Professional Documents

Culture Documents

4fbc6dd6-6ce1-4603-9237-b0b4bf3ca65a_904-15

4fbc6dd6-6ce1-4603-9237-b0b4bf3ca65a_904-15

Uploaded by

haviettuanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4fbc6dd6-6ce1-4603-9237-b0b4bf3ca65a_904-15

4fbc6dd6-6ce1-4603-9237-b0b4bf3ca65a_904-15

Uploaded by

haviettuanCopyright:

Available Formats

9 04-15

1 9 04-15

SUBJECT DATE

SPN 651 (MCM) (EPA10); SPN 652 (MCM) (EPA10); SPN 653

(MCM) (EPA10); SPN 654 (MCM) (EPA10); SPN 655 (MCM) September 2015

(EPA10); SPN 656 (MCM) (EPA10)

Additions, Revisions, or Updates

Publication Number / Title Platform Section Title Change

SPN 651/FMI 3 - EPA10

SPN 652/FMI 3 - EPA10

DD SPN 653/FMI 3 - EPA10 Revised step 11 and step 15 on how to recognize if MCM

DDC-SVC-MAN-0084

Platform/ already has campaigned MCM.

DDC-SVC-MAN-S084 SPN 654/FMI 3 - EPA10

EPA10 Added a new Picture of the MCM.

SPN 655/FMI 3 - EPA10

SPN 656/FMI 3 - EPA10

All information subject to change without notice. 3

9 04-15 Copyright © 2015 DETROIT DIESEL CORPORATION

2 SPN 651/FMI 3 - EPA10

2 SPN 651/FMI 3 - EPA10

Injector Cylinder #1 Needle Control Valve Abnormal Operation (MAX)

Table 1.

SPN 651/FMI 3

Description This code will set when the Needle solenoid current response time

does not meet requirement.

Monitored Parameter Injector Cylinder #1 Needle Control Valve Current

Typical Enabling Conditions Always enabled

Monitor Sequence None

Execution Frequency Continuous

Typical Duration 5 sec

Dash Lamps MIL, CEL

Engine Reaction Derate 25%, EGR Valve shut, DPF Inhibit Regeneration, Limit DEF

dosing

Verification Engine Idle (1 minute)

Check as follows:

NOTE: Submit completed diagnostics with warranty claim.

NOTE: Injector chart PDF available on DDCSN/SUPPORT/SPECIALIZED SERVICE.

4 All information subject to change without notice.

Copyright © 2015 DETROIT DIESEL CORPORATION 9 04-15

9 04-15

1. Check for multiple codes. Using DiagnosticLink ®, retain log file of active fault and clear codes (code active for one

key cycle).

a. If SPN fault code 168 or 723/FMI any is present, service those faults first.

b. If SPN fault code 168 or 723/FMI any is NOT present, Go to step 2.

WARNING: ENGINE EXHAUST

To avoid injury from inhaling engine exhaust, always operate the engine in a well-ventilated area.

Engine exhaust is toxic.

WARNING: PERSONAL INJURY

To avoid injury before starting and running the engine, ensure the vehicle is parked on a level

surface, parking brake is set, and the wheels are blocked.

2. Start and warm the engine until the coolant temperature is above 71°C (160°F).

3. Turn the engine OFF.

4. Disconnect the front fuel injector harness 14-pin injector connector.

5. Inspect the front fuel injector harness 14-pin injector connectors for bent or spread pins; inspect the connector seal for

damage (signs of water or oil intrusion). Is there any damage found?

a. Yes; repair as necessary.

b. No; Go to step 6.

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

6. Using the appropriate chart below, measure and record the resistance values between the corresponding pins on the

valve cover side of the front fuel injector harness listed below. Are the resistances within range?

Table 2.

Front Fuel Injector Harness 14-Pin Connector Resistance Chart (Valve Cover Side)

Pin 2 and Pin 8 and

Pins 1 and 2 Pins 1 and 8

ground ground

Injector #1

Greater than Greater than Greater than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pin 3 and Pin 9 and

Pins 1 and 3 Pins 1 and 9

ground ground

Injector #2

Greater than Greater than Greater than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pin 4 and Pin 12 and

Pins 1 and 4 Pins 1 and 12

ground ground

Injector #3

Greater than Greater than Greater than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

All information subject to change without notice. 5

9 04-15 Copyright © 2015 DETROIT DIESEL CORPORATION

2 SPN 651/FMI 3 - EPA10

Table 3.

Front Fuel Injector Harness 14-Pin Connector Resistance Chart (Using J-48671-10 Injector Breakout Box)

Note: Ensure J-48671-10 ground strap is connected to cylinder head.

Pins 3 and 4 Pins 2 and 3 Pin 2 and Pin 3 and

ground ground

Injector #1

1.3 to 2.5Ω* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 2 and 3 Pin 2 and Pin 3 and

ground ground

Injector #2

1.3 to 2.5Ω* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 2 and 3 Pin 2 and Pin 3 and

ground ground

Injector #3

1.3 to 2.5Ω* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

a. Yes; Go to step 12.

b. No; Go to step 7.

7. Remove the rocker cover. Refer to section "Removal of the Rocker Cover".

8. Remove the front fuel injector harness from the engine.

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Three-Filter System".

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Two-Filter System".

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

9. Using the chart below, measure and record the resistance values between the injector pins listed below. Are the

resistances within range?

6 All information subject to change without notice.

Copyright © 2015 DETROIT DIESEL CORPORATION 9 04-15

9 04-15

Table 4.

Injector Needle Resistance Chart (Injector Harness must be removed from engine)

Pins 3 and 4 Pins 3 and 2 Pin 2 and Pin 3 and

ground ground

Injector #1

2.0Ω or less* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 3 and 2 Pin 2 and Pin 3 and

ground ground

Injector #2

2.0Ω or less* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 3 and 2 Pin 2 and Pin 3 and

ground ground

Injector #3

2.0Ω or less* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

a. Yes; replace the front fuel injector harness.

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Three-Filter System".

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Two-Filter System".

b. No; Go to step 10.

10. Inspect the Injector connector pins and determine whether they are copper or stainless steel. Are all the injectors on the

front bank stainless steel?

Table 5.

Stainless Steel Terminals Copper Alloy Terminals

a. Yes; replace the injector with the out-of-range resistance.

Refer to section "Removal of the Fuel Injector - Three-Filter System".

Refer to section "Removal of the Fuel Injector - Two-Filter System".

b. No; Go to step 11.

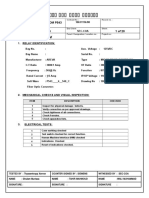

11. Review the MCM Hardware Part Number on the sticker located on the front of the MCM, shown in the figure below. Is

the MCM Hardware part number RA0014469935 or RA0024460135?

All information subject to change without notice. 7

9 04-15 Copyright © 2015 DETROIT DIESEL CORPORATION

2 SPN 651/FMI 3 - EPA10

a. Yes; replace all the copper connector pin injectors on the engine. Verify Repairs.

Refer to section "Removal of the Fuel Injector - Three-Filter System".

Refer to section "Removal of the Fuel Injector - Two-Filter System".

b. No; replace the MCM with MCM part number RA0014469935. Refer to section "Removal of the Motor Control

Module". Verify repairs. See 15TS-16 (http://ddcsn-ddc.freightliner.com/cps/rde/xbcr/ddcsn/15TS16.pdf) for

further information.

12. Disconnect the Motor Control Module (MCM) 120-pin connector.

13. Inspect the MCM 120-pin connector and 120-pin harness connector for signs of corrosion, spread, unseated (pushed

out) or damaged pins, connector seal for damage (signs of water or oil intrusion) or signs of wire damage.

a. If signs of damage are found, repair as necessary. Verify repairs.

b. If no signs of damage, Go to step 14.

8 All information subject to change without notice.

Copyright © 2015 DETROIT DIESEL CORPORATION 9 04-15

9 04-15

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

14. Using the chart below, measure and record the resistance values between the engine side of the front valve cover 14-pin

connector and the MCM 120-pin connector. Are the resistances within range?

Table 6.

Engine Harness Injector Circuit Resistance Table

Front Engine Side Front Engine Side

MCM 120-Pin Harness Acceptable Resistance Acceptable Resistance

Valve Cover 14-pin Valve Cover 14 pin

Connector 1Ω or less 1KΩ or greater

connector # connector #

1 25 Ω 1 and ground Ω

2 26 Ω 2 and ground Ω

3 22 Ω 3 and ground Ω

4 24 Ω 4 and ground Ω

a. Yes; Go to step 15.

b. No; repair the engine side harness. Verify repairs.

15. Review the MCM Hardware Part Number on the sticker located on the front of the MCM, shown in the figure below. Is

the MCM Hardware part number RA0014469935 or RA0024460135?

All information subject to change without notice. 9

9 04-15 Copyright © 2015 DETROIT DIESEL CORPORATION

2 SPN 651/FMI 3 - EPA10

a. Yes; replace all the copper connector pin injectors on the engine. Verify Repairs.

Refer to section "Removal of the Fuel Injector - Three-Filter System".

Refer to section "Removal of the Fuel Injector - Two-Filter System".

b. No, replace the MCM with MCM part number RA0014469935. Refer to section "Removal of the Motor Control

Module". Verify repairs. See 15TS-16 (http://ddcsn-ddc.freightliner.com/cps/rde/xbcr/ddcsn/15TS16.pdf) for

further information.

10 All information subject to change without notice.

Copyright © 2015 DETROIT DIESEL CORPORATION 9 04-15

9 04-15

3 SPN 652/FMI 3 - EPA10

Injector Cylinder #2 Needle Control Valve Abnormal Operation (MAX)

Table 7.

SPN 652/FMI 3

Description This code will set when the Needle solenoid current response time

does not meet requirement.

Monitored Parameter Injector Cylinder #2 Needle Control Valve Current

Typical Enabling Conditions Always enabled

Monitor Sequence None

Execution Frequency Continuous

Typical Duration .02 msec

Dash Lamps MIL, CEL

Engine Reaction Derate 25%, EGR Valve shut, DPF Inhibit Regeneration, Limit DEF

dosing

Verification Engine Idle (1 minute)

Check as follows:

NOTE: Submit completed diagnostics with warranty claim.

NOTE: Injector chart PDF available on DDCSN/SUPPORT/SPECIALIZED SERVICE.

All information subject to change without notice. 11

9 04-15 Copyright © 2015 DETROIT DIESEL CORPORATION

3 SPN 652/FMI 3 - EPA10

1. Check for multiple codes. Using DiagnosticLink ®, retain log file of active fault and clear codes (code active for one

key cycle).

a. If SPN fault code 168 or 723/FMI any is present, service those faults first.

b. If SPN fault code 168 or 723/FMI any is NOT present, Go to step 2.

WARNING: ENGINE EXHAUST

To avoid injury from inhaling engine exhaust, always operate the engine in a well-ventilated area.

Engine exhaust is toxic.

WARNING: PERSONAL INJURY

To avoid injury before starting and running the engine, ensure the vehicle is parked on a level

surface, parking brake is set, and the wheels are blocked.

2. Start and warm the engine until the coolant temperature is above 71°C (160°F).

3. Turn the engine OFF.

4. Disconnect the front fuel injector harness 14-pin injector connector.

5. Inspect the front fuel injector harness 14-pin injector connectors for bent or spread pins; inspect the connector seal for

damage (signs of water or oil intrusion). Is there any damage found?

a. Yes; repair as necessary

b. No; Go to step 6.

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

6. Using the appropriate chart below, measure and record the resistance values between the corresponding pins on the

valve cover side of the front fuel injector harness listed below. Are the resistances within range?

Table 8.

Front Fuel Injector Harness 14-Pin Connector Resistance Chart (Valve Cover Side)

Pin 2 and Pin 8 and

Pins 1 and 2 Pins 1 and 8

ground ground

Injector #1

Greater than Greater than Greater than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pin 3 and Pin 9 and

Pins 1 and 3 Pins 1 and 9

ground ground

Injector #2

Greater than Greater than Greater than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pin 4 and Pin 12 and

Pins 1 and 4 Pins 1 and 12

ground ground

Injector #3

Greater than Greater than Greater than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

12 All information subject to change without notice.

Copyright © 2015 DETROIT DIESEL CORPORATION 9 04-15

9 04-15

Table 9.

Front Fuel Injector Harness 14-Pin Connector Resistance Chart (Using J-48671-10 Injector Breakout Box)

Note: Ensure J-48671-10 ground strap is connected to cylinder head.

Pins 3 and 4 Pins 2 and 3 Pin 2 and Pin 3 and

ground ground

Injector #1

1.3 to 2.5Ω* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 2 and 3 Pin 2 and Pin 3 and

ground ground

Injector #2

1.3 to 2.5Ω* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 2 and 3 Pin 2 and Pin 3 and

ground ground

Injector #3

1.3 to 2.5Ω* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

a. Yes; Go to step 12.

b. No; Go to step 7.

7. Remove the rocker cover. Refer to section "Removal of the Rocker Cover".

8. Remove the front fuel injector harness from the engine.

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Three-Filter System".

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Two-Filter System".

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

9. Using the chart below, measure and record the resistance values between the injector pins listed below. Are the

resistances within range?

All information subject to change without notice. 13

9 04-15 Copyright © 2015 DETROIT DIESEL CORPORATION

3 SPN 652/FMI 3 - EPA10

Table 10.

Injector Needle Resistance Chart (Injector Harness must be removed from engine)

Pins 3 and 4 Pins 3 and 2 Pin 2 and Pin 3 and

ground ground

Injector #1

2.0Ω or less* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 3 and 2 Pin 2 and Pin 3 and

ground ground

Injector #2

2.0Ω or less* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 3 and 2 Pin 2 and Pin 3 and

ground ground

Injector #3

2.0Ω or less* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

a. Yes; replace the front fuel injector harness.

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Three-Filter System".

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Two-Filter System".

b. No; Go to step 10.

10. Inspect the Injector connector pins and determine whether they are copper or stainless steel. Are all the injectors on the

front bank stainless steel?

Table 11.

Stainless Steel Terminals Copper Alloy Terminals

a. Yes; replace the injector with the out-of-range resistance.

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Three-Filter System".

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Two-Filter System".

b. No; Go to step 11.

11. Review the MCM Hardware Part Number on the sticker located on the front of the MCM, shown in the figure below. Is

the MCM Hardware part number RA0014469935 or RA0024460135?

14 All information subject to change without notice.

Copyright © 2015 DETROIT DIESEL CORPORATION 9 04-15

9 04-15

a. Yes; replace all the copper connector pin injectors on the engine . Verify Repairs.

Refer to section "Removal of the Fuel Injector - Three-Filter System".

Refer to section "Removal of the Fuel Injector - Two-Filter System".

b. No; replace the MCM with MCM part number RA0014469935. Refer to section "Removal of the Motor Control

Module". Verify repairs. See 15TS-16 (http://ddcsn-ddc.freightliner.com/cps/rde/xbcr/ddcsn/15TS16.pdf) for

further information.

12. Disconnect the Motor Control Module (MCM) 120-pin connector.

13. Inspect the MCM 120-pin connector and 120-pin harness connector for signs of corrosion, spread, unseated (pushed

out) or damaged pins, connector seal for damage (signs of water or oil intrusion) or signs of wire damage.

a. If signs of damage are found, repair as necessary. Verify repairs.

b. If no signs of damage, Go to step 14.

All information subject to change without notice. 15

9 04-15 Copyright © 2015 DETROIT DIESEL CORPORATION

3 SPN 652/FMI 3 - EPA10

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

14. Using the chart below, measure and record the resistance values between the engine side of the front valve cover 14-pin

connector and the MCM 120-pin connector. Are the resistances within range?

Table 12.

Engine Harness Injector Circuit Resistance Table

Front Engine Side Front Engine Side

MCM 120-Pin Harness Acceptable Resistance Acceptable Resistance

Valve Cover 14-pin Valve Cover 14 pin

Connector 1Ω or less 1KΩ or greater

connector # connector #

1 25 Ω 1 and ground Ω

2 26 Ω 2 and ground Ω

3 22 Ω 3 and ground Ω

4 24 Ω 4 and ground Ω

a. Yes; Go to step 15.

b. No; repair the engine side harness. Verify repairs.

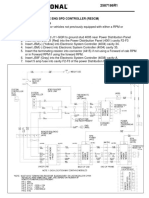

15. Review the MCM Hardware Part Number on the sticker located on the front of the MCM, under the Instrumentation

window in DiagnosticLink as shown in the figure below. Is the MCM Hardware part number RA0014469935 or

RA0024460135?

16 All information subject to change without notice.

Copyright © 2015 DETROIT DIESEL CORPORATION 9 04-15

9 04-15

a. Yes; replace all the copper connector pin injectors on the engine. Verify repairs.

Refer to section "Removal of the Fuel Injector - Three-Filter System".

Refer to section "Removal of the Fuel Injector - Two-Filter System".

b. No, replace the MCM with MCM part number RA0014469935. Refer to section "Removal of the Motor Control

Module" . Verify repairs. See 15TS-16 (http://ddcsn-ddc.freightliner.com/cps/rde/xbcr/ddcsn/15TS16.pdf) for

further information.

All information subject to change without notice. 17

9 04-15 Copyright © 2015 DETROIT DIESEL CORPORATION

4 SPN 653/FMI 3 - EPA10

4 SPN 653/FMI 3 - EPA10

Injector Cylinder #3 Needle Control Valve Abnormal Operation (MAX)

Table 13.

SPN 653/FMI 3

Description This code will set when the Needle solenoid current response time

does not meet requirement

Monitored Parameter Injector Cylinder #3 Needle Control Valve Current

Typical Enabling Conditions Always enabled

Monitor Sequence None

Execution Frequency Continuous

Typical Duration .02 msec

Dash Lamps MIL, CEL

Engine Reaction Derate 25%, EGR Valve shut, DPF Inhibit Regeneration, Limit DEF

dosing

Verification Engine Idle (1 minute)

Check as follows:

NOTE: Submit completed diagnostics with warranty claim.

NOTE: Injector chart PDF available on DDCSN/SUPPORT/SPECIALIZED SERVICE.

18 All information subject to change without notice.

Copyright © 2015 DETROIT DIESEL CORPORATION 9 04-15

9 04-15

1. Check for multiple codes. Using DiagnosticLink ®, retain log file of active fault and clear codes (code active for one

key cycle).

a. If SPN fault code 168 or 723/FMI any is present, service those faults first.

b. If SPN fault code 168 or 723/FMI any is NOT present, Go to step 2.

WARNING: PERSONAL INJURY

To avoid injury before starting and running the engine, ensure the vehicle is parked on a level

surface, parking brake is set, and the wheels are blocked.

WARNING: ENGINE EXHAUST

To avoid injury from inhaling engine exhaust, always operate the engine in a well-ventilated area.

Engine exhaust is toxic.

2. Start and warm the engine until the coolant temperature is above 71°C (160°F).

3. Turn the engine OFF.

4. Disconnect the front fuel injector harness 14-pin injector connector.

5. Inspect the front fuel injector harness 14-pin injector connectors for bent or spread pins; inspect the connector seal for

damage (signs of water or oil intrusion). Is there any damage found?

a. Yes; repair as necessary.

b. No; Go to step 6.

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

6. Using the appropriate chart below, measure and record the resistance values between the corresponding pins on the

valve cover side of the front fuel injector harness listed below. Are the resistances within range?

Table 14.

Front Fuel Injector Harness 14-Pin Connector Resistance Chart (Valve Cover Side)

Pin 2 and Pin 8 and

Pins 1 and 2 Pins 1 and 8

ground ground

Injector #1

Greater Than Greater Than Greater Than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pin 3 and Pin 9 and

Pins 1 and 3 Pins 1 and 9

ground ground

Injector #2

Greater Than Greater Than Greater Than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pin 4 and Pin 12 and

Pins 1 and 4 Pins 1 and 12

ground ground

Injector #3

Greater Than Greater Than Greater Than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

All information subject to change without notice. 19

9 04-15 Copyright © 2015 DETROIT DIESEL CORPORATION

4 SPN 653/FMI 3 - EPA10

Table 15.

Front Fuel Injector Harness 14-Pin Connector Resistance Chart (Using J-48671-10 Injector Breakout Box)

Note: Ensure J-48671-10 ground strap is connected to cylinder head.

Pins 3 and 4 Pins 2 and 3 Pin 2 and Pin 3 and

ground ground

Injector #1

1.3 to 2.5Ω* Greater Than Greater Than Greater Than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 2 and 3 Pin 2 and Pin 3 and

ground ground

Injector #2

1.3 to 2.5Ω* Greater Than Greater Than Greater Than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 2 and 3 Pin 2 and Pin 3 and

ground ground

Injector #3

1.3 to 2.5Ω* Greater Than Greater Than Greater Than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

a. Yes; Go to step 12.

b. No; Go to step 7.

7. Remove the rocker cover. Refer to section "Removal of the Rocker Cover".

8. Remove the front fuel injector harness from the engine.

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Three-Filter System".

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Two-Filter System" .

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

9. Using the chart below, measure and record the resistance values between the injector pins listed below. Are the

resistances within range?

20 All information subject to change without notice.

Copyright © 2015 DETROIT DIESEL CORPORATION 9 04-15

9 04-15

Table 16.

Injector Needle Resistance Chart (Injector Harness must be removed from engine)

Pins 3 and 4 Pins 3 and 2 Pin 2 and Pin 3 and

ground ground

Injector #1

2.0Ω or less* Greater Than Greater Than Greater Than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 3 and 2 Pin 2 and Pin 3 and

ground ground

Injector #2

2.0Ω or less* Greater Than Greater Than Greater Than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 3 and 2 Pin 2 and Pin 3 and

ground ground

Injector #3

2.0Ω or less* Greater Than Greater Than Greater Than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

a. Yes; replace the front fuel injector harness.

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Three-Filter System".

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Two-Filter System".

b. No; Go to step 10.

10. Inspect the Injector connector pins and determine whether they are copper or stainless steel. Are all the injectors on the

front bank stainless steel?

Table 17.

Stainless Steel Terminals Copper Alloy Terminals

a. Yes; replace the injector with the out-of-range resistance.

Refer to section "Removal of the Fuel Injector - Three-Filter System"

Refer to section "Removal of the Fuel Injector - Two-Filter System"

b. No; Go to step 11.

11. Review the MCM Hardware Part Number on the sticker located on the front of the MCM, shown in the figure below. Is

the MCM Hardware part number RA0014469935 or RA0024460135?

All information subject to change without notice. 21

9 04-15 Copyright © 2015 DETROIT DIESEL CORPORATION

4 SPN 653/FMI 3 - EPA10

a. Yes; replace all the copper connector pin injectors on the engine. Verify Repairs.

Refer to section "Removal of the Fuel Injector - Three-Filter System".

Refer to section "Removal of the Fuel Injector - Two-Filter System".

b. No; replace the MCM with MCM part number RA0014469935. Refer to section "Removal of the Motor Control

Module" . Verify repairs. See 15TS-16 (http://ddcsn-ddc.freightliner.com/cps/rde/xbcr/ddcsn/15TS16.pdf) for

further information.

12. Disconnect the Motor Control Module (MCM) 120-pin connector.

13. Inspect the MCM 120-pin connector and 120-pin harness connector for signs of corrosion, spread, unseated (pushed

out) or damaged pins, connector seal for damage (signs of water or oil intrusion) or signs of wire damage.

a. If signs of damage are found, repair as necessary. Verify repairs.

b. If no signs of damage, Go to step 14.

22 All information subject to change without notice.

Copyright © 2015 DETROIT DIESEL CORPORATION 9 04-15

9 04-15

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

14. Using the chart below, measure and record the resistance values between the engine side of the front valve cover 14-pin

connector and the MCM 120-pin connector. Are the resistances within range?

Table 18.

Engine Harness Injector Circuit Resistance Table

Front Engine Side Front Engine Side

MCM 120-Pin Harness Acceptable Resistance Acceptable Resistance

Valve Cover 14-pin Valve Cover 14 pin

Connector 1Ω or less 1KΩ or greater

connector # connector #

1 25 Ω 1 and ground Ω

2 26 Ω 2 and ground Ω

3 22 Ω 3 and ground Ω

4 24 Ω 4 and ground Ω

a. Yes; Go to step 15.

b. No; repair the engine side harness. Verify repairs.

15. Review the MCM Hardware Part Number on the sticker located on the front of the MCM, under the Instrumentation

window in DiagnosticLink as shown in the figure below. Is the MCM Hardware part number RA0014469935 or

RA0024460135?

All information subject to change without notice. 23

9 04-15 Copyright © 2015 DETROIT DIESEL CORPORATION

4 SPN 653/FMI 3 - EPA10

a. Yes; replace all the copper connector pin injectors on the engine. Verify Repairs.

Refer to section "Removal of the Fuel Injector - Three-Filter System".

Refer to section "Removal of the Fuel Injector - Two-Filter System".

b. No; replace the MCM with MCM part number RA0014469935. Refer to section "Removal of the Motor Control

Module". Verify repairs. See 15TS-16 (http://ddcsn-ddc.freightliner.com/cps/rde/xbcr/ddcsn/15TS16.pdf) for

further information.

24 All information subject to change without notice.

Copyright © 2015 DETROIT DIESEL CORPORATION 9 04-15

9 04-15

5 SPN 654/FMI 3 - EPA10

Injector Cylinder #4 Needle Control Valve Abnormal Operation (MAX)

Table 19.

SPN 654/FMI 3

Description This code will set when the Needle solenoid current response time

does not meet requirement.

Monitored Parameter Injector Cylinder #4 Needle Control Valve Current

Typical Enabling Conditions Always enabled

Monitor Sequence None

Execution Frequency Continuous

Typical Duration .02 msec

Dash Lamps MIL, CEL

Engine Reaction Derate 25% , EGR Valve shut, DPF Inhibit Regeneration, Limit DEF

dosing

Verification Engine Idle (1 minute)

Check as follows:

NOTE: Submit completed diagnostics with warranty claim.

NOTE: Injector chart PDF available on DDCSN/SUPPORT/SPECIALIZED SERVICE.

All information subject to change without notice. 25

9 04-15 Copyright © 2015 DETROIT DIESEL CORPORATION

5 SPN 654/FMI 3 - EPA10

1. Check for multiple codes. Using DiagnosticLink ®, retain log file of active fault and clear codes (code active for one

key cycle).

a. If SPN fault code 168 or 723/FMI any is present, service those faults first.

b. If SPN fault code 168 or 723/FMI any is NOT present, Go to step 2.

WARNING: ENGINE EXHAUST

To avoid injury from inhaling engine exhaust, always operate the engine in a well-ventilated area.

Engine exhaust is toxic.

WARNING: PERSONAL INJURY

To avoid injury before starting and running the engine, ensure the vehicle is parked on a level

surface, parking brake is set, and the wheels are blocked.

2. Start and warm the engine until the coolant temperature is above 71°C (160°F).

3. Turn the engine OFF.

4. Disconnect the rear fuel injector harness 14-pin injector connector.

5. Inspect the rear fuel injector harness 14-pin injector connectors for bent or spread pins; inspect the connector seal for

damage (signs of water or oil intrusion). Is there any damage found?

a. Yes; repair as necessary.

b. No; Go to step 6.

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

6. Using the appropriate chart below, measure and record the resistance values between the corresponding pins on the

valve cover side of the rear fuel injector harness listed below. Are the resistances within range?

Table 20.

Rear Fuel Injector Harness 14-Pin Connector Resistance Chart (Valve Cover Side)

Pin 2 and Pin 8 and

Pins 1 and 2 Pins 1 and 8

ground ground

Injector #4

Greater than Greater than Greater than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pin 3 and Pin 9 and

Pins 1 and 3 Pins 1 and 9

ground ground

Injector #5

Greater than Greater than Greater than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pin 4 and Pin 12 and

Pins 1 and 4 Pins 1 and 12

ground ground

Injector #6

Greater than Greater than Greater than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

26 All information subject to change without notice.

Copyright © 2015 DETROIT DIESEL CORPORATION 9 04-15

9 04-15

Table 21.

Rear Fuel Injector Harness 14-Pin Connector Resistance Chart (Using J-48671-10 Injector Breakout Box)

Note: Ensure J-48671-10 ground strap is connected to cylinder head.

Pins 3 and 4 Pins 2 and 3 Pin 2 and ground Pin 3 and

ground

Injector #4

1.3 to 2.5Ω* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 2 and 3 Pin 2 and ground Pin 3 and

ground

Injector #5

1.3 to 2.5Ω* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 2 and 3 Pin 2 and ground Pin 3 and

ground

Injector #6

1.3 to 2.5Ω* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

a. Yes; Go to step 12.

b. No; Go to step 7.

7. Remove the rocker cover. Refer to section "Removal of the Rocker Cover".

8. Remove the rear fuel injector harness from the engine.

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Three-Filter System".

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Two-Filter System".

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

9. Using the chart below, measure and record the resistance values between the injector pins listed below. Are the

resistances within range?

All information subject to change without notice. 27

9 04-15 Copyright © 2015 DETROIT DIESEL CORPORATION

5 SPN 654/FMI 3 - EPA10

Table 22.

Injector Needle Resistance Chart (Injector Harness must be removed from engine)

Pins 3 and 4 Pins 2 and 3 Pin 2 and ground Pin 3 and

ground

Injector #4

2.0Ω or less* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 2 and 3 Pin 2 and ground Pin 3 and

ground

Injector #5

2.0Ω or less* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 2 and 3 Pin 2 and ground Pin 3 and

ground

Injector #6

2.0Ω or less* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

a. Yes; replace the rear fuel injector harness.

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Three-Filter System".

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Two-Filter System".

b. No; Go to step 10.

10. Inspect the Injector connector pins and determine whether they are copper or stainless steel. Are all the injectors on the

rear bank stainless steel?

Table 23.

Stainless Steel Terminals Copper Alloy Terminals

a. Yes; replace the injector with the out-of-range resistance.

Refer to section "Removal of the Fuel Injector - Three-Filter System".

Refer to section "Removal of the Fuel Injector - Two-Filter System".

b. No; Go to step 11.

11. Review the MCM Hardware Part Number on the sticker located on the front of the MCM, shown in the figure below. Is

the MCM Hardware part number RA0014469935 or RA0024460135?

28 All information subject to change without notice.

Copyright © 2015 DETROIT DIESEL CORPORATION 9 04-15

9 04-15

a. Yes; replace all the copper connector pin injectors on the engine. Verify Repairs.

Refer to section "Removal of the Fuel Injector - Three-Filter System".

Refer to section "Removal of the Fuel Injector - Two-Filter System".

b. No; replace the MCM with MCM part number RA0014469935. Refer to section "Removal of the Motor Control

Module". Verify repairs. See 15TS-16 (http://ddcsn-ddc.freightliner.com/cps/rde/xbcr/ddcsn/15TS16.pdf) for

further information.

12. Disconnect the Motor Control Module (MCM) 120-pin connector.

13. Inspect the MCM 120-pin connector and 120-pin harness connector for signs of corrosion, spread, unseated (pushed

out) or damaged pins, connector seal for damage (signs of water or oil intrusion) or signs of wire damage.

a. If signs of damage are found, repair as necessary. Verify repairs.

b. If no signs of damage, Go to step 14.

All information subject to change without notice. 29

9 04-15 Copyright © 2015 DETROIT DIESEL CORPORATION

5 SPN 654/FMI 3 - EPA10

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

14. Using the chart below, measure and record the resistance values between the engine side of the front valve cover 14-pin

connector and the MCM 120-pin connector. Are the resistances within range?

Table 24.

Engine Harness Injector Circuit Resistance Table

Rear Engine Side Valve Rear Engine Side Valve

MCM 120-Pin Harness Acceptable Resistance Acceptable Resistance

Cover 14-pin connector Cover 14 pin connector

Connector 1Ω or less 1KΩ or greater

# #

1 19 Ω 1 and ground Ω

2 16 Ω 2 and ground Ω

3 20 Ω 3 and ground Ω

4 18 Ω 4 and ground Ω

a. Yes; Go to step 15.

b. No; repair the engine side harness. Verify repairs.

15. Review the MCM Hardware Part Number on the sticker located on the front of the MCM, under the Instrumentation

window in DiagnosticLink as shown in the figure below. Is the MCM Hardware part number RA0014469935 or

RA0024460135?

30 All information subject to change without notice.

Copyright © 2015 DETROIT DIESEL CORPORATION 9 04-15

9 04-15

a. Yes; replace all the copper connector pin injectors on the engine. Verify Repairs.

Refer to section "Removal of the Fuel Injector - Three-Filter System".

Refer to section "Removal of the Fuel Injector - Two-Filter System".

b. No, replace the MCM with MCM part number RA0014469935. Refer to section "Removal of the Motor Control

Module" . Verify repairs. See 15TS-16 (http://ddcsn-ddc.freightliner.com/cps/rde/xbcr/ddcsn/15TS16.pdf) for

further information

All information subject to change without notice. 31

9 04-15 Copyright © 2015 DETROIT DIESEL CORPORATION

6 SPN 655/FMI 3 - EPA10

6 SPN 655/FMI 3 - EPA10

Injector Cylinder #5 Needle Control Valve Abnormal Operation (MAX)

Table 25.

SPN 655/FMI 3

Description This code will set when the Needle solenoid current response time

does not meet requirement.

Monitored Parameter Injector Cylinder #5 Needle Control Valve Current

Typical Enabling Conditions Always enabled

Monitor Sequence None

Execution Frequency Continuous

Typical Duration .02 msec

Dash Lamps MIL, CEL

Engine Reaction Derate 25% , EGR Valve shut, DPF Inhibit Regeneration, Limit DEF

dosing

Verification Engine Idle (1 minute)

Check as follows:

NOTE: Submit completed diagnostics with warranty claim

NOTE: Injector chart PDF available on DDCSN/SUPPORT/SPECIALIZED SERVICE.

32 All information subject to change without notice.

Copyright © 2015 DETROIT DIESEL CORPORATION 9 04-15

9 04-15

1. Check for multiple codes. Using DiagnosticLink ®, retain log file of active fault and clear codes (code active for one

key cycle).

a. If SPN fault code 168 or 723/FMI any is present, service those faults first.

b. If SPN fault code 168 or 723/FMI any is NOT present, Go to step 2.

WARNING: ENGINE EXHAUST

To avoid injury from inhaling engine exhaust, always operate the engine in a well-ventilated area.

Engine exhaust is toxic.

WARNING: PERSONAL INJURY

To avoid injury before starting and running the engine, ensure the vehicle is parked on a level

surface, parking brake is set, and the wheels are blocked.

2. Start and warm the engine until the coolant temperature is above 71°C (160°F).

3. Turn the engine OFF.

4. Disconnect the rear fuel injector harness 14-pin injector connector.

5. Inspect the rear fuel injector harness 14-pin injector connectors for bent or spread pins; inspect the connector seal for

damage (signs of water or oil intrusion). Is there any damage found?

a. Yes; repair as necessary.

b. No; Go to step 6.

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

6. Using the appropriate chart below, measure and record the resistance values between the corresponding pins on the

valve cover side of the rear fuel injector harness listed below. Are the resistances within range?

Table 26.

Rear Fuel Injector Harness 14-Pin Connector Resistance Chart (Valve Cover Side)

Pin 2 and Pin 8 and

Pins 1 and 2 Pins 1 and 8

ground ground

Injector #4

Greater than Greater than Greater than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pin 3 and Pin 9 and

Pins 1 and 3 Pins 1 and 9

ground ground

Injector #5

Greater than Greater than Greater than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pin 4 and Pin 12 and

Pins 1 and 4 Pins 1 and 12

ground ground

Injector #6

Greater than Greater than Greater than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

All information subject to change without notice. 33

9 04-15 Copyright © 2015 DETROIT DIESEL CORPORATION

6 SPN 655/FMI 3 - EPA10

Table 27.

Rear Fuel Injector Harness 14-Pin Connector Resistance Chart (Using J-48671-10 Injector Breakout Box)

Note: Ensure J-48671-10 ground strap is connected to cylinder head.

Pins 3 and 4 Pins 2 and 3 Pin 2 and ground Pin 3 and

ground

Injector #4

1.3 to 2.5Ω* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 2 and 3 Pin 2 and ground Pin 3 and

ground

Injector #5

1.3 to 2.5Ω* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 2 and 3 Pin 2 and ground Pin 3 and

ground

Injector #6

1.3 to 2.5Ω* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

a. Yes; Go to step 12.

b. No; Go to step 7.

7. Remove the rocker cover. Refer to section "Removal of the Rocker Cover".

8. Remove the rear fuel injector harness from the engine.

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Three-Filter System".

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Two-Filter System".

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

9. Using the chart below, measure and record the resistance values between the injector pins listed below. Are the

resistances within range?

34 All information subject to change without notice.

Copyright © 2015 DETROIT DIESEL CORPORATION 9 04-15

9 04-15

Table 28.

Injector Needle Resistance Chart (Injector Harness must be removed from engine)

Pins 3 and 4 Pins 2 and 3 Pin 2 and ground Pin 3 and

ground

Injector #4

2.0Ω or less* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 2 and 3 Pin 2 and ground Pin 3 and

ground

Injector #5

2.0Ω or less* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 2 and 3 Pin 2 and ground Pin 3 and

ground

Injector #6

2.0Ω or less* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

a. Yes; replace the rear fuel injector harness.

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Three-Filter System".

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Two-Filter System".

b. No; Go to step 10.

10. Inspect the Injector connector pins and determine whether they are copper or stainless steel. Are all the injectors on the

rear bank stainless steel?

Table 29.

Stainless Steel Terminals Copper Alloy Terminals

a. Yes; replace the injector with the out-of-range resistance.

Refer to section "Removal of the Fuel Injector - Three-Filter System".

Refer to section "Removal of the Fuel Injector - Two-Filter System".

b. No; Go to step 11.

11. Review the MCM Hardware Part Number on the sticker located on the front of the MCM, shown in the figure below. Is

the MCM Hardware part number RA0014469935 or RA0024460135?

All information subject to change without notice. 35

9 04-15 Copyright © 2015 DETROIT DIESEL CORPORATION

6 SPN 655/FMI 3 - EPA10

a. Yes; replace all the copper connector pin injectors on the engine. Verify repairs.

Refer to section "Removal of the Fuel Injector - Three-Filter System".

Refer to section "Removal of the Fuel Injector - Two-Filter System".

b. No; replace the MCM with MCM part number RA0014469935. Refer to section "Removal of the Motor Control

Module". Verify repairs. See 15TS-16 (http://ddcsn-ddc.freightliner.com/cps/rde/xbcr/ddcsn/15TS16.pdf) for

further information.

12. Disconnect the Motor Control Module (MCM) 120-pin connector.

13. Inspect the MCM 120-pin connector and 120-pin harness connector for signs of corrosion, spread, unseated (pushed

out) or damaged pins, connector seal for damage (signs of water or oil intrusion) or signs of wire damage.

a. If signs of damage are found, repair as necessary. Verify repairs.

b. If no signs of damage, Go to step 14.

36 All information subject to change without notice.

Copyright © 2015 DETROIT DIESEL CORPORATION 9 04-15

9 04-15

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

14. Using the chart below, measure and record the resistance values between the engine side of the front valve cover 14-pin

connector and the MCM 120-pin connector. Are the resistances within range?

Table 30.

Engine Harness Injector Circuit Resistance Table

Rear Engine Side Valve Rear Engine Side Valve

MCM 120-Pin Harness Acceptable Resistance Acceptable Resistance

Cover 14-pin connector Cover 14 pin connector

Connector 1Ω or less 1KΩ or greater

# #

1 19 Ω 1 and ground Ω

2 16 Ω 2 and ground Ω

3 20 Ω 3 and ground Ω

4 18 Ω 4 and ground Ω

a. Yes; Go to step 15.

b. No; repair the engine side harness. Verify repairs.

15. Review the MCM Hardware Part Number on the sticker located on the front of the MCM, under the Instrumentation

window in DiagnosticLink as shown in the figure below. Is the MCM Hardware part number RA0014469935 or

RA0024460135?

All information subject to change without notice. 37

9 04-15 Copyright © 2015 DETROIT DIESEL CORPORATION

6 SPN 655/FMI 3 - EPA10

a. Yes; replace all the copper connector pin injectors on the engine. Verify repairs.

Refer to section "Removal of the Fuel Injector - Three-Filter System".

Refer to section "Removal of the Fuel Injector - Two-Filter System".

b. No; replace the MCM with MCM part number RA0014469935. Refer to section "Removal of the Motor Control

Module" . Verify repairs. See 15TS-16 (http://ddcsn-ddc.freightliner.com/cps/rde/xbcr/ddcsn/15TS16.pdf) for

further information.

38 All information subject to change without notice.

Copyright © 2015 DETROIT DIESEL CORPORATION 9 04-15

9 04-15

7 SPN 656/FMI 3 - EPA10

Injector Cylinder #6 Needle Control Valve Abnormal Operation (MAX)

Table 31.

SPN 656/FMI 3

Description This code will set when the Needle solenoid current response time

does not meet requirement.

Monitored Parameter Injector Cylinder #6 Needle Control Valve Current

Typical Enabling Conditions Always enabled

Monitor Sequence None

Execution Frequency Continuous

Typical Duration .02 msec

Dash Lamps MIL, CEL

Engine Reaction Derate 25%, EGR Valve shut, DPF Inhibit Regeneration, Limit DEF

dosing

Verification Engine Idle (1 minute)

Check as follows:

NOTE: Submit completed diagnostics with warranty claim.

NOTE: Injector chart PDF available on DDCSN/SUPPORT/SPECIALIZED SERVICE.

All information subject to change without notice. 39

9 04-15 Copyright © 2015 DETROIT DIESEL CORPORATION

7 SPN 656/FMI 3 - EPA10

1. Check for multiple codes. Using DiagnosticLink ®, retain log file of active fault and clear codes (code active for one

key cycle).

a. If SPN fault code 168 or 723/FMI any is present, service those faults first.

b. If SPN fault code 168 or 723/FMI any is NOT present, Go to step 2.

WARNING: ENGINE EXHAUST

To avoid injury from inhaling engine exhaust, always operate the engine in a well-ventilated area.

Engine exhaust is toxic.

WARNING: PERSONAL INJURY

To avoid injury before starting and running the engine, ensure the vehicle is parked on a level

surface, parking brake is set, and the wheels are blocked.

2. Start and warm the engine until the coolant temperature is above 71°C (160°F).

3. Turn the engine OFF.

4. Disconnect the rear fuel injector harness 14-pin injector connector.

5. Inspect the rear fuel injector harness 14-pin injector connectors for bent or spread pins; inspect the connector seal for

damage (signs of water or oil intrusion). Is there any damage found?

a. Yes; repair as necessary.

b. No; Go to step 6.

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

6. Using the appropriate chart below, measure and record the resistance values between the corresponding pins on the

valve cover side of the rear fuel injector harness listed below. Are the resistances within range?

Table 32.

Rear Fuel Injector Harness 14-Pin Connector Resistance Chart (Valve Cover Side)

Pin 2 and Pin 8 and

Pins 1 and 2 Pins 1 and 8

ground ground

Injector #4

Greater than Greater than Greater than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pin 3 and Pin 9 and

Pins 1 and 3 Pins 1 and 9

ground ground

Injector #5

Greater than Greater than Greater than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pin 4 and Pin 12 and

Pins 1 and 4 Pins 1 and 12

ground ground

Injector #6

Greater than Greater than Greater than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

40 All information subject to change without notice.

Copyright © 2015 DETROIT DIESEL CORPORATION 9 04-15

9 04-15

Table 33.

Rear Fuel Injector Harness 14-Pin Connector Resistance Chart (Using J-48671-10 Injector Breakout Box)

Note: Ensure J-48671-10 ground strap is connected to cylinder head.

Pins 3 and 4 Pins 2 and 3 Pin 2 and ground Pin 3 and

ground

Injector #4

1.3 to 2.5Ω* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 2 and 3 Pin 2 and ground Pin 3 and

ground

Injector #5

1.3 to 2.5Ω* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 2 and 3 Pin 2 and ground Pin 3 and

ground

Injector #6

1.3 to 2.5Ω* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

a. Yes; Go to step 12.

b. No; Go to step 7.

7. Remove the rocker cover. Refer to section "Removal of the Rocker Cover".

8. Remove the rear fuel injector harness from the engine.

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Three-Filter System".

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Two-Filter System".

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

9. Using the chart below, measure and record the resistance values between the injector pins listed below. Are the

resistances within range?

All information subject to change without notice. 41

9 04-15 Copyright © 2015 DETROIT DIESEL CORPORATION

7 SPN 656/FMI 3 - EPA10

Table 34.

Injector Needle Resistance Chart (Injector Harness must be removed from engine)

Pins 3 and 4 Pins 2 and 3 Pin 2 and Pin 3 and

ground ground

Injector #4

2.0Ω or less* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 2 and 3 Pin 2 and Pin 3 and

ground ground

Injector #5

2.0Ω or less* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 2 and 3 Pin 2 and Pin 3 and

ground ground

Injector #6

2.0Ω or less* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

a. Yes; replace the rear fuel injector harness.

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Three-Filter System".

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Two-Filter System".

b. No; Go to step 10.

10. Inspect the Injector connector pins and determine whether they are copper or stainless steel. Are all the injectors on the

rear bank stainless steel?

Table 35.

Stainless Steel Terminals Copper Alloy Terminals

a. Yes; replace the injector with the out-of-range resistance.

Refer to section "Removal of the Fuel Injector - Three-Filter System".

Refer to section "Removal of the Fuel Injector - Two-Filter System".

b. No; Go to step 11.

11. Review the MCM Hardware Part Number on the sticker located on the front of the MCM, shown in the figure below. Is

the MCM Hardware part number RA0014469935 or RA0024460135?

42 All information subject to change without notice.

Copyright © 2015 DETROIT DIESEL CORPORATION 9 04-15

9 04-15

a. Yes; replace all the copper connector pin injectors on the engine. Verify repairs.

Refer to section "Removal of the Fuel Injector - Three-Filter System".

Refer to section "Removal of the Fuel Injector - Two-Filter System".

b. No; replace the MCM with MCM part number RA0014469935. Refer to section "Removal of the Motor Control

Module". Verify repairs. See 15TS-16 (http://ddcsn-ddc.freightliner.com/cps/rde/xbcr/ddcsn/15TS16.pdf) for

further information.

12. Disconnect the Motor Control Module (MCM) 120-pin connector.

13. Inspect the MCM 120-pin connector and 120-pin harness connector for signs of corrosion, spread, unseated (pushed

out) or damaged pins, connector seal for damage (signs of water or oil intrusion) or signs of wire damage.

a. If signs of damage are found, repair as necessary. Verify repairs.

b. If no signs of damage, Go to step 14.

All information subject to change without notice. 43

9 04-15 Copyright © 2015 DETROIT DIESEL CORPORATION

7 SPN 656/FMI 3 - EPA10

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

14. Using the chart below, measure and record the resistance values between the engine side of the front valve cover 14-pin

connector and the MCM 120-pin connector. Are the resistances within range?

Table 36.

Engine Harness Injector Circuit Resistance Table

Rear Engine Side Valve Rear Engine Side Valve

MCM 120-Pin Harness Acceptable Resistance Acceptable Resistance

Cover 14-pin connector Cover 14 pin connector

Connector 1Ω or less 1KΩ or greater

# #

1 19 Ω 1 and ground Ω

2 16 Ω 2 and ground Ω

3 20 Ω 3 and ground Ω

4 18 Ω 4 and ground Ω

a. Yes; Go to step 15.

b. No; repair the engine side harness. Verify repairs.

15. Review the MCM Hardware Part Number on the sticker located on the front of the MCM, under the Instrumentation

window in DiagnosticLink as shown in the figure below. Is the MCM Hardware part number RA0014469935 or

RA0024460135?

44 All information subject to change without notice.

Copyright © 2015 DETROIT DIESEL CORPORATION 9 04-15

9 04-15

a. Yes; replace all the copper connector pin injectors on the engine. Verify repairs.

Refer to section "Removal of the Fuel Injector - Three-Filter System".

Refer to section "Removal of the Fuel Injector - Two-Filter System".

b. No; replace the MCM with MCM part number RA0014469935. Refer to section "Removal of the Motor Control

Module". Verify repairs. See 15TS-16 (http://ddcsn-ddc.freightliner.com/cps/rde/xbcr/ddcsn/15TS16.pdf) for

further information.

All information subject to change without notice. 45

9 04-15 Copyright © 2015 DETROIT DIESEL CORPORATION

You might also like

- Indmar Diagnostic Manual Version 1.2Document341 pagesIndmar Diagnostic Manual Version 1.2Cheohdez0% (2)

- Cascadia - SE PDFDocument387 pagesCascadia - SE PDFLuisArturoAcevedoTapia95% (20)

- D6CC Schematic Diagrams Engine Electrical System Engine Control SystemDocument1 pageD6CC Schematic Diagrams Engine Electrical System Engine Control SystemhaviettuanNo ratings yet

- Automotive Sensor Testing and Waveform AnalysisFrom EverandAutomotive Sensor Testing and Waveform AnalysisRating: 4.5 out of 5 stars4.5/5 (13)

- THE OWNER OF THIS EDM-700/800/730/830 Must Keep This ManualDocument30 pagesTHE OWNER OF THIS EDM-700/800/730/830 Must Keep This ManualAvionicsfNo ratings yet

- Fault Code: 3348 Turbocharger 1 Compressor Inlet Pressure - Data Valid But Below Normal Operating Range - Most Severe LevelDocument4 pagesFault Code: 3348 Turbocharger 1 Compressor Inlet Pressure - Data Valid But Below Normal Operating Range - Most Severe LevelhaviettuanNo ratings yet

- 808 10 PDFDocument74 pages808 10 PDFHamilton miranda100% (1)

- SPN 164/fmi 2 - Epa07Document3 pagesSPN 164/fmi 2 - Epa07Hyo Won Lee60% (5)

- EX-GM-006 - GMW 14698 - 200709 - EN - Scratch Resistance of Orangnic Coatings and Self-Adhesion Foils PDFDocument3 pagesEX-GM-006 - GMW 14698 - 200709 - EN - Scratch Resistance of Orangnic Coatings and Self-Adhesion Foils PDFEd RiNo ratings yet

- SB 10054469 8890Document27 pagesSB 10054469 8890Youssef MoutaouadiNo ratings yet

- GHG17 Heavy Duty Troubleshooting Manual (DDC-SVC-MAN-0191)Document17 pagesGHG17 Heavy Duty Troubleshooting Manual (DDC-SVC-MAN-0191)Octavio Hernandez RodriguezNo ratings yet

- 1218 10Document19 pages1218 10Hamilton mirandaNo ratings yet

- Riello G750 ManuelDocument21 pagesRiello G750 Manuelmelvin hoferNo ratings yet

- IS132 - R8865 Digital Hourmeter RevbDocument2 pagesIS132 - R8865 Digital Hourmeter RevbHilman Adi LuhungNo ratings yet

- DetruitDocument4 pagesDetruitfaiz aliNo ratings yet

- ESPCP - Ken Saveth - OilProductionDocument14 pagesESPCP - Ken Saveth - OilProductionJude RodriguesNo ratings yet

- Emanagebasicoperation PDFDocument23 pagesEmanagebasicoperation PDFanthony dizonNo ratings yet

- MC 10124184 9999 PDFDocument8 pagesMC 10124184 9999 PDFTracto Rescates de Occidente CtrlNo ratings yet

- Fabrication Pnuematic Trainer Kit For Educational PurposesDocument15 pagesFabrication Pnuematic Trainer Kit For Educational PurposesUday Bagade100% (1)

- Operating Instruction Manual FOR Optical Interferometic Gas Analyzer MODEL FI-800Document23 pagesOperating Instruction Manual FOR Optical Interferometic Gas Analyzer MODEL FI-800Hoàn NguyễnNo ratings yet

- TycoDocument10 pagesTycoTahseenNo ratings yet

- 3000 Liter Undergorund LPG TankDocument4 pages3000 Liter Undergorund LPG TankHarshana AtapattuNo ratings yet

- Codigo de Falla DdecDocument9 pagesCodigo de Falla DdecAnonymous nhF45CNo ratings yet

- Informacion Producto Martillo MX60Document20 pagesInformacion Producto Martillo MX60ING MANTENIMIENTO CONINTEL S.ANo ratings yet

- Rociador Rango Extendido EC5Document6 pagesRociador Rango Extendido EC5victorNo ratings yet

- Product Information: Air Impact WrenchDocument12 pagesProduct Information: Air Impact WrenchkareemNo ratings yet

- Diff Micom P543 GT1 3 Line DiffDocument20 pagesDiff Micom P543 GT1 3 Line DiffPandrayar MaruthuNo ratings yet

- Atb 1582Document3 pagesAtb 1582gpearson1002471No ratings yet

- MPM 312 03 07Document5 pagesMPM 312 03 07Mousa PetrolNo ratings yet

- Injector Solenoid Circuit - Test (RENR9348-20)Document16 pagesInjector Solenoid Circuit - Test (RENR9348-20)Guido Emanuel SteinbachNo ratings yet

- Intro To Auto Sprinkler 2020Document69 pagesIntro To Auto Sprinkler 2020Muhammed100% (1)

- Ingecon Sun Storage 1play TL M: List of Approved Power MetersDocument6 pagesIngecon Sun Storage 1play TL M: List of Approved Power MetersalarmaNo ratings yet

- Technical Data: 1. DescriptionDocument4 pagesTechnical Data: 1. DescriptionCanh RocNo ratings yet

- 1010 14 PDFDocument5 pages1010 14 PDFruddyNo ratings yet

- Samsung GT-i9505 Galaxy S4 00 01 02 03 04 05 PDFDocument36 pagesSamsung GT-i9505 Galaxy S4 00 01 02 03 04 05 PDFluiz232315No ratings yet

- Manual Cabezal 11-31338Document37 pagesManual Cabezal 11-31338producciontecnolaminasNo ratings yet

- Manual BEST RIGHT DWDocument7 pagesManual BEST RIGHT DWJohann BrionesNo ratings yet

- Tds 10p42nf en April 2024 Supersedes September 2021Document4 pagesTds 10p42nf en April 2024 Supersedes September 2021AlperNo ratings yet

- Series TY-B - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Standard Response, Standard CoverageDocument8 pagesSeries TY-B - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Standard Response, Standard CoverageFlorin IordacheNo ratings yet

- FD 8030 User ManualDocument2 pagesFD 8030 User ManualPopa DanNo ratings yet

- Service LubricatorsDocument52 pagesService LubricatorsmecambNo ratings yet

- Nota Praktikal 5 (Inspect - Testing) - EditDocument11 pagesNota Praktikal 5 (Inspect - Testing) - EditMuhammad Ilyasak Abdul HalimNo ratings yet

- Grass Trimmer/Brush Cutter: Operator's ManualDocument36 pagesGrass Trimmer/Brush Cutter: Operator's ManualGonzalo AlvarezNo ratings yet

- GL General Industries Corp.-Tfp1306!08!2019 (Remarcado)Document34 pagesGL General Industries Corp.-Tfp1306!08!2019 (Remarcado)Fabian Andres Reyes SerranoNo ratings yet

- Samsung Galaxy Tab S Sm-t805 Service ManualDocument184 pagesSamsung Galaxy Tab S Sm-t805 Service ManualIsaac Canul GNo ratings yet

- Veego Matic MD PDFDocument38 pagesVeego Matic MD PDFRavi ParikhNo ratings yet

- KobelionII-VS420-730A Instruction Manual (English) (4H50ZC4577P1-01)Document78 pagesKobelionII-VS420-730A Instruction Manual (English) (4H50ZC4577P1-01)Nguyen Anh SangNo ratings yet

- AOP Series D Trunnion 5000 WP Ball Valve: Installation, Operation and Maintenance ManualDocument18 pagesAOP Series D Trunnion 5000 WP Ball Valve: Installation, Operation and Maintenance ManualDennys SandriniNo ratings yet

- Reservior Skid Assl Qap AlfaDocument1 pageReservior Skid Assl Qap AlfaajmainNo ratings yet

- SPN 4334 - Fmi 4 - GHG17Document5 pagesSPN 4334 - Fmi 4 - GHG17Francisco Javier TorresNo ratings yet

- DV-5 Automatic Water Control Valve Deluge Fire Protection Systems 1-1/2 Inch To 8 Inch (DN40 To DN200) General DescriptionDocument34 pagesDV-5 Automatic Water Control Valve Deluge Fire Protection Systems 1-1/2 Inch To 8 Inch (DN40 To DN200) General DescriptionOscar GallettoNo ratings yet

- 4runner Limited 2009 2UZ FEDocument314 pages4runner Limited 2009 2UZ FEarmotrixmecNo ratings yet

- 351 352 ManualDocument7 pages351 352 ManualsakornthiemNo ratings yet

- ANNEX1 Jimny (A6G415) - Replacement Procedure For Fuel-PumpDocument35 pagesANNEX1 Jimny (A6G415) - Replacement Procedure For Fuel-Pumpm.gavrielNo ratings yet

- Owner'S Manual: Manual Do UsuárioDocument44 pagesOwner'S Manual: Manual Do Usuáriojuan c GimenoNo ratings yet

- Tyco - MlazniceDocument8 pagesTyco - MlazniceMuhidin KozicaNo ratings yet

- Page 1 of 13: Exc K oDocument13 pagesPage 1 of 13: Exc K oSARAVANAN ANo ratings yet

- Rev B mm10 Dual Cartridge Dispensers ManualDocument12 pagesRev B mm10 Dual Cartridge Dispensers ManualRajarshiNo ratings yet

- 7SJ82 50 51Document4 pages7SJ82 50 51Santhosh Kumar VinayagamNo ratings yet

- Penetrometer MANUALDocument4 pagesPenetrometer MANUALafzal baigNo ratings yet

- Completion Program For YRNS-009-10.14Document20 pagesCompletion Program For YRNS-009-10.14hoss mosafaNo ratings yet

- Series TY-B - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Standard Response, Standard Coverage General DescriptionDocument8 pagesSeries TY-B - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Standard Response, Standard Coverage General DescriptionDanilo Arturo Paredes ErazoNo ratings yet

- Rociador TY3131Document10 pagesRociador TY3131Pavel RamirezNo ratings yet

- R1 RESCMInstructionsDocument7 pagesR1 RESCMInstructionshaviettuanNo ratings yet

- D6CB Engine Control (ETC) SystemDocument1 pageD6CB Engine Control (ETC) SystemhaviettuanNo ratings yet

- New Cascadia Driver's ManualDocument326 pagesNew Cascadia Driver's Manualhaviettuan100% (1)

- Additions, Revisions, or Updates: Subject DateDocument7 pagesAdditions, Revisions, or Updates: Subject DatehaviettuanNo ratings yet

- Weichai EngineDocument114 pagesWeichai Enginehaviettuan100% (1)

- Of Contents: Air Temperature (AAT) Sensor Faults/Location/DiagnosticsDocument11 pagesOf Contents: Air Temperature (AAT) Sensor Faults/Location/DiagnosticshaviettuanNo ratings yet

- Cummins - ISB6.7 CM2150 (2007-09)Document6 pagesCummins - ISB6.7 CM2150 (2007-09)haviettuanNo ratings yet

- Isx 870 IfsmDocument20 pagesIsx 870 IfsmhaviettuanNo ratings yet

- Isx 870 IfsmDocument20 pagesIsx 870 IfsmhaviettuanNo ratings yet

- Freightliner Audio 10 Operating Instructions ManualDocument50 pagesFreightliner Audio 10 Operating Instructions ManualhaviettuanNo ratings yet

- Cascadia Driver's ManualDocument238 pagesCascadia Driver's Manualhaviettuan100% (1)

- K-TAG Master: Instruction Manual and User's GuideDocument45 pagesK-TAG Master: Instruction Manual and User's Guidehaviettuan100% (4)

- Change Log: Title 2010+ DT/9/10 EGR Valve DiagnosticsDocument8 pagesChange Log: Title 2010+ DT/9/10 EGR Valve DiagnosticshaviettuanNo ratings yet

- Steel Reference GuideDocument36 pagesSteel Reference GuideCésar VenegasNo ratings yet

- Berco Products DetailDocument12 pagesBerco Products DetailDilip BhargavaNo ratings yet

- J 403-Aisi 1060Document1 pageJ 403-Aisi 1060Cho thuê chung cư Cầu GiấyNo ratings yet

- Mil T 8606CDocument13 pagesMil T 8606C柏斯材料科學檢驗有限公司公司No ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: Weldox 700 EDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: Weldox 700 Ebaskaran ayyapparajNo ratings yet

- ISO 9606-3 1999 Qualification Testing of Welders-Fusion Welding Part 3 Copper and Copper AlloysDocument30 pagesISO 9606-3 1999 Qualification Testing of Welders-Fusion Welding Part 3 Copper and Copper AlloysJames HurtadoNo ratings yet

- Equivalent Material Cross Valve CastDocument2 pagesEquivalent Material Cross Valve CastsviswaNo ratings yet

- Smarajit Sarkar Department of Metallurgical and Materials Engineering NIT RourkelaDocument219 pagesSmarajit Sarkar Department of Metallurgical and Materials Engineering NIT RourkelaJEANNo ratings yet

- FWDS 0246 ADocument3 pagesFWDS 0246 AAlanka PrasadNo ratings yet

- FastenalTechnicalReferenceGuide PDFDocument62 pagesFastenalTechnicalReferenceGuide PDFikirby77No ratings yet

- RMD® (Regulated Metal Deposition)Document2 pagesRMD® (Regulated Metal Deposition)Jeffin JojimonNo ratings yet

- Ce 304 Lesson 6Document5 pagesCe 304 Lesson 6Lester Khiets RoaNo ratings yet

- Misi PipesDocument32 pagesMisi PipesMehreen ShaukatNo ratings yet

- Cushion Tee: Butt Weld Ends DetailsDocument1 pageCushion Tee: Butt Weld Ends DetailsEHT pipeNo ratings yet

- DEC OSS Business IntroductionDocument28 pagesDEC OSS Business Introductionamr kouranyNo ratings yet

- Bacayan, Carmela C. Honesty Module 1 (2 Weeks) Core13-Cpar 2021-2022Document21 pagesBacayan, Carmela C. Honesty Module 1 (2 Weeks) Core13-Cpar 2021-2022Carmela Bacayan0% (1)

- According To Products - SKW MetallurgieDocument2 pagesAccording To Products - SKW MetallurgieVishav SharmaNo ratings yet

- Astm A111 PDFDocument3 pagesAstm A111 PDFbanglvhNo ratings yet

- Product Catalogue: Cultivation Parts & Specialist SolutionsDocument28 pagesProduct Catalogue: Cultivation Parts & Specialist SolutionsPetrNo ratings yet

- AluminiumDocument239 pagesAluminiumAgustine SetiawanNo ratings yet

- Equiaxed Zone and Ridging in Ferritic SteelDocument9 pagesEquiaxed Zone and Ridging in Ferritic SteelRinku Singroha (JSHL-QUALITY)No ratings yet

- CWC-BookletF1 29 PDFDocument1 pageCWC-BookletF1 29 PDFJagannath SahuNo ratings yet

- Aws A5 5 PDFDocument55 pagesAws A5 5 PDFNO ONE100% (1)

- Helicopter Crash EquipmentDocument5 pagesHelicopter Crash Equipmentcupid75No ratings yet

- Tables For EN 10216-2 PDFDocument18 pagesTables For EN 10216-2 PDFAli BariNo ratings yet

- Calsens - Product - Profile - FinalDocument6 pagesCalsens - Product - Profile - FinalAkshat Engineers Private LimitedNo ratings yet

- Astm A 269Document7 pagesAstm A 269Victor Martinez MartinezNo ratings yet

- Materials AvailableDocument3 pagesMaterials AvailableKmt_AeNo ratings yet

- LSS Catalogue enDocument68 pagesLSS Catalogue enArzu AliyevaNo ratings yet