced HP/HT Coiled-Tubing-Conveyed PerforatingDocument5 pagesUltradeep-Field Study: Extreme-Underbalanced HP/HT Coiled-Tubing-Conveyed PerforatingАлександр ГераськинNo ratings yet

- MS (Fin Fan Coolers)Document3 pagesMS (Fin Fan Coolers)Zubair Ahmed KhaskheliNo ratings yet

- Safety Alert Blind RemovalDocument3 pagesSafety Alert Blind Removalav7867No ratings yet

- Ongc &: Oil Well Production TestingDocument35 pagesOngc &: Oil Well Production TestingDayanand Singh100% (1)

- Refinery TroubleshootingDocument5 pagesRefinery TroubleshootingDương Nguyễn TùngNo ratings yet

- High Pressure CleaningDocument8 pagesHigh Pressure Cleaningmc chesterNo ratings yet

- IMCASF - Jul 16Document4 pagesIMCASF - Jul 16Shivkumar JadhavNo ratings yet

- Case M Stank FireDocument4 pagesCase M Stank FireDeepak KumarNo ratings yet

- Crankcase Explosion Casualty Investigation British ValourDocument23 pagesCrankcase Explosion Casualty Investigation British Valoursevero97100% (1)

- A3E4U9 - Appendix A - A3 Surerus Hydrostatic Test PlanDocument49 pagesA3E4U9 - Appendix A - A3 Surerus Hydrostatic Test PlanGilberto Yoshida100% (1)

- Riopipeline2019 1121 201906051235ibp1121 19 Final PDFDocument8 pagesRiopipeline2019 1121 201906051235ibp1121 19 Final PDFMarcelo Varejão CasarinNo ratings yet

- Recomendacion Llenado Tuberia CH Los Cóndores - Rev B (1)Document9 pagesRecomendacion Llenado Tuberia CH Los Cóndores - Rev B (1)Alejandro López ZelayaNo ratings yet

- Case Study On Incident AT Isom Unit of Iocl-Haldia Refinery: by PNGRB & HPCLDocument16 pagesCase Study On Incident AT Isom Unit of Iocl-Haldia Refinery: by PNGRB & HPCLGajendra SinghNo ratings yet

- Deepwater Horizon Project DetailsDocument10 pagesDeepwater Horizon Project DetailsPurushottam Lal SumanNo ratings yet

- 2750 - MS For Cable Crossing Under ORPIC PipelinesDocument6 pages2750 - MS For Cable Crossing Under ORPIC PipelinesGeeks PondNo ratings yet

- Work Permit Compliance (Presentation)Document52 pagesWork Permit Compliance (Presentation)Ramzan Nazir100% (1)

- Hot TappingDocument2 pagesHot TappingParag ChandankhedeNo ratings yet

- Submitted By: Abhishant Baishya M.Tech HSE UPES, DehradunDocument22 pagesSubmitted By: Abhishant Baishya M.Tech HSE UPES, Dehradunjacobpm2010No ratings yet

- IChemE - LPB 117-1994 - Flixborough 20 Years OnDocument3 pagesIChemE - LPB 117-1994 - Flixborough 20 Years Onsl1828100% (1)

- Ibp1236 12Document8 pagesIbp1236 12Marcelo Varejão CasarinNo ratings yet

- 01.hazards of Trapped Pressure & Vacuum-22Document2 pages01.hazards of Trapped Pressure & Vacuum-22rahulNo ratings yet

- Feyzin Oil Refinery DisasterDocument8 pagesFeyzin Oil Refinery DisasterDavid Alonso Cedano EchevarriaNo ratings yet

- A Tale of Three Pigs: Pigging Incident 1Document4 pagesA Tale of Three Pigs: Pigging Incident 1biksutong100% (1)

- Chapter 2 Maintenance Procedure - PlanningDocument69 pagesChapter 2 Maintenance Procedure - PlanningHafizuddin Pjoe100% (1)

- Hot Tap Form Proposed SignatoriesDocument43 pagesHot Tap Form Proposed SignatoriesSongAn BuiNo ratings yet

- Cleaning Pre Heater Cyclone Chokes 1666326335Document5 pagesCleaning Pre Heater Cyclone Chokes 1666326335syeedismailNo ratings yet

- OISD - Fire Incident at Process Cooling TowerDocument5 pagesOISD - Fire Incident at Process Cooling Towerjdgh1986No ratings yet

- M B Lal Report On Jaipur Fire - Mr.royDocument82 pagesM B Lal Report On Jaipur Fire - Mr.royMIRACLE26100% (1)

- Vdu Fire StarinerDocument6 pagesVdu Fire StarinerkrishnanshwetaNo ratings yet

- Safety Work PermitDocument36 pagesSafety Work PermitAshwani Dogra100% (1)

- Design Guidelines For Safety in Piping NetworkDocument15 pagesDesign Guidelines For Safety in Piping NetworkrvnesariNo ratings yet

- S.K. Bhatnagar Mohan SharanDocument36 pagesS.K. Bhatnagar Mohan SharanDipin RajNo ratings yet

- MRPL NHT Heater DecokingDocument7 pagesMRPL NHT Heater DecokingsmrndrdasNo ratings yet

- NTPC Singrauli 1-2021-03-30-04 21 23Document28 pagesNTPC Singrauli 1-2021-03-30-04 21 23Shashivendra ShuklaNo ratings yet

- Hotwork Implementation Verification Checklist Rev 5Document3 pagesHotwork Implementation Verification Checklist Rev 5anjangandak2932100% (1)

- Method Statement: Company: Naseem & Son Project: Date: 21/05/2022 1. Description of WorksDocument3 pagesMethod Statement: Company: Naseem & Son Project: Date: 21/05/2022 1. Description of WorksSagar SharmaNo ratings yet

- CSB - Safety Bulletin - Removal of Hazardous Material From Piping Systems (2004)Document4 pagesCSB - Safety Bulletin - Removal of Hazardous Material From Piping Systems (2004)sl1828No ratings yet

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Air Crash Investigations - Loss of Cargo Door - The Near Crash of United Airlines Flight 811From EverandAir Crash Investigations - Loss of Cargo Door - The Near Crash of United Airlines Flight 811No ratings yet

- Machines, Tools and Methods of Automobile ManufactureFrom EverandMachines, Tools and Methods of Automobile ManufactureRating: 4 out of 5 stars4/5 (1)

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentFrom EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentNo ratings yet

- Multy Storey CarparksDocument20 pagesMulty Storey Carparksfritzstrobl100% (2)

- Sor RR 2020-21Document170 pagesSor RR 2020-21riazul islamNo ratings yet

- Polybond Insulation BrochureDocument24 pagesPolybond Insulation BrochureAmit GoyalNo ratings yet

- Influences On Architectural DesignDocument25 pagesInfluences On Architectural DesignJera MallariNo ratings yet

- Drip Rings STD - Tb.Dri.5011 FF RFDocument1 pageDrip Rings STD - Tb.Dri.5011 FF RFANDERSON NERESNo ratings yet

- LAB 7 - Aggregate Impact Test OEL 0Document3 pagesLAB 7 - Aggregate Impact Test OEL 0Muhd Alif MikhailNo ratings yet

- Metode Kerja Umum PDA Test - 2021Document23 pagesMetode Kerja Umum PDA Test - 2021WannNo ratings yet

- Rigging Plant Design For Installing Actuator at CGP Based On Tadano TR 200EDocument2 pagesRigging Plant Design For Installing Actuator at CGP Based On Tadano TR 200EMuhamad HasbiNo ratings yet

- Gantt Chart New ClinicDocument1 pageGantt Chart New ClinicRamvill GanzoNo ratings yet

- 1.3 SCP201 Assignment Worksheet - Jan 2023 PDFDocument4 pages1.3 SCP201 Assignment Worksheet - Jan 2023 PDFfang weiNo ratings yet

- Aqueducts - Quenching Rome's ThirstDocument6 pagesAqueducts - Quenching Rome's Thirst1954zapaNo ratings yet

- Fork Extension User GuideDocument1 pageFork Extension User Guider440scpNo ratings yet

- Latch-Type Toggle Clamps: HandleDocument2 pagesLatch-Type Toggle Clamps: HandleAlexandruNo ratings yet

- Mill Certificate BJTS 420B S.10-S.32Document1 pageMill Certificate BJTS 420B S.10-S.32Ghes Rachman BasalamahNo ratings yet

- Chapter 07 - MPWRD PDFDocument7 pagesChapter 07 - MPWRD PDFVarshil ParikhNo ratings yet

- Regie LacernaDocument69 pagesRegie LacernaRvin Jay Cabontocan MarianoNo ratings yet

- List of Miscellenious DrawingDocument1 pageList of Miscellenious DrawingRamBhuvan SonkarNo ratings yet

- Power Line Inspection PPT Rev.1Document16 pagesPower Line Inspection PPT Rev.1Eka Sastra WibawaNo ratings yet

- Part 1-8 Joint DesignDocument8 pagesPart 1-8 Joint DesignChweNo ratings yet

- Technical Schedule A To D & H Pkg-2Document101 pagesTechnical Schedule A To D & H Pkg-2vinodNo ratings yet

- Concrete and Formwork in NYCDocument60 pagesConcrete and Formwork in NYCKannon TamNo ratings yet

- (L5 - 002) SOLN-SD-DR-MSI-BB623-L5-00391 - D-04.1 (HW-4H.2) at LEVEL 5 0 - B APPROVED WC 0Document1 page(L5 - 002) SOLN-SD-DR-MSI-BB623-L5-00391 - D-04.1 (HW-4H.2) at LEVEL 5 0 - B APPROVED WC 0Michael TugawenNo ratings yet

- Concrete Made by Volumetric Batching and Continuous Mixing: Standard Specification ForDocument6 pagesConcrete Made by Volumetric Batching and Continuous Mixing: Standard Specification ForFRANZ RICHARD SARDINAS MALLCONo ratings yet

- Sigma 2 Diaphragm Metering Pumps Exploded Views Spare PartsDocument8 pagesSigma 2 Diaphragm Metering Pumps Exploded Views Spare Partsshiyas.jf605No ratings yet

- Development of Modular Insulated Sandwich Wall Panel Using Nylon-Fiber-Reinforced Styrocrete As Core LayerDocument2 pagesDevelopment of Modular Insulated Sandwich Wall Panel Using Nylon-Fiber-Reinforced Styrocrete As Core LayerChristine Joyce BunyiNo ratings yet

- AppendixDocument24 pagesAppendixSecret SecretNo ratings yet

Learning From Incident-9

Learning From Incident-9

Uploaded by

Omprakash DansenaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Learning From Incident-9

Learning From Incident-9

Uploaded by

Omprakash DansenaCopyright:

Available Formats

High Potential Incident Safety Alert Issue No: HIPO-2024-25/01

Incident Date: 17.04.2024 Time: 05:35 PM

Brief Description of Incident:

A defect notification was raised by Operation Dept, on 04.04.2024 on noticing reduction of bleed flow of HPH-2 extraction

leading to efficiency loss. However, it was decided to attend the said defect during short shutdown of the unit. On 17.04.2024,

the unit-3 had to be taken into shut-down at about 3.12 PM to attend LP Heater bellow leakage. Then it was decided to attend

the notification defect in this shut down. Accordingly, TMD Engineer applied for Permit duly submitting the Job Safety Analysis

(JSA) for the job. Before issuing the PTW, the HP Heater-2 extraction line was drained and depressurrised and permit was

issued for 24 hours from the time of issue. The pressure and flow both are shown 0 (zero) in DCS system.

On obtaining the permit at 04.55 PM, a team of 3 workmen namely (1) Sh. YYY, Rigger, (2) Sh. ZZZ, Fitter and (3) Sh. LLL, Helper

of M/s. XXX were engaged for the job of inspection of QCNRV. Sh. OOO, Dy. Manager, Turbine Maintenance who has received

the Permit and supervising the work.

At about 5.35 PM, the above team started inspection after duly confirming the Pressure, flow and opening of drain Manual

Isolating Valve. During inspection, the fitter and the rigger went to the scaffolding platform provided at QCNRV, which is

located at 3 M above the working floor. Taking position on platform near the NRV duly anchoring the safety harness and

wearing leather handgloves & faceshield, together they opened the bolts of NRV bonnet. On trying to loosen the bonnet cover

by tapping, the cover opened up swiftly resulting in atmospheric air entering in the piping. Few seconds later a small quantity

of hot water suddenly ejected out from the bonnet cover and fell over the rigger who was nearer to the NRV.

Sh. YYY, Rigger,aged 54 yrs, working for M/s. XXX suffered superficial burn injuries on front of his body and under

treatment in nearest Hospital.

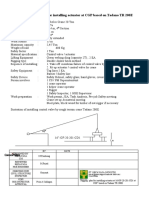

Observation Findings: Schematic Diagram of HPT Extraction to HP Heater-2

• The work was undertaken by the team after receiving a valid work

permit.

• There is a scaffold platform available there with safe ingress /egress

to safely perform the job at QCNRV.

• Job specific PPEs including Safety Harness, leather hand-gloves and

face shields were used by both the workers who were working on

platform.

• Both the drain lines beneath QCNRV and the loop between HP

Extraction point and QC NRV, are through and through, however

there is a chance of water accumulation (condensate) in the vertical

section of downstream piping (near HPH-2) as shown in the

schematic diagram given above.

• The flap of QCNRV was found detached from its position. (found

during inspection)

• There was a possibility of more than 1000C metal temperature at

the time of opening the bonnet cover.

• From the statements of the witness, it is revealed that while tapping

on the bonnet cover, atmospheric air stated gushing in to the system

piping

Preliminary Findings:

- On opening the bonnet nuts, the air ingress started causing pulling of the residual hot condensate (mixture

steam and water) from the downstream vertical line (as shown in the scheme above) which they have not

expected. (It might be due to phenomenon of Venturi effect, due to which the deposited hot condensate in

the downstream vertical line might have ejected out when atmospheric air entered in to the piping system).

- Existence of metal temperature above 1000 C at the time of work.

- Presence of very hot condensate water in the downstream vertical line.

- Attempt to open the bonnet cover by tapping instead of crack opening (i.e., by lifting jack bolts).

Lesson Learnt from Incident: JSA to be reviewed. Before starting the work complete condensate removal to be ensured .

-

You might also like

- 1720.3-2016 - Timber Structures - Residential BuildingsDocument121 pages1720.3-2016 - Timber Structures - Residential BuildingsMark Carroll-Chilts100% (1)

- Low Cost Housing PDFDocument26 pagesLow Cost Housing PDFJitendriya78% (40)

- Method Statement For Heat Exchanger Revise1Document19 pagesMethod Statement For Heat Exchanger Revise1DanielLeeNo ratings yet

- Restaurant Floor Plan (1st Floor)Document1 pageRestaurant Floor Plan (1st Floor)Ma. Isabel RodriguezNo ratings yet

- Unit 3Document133 pagesUnit 3Tamilvanan GovindanNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Hot Tap PipingDocument21 pagesHot Tap PipingRachel FloresNo ratings yet

- CCPS - Building Process Safety Culture - Tools To Enhance PS Performance - Flixborough Case HistoryDocument5 pagesCCPS - Building Process Safety Culture - Tools To Enhance PS Performance - Flixborough Case Historysl1828No ratings yet

- Hot Tap ProcedureDocument21 pagesHot Tap ProcedureImanuel Sitepu100% (1)

- What Went Wrong: TopicDocument35 pagesWhat Went Wrong: Topickara_25No ratings yet

- Formosa PVC ExplosionDocument11 pagesFormosa PVC ExplosionNatasha OliviaNo ratings yet

- Maintenance Craftsman Burned by Bitumen: Lessons LearnedDocument2 pagesMaintenance Craftsman Burned by Bitumen: Lessons Learnedkirandevi1981No ratings yet

- MBLalreportonJaipurFire MR RoyDocument82 pagesMBLalreportonJaipurFire MR Royeshwarvv100% (2)

- Collision Between TDS and Pipe Racker - Ver 6Document12 pagesCollision Between TDS and Pipe Racker - Ver 6vikrant911No ratings yet

- Case StudyDocument4 pagesCase StudyShubham ChauhanNo ratings yet

- Learnings From Fatal Accident at Refinery On 27.05.2023Document1 pageLearnings From Fatal Accident at Refinery On 27.05.202300083583rfNo ratings yet

- Fire Leak FinalDocument46 pagesFire Leak FinalRemington ManalotoNo ratings yet

- Compressed Air Working: Environment, Health and SafetyDocument3 pagesCompressed Air Working: Environment, Health and SafetyDinesh BadheNo ratings yet

- Preparation For MaintenanceDocument1 pagePreparation For Maintenancekara_25No ratings yet

- Texas City Refinery Explosion - WikipediaDocument18 pagesTexas City Refinery Explosion - WikipediaMOHAN RAVICHANDRANNo ratings yet

- Ultradeep-Field Study: Extreme-Underbalanced HP/HT Coiled-Tubing-Conveyed PerforatingDocument5 pagesUltradeep-Field Study: Extreme-Underbalanced HP/HT Coiled-Tubing-Conveyed PerforatingАлександр ГераськинNo ratings yet

- MS (Fin Fan Coolers)Document3 pagesMS (Fin Fan Coolers)Zubair Ahmed KhaskheliNo ratings yet

- Safety Alert Blind RemovalDocument3 pagesSafety Alert Blind Removalav7867No ratings yet

- Ongc &: Oil Well Production TestingDocument35 pagesOngc &: Oil Well Production TestingDayanand Singh100% (1)

- Refinery TroubleshootingDocument5 pagesRefinery TroubleshootingDương Nguyễn TùngNo ratings yet

- High Pressure CleaningDocument8 pagesHigh Pressure Cleaningmc chesterNo ratings yet

- IMCASF - Jul 16Document4 pagesIMCASF - Jul 16Shivkumar JadhavNo ratings yet

- Case M Stank FireDocument4 pagesCase M Stank FireDeepak KumarNo ratings yet

- Crankcase Explosion Casualty Investigation British ValourDocument23 pagesCrankcase Explosion Casualty Investigation British Valoursevero97100% (1)

- A3E4U9 - Appendix A - A3 Surerus Hydrostatic Test PlanDocument49 pagesA3E4U9 - Appendix A - A3 Surerus Hydrostatic Test PlanGilberto Yoshida100% (1)

- Riopipeline2019 1121 201906051235ibp1121 19 Final PDFDocument8 pagesRiopipeline2019 1121 201906051235ibp1121 19 Final PDFMarcelo Varejão CasarinNo ratings yet

- Recomendacion Llenado Tuberia CH Los Cóndores - Rev B (1)Document9 pagesRecomendacion Llenado Tuberia CH Los Cóndores - Rev B (1)Alejandro López ZelayaNo ratings yet

- Case Study On Incident AT Isom Unit of Iocl-Haldia Refinery: by PNGRB & HPCLDocument16 pagesCase Study On Incident AT Isom Unit of Iocl-Haldia Refinery: by PNGRB & HPCLGajendra SinghNo ratings yet

- Deepwater Horizon Project DetailsDocument10 pagesDeepwater Horizon Project DetailsPurushottam Lal SumanNo ratings yet

- 2750 - MS For Cable Crossing Under ORPIC PipelinesDocument6 pages2750 - MS For Cable Crossing Under ORPIC PipelinesGeeks PondNo ratings yet

- Work Permit Compliance (Presentation)Document52 pagesWork Permit Compliance (Presentation)Ramzan Nazir100% (1)

- Hot TappingDocument2 pagesHot TappingParag ChandankhedeNo ratings yet

- Submitted By: Abhishant Baishya M.Tech HSE UPES, DehradunDocument22 pagesSubmitted By: Abhishant Baishya M.Tech HSE UPES, Dehradunjacobpm2010No ratings yet

- IChemE - LPB 117-1994 - Flixborough 20 Years OnDocument3 pagesIChemE - LPB 117-1994 - Flixborough 20 Years Onsl1828100% (1)

- Ibp1236 12Document8 pagesIbp1236 12Marcelo Varejão CasarinNo ratings yet

- 01.hazards of Trapped Pressure & Vacuum-22Document2 pages01.hazards of Trapped Pressure & Vacuum-22rahulNo ratings yet

- Feyzin Oil Refinery DisasterDocument8 pagesFeyzin Oil Refinery DisasterDavid Alonso Cedano EchevarriaNo ratings yet

- A Tale of Three Pigs: Pigging Incident 1Document4 pagesA Tale of Three Pigs: Pigging Incident 1biksutong100% (1)

- Chapter 2 Maintenance Procedure - PlanningDocument69 pagesChapter 2 Maintenance Procedure - PlanningHafizuddin Pjoe100% (1)

- Hot Tap Form Proposed SignatoriesDocument43 pagesHot Tap Form Proposed SignatoriesSongAn BuiNo ratings yet

- Cleaning Pre Heater Cyclone Chokes 1666326335Document5 pagesCleaning Pre Heater Cyclone Chokes 1666326335syeedismailNo ratings yet

- OISD - Fire Incident at Process Cooling TowerDocument5 pagesOISD - Fire Incident at Process Cooling Towerjdgh1986No ratings yet

- M B Lal Report On Jaipur Fire - Mr.royDocument82 pagesM B Lal Report On Jaipur Fire - Mr.royMIRACLE26100% (1)

- Vdu Fire StarinerDocument6 pagesVdu Fire StarinerkrishnanshwetaNo ratings yet

- Safety Work PermitDocument36 pagesSafety Work PermitAshwani Dogra100% (1)

- Design Guidelines For Safety in Piping NetworkDocument15 pagesDesign Guidelines For Safety in Piping NetworkrvnesariNo ratings yet

- S.K. Bhatnagar Mohan SharanDocument36 pagesS.K. Bhatnagar Mohan SharanDipin RajNo ratings yet

- MRPL NHT Heater DecokingDocument7 pagesMRPL NHT Heater DecokingsmrndrdasNo ratings yet

- NTPC Singrauli 1-2021-03-30-04 21 23Document28 pagesNTPC Singrauli 1-2021-03-30-04 21 23Shashivendra ShuklaNo ratings yet

- Hotwork Implementation Verification Checklist Rev 5Document3 pagesHotwork Implementation Verification Checklist Rev 5anjangandak2932100% (1)

- Method Statement: Company: Naseem & Son Project: Date: 21/05/2022 1. Description of WorksDocument3 pagesMethod Statement: Company: Naseem & Son Project: Date: 21/05/2022 1. Description of WorksSagar SharmaNo ratings yet

- CSB - Safety Bulletin - Removal of Hazardous Material From Piping Systems (2004)Document4 pagesCSB - Safety Bulletin - Removal of Hazardous Material From Piping Systems (2004)sl1828No ratings yet

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Air Crash Investigations - Loss of Cargo Door - The Near Crash of United Airlines Flight 811From EverandAir Crash Investigations - Loss of Cargo Door - The Near Crash of United Airlines Flight 811No ratings yet

- Machines, Tools and Methods of Automobile ManufactureFrom EverandMachines, Tools and Methods of Automobile ManufactureRating: 4 out of 5 stars4/5 (1)

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentFrom EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentNo ratings yet

- Multy Storey CarparksDocument20 pagesMulty Storey Carparksfritzstrobl100% (2)

- Sor RR 2020-21Document170 pagesSor RR 2020-21riazul islamNo ratings yet

- Polybond Insulation BrochureDocument24 pagesPolybond Insulation BrochureAmit GoyalNo ratings yet

- Influences On Architectural DesignDocument25 pagesInfluences On Architectural DesignJera MallariNo ratings yet

- Drip Rings STD - Tb.Dri.5011 FF RFDocument1 pageDrip Rings STD - Tb.Dri.5011 FF RFANDERSON NERESNo ratings yet

- LAB 7 - Aggregate Impact Test OEL 0Document3 pagesLAB 7 - Aggregate Impact Test OEL 0Muhd Alif MikhailNo ratings yet

- Metode Kerja Umum PDA Test - 2021Document23 pagesMetode Kerja Umum PDA Test - 2021WannNo ratings yet

- Rigging Plant Design For Installing Actuator at CGP Based On Tadano TR 200EDocument2 pagesRigging Plant Design For Installing Actuator at CGP Based On Tadano TR 200EMuhamad HasbiNo ratings yet

- Gantt Chart New ClinicDocument1 pageGantt Chart New ClinicRamvill GanzoNo ratings yet

- 1.3 SCP201 Assignment Worksheet - Jan 2023 PDFDocument4 pages1.3 SCP201 Assignment Worksheet - Jan 2023 PDFfang weiNo ratings yet

- Aqueducts - Quenching Rome's ThirstDocument6 pagesAqueducts - Quenching Rome's Thirst1954zapaNo ratings yet

- Fork Extension User GuideDocument1 pageFork Extension User Guider440scpNo ratings yet

- Latch-Type Toggle Clamps: HandleDocument2 pagesLatch-Type Toggle Clamps: HandleAlexandruNo ratings yet

- Mill Certificate BJTS 420B S.10-S.32Document1 pageMill Certificate BJTS 420B S.10-S.32Ghes Rachman BasalamahNo ratings yet

- Chapter 07 - MPWRD PDFDocument7 pagesChapter 07 - MPWRD PDFVarshil ParikhNo ratings yet

- Regie LacernaDocument69 pagesRegie LacernaRvin Jay Cabontocan MarianoNo ratings yet

- List of Miscellenious DrawingDocument1 pageList of Miscellenious DrawingRamBhuvan SonkarNo ratings yet

- Power Line Inspection PPT Rev.1Document16 pagesPower Line Inspection PPT Rev.1Eka Sastra WibawaNo ratings yet

- Part 1-8 Joint DesignDocument8 pagesPart 1-8 Joint DesignChweNo ratings yet

- Technical Schedule A To D & H Pkg-2Document101 pagesTechnical Schedule A To D & H Pkg-2vinodNo ratings yet

- Concrete and Formwork in NYCDocument60 pagesConcrete and Formwork in NYCKannon TamNo ratings yet

- (L5 - 002) SOLN-SD-DR-MSI-BB623-L5-00391 - D-04.1 (HW-4H.2) at LEVEL 5 0 - B APPROVED WC 0Document1 page(L5 - 002) SOLN-SD-DR-MSI-BB623-L5-00391 - D-04.1 (HW-4H.2) at LEVEL 5 0 - B APPROVED WC 0Michael TugawenNo ratings yet

- Concrete Made by Volumetric Batching and Continuous Mixing: Standard Specification ForDocument6 pagesConcrete Made by Volumetric Batching and Continuous Mixing: Standard Specification ForFRANZ RICHARD SARDINAS MALLCONo ratings yet

- Sigma 2 Diaphragm Metering Pumps Exploded Views Spare PartsDocument8 pagesSigma 2 Diaphragm Metering Pumps Exploded Views Spare Partsshiyas.jf605No ratings yet

- Development of Modular Insulated Sandwich Wall Panel Using Nylon-Fiber-Reinforced Styrocrete As Core LayerDocument2 pagesDevelopment of Modular Insulated Sandwich Wall Panel Using Nylon-Fiber-Reinforced Styrocrete As Core LayerChristine Joyce BunyiNo ratings yet

- AppendixDocument24 pagesAppendixSecret SecretNo ratings yet