Professional Documents

Culture Documents

INTRODUCTION TO WELDING PROCESSES WELDING CONSUMABLE

INTRODUCTION TO WELDING PROCESSES WELDING CONSUMABLE

Uploaded by

VenkateshCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

INTRODUCTION TO WELDING PROCESSES WELDING CONSUMABLE

INTRODUCTION TO WELDING PROCESSES WELDING CONSUMABLE

Uploaded by

VenkateshCopyright:

Available Formats

Introduction to Welding Processes Welding

Consumables

Welding Stages:

1-Solid State Friction Welding Plasticity

2-Solidering Liquid Filler Material Liquid Soldering > 450°C

Base Metal Not Melted Brazing upto 450°C Furnace

3- Liquid State Heat Source

i) Chemical (Oxy Fuel Welding / Cutting)

ii) Electrical (Arc & Resistance)

ARC Resistance

Consumable / Non-Consumable Spot & Seam Welding

SMAW GTAW

GMAW SAW

FOR: SMAW, GMAW, SAW

SMAW DC+ AC DC- High

Deposition

GMAW

SAW

LOF Spatter

LOP Undercut Deep Penetration /

Poor Toe Ampere Low to High Ex Penetraion Contour Bead

Slag BT

Amp

Spatter on Bead

If Amp Low:

Poor starting, Slag inclusions, Weld bead contour too high, Lack of fusion/penetration

If Amp High:

Spatter, Excess penetration, Undercut, Burn-through

Arc Volt / Length Low to High

Wider Bead

Arc

Voltage

Arc

Length

Arc length = arc voltage Spatter on Sides of Bead

If Arc Length Low:

Arc can be extinguished, “stubbing” Ex Penetration,

BT If Arc Length High:

Spatter, Porosity, Excess penetration, Undercut, LOP, LOF Travel Speed Slow to High Thin Bead

Travel Speed

If Travel Speed is Low: Slow Speed =

Wide weld bead contour, Excess penetration, Burn-through Deep Penetration

If Travel Speed is Too High:

Lack of root fusion, incomplete root penetration, undercut, Poor bead profile, difficult slag removal

contact Email: seemab112272@gmail.com SAW

QA/QC Ch Seemab

You might also like

- Digital Electronics, Volume 1 Combinational Logic Circuits by Tertulien Ndjountche (Z-Lib - Org) - 178-190Document13 pagesDigital Electronics, Volume 1 Combinational Logic Circuits by Tertulien Ndjountche (Z-Lib - Org) - 178-190Shendy ArsellaNo ratings yet

- 12 TIG WeldingDocument27 pages12 TIG WeldingPraviBeetlesNo ratings yet

- Welcome YOU: Institute of Welding & Testing TechnologyDocument92 pagesWelcome YOU: Institute of Welding & Testing TechnologyHimanshu MishraNo ratings yet

- Welding Processes (Compatibility Mode)Document36 pagesWelding Processes (Compatibility Mode)Bharat KhandekarNo ratings yet

- Welding Fundamentals 3Document68 pagesWelding Fundamentals 3Saiprasad Thakar100% (1)

- Welding Course NPTELDocument39 pagesWelding Course NPTELAbhijeetSethi0% (1)

- Welding Process Techniques: KG - Pandithan, Iwe Technical Advisor, RiboDocument51 pagesWelding Process Techniques: KG - Pandithan, Iwe Technical Advisor, RibojswldeepNo ratings yet

- UT-Bai 5-Han Va KTDocument43 pagesUT-Bai 5-Han Va KTWill SmithNo ratings yet

- Arc WeldingDocument29 pagesArc WeldinguditNo ratings yet

- Joint Restraint - Improper Bead Shape - Hydrogen Pickup - Rapid Cooling Rate - High Carbon/Alloy Content - Low Melting Point ContaminantsDocument1 pageJoint Restraint - Improper Bead Shape - Hydrogen Pickup - Rapid Cooling Rate - High Carbon/Alloy Content - Low Melting Point ContaminantsLucian HoudiniNo ratings yet

- Commonly Used Welding Process Techniques-OverviewDocument51 pagesCommonly Used Welding Process Techniques-OverviewaadmaadmNo ratings yet

- Welding 1Document2 pagesWelding 1GlennNo ratings yet

- Welding Processes OverviewDocument52 pagesWelding Processes OverviewAnil Kumar TNo ratings yet

- Welding Types and DefectsDocument30 pagesWelding Types and DefectsHarisagar ThulasiramanNo ratings yet

- 10 MMA WeldingDocument16 pages10 MMA WeldingAdhanom G.No ratings yet

- Silde - Cswip - 3.1 079 156 07Document1 pageSilde - Cswip - 3.1 079 156 07cswip2024No ratings yet

- RTFI-weld-defect-repairs-twiDocument61 pagesRTFI-weld-defect-repairs-twismsunil12345No ratings yet

- D-Sub 2018Document8 pagesD-Sub 2018samyghallabNo ratings yet

- Silde - Cswip - 3.1 079 156 09Document1 pageSilde - Cswip - 3.1 079 156 09cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 06Document1 pageSilde - Cswip - 3.1 079 156 06cswip2024No ratings yet

- Various Welding ProcessDocument50 pagesVarious Welding Processsachin G.No ratings yet

- Arc Welding Length (SAWL), Submerged Arc Welding Helix (SAWH), High Frequency Welding (HFW)Document1 pageArc Welding Length (SAWL), Submerged Arc Welding Helix (SAWH), High Frequency Welding (HFW)Wojciech SpychalskiNo ratings yet

- Tungsten Inert Gas or Gas Tungsten Arc WeldingDocument35 pagesTungsten Inert Gas or Gas Tungsten Arc WeldingLương Hồ Vũ75% (4)

- LOTHERME Ready Reckoner PDFDocument40 pagesLOTHERME Ready Reckoner PDFAmit DuttaNo ratings yet

- Welding Process: Mma (Manual Metal Arc)Document1 pageWelding Process: Mma (Manual Metal Arc)Fauzan RusmayadiNo ratings yet

- Welding Technology: by Ravish KambojDocument30 pagesWelding Technology: by Ravish KambojVarun VaruNo ratings yet

- WPS Butt Repair A 53 FAB-GTAW-GMAW-FCAWDocument1 pageWPS Butt Repair A 53 FAB-GTAW-GMAW-FCAWRaja HoneNo ratings yet

- C.25LAS01.026.01 Sesi 3 - Jenis Cacat Las (2JP)Document57 pagesC.25LAS01.026.01 Sesi 3 - Jenis Cacat Las (2JP)vnrfjrnNo ratings yet

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- Additional Width Reduction For HRPO SteelDocument24 pagesAdditional Width Reduction For HRPO SteelDali HariswijayaNo ratings yet

- Welding Methods & Technology.: V.R.Ekbote Ces (Insp), Ril (PG)Document52 pagesWelding Methods & Technology.: V.R.Ekbote Ces (Insp), Ril (PG)cyNo ratings yet

- WPS Welding Performance SpecialistDocument2 pagesWPS Welding Performance SpecialistGobinath GovindarajNo ratings yet

- Piping Material CompositionDocument11 pagesPiping Material CompositionrezzdezzNo ratings yet

- Afcons Infrastructure Limited: Procedure Qualification Record (PQR)Document21 pagesAfcons Infrastructure Limited: Procedure Qualification Record (PQR)GaapchuNo ratings yet

- Silde - Cswip - 3.1 079 156 08Document1 pageSilde - Cswip - 3.1 079 156 08cswip2024No ratings yet

- Comparisons Between GRP Pipes With Various PipesDocument21 pagesComparisons Between GRP Pipes With Various PipesraghuramNo ratings yet

- Product Technology: NDT Training & CertificationDocument41 pagesProduct Technology: NDT Training & CertificationSANUNo ratings yet

- P WPS Smaw Ceym 001 021Document1 pageP WPS Smaw Ceym 001 021juan carlos garavitoNo ratings yet

- Welding Defects Poster 600x900 Lores enDocument1 pageWelding Defects Poster 600x900 Lores enMostafa ZedNo ratings yet

- WPS Mig 2Document1 pageWPS Mig 2rafetguzelsoyNo ratings yet

- 11 TIG WeldingDocument29 pages11 TIG WeldingudomNo ratings yet

- Gas Metal Arc WeldingDocument52 pagesGas Metal Arc WeldingBalakumarNo ratings yet

- Welding Record FormatDocument2 pagesWelding Record FormatGaurang PandyaNo ratings yet

- Welding ProcessDocument29 pagesWelding ProcessKoon AnuNo ratings yet

- Hoppeck Battery TypeDocument2 pagesHoppeck Battery TypedinanibnuNo ratings yet

- Welding Defect InfoDocument7 pagesWelding Defect Infobriggswill7No ratings yet

- Untitled 6Document1 pageUntitled 6அன்புடன் அஸ்வின்No ratings yet

- Welding ProcessesDocument20 pagesWelding Processesvikasbhadoria9894No ratings yet

- Surface Finish Cross ReferenceDocument1 pageSurface Finish Cross ReferencemarcalpiNo ratings yet

- Welding Defects: Ganesan V Assistant Manager-TSD D&H Secheron Electrodes PVT - LTDDocument49 pagesWelding Defects: Ganesan V Assistant Manager-TSD D&H Secheron Electrodes PVT - LTDPrakash RajNo ratings yet

- Thermal Spray CoatingsDocument12 pagesThermal Spray CoatingsRobert ShinNo ratings yet

- Aramco Hot Tap Welding Procedure Rev 1Document3 pagesAramco Hot Tap Welding Procedure Rev 1BWQNo ratings yet

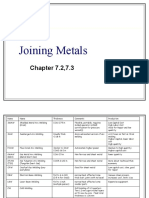

- Joining Metals: Chapter 7.2,7.3Document38 pagesJoining Metals: Chapter 7.2,7.3thankz4venomNo ratings yet

- Welding With METRODE Gas Shielded FCW'S: Metrode Products Limited Hanworth Lane Chertsey, Surrey, KT16 9LL UKDocument19 pagesWelding With METRODE Gas Shielded FCW'S: Metrode Products Limited Hanworth Lane Chertsey, Surrey, KT16 9LL UKSanthosh Kumar100% (1)

- Wps Aws d1.1 NEWDocument2 pagesWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- Brass Rods - High Tensile Brass Rod, Forging Brass Rod, Free Cutting Brass Rod ManufacturerDocument6 pagesBrass Rods - High Tensile Brass Rod, Forging Brass Rod, Free Cutting Brass Rod Manufacturerk4kuldeepNo ratings yet

- BGR Energy Systems Limited: Oil & Gas Equipment Division Welding Procedure Specification (WPS) - Aws D1.1Document1 pageBGR Energy Systems Limited: Oil & Gas Equipment Division Welding Procedure Specification (WPS) - Aws D1.1Eswar Enterprises QcNo ratings yet

- Cacat Yang Umum Terdapat Pada PipaDocument10 pagesCacat Yang Umum Terdapat Pada PipaAntrasit CoffeeNo ratings yet

- Common Weld DiscontinuitiesDocument43 pagesCommon Weld DiscontinuitiesNader GaafarNo ratings yet

- Tackle Business WastesDocument15 pagesTackle Business WastesVenkateshNo ratings yet

- Engineering PropertiesDocument28 pagesEngineering PropertiesVenkateshNo ratings yet

- Quality CultureDocument33 pagesQuality CultureVenkateshNo ratings yet

- IMS Audit CriteriaDocument1 pageIMS Audit CriteriaVenkateshNo ratings yet

- Overview On PreheatingDocument24 pagesOverview On PreheatingVenkateshNo ratings yet

- Severn Glocon Liquid Penetrant TestingDocument11 pagesSevern Glocon Liquid Penetrant TestingVenkateshNo ratings yet

- Toyota Way Principle 1Document12 pagesToyota Way Principle 1VenkateshNo ratings yet

- The Six RulesDocument9 pagesThe Six RulesVenkateshNo ratings yet

- Pyrite Hopper Witnessed Report 1278Document6 pagesPyrite Hopper Witnessed Report 1278VenkateshNo ratings yet

- All About APQPDocument1 pageAll About APQPVenkateshNo ratings yet

- API Product MonogramsDocument8 pagesAPI Product MonogramsVenkateshNo ratings yet

- Dail Work Management System-1Document17 pagesDail Work Management System-1VenkateshNo ratings yet

- Multistage AmplifiersDocument22 pagesMultistage AmplifiersParvinder SinghNo ratings yet

- DSP Project ReportDocument14 pagesDSP Project ReportMuhammad RashidNo ratings yet

- Reverse-Feed Applications For Circuit Breakers: Technical Publication PU01200001EDocument8 pagesReverse-Feed Applications For Circuit Breakers: Technical Publication PU01200001EgoutammandNo ratings yet

- Section C Section C: Circuit Schematic - Basic MachineDocument9 pagesSection C Section C: Circuit Schematic - Basic MachineDominik PękalNo ratings yet

- Panasonic TX P65vt50e TX p65vt50j TX p65vt50tDocument120 pagesPanasonic TX P65vt50e TX p65vt50j TX p65vt50tVjacheslaw Timoshkov100% (1)

- 441 Home Work7Document2 pages441 Home Work7python1750% (2)

- IIA - 6th ModuleDocument26 pagesIIA - 6th ModuleSreekesh GiriNo ratings yet

- Considerations of Photovoltaic System Structure Design For Effective Lightning ProtectionDocument9 pagesConsiderations of Photovoltaic System Structure Design For Effective Lightning ProtectionRodrigoNo ratings yet

- GFK2220F Modbus RTU Master Comm User Manual 20150202 WebDocument50 pagesGFK2220F Modbus RTU Master Comm User Manual 20150202 WebSudipto MajumderNo ratings yet

- 2013-14 AC Motors StartersDocument20 pages2013-14 AC Motors StartersFiqri Permana MohamadNo ratings yet

- AC Machines (Transformer) : By: E.M. Morales, ReeDocument28 pagesAC Machines (Transformer) : By: E.M. Morales, ReeJocel GuzmanNo ratings yet

- DS TSP1x1 EN GDocument56 pagesDS TSP1x1 EN GUMER SHAFAATNo ratings yet

- Bladeless WindmillDocument22 pagesBladeless WindmillSudarsan reddyNo ratings yet

- Chapter 06 Synchronous Sequential CircuitsDocument56 pagesChapter 06 Synchronous Sequential Circuitskidgod2111No ratings yet

- SDH NERA Overview 1Document60 pagesSDH NERA Overview 1alifkusumahNo ratings yet

- HL19T CH MT5380P1 V2Document61 pagesHL19T CH MT5380P1 V2Jazziel DomínguezNo ratings yet

- Plano Elect r1600h6 9sd1-UpDocument7 pagesPlano Elect r1600h6 9sd1-UpGian GallardoNo ratings yet

- IG NTC BB Datasheet - 1Document4 pagesIG NTC BB Datasheet - 1Tiên Lê Trần MỹNo ratings yet

- Schneider Micrologic 6.0eDocument28 pagesSchneider Micrologic 6.0eIsmet KoracNo ratings yet

- Exercises Problems: 26-2 Capacitance IEDocument4 pagesExercises Problems: 26-2 Capacitance IEBárbara MourãoNo ratings yet

- 2006 - 08 Test of Analog Communiaction Made EasyDocument12 pages2006 - 08 Test of Analog Communiaction Made EasyNikhil Singh0% (2)

- Physical Science Grade 10 Nov 2023 P1 QP Eng VerifiedDocument12 pagesPhysical Science Grade 10 Nov 2023 P1 QP Eng VerifiedLesedi RamarumoNo ratings yet

- Manual Inversor-Vlt2800 PDFDocument165 pagesManual Inversor-Vlt2800 PDFLeandro de FigueiredoNo ratings yet

- Chapter 1 - Introduction To WANsDocument4 pagesChapter 1 - Introduction To WANsAlexandrosAristeridisNo ratings yet

- ISEI 2010-Diagnostics Techniques of Power TransformersDocument80 pagesISEI 2010-Diagnostics Techniques of Power TransformersAli Naderian100% (3)

- Ceng in 7 Days Second EditionDocument89 pagesCeng in 7 Days Second EditionSelorm100% (3)

- Wheatstone BridgeDocument13 pagesWheatstone Bridgeshawky allam100% (2)

- IEC 61439 Sunlight - Technical - HandBook PDFDocument26 pagesIEC 61439 Sunlight - Technical - HandBook PDFJaggu JrzNo ratings yet

- 0000 PDFDocument1,328 pages0000 PDFLuan MoreiraNo ratings yet