Professional Documents

Culture Documents

%28ASCE%29MT.1943-5533.0000483

%28ASCE%29MT.1943-5533.0000483

Uploaded by

sivabathyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

%28ASCE%29MT.1943-5533.0000483

%28ASCE%29MT.1943-5533.0000483

Uploaded by

sivabathyCopyright:

Available Formats

Laboratory Studies on Stabilization of an Expansive

Soil by Lime Precipitation Technique

T. Thyagaraj1; Sudhakar M. Rao2; P. Sai Suresh3; and U. Salini4

Downloaded from ascelibrary.org by Sri Sivasubramaniya Nadar College Of Engineering on 08/11/18. Copyright ASCE. For personal use only; all rights reserved.

Abstract: Lime stabilization prevails to be the most widely adopted in situ stabilization method for controlling the swell-shrink potentials

of expansive soils despite construction difficulties and its ineffectiveness in certain conditions. In addition to the in situ stabilization

methods presently practiced, it is theoretically possible to facilitate in situ precipitation of lime in soil by successive permeation of calcium

chloride (CaCl2 ) and sodium hydroxide (NaOH) solutions into the expansive soil. In this laboratory investigation, an attempt is made to study

the precipitation of lime in soil by successive mixing of CaCl2 and NaOH solutions with the expansive soil in two different sequences.

Experimental results indicated that in situ precipitation of lime in soil by sequential mixing of CaCl2 and NaOH solutions with expansive

soil developed strong lime-modification and soil-lime pozzolanic reactions. The lime-modification reactions together with the poorly de-

veloped cementation products controlled the swelling potential, reduced the plasticity index, and increased the unconfined compressive

strength of the expansive clay cured for 24 h. Comparatively, both lime-modification reactions and well-developed crystalline cementation

products (formed by lime-soil pozzolanic reactions) contributed to the marked increase in the unconfined compressive strength of the ex-

pansive soil that was cured for 7–21 days. Results also show that the sequential mixing of expansive soil with CaCl2 solution followed by

NaOH solution is more effective than mixing expansive soil with NaOH solution followed by CaCl2 solution. DOI: 10.1061/(ASCE)MT

.1943-5533.0000483. © 2012 American Society of Civil Engineers.

CE Database subject headings: Expansive soils; Soil stabilization; Compressive strength; Swelling (material); Shrinkage; Lime;

Laboratory tests.

Author keywords: Expansive soils; Soil stabilization; Compressive strength; Swelling; Shrinkage; Lime.

Introduction and soil is the most efficient and cost-effective method of stabiliz-

ing expansive soils to shallow depths (Rao and Thyagaraj 2003).

Expansive soils occur in arid and semiarid regions of the world. In situ stabilization methods using lime have been pioneered in

The high swelling and shrinkage potentials of these soils cause se- Sweden, Japan, and the United States, and these methods are

vere damages to pavements, runways, and building foundations, mostly restricted to improve the engineering properties of soft clays

which are founded on these soils (Chen 1988; Nelson and Miller (Tsytovich et al. 1971; Broms and Boman 1975; Holm et al. 1981;

1992). Chemical stabilization is one of the alternative solutions to Bell 1988b; Wang 1989; Chew et al. 1993; Porbaha 1998; Rogers

overcome the undesirable swell-shrink potentials of the expansive et al. 2000).

soils. Among the chemical stabilization methods for expansive In situ stabilization methods using lime can be divided into three

soils, lime stabilization is most widely adopted method for control- primary groups: lime columns, lime piles, and lime slurry injection

ling the swell-shrink potentials by chemically modifying the soil (Glendinning and Rogers 1996). Lime columns refer to deep ver-

characteristics. tical columns of lime-stabilized material formed by in situ mixing

Lime stabilization of expansive soils in the field is achieved of lime and soft clays. Lime column stabilization is mostly re-

stricted to soft clays, because the construction of lime columns

by shallow mixing of lime or by in situ deep stabilization methods

in expansive soil deposits by in situ mixing of lime and expansive

using lime columns, lime piles, and lime slurry injection methods

soils is very difficult owing to the very stiff nature of these soils.

(Bell 1988b; Rao and Thyagaraj 2003). Physical mixing of lime

Lime piles refer to holes in the ground filled with lime. Recently,

1 Rao and Venkataswamy (2002) found that lime pile treatment of

Assistant Professor, Dept. of Civil Engineering, Indian Institute of

Technology Madras, Chennai 600 036, India (corresponding author).

expansive soils could not promote soil-lime pozzolanic reactions;

E-mail: ttraj@iitm.ac.in it only facilitated short-term lime-modification reactions. Lime pile

2

Professor, Dept. of Civil Engineering, and Chairman, Center for treatment of expansive soil could not raise the soil pH levels to ≥ 12

Sustainable Technologies, Indian Institute of Science, Bangalore 560 012, owing to the low solubility of lime and the impervious nature of

India. expansive soil, which inhibited the migration of lime.

3

Former Postgraduate Student, Dept. of Civil Engineering, National Long-term soil-lime pozzolanic reactions occur at pH values

Institute of Technology Warangal, Warangal 506 004, India.

4

> 12 from the increase in the solubility of siliceous and aluminous

Research Student, Dept. of Civil Engineering, Indian Institute of compounds in the clay minerals. These compounds react with cal-

Technology Madras, Chennai 600 036, India.

cium to form calcium silicate hydrate (CSH) and calcium aluminate

Note. This manuscript was submitted on February 16, 2011; approved

on January 23, 2012; published online on January 25, 2012. Discussion

hydrate (CAH) gels, which coat the soil particles and subsequently

period open until January 1, 2013; separate discussions must be submitted crystallize to bond them (Eades and Grim 1960; Diamond et al.

for individual papers. This paper is part of the Journal of Materials in Civil 1963; Rogers et al. 1997). Because of the imperviousness and very

Engineering, Vol. 24, No. 8, August 1, 2012. ©ASCE, ISSN 0899-1561/ stiff nature of the expansive soils, the lime column and lime pile

2012/8-1067–1075/$25.00. stabilization methods are either difficult to construct or ineffective

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / AUGUST 2012 / 1067

J. Mater. Civ. Eng., 2012, 24(8): 1067-1075

in stabilizing these soils. Hence, a need exists for new treatment Table 1. Properties of Expansive Soil

methods and for improvement of stabilization methods, which Property Value

can effectively stabilize expansive soils.

In addition to migration of lime into the expansive soil from pH 8.0

a lime pile/column, it is theoretically possible to facilitate in situ Specific gravity (GS ) 2.70

precipitation of lime in the expansive soil by successive permeation Liquid limit (%) 75

of calcium chloride (CaCl2 ) and sodium hydroxide (NaOH) solu- Plastic limit (%) 25

tions into the expansive soil. Successive permeation of CaCl2 and Plasticity index (%) 50

NaOH solutions is expected to facilitate in situ precipitation of lime Shrinkage limit (%) 13

Downloaded from ascelibrary.org by Sri Sivasubramaniya Nadar College Of Engineering on 08/11/18. Copyright ASCE. For personal use only; all rights reserved.

according to the reaction Grain size distribution: (%)

CaCl2 þ 2NaOH ⇒ CaðOHÞ2 þ 2NaCl ð1Þ Sand 16

Silt 28

The precipitated lime is expected to modify the properties of Clay 56

expansive soil by lime-modification and soil-lime pozzolanic Unified soil classification symbol CH

reactions. Compaction characteristics:

In this laboratory investigation, an attempt is made to under-

Maximum dry density (Mg∕m3 ) 1.45

stand and develop criteria for in situ stabilization of expansive soil

Optimum moisture content (%) 25

by sequential mixing of CaCl2 and NaOH solutions with expansive

soil in two different sequences. The effect of consecutive mixing Oedometer swell potential at 6.25 kPaa (%) 4.95

of CaCl2 solution and NaOH solution in two different sequences Unconfined compressive strengtha (kPa) 127

a

on the physicochemical properties, index properties, swell poten- Specimen compacted at optimum moisture content to maximum dry

tial, and unconfined compressive strength (UCS) of compacted density.

expansive soil are evaluated.

NaOH solutions into the expansive soil. According to the reaction

in Eq. (1), 110 g of CaCl2 reacts with 80 g of NaOH to form 74 g of

Materials and Methods

calcium hydroxide [CaðOHÞ2 ]. In Eq. (1), the weights of CaCl2 and

NaOH combining to form CaðOHÞ2 are in the ratio of 1:375∶1

Materials (110∕80 ¼ 1:375). Maintaining the same ratio, 10% CaCl2 solu-

Expansive soil from the National Institute of Technology Warangal, tion and 7.3% NaOH solution were mixed sequentially with the

Andhra Pradesh, India, was used in this investigation. The soil was expansive soil to precipitate 2.5% lime in the soil. A 10% CaCl2

air dried and pulverized to pass through a 2-mm sieve. The soil- solution was prepared by dissolving 10 g of CaCl2 in 100 mL of

passing 2-mm sieve was used for conducting standard Proctor distilled water and 7.3% NaOH solution was prepared by dissolv-

compaction, oedometer swell potential, and UCS tests. Index prop- ing 7.3 g of NaOH in 100 mL of distilled water. To increase the

erties were determined on the soil fraction passing through a amount of lime precipitation, the expansive soil was mixed with

425-μm sieve. Commercial-grade CaCl2 and NaOH were used higher concentrations of CaCl2 and NaOH solutions.

for preparing CaCl2 and NaOH solutions in this investigation. To bring out the significance of sequence of mixing CaCl2 and

NaOH solutions on the expansive soil properties, the expansive

Properties of Representative Expansive Soil soil was mixed with CaCl2 and NaOH in two different sequences.

In the first sequence, expansive soil was mixed with CaCl2 solution

The pH of the representative soil was obtained by standard method. before mixing with NaOH solution. This paper refers to experi-

Soil-water suspension with a solids-to-water ratio of 1∶2:5 was used ments performed with this sequence of mixing CaCl2 and NaOH

in the determinations. Initial consumption of lime (ICL) of the solutions with expansive soil as Series 1 experiments. In the second

expansive soil was determined according to BS 1924 (British sequence, NaOH solution was mixed before CaCl2 solution. This

Standards Institution 1990). The ICL value of expansive soil cor- paper refers to experiments performed with this sequence of mix-

responded to 2.5%. The specific gravity (Gs ) of the expansive soil ing NaOH and CaCl2 solutions with expansive soil as Series 2

specimen was determined according to IS 2720 (Part 3) (Bureau of experiments.

Indian Standards 1980a). The grain size distribution of the expan-

sive soil specimen was determined according to IS 2720 (Part 4) Index Properties

(Bureau of Indian Standards 1985a). Atterberg limits of the expan-

sive soil specimen was determined according to IS 2720 (Part 5; Because the liquid limit of untreated expansive soil was 75%, 120 g

Bureau of Indian Standards 1985b) and IS 2720 (Part 6; Bureau of air-dried expansive soil passing 425 μm was mixed with 45 mL

of Indian Standards 1972). The standard Proctor compaction test of CaCl2 solution of desired concentration (10, 20, 35, 50 or 65%)

was performed according to IS 2720 (Part 7; Bureau of Indian and placed in an air tight polythene bag for moisture equilibration

Standards 1980b). The expansive clay has a maximum dry density for 1 h. After this equilibration time, 45 mL of NaOH solution of

(MDD) of 1:45 Mg∕m3 and optimum moisture content (OMC) of desired concentration (7.3, 14.6, 25.5, 36.4 or 47.3%) was mixed

25%. Table 1 shows the physicochemical properties, index proper- with expansive soil and placed in desiccators for moisture equili-

ties, and engineering properties of the expansive soil used in this bration for 24 h. Index properties were determined on the moisture-

investigation. equilibrated specimens to find the effect of sequential mixing of

CaCl2 and NaOH solutions on expansive soil. Index properties per-

formed with this sequence of mixing CaCl2 and NaOH solutions

Procedure for Precipitation of Lime with expansive soil are referred to as Series 1 experiments.

In Series 2 experiments, 45 mL of NaOH solution of desired

As stated, it is theoretically possible to facilitate in situ precipitation concentration (7.3, 14.6, 25.5, 36.4 or 47.3%) was mixed with ex-

of lime in the soil by sequential permeation/mixing of CaCl2 and pansive soil and placed in desiccators for moisture equilibration

1068 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / AUGUST 2012

J. Mater. Civ. Eng., 2012, 24(8): 1067-1075

Table 2. Details of Liquid Limit and Plastic Limit Tests

Calculated percentage

Percentage of solution concentration Calculated amount of of lime precipitation by Liquid

Series designation on weight basis (%)a lime precipitation (g) dry weight of soil (%) limit (%)

Series 1: CaCl2 þ NaOH 10% CaCl2 ; 7.3% NaOH 3.03 2.5 60

20% CaCl2 ; 14.6% NaOH 6.05 5.0 58

35% CaCl2 ; 25.5% NaOH 10.59 8.8 55

50% CaCl2 ; 36.4% NaOH 15.14 12.6 43

Downloaded from ascelibrary.org by Sri Sivasubramaniya Nadar College Of Engineering on 08/11/18. Copyright ASCE. For personal use only; all rights reserved.

65% CaCl2 ; 47.3% NaOH 19.68 16.4 43

Series 2: CaCl2 þ NaOH 7.3% NaOH; 10% CaCl2 3.03 2.5 55

14.6% NaOH; 20% CaCl2 6.05 5.0 50

25.5% NaOH; 35% CaCl2 10.59 8.8 52

36.4% NaOH; 50% CaCl2 15.14 12.6 48

47.3% NaOH; 65% CaCl2 19.68 16.4 50

a

Volume of solution mixed = 45 mL.

for 1 h. After 1-h equilibration time, 45 mL of CaCl2 solution of compacted to a dry density of 1:45 Mg∕m3 using a hand-operated

desired concentration (10, 20, 35, 50 or 65%) was mixed with ex- static press. Compacted specimens were placed in desiccators for

pansive soil and placed in desiccators for moisture equilibration moisture equilibration for 24 h. After this equilibration time, the

for 24 h. Index properties were determined on the moisture- compacted soil specimens (w ¼ 25%) were placed between two

equilibrated specimens for finding the effect of sequential mixing oven-dried porous stones with oven-dried filter papers and were

of NaOH and CaCl2 solutions on expansive soil. Table 2 shows set up in the fixed ring oedometer assembly. A nominal seating load

details of the CaCl2 and NaOH solution concentrations used and of 6.25 kPa was applied, and the specimens were inundated with

the sequence of mixing CaCl2 and NaOH solutions with the expan- distilled water for swell potential determination. These oedometer

sive soil. swell tests are designated as Tests 1 and 2, respectively (Table 3).

Table 2 also shows the calculated amount of lime precipitation Similar oedometer swell potential tests were also conducted

in the soil and the percentage of lime precipitation by dry weight of with expansive soil specimens remolded with 7.2 mL of NaOH sol-

soil. The amount of lime precipitation in the soil is calculated on ution (14.6 or 36.4%) and placed in an air tight polythene bag

the basis of Eq. (1). According to the Eq. (1), 110 g of CaCl2 reacts for moisture equilibration for 1 h. After this equilibration time,

with 80 g of NaOH to form 74 g of CaðOHÞ2 . When 45 mL of 10% 7.2 mL of CaCl2 solution of desired concentration (20 or 50%)

CaCl2 solution and 45 mL of 7.3% NaOH solution are mixed se- was mixed with expansive soil and compacted to a dry density of

quentially with the expansive soil, the amount of lime precipitation 1:45 Mg∕m3 using a hand-operated static press. Compacted spec-

in the soil may be calculated as imens (w ¼ 25%) were placed in desiccators for moisture equili-

bration for 24 h. These specimens were inundated with distilled

74 10 water at a seating load of 6.25 kPa for swell potential determina-

× × 45 ¼ 3:03 g ð2Þ

110 100 tion. These oedometer swell tests are designated as Tests 3 and 4,

respectively. Table 3 shows the details of swell potential tests.

By knowing the dry weight of the soil, the percentage of lime

Table 3 also shows the calculated amount of lime precipitation

precipitated in the soil can be calculated.

in the soil and the percentage of lime precipitation by dry weight of

soil. The amount of lime precipitated when 7.2 mL of 20% CaCl2

Oedometer Swell Potential Tests

solution and 7.2 mL of 14.6% NaOH solution are mixed sequen-

All of the specimens for oedometer swell tests were compacted tially with the expansive soil may be calculated as

in oedometer rings of 60-mm diameter and 20-mm height, which

needed 57.4 g of expansive soil by dry weight (dry density ¼ 74

×

20

× 7:2 ¼ 0:97 g ð3Þ

1:45 Mg∕m3 ) for 14-mm thick specimens. A total of 57.4 g of ex- 110 100

pansive soil passing 2 mm was thoroughly hand-mixed with 7.2 mL

of desired concentration of CaCl2 solution (20 or 50%) and placed

Unconfined Compressive Strength Tests

in an air tight polythene bag for moisture equilibration for 1 h. After

this equilibration time, 7.2 mL of NaOH solution of desired con- All UCS test specimens were of 38-mm diameter and 76-mm

centration (14.6 or 36.4%) was mixed with expansive soil and length, which needed 125 g of expansive soil by dry weight

Table 3. Details of Oedometer Tests with Test Designation

Calculated percentage Swell

Test Percentage of solution concentration Calculated amount of of lime precipitation by potential

Series designation designation on weight basisa (%) lime precipitation (g) dry weight of soil (%) (%)

Series 1: CaCl2 þ NaOH Test 1 20% CaCl2 , 14.6% NaOH 0.97 1.7 0.0

Test 2 50% CaCl2 , 36.4% NaOH 2.42 4.2 0.0

Series 2: NaOH þ CaCl2 Test 3 14.6% NaOH, 20% CaCl2 0.97 1.7 0.0

Test 4 36.4% NaOH, 50% CaCl2 2.42 4.2 0.0

a

Volume of solution mixed = 10.25 mL.

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / AUGUST 2012 / 1069

J. Mater. Civ. Eng., 2012, 24(8): 1067-1075

(dry density ¼ 1:45 Mg∕m3 ). A total of 125 g of expansive soil of 7 and 21 days curing period, the UCS was determined to bring

passing 2 mm was mixed with 15.6 mL of CaCl2 solution of desired out the effect of sequential mixing of CaCl2 and NaOH solutions in

concentration (10, 20, 35, 50 or 65%) and placed in an air tight two different sequences (Series 1 and 2).

polythene bag for moisture equilibration for 1 h. After this equili-

bration time, 15.6 mL of NaOH solution of desired concentration

(7.3, 14.6, 25.5, 36.4 or 47.3%) was mixed with expansive soil Results and Discussions

and placed in desiccators for moisture equilibration for 24 h. The

moisture-equilibrated specimens were statically compacted to a Index Properties

dry density of 1:45 Mg∕m3 using a hand-operated static press. The

Fig. 1 shows the variations in liquid limit and soil pH with the cal-

Downloaded from ascelibrary.org by Sri Sivasubramaniya Nadar College Of Engineering on 08/11/18. Copyright ASCE. For personal use only; all rights reserved.

UCS tests performed with this sequence of mixing CaCl2 and

NaOH solutions with expansive soil are referred to as Series 1 culated percentage of lime precipitation on sequential mixing of

experiments. expansive soil with CaCl2 and NaOH solutions in two different se-

In Series 2 experiments, 15.6 mL of NaOH solution of desired quences. The liquid limit decreased as the calculated percentage of

concentration (7.3, 14.6, 25.5, 36.4 or 47.3%) was mixed with ex- lime precipitation increased up to 12.6 and 5% in Series 1 and 2

pansive soil and placed in a desiccator for moisture equilibration specimens, respectively, and further lime precipitation did not alter

for 1 h. After 1 h equilibration time, 15.6 mL of CaCl2 solution the liquid limit significantly (Fig. 1). At a lime precipitation per-

of desired concentration (10, 20, 35, 50 or 65%) was mixed with centage of 12.6 and 5% in Series 1 and 2 specimens, the liquid limit

expansive soil and placed in a desiccator for moisture equilibration notably reduced from 75% to 43 and 50%, respectively.

for 24 h. The moisture-equilibrated specimens were statically com- The variations in plasticity index and soil pH with the calculated

pacted to a dry density of 1:45 Mg∕m3 using a hand-operated static percentage of lime precipitation on sequential mixing of expansive

press. The UCS tests performed with this sequence of mixing soil with CaCl2 and NaOH solutions in two different sequences

NaOH and CaCl2 solutions with expansive soil are referred to as are shown in Fig. 2. The plasticity index of Series 1 and 2 spec-

Series 2 experiments. Both series of UCS tests were conducted at a imens at a lime precipitation percentage of 12.6 and 5% decreased

strain rate of 0:8%∕ min. Table 4 shows the details of the specimens from 50% to 8 and 17%, respectively (Fig. 2). Figs. 1 and 2 also

prepared by mixing expansive soil with CaCl2 and NaOH solutions show that the pH of expansive soil increased to 12 at an approx-

in two different sequences. Table 4 also shows the calculated imately 5% calculated percentage of lime precipitation for both

amount of lime precipitation in the soil and the percentage of lime Series 1 and 2 specimens, which is conducive for the pozzolanic

precipitation by dry weight of soil. Calculation of the amount of reactions to occur.

lime precipitation in the soil and the percentage of lime precipita- The Atterberg limits of the Series 1 and 2 specimens were de-

tion is discussed in the “Index Properties” section. termined after a 24-h curing period. Although the pH of these soils

Few additional specimens were prepared to study the effect (12) is conducive for pozzolanic reactions to occur, the curing

of curing on the UCS of the expansive soil. The compacted spec- period (24 h) is insufficient; earlier studies indicate that curing

imens were also cured for 7 and 21 days in a dessicator. At the end periods > 7 days (at room temperature) facilitate a substantial

Table 4. Details of Unconfined Compressive Tests

Calculated percentage of Unconfined

Percentage of solution concentration Calculated amount of lime precipitation by dry compressive

Series on weight basisa (%) lime precipitation (g) weight of soil (%) strength (kPa)

Series 1: CaCl2 þ NaOH 10% CaCl2 , 7.3% NaOH 1.05 0.8 241

20% CaCl2 , 14.6% NaOH 2.10 1.7 505

35% CaCl2 , 25.5% NaOH 3.67 2.9 552

50% CaCl2 , 36.4% NaOH 5.25 4.2 841

65% CaCl2 , 47.3% NaOH 6.82 5.5 664

Series 2: NaOH þ CaCl2 7.3% NaOH, 10% CaCl2 1.05 0.8 166

14.6% NaOH, 20% CaCl2 2.10 1.7 169

25.5% NaOH, 35% CaCl2 3.67 2.9 272

36.4% NaOH, 50% CaCl2 5.25 4.2 164

47.3% NaOH, 65% CaCl2 6.82 5.5 494

a

Volume of solution mixed = 15.6 mL.

Table 5. pH and Pore Salinity Values of Series 1 and 2 Unconfined Compressive Test Specimens

pH Pore salinity (mg∕L)

Percentage of solution concentration

Series on weight basis (%) 1 day 7 days 14 days 21 days 1 day 7 days 14 days 21 days

Series 1: CaCl2 þ NaOH 20% CaCl2 , 14.6% NaOH 10.73 10.76 10.83 10.76 763 821 833 859

35% CaCl2 , 25.5% NaOH 11.47 — 11.46 11.42 1,224 — 1,244 1,686

50% CaCl2 , 36.4% NaOH 11.73 11.76 11.82 11.78 1,558 1,583 1,878 2,173

Series 2: NaOH þ CaCl2 14.6% NaOH, 20% CaCl2 11.00 10.99 11.00 10.74 788 1,051 1,058 1,096

25.5% NaOH, 35% CaCl2 11.57 11.60 11.65 11.37 1,109 1,795 1,865 1,897

36.4% NaOH, 50% CaCl2 11.63 11.62 11.65 11.63 1,301 1,795 1,865 2,071

1070 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / AUGUST 2012

J. Mater. Civ. Eng., 2012, 24(8): 1067-1075

80 14 6

13 Untreated

5

70 Test 1

Series 1:LL 12

Liquid limit (%)

4 Test 2

Series 2: LL

Swell (%)

Series 1: pH 11

pH

60 Series 2: pH 3

10

9 2

50

Downloaded from ascelibrary.org by Sri Sivasubramaniya Nadar College Of Engineering on 08/11/18. Copyright ASCE. For personal use only; all rights reserved.

8 1

40 7

0

0 5 10 15 20

0.1 1 10 100 1000 10000

Lime precipitation (%)

Time (min)

Fig. 1. Variations of liquid limit and soil pH with calculated percentage

of lime precipitation on sequential mixing of expansive soil with Fig. 3. Time-swell plots of untreated, Test 1, and Test 2 specimens

calcium chloride (CaCl2 ) and sodium hydroxide (NaOH) solutions

in two different sequences (Series 1 and 2)

60 14 Untreated

5 Test 3

13 Test 4

4

Plasticity index (%)

Series 1: PI 12

Swell (%)

40 Series 2: PI 3

Series 1: pH 11

pH

Series 2: pH 2

10

20

9 1

8

0

0.1 1 10 100 1000 10000

0 7

Time (min)

0 5 10 15 20

Lime precipitation (%) Fig. 4. Time-swell plots of untreated, Test 3, and Test 4 specimens

Fig. 2. Variations of plasticity index and soil pH with calculated

percentage of lime precipitation on sequential mixing of expansive

soil with calcium chloride (CaCl2 ) and sodium hydroxide (NaOH)

solutions in two different sequences (Series 1 and 2) and NaOH solutions is again primarily attributed to strong short-

term lime-modification reactions and an increase in pore water

salinity. As subsequently discussed, the reductions in plasticity in-

dex and odeometer swell potentials are also likely to be contributed

degree of pozzolanic reactions (Prakash et al. 1989; Bell 1988a). by poorly formed cementation products that appear during early

The significant reduction in liquid limit and plasticity index of ex- stages of curing.

pansive soil on sequential mixing of CaCl2 and NaOH solutions

with expansive soil is primarily attributed to strong short-term Unconfined Compressive Strength

lime-modification reactions involving replacement of native mono- Fig. 5 shows the variation of UCS with the calculated percentage of

valent exchangeable cations by divalent calcium ions (source of lime precipitation on sequential mixing of expansive soil with

calcium is added CaCl2 solution). The addition of CaCl2 and NaOH CaCl2 and NaOH solutions in two different sequences. The UCS

solutions would also increase the pore water salinity, which in turn increased as the calculated percentage of lime precipitation in-

would act to suppress the diffuse ion layer and liquid limit values creased up to 4.2%, and further lime precipitation slightly reduced

(Yong and Warkentin 1975; Mitchell 1993; Sridharan et al. 1986). the UCS of Series 1 specimen. Interestingly, the compressive

strength of Series 2 specimen is nearly constant up to 4.2% lime

Oedometer Swell Potential

precipitation and thereafter increases to 494 kPa at 5.5% lime pre-

Fig. 3 compares the time-swell plots of Test 1 specimen and Test 2 cipitation. Fig. 5 also shows that the pH of the Series 1 and 2 spec-

specimen with untreated soil specimen. Fig. 4 compares the time- imens increases to 10.73–11.00 at 1.7% lime precipitation and

swell plots of Test 3 specimen and Test 4 specimen with untreated reaches a maximum (11.63–11.73) at 4.2% lime precipitation.

soil specimen. The Test 1, Test 2, Test 3, and Test 4 specimens do At these pH levels, alumina and silica dissolve from clay lattice

not swell (swell potential ¼ 0%); in comparison, the untreated soil and combine with calcium ions to form CSH and CAH, which ce-

exhibits swell potential of 4.95%. The oedometer swell potentials ment the clay particles together, leading to an increase in strength

of the Test 1 to Test 4 specimens were determined after 24 h of (Eades and Grim 1960; Wang et al. 1963; Diamond et al. 1963;

curing period. The significant reduction in the oedometer swell po- Rajasekaran and Narasimha Rao 1998; Boardman et al. 2001).

tential of expansive soil specimens on sequential mixing of CaCl2 The Series 1 and 2 specimens shown in Fig. 5 were cured for

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / AUGUST 2012 / 1071

J. Mater. Civ. Eng., 2012, 24(8): 1067-1075

1000 12.0 600 11.1

Unconfined compressive strength (kPa)

Unconfined compressive strength (kPa)

11.5

800 11.0 500

10.9

10.5

400

600 Series 1: UCS 10.0 10.7

Series 2: UCS

pH

pH

Series 1: pH 9.5 300

400 Series 2: pH 9.0 10.5

8.5 200 Series 1: UCS

200 8.0 Series 2: UCS

10.3

Downloaded from ascelibrary.org by Sri Sivasubramaniya Nadar College Of Engineering on 08/11/18. Copyright ASCE. For personal use only; all rights reserved.

100 Series 1: pH

7.5

Series 2: pH

0 7.0 0 10.1

0 2 4 6

Lime precipitation (%) 0 5 10 15 20 25

Curing period (days)

Fig. 5. Variations of unconfined compressive strength and soil pH with

Fig. 6. Variations of unconfined compressive strength and soil pH with

calculated percentage of lime precipitation on sequential mixing of

curing period for compacted expansive soil mixed with 20% calcium

expansive soil with calcium chloride (CaCl2 ) and sodium hydroxide

chloride (CaCl2 ) solution and 14.6% sodium hydroxide (NaOH)

(NaOH) solutions in two different sequences (Series 1 and 2)

solution in two different sequences (1.7% lime precipitation)

24 h. According to Bell (1988a), the compressive strength devel-

1400

oped at early stages of curing is contributed by poorly formed

Unconfined compressive strength (kPa)

11.8

cementation products. 1200

At any given lime precipitation content, Series 1 specimens

are characterized with higher UCS than Series 2 specimens. For 1000 11.6

example, at lime precipitation of 1.7%, the UCS of Series 1 speci-

800

men is 505 kPa, whereas the UCS of Series 2 specimen is 169 kPa.

pH

The UCS test results also indicate that mixing CaCl2 and NaOH 11.4

600

solutions sequentially with expansive soils (Series 1 specimens)

Series 1: UCS

is preferred over mixing NaOH and CaCl2 solutions (Series 2 400

Series 2: UCS 11.2

specimens). Series 1: pH

200

Series 2: pH

Effect of Curing Period on Unconfined Compressive

0 11.0

Strength

0 5 10 15 20 25

The effect of curing period on the UCS developed by the com- Curing period (days)

pacted expansive soil specimens subjected to lime precipitation is

discussed in this section. As mentioned previously, theoretically, Fig. 7. Variations of unconfined compressive strength and soil pH with

1.7% of lime is precipitated by mixing expansive soil sequentially curing period for compacted expansive soil mixed with 50% calcium

with 20% CaCl2 and 14.6% NaOH solutions. Similarly, 4.2% of chloride (CaCl2 ) solution and 36.4% sodium hydroxide (NaOH)

lime is precipitated by mixing expansive soil sequentially with solution in two different sequences (4.2% lime precipitation)

50% CaCl2 and 36.4% NaOH solutions. Because the ICL for the

expansive soil is 2.5%, calculated lime precipitation contents of

1.7% (less than ICL) and 4.2% (greater than ICL) are chosen. 20% CaCl2 and 14:6% NaOH solutions and 11.62–11.82 on mix-

Fig. 6 shows the variation in UCS with curing period for com- ing 50% CaCl2 and 36:4%NaOH solutions. It is known that long-

pacted expansive soil specimens subjected to 1.7% lime precipita- term pozzolanic reactions are favored at soil pH ≥ 12 (Eades and

tion. Fig. 7 shows the variation in UCS strength with curing period Grim 1960; Diamond et al. 1963; Rogers et al. 1997). The soil pH

for compacted expansive soil specimens subjected to 4.2% lime values of the sequentially mixed specimens are < 12 (Figs. 6 and 7;

precipitation. The 1.7% lime-precipitated Series 1 specimens Table 5). To examine the possible contribution of pozzolanic reac-

developed compressive strength of 430 and 509 kPa after 1 and tions to soil strength, the compressive strengths of lime pile–treated

21 days of curing period, respectively (Fig. 6). Comparatively, specimens (data from Thyagaraj 2001; Table 7) are compared with

the 1.7% lime-precipitated Series 2 specimens developed com- this study (Figs. 6 and 7). Thyagaraj (2001) had observed that the

pressive strength of 169 and 268 kPa after 1 and 21 days of lime pile technique led to minor increase in pH (from 8 to 8.4) that

curing period, respectively (Fig. 6). The data in Fig. 7 show that was not conducive for promotion of pozzolanic reactions and there-

4.2% lime-precipitated Series 1 specimens developed compressive fore did not alter the compressive strength. Sequential mixing of the

strength of 841 and 1,188 kPa, whereas Series 2 specimens devel- soil, however, led to 239–835 and 29–417% (1–21 days cured) in-

oped compressive strength of 164 and 656 kPa after 1 and 21 days creases in compressive strengths for Series 1 and 2 specimens, re-

of curing period, respectively. The trends of the results in Figs. 6 spectively. The much larger strengths developed by the sequentially

and 7 indicate that lime-precipitated specimens gain anywhere from mixed specimens indicate that in addition to modification reactions,

18–41 and 58–300% increase in compressive strength on increas- pozzolanic reactions have also occurred. However, the inability of

ing the curing period from 1 to 21 days for Series 1 and 2 spec- the technique to mobilize pH values ≥ 12 could have restrained the

imens, respectively. The results bring out the role of crystallization complete realization of the pozzolanic reactions that would have

of cementation products in strength gain. led to even larger strengths. According to Boardman et al. (2001),

Figs. 6 and 7 also show the variation in soil pH with initiation of dissolution of silica and alumina in clay lattice occurs

curing period which increased to 10.73–11.00 on mixing at pH of approximately 9–10, which explains the occurrence

1072 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / AUGUST 2012

J. Mater. Civ. Eng., 2012, 24(8): 1067-1075

Table 6. Comparison of Index Properties of Expansive Soil Specimens Directly Mixed with Lime and Subjected to Lime Precipitation

Series 1: CaCl2 þ NaOH Series 2: NaOH þ CaCl2 Directly mixed with lime

Calculated percentage of Percentage of solution

lime precipitation (%) concentrationa (%) wL (%) wP (%) I P (%) wL (%) wP (%) I P (%) Lime (%) wL (%) wP (%) I P (%)

2.5 10% CaCl2 , 7.3% NaOH 60 32 28 55 33 22 2 63 36 27

5.0 20% CaCl2 , 14.6% NaOH 58 36 22 50 33 17 4 57 37 20

8.8 35% CaCl2 , 25.5% NaOH 55 35 20 52 34 18 6 52 37 15

12.6 50% CaCl2 , 36.4% NaOH 43 35 8 48 31 17 8 50 37 13

16.4 65% CaCl2 , 47.3% NaOH 43 32 11 50 32 18 10 48 37 11

Downloaded from ascelibrary.org by Sri Sivasubramaniya Nadar College Of Engineering on 08/11/18. Copyright ASCE. For personal use only; all rights reserved.

Note: wL = liquid limit; wP = plastic limit; I P = plasticity index.

a

Volume of solution mixed = 45 mL.

of pozzolanic reactions in the sequentially treated specimens. technique in improving the compressive strength of the expansive

Figs. 6 and 7 also show that UCS of Series 1 specimens is higher soil shows its superiority over the lime pile technique.

in comparison with Series 2 specimens at all the curing periods. Table 7 also shows a comparison of the properties of expan-

sive soil specimens treated with lime slurry technique (Rao and

Comparison of Lime Precipitation Technique with Thyagaraj 2003) and lime precipitation technique. Both techniques

Other Techniques could raise the pH of soil (11.62–11.95, Table 7) to levels that

Table 6 shows a comparison of the index properties of expansive are conducive for the pozzolanic reactions to occur (Boardman

soil specimens directly mixed with lime and subjected to lime et al. 2001). The swell potential of lime slurry–treated specimen

precipitation. Data in Table 6 show that both methods are equally reduced to 0% from an untreated value of 1.4%, whereas the lime

effective in reducing the liquid limit and plasticity index of the precipitation technique reduced the swell potential to 0% from an

expansive soil. untreated value of 4.95%. The UCS of 10 days, cured lime slurry–

Table 7 shows a comparison of the properties of expansive soil treated specimens increased to 113 from 77 kPa. Comparatively,

specimens treated with lime pile technique (Thyagaraj 2001) and the lime precipitation technique increased the UCS of 7 days, cured

lime precipitation technique. Thyagaraj (2001) reported that the specimens to 619–895 from 127 kPa (untreated value). This shows

lime pile treatment increased the soil pH and pore salinity to that both methods could promote the soil-lime pozzolanic reac-

8.40 and 517 mg∕L from untreated values of 8.00 and 244 mg∕L, tions. However, the higher strengths exhibited by the lime precipi-

respectively (Table 7). The swell potential of lime pile–treated tation technique–treated specimens are attributed to flocculation of

specimen reduced to 0.4% from 2.1%, whereas the lime precipita- clay particles owing to lime precipitation in addition to pozzolanic

tion technique reduced the swell potential to 0% from untreated reactions.

value of 4.95%. The pH of lime pile–treated soil (8.4) was not

conducive for the pozzolanic reactions to occur, and as a result,

the compressive strength of lime pile–treated specimens was unaf- Practical Significance

fected (Table 7). Comparatively, the lime precipitation technique

increased the soil pH to 11.62–11.76 (7 days, cured), which is pre- Sequential mixing of CaCl2 and NaOH solutions with expansive

sumably conducive for pozzolanic reactions to occur. Therefore, soil resulted in precipitation of lime. The precipitated lime could

the UCS of lime precipitation technique–treated specimens in- promote strong lime-modification reactions and strong soil-lime

creased to 619–895 kPa (7 days, cured) from an untreated value pozzolanic reactions. The lime-modification reactions together

of 127 kPa (Table 7). The greater efficiency of lime precipitation with the poorly developed cementation products controlled the

Table 7. Comparison of Properties of Expansive Soil Specimens Treated with Lime Pile, Lime Slurry, and Lime Precipitation Techniques

Unconfined

Percentage Radial Curing Swell compressive

of lime distance/ period Pore salinity potentiala strength

Source Treatment (%) series (days) pH (mg∕L) wL (%) wP (%) I P (%) (%) (kPa)a

Thyagaraj Lime pile 5.5 1.5d 10 8.40 (8.00) 517 (244) 93 (95) 26 (24) 67 (71) 0.4 (2.1) 68 (68)

(2001) treated

Rao and Lime slurry 6 1.5d 10 11.95 (8.00) 1,436 (244) 86 (95) 44 (24) 42 (71) 0.0 (1.4) 113 (77)

Thyagaraj treated

(2003)

This Untreated – – – 8.00 340 75b 25b 50b 4.95c 127

investigation Lime 4.2 Series 1: 1 11.73 1,558 58b 36b 22b 0.0c 841

precipitation CaCl2 þ NaOH 7 11.76 1,583 – – – – 895

treated Series 2: 1 11.63 1,301 50b 33b 17b 0.0c 164

NaOH þ CaCl2 7 11.62 1,795 – – – – 619

Note: Values in the parenthesis are of untreated specimen; d = diameter of hole for lime pile or lime slurry injection.

a

Swell potential and unconfined compressive strength of untreated specimens were determined at moisture content and dry densities similar to those of treated

specimens.

b

Atterberg limits were determined with 5% lime precipitation.

c

Swell potentials were determined with 3.4% lime precipitation.

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / AUGUST 2012 / 1073

J. Mater. Civ. Eng., 2012, 24(8): 1067-1075

swelling potential, reduced the plasticity index, and increased the the UCS of the expansive soil specimens cured for 24 h.

UCS of the expansive clay as the specimens were cured for 24 h. The marked increase in UCS exhibited by 7–21 days’ cured

Comparatively, both lime-modification and well-developed crystal- expansive soil specimens is apparently a consequence of lime-

line cementation products contributed to the marked increase in modification reactions and well-developed crystalline cemen-

the UCS strength of the expansive soil that was cured for periods tation products formed in the treated specimens.

of 7–21 days. However, further investigation is needed for exam- 4. Atterberg limits and UCS results show that the sequential mix-

ining the efficacy of lime precipitation technique in stabilizing the ing of expansive soil with CaCl2 solution followed by NaOH

in situ expansive soils by sequential permeation of CaCl2 and solution is more effective than mixing expansive soil with

NaOH solutions into the in situ soil, either through ponding or NaOH solution followed by CaCl2 solution.

Downloaded from ascelibrary.org by Sri Sivasubramaniya Nadar College Of Engineering on 08/11/18. Copyright ASCE. For personal use only; all rights reserved.

boreholes.

The amount of lime precipitation in the soil should be greater

References

than the ICL value, because the amount of lime precipitation in

excess of the ICL value is used in the cementation process only. Bell, F. G. (1988a). “Stabilisation and treatment of clay soils with lime.

The ICL values for most of the expansive soils range from 3–8%. Part 1: Basic principles.” Ground Eng., 21(1), 10–15.

The amount of lime precipitation can be increased either by increas- Bell, F. G. (1988b). “Stabilisation and treatment of clay soils with lime.

ing the concentration of CaCl2 and NaOH solutions used for per- Part 2: Some applications.” Ground Eng., 21(2), 22–30.

meation or by increasing the volume of CaCl2 and NaOH solutions. Boardman, D. I., Glendinning, S., and Rogers, C. D. F. (2001).

This method of stabilization may prove to be advantageous over “Development of stabilisation and solidification in lime-clay mixes.”

Geotechnique, 50(6), 533–543.

the other techniques in the following conditions:

British Standards Institution (BSI). (1990). “Method of test for stabilized

• Stabilization of expansive soils below the existing structures soils.” BS 1924, Milton Keynes, U.K.

on which lime piles construction is not possible because of Broms, B. B., and Boman, P. (1975). “Lime-stabilized columns.” Proc., 5th

the existing structures. In such a situation, boreholes have to Asian Regional Conf. on Soil Mechanics and Foundation Engineering,

be made along the periphery of existing structures with required Vol. 1, INSDOC Regional Centre, Bangalore, India, 227–234.

spacing. These boreholes have to be filled with coarse sand, and Bureau of Indian Standards. (1972). “Methods of test for soils: Determi-

CaCl2 and NaOH solutions are sequentially permeated for the in nation of shrinkage factors (first revision).” IS 2720 (Part 6), New Delhi,

situ precipitation of lime below the existing structures. This India.

method of stabilization will be far superior to the lime pile tech- Bureau of Indian Standards. (1980a). “Methods of test for soils: Determi-

nique owing to the very high solubility and diffusion rates of nation of specific gravity. Section 1: Fine grained soils (First revision).”

IS 2720 (Part 3), New Delhi, India.

CaCl2 and NaOH solutions in water in contrast to the solubility

Bureau of Indian Standards. (1980b). “Methods of test for soils: Determi-

and diffusion rates of lime. nation of water content-dry density relation using light compaction

• In stiff to very stiff expansive soils, it is very difficult to form (second revision).” IS 2720 (Part 7), New Delhi, India.

lime columns in situ. In such a situation, in situ lime precipita- Bureau of Indian Standards. (1985a). “Methods of test for soils: Grain size

tion through boreholes may prove to be the most effective and analysis (second revision).” IS 2720 (Part 4), New Delhi, India.

viable method of stabilization. Bureau of Indian Standards. (1985b). “Methods of test for soils: Determi-

• This technique will have an added advantage in a site contami- nation of liquid limit and plastic limit (second revision).” IS 2720,

nated with NaOH solution. In such a case, CaCl2 solution alone (Part 5), New Delhi, India.

needs to be permeated through the contaminated soils for in situ Chen, F. H. (1988). Foundations on expansive soils, Elsevier, New York.

precipitation of lime and, thus, stabilization of the contami- Chew, H. H., Talkeda, T., Ichikawa, K., and Hosoi, T. (1993). “Chemico

lime pile soil improvement used for soft clay ground.” Proc., 11th

nated soil.

South East Asian Geotechnical Conf., Singapore, 319–324.

Diamond, S., White, J. L., and Dolch, W. L. (1963). “Transformation of

clay mineral by calcium hydroxide attack.” Proc., 12th National Conf.

Conclusions on Clays and Clay Minerals, E. Ingerson and W. K. Brakely, eds.,

Clay Mineral Society, Chantilly, VA, 359–379.

The efficacy of lime precipitation technique in stabilizing an expan- Eades, J. L., and Grim, R. E. (1960). “The reaction of hydrated lime with

sive soil is examined through laboratory investigation. Precipitation pure clay minerals in soil stabilization.” Highw. Res. Board, Bull., 262,

of lime is achieved by sequential mixing of expansive soil with 51–63.

CaCl2 and NaOH solutions in two different sequences. The follow- Glendinning, S., and Rogers, C. P. F. (1996). “Deep stabilisation using

ing conclusions are drawn from this investigation: lime.” Proc., Seminar on Lime Stabilization, Loughborough Univ.,

Thomas Telford, London, 127–136.

1. Sequential mixing of CaCl2 þ NaOH or NaOH þ CaCl2 solu-

Holm, G., Bredenberg, H., and Broms, B. B. (1981). “Lime columns as

tions with expansive soil led to drastic reduction in the liquid foundation for light structures.” Proc. 10th Int. Conf., Soil Mechanics

limit and plasticity index of expansive soil. The considerable and Foundation Eng., Vol. 3, A. A. Balkema, Rotterdam, 687–694.

reduction in the liquid limit and plasticity index of the expan- Mitchell, J. K. (1993). Fundamentals of soil behavior, 2nd Ed., Wiley,

sive soil is primarily attributed to strong short-term lime- New York.

modification reactions occurring between precipitated lime Nelson, J. D., and Miller, D. J. (1992). Expansive soils: Problems and prac-

and the soil. tice in foundation and pavement engineering, Wiley, New York.

2. The swell potential of the expansive soil specimens reduced Porbaha, A. (1998). “State-of-the-art in deep mixing technology: Part I.

to 0% from untreated value of 4.95% as a consequence of the Basic concepts and overview.” Ground Improv., 2(2), 81–92.

strong lime-modification reactions and poorly developed ce- Prakash, K., Sridharan, A., and Rao, S. M. (1989). “Lime addition and cur-

ing effects on the index and compaction characteristics of a montmo-

mentation products formed during early stages of curing in

rillonitic soil.” Geotech. Eng., 20(1), 39–47.

the treated soil. Rajasekaran, G., and Narasimha Rao, S. (1998). “X-ray diffraction and mi-

3. The UCS increased as the percentage of lime precipitation in- crostructural studies of lime-marine clay reaction products.” Geotech.

creased in both sequences of mixing expansive soil with CaCl2 Eng., 29(1), 1–27.

and NaOH solutions. The lime-modification reactions together Rao, S. M., and Thyagaraj, T. (2003). “Lime slurry stabilization of an

with the poorly developed cementation products increased expansive soil.” Geotech. Eng., 156(3), 139–146.

1074 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / AUGUST 2012

J. Mater. Civ. Eng., 2012, 24(8): 1067-1075

Rao, S. M., and Venkataswamy, B. (2002). “Lime pile treatment of black Tsytovich, N. A., Abelev, M. Yu., and Takhirov, I. G. (1971). “Compacting

cotton soils.” Ground Improv., 6(2), 85–93. saturated loess by means of lime piles.” Proc., 4th Int. Conf. on Soil

Rogers, C. D. F., Glendinning, S., and Holt, C. C. (2000). “Slope stabili- Mechanics and Foundation Engineering, Akademiai Kiado, Budapest,

zation using lime piles: A case study.” Ground Improv., 4(4), 165–176. 837–842.

Rogers, C. D. F., Glendinning, S., and Roff, T. E. J. (1997). “Lime modi- Wang, W. T. (1989). “Experimentation of improving soft clay with lime

fication of clay soils for construction expediency.” Geotech. Eng., column.” Proc., Int. Conf. on Engineering Problems on Regional Soils,

125(4), 242–249. International Academic Publishers, Beijing, 477–480.

Sridharan, A., Rao, S. M., and Murthy, N. S. (1986). “Compressibility Wang, J. W. H., Mateos, M., and Davidson, D. T. (1963). “Comparative

behaviour of homoionised bentonites.” Geotechnique, 36(4), 551–564. effects of hydraulic, calcitic and dolomitic limes and cement in soil

Thyagaraj, T. (2001). “Laboratory studies on in-situ chemical stabilization stabilization.” Highw. Res. Board, Bull., 59, 42–54.

Downloaded from ascelibrary.org by Sri Sivasubramaniya Nadar College Of Engineering on 08/11/18. Copyright ASCE. For personal use only; all rights reserved.

of black cotton soil.” M.Sc. (Engg.) dissertation, Indian Institute of Yong, R. N., and Warkentin, B. P. (1975). Soil properties and behaviour,

Science, Bangalore, India. Elsevier, New York.

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / AUGUST 2012 / 1075

J. Mater. Civ. Eng., 2012, 24(8): 1067-1075

You might also like

- General Organic and Biological Chemistry 5Th Edition Janice Gorzynski Smith DR Full ChapterDocument51 pagesGeneral Organic and Biological Chemistry 5Th Edition Janice Gorzynski Smith DR Full Chapterlisa.covington970100% (19)

- Geological Carbon Storage: Subsurface Seals and Caprock IntegrityFrom EverandGeological Carbon Storage: Subsurface Seals and Caprock IntegrityStéphanie VialleNo ratings yet

- Paper-6-The-use-of-Geosynthetics-in-Pavements-Edoardo-ZannoniDocument7 pagesPaper-6-The-use-of-Geosynthetics-in-Pavements-Edoardo-ZannonisivabathyNo ratings yet

- James, Lakshmi, Pandian - 2014 - Strength and Index Properties of Phosphogypsum Stabilized Expansive SoilDocument12 pagesJames, Lakshmi, Pandian - 2014 - Strength and Index Properties of Phosphogypsum Stabilized Expansive SoilsivabathyNo ratings yet

- 073Document4 pages073sivabathyNo ratings yet

- Zukri 2018 IOP Conf. Ser. Mater. Sci. Eng. 342 012001Document14 pagesZukri 2018 IOP Conf. Ser. Mater. Sci. Eng. 342 012001sivabathyNo ratings yet

- 15 Chapter 7Document24 pages15 Chapter 7sivabathyNo ratings yet

- Conic Section: MATH-002 Dr. Farhana ShaheenDocument30 pagesConic Section: MATH-002 Dr. Farhana ShaheensivabathyNo ratings yet

- 01 07 P01RationalAssessment PoulosSEAGSE J2018 03Document7 pages01 07 P01RationalAssessment PoulosSEAGSE J2018 03sivabathyNo ratings yet

- Recent Advancements in Chemical, Energy and Environmental EngineeringDocument2 pagesRecent Advancements in Chemical, Energy and Environmental EngineeringsivabathyNo ratings yet

- Theory and Practice of The Fall Cone TestDocument13 pagesTheory and Practice of The Fall Cone TestsivabathyNo ratings yet

- Recent Advancements in Chemical, Energy and Environmental EngineeringDocument2 pagesRecent Advancements in Chemical, Energy and Environmental EngineeringsivabathyNo ratings yet

- Brick DetailsDocument3 pagesBrick DetailssivabathyNo ratings yet

- Innovative Utilization of Lignosulphonate - A Non-Traditional Stabilizer On Control and Management of Swell-Shrink Behavior of Expansive ClaysDocument42 pagesInnovative Utilization of Lignosulphonate - A Non-Traditional Stabilizer On Control and Management of Swell-Shrink Behavior of Expansive ClayssivabathyNo ratings yet

- Bridge Model Estimate With Well FoundationDocument47 pagesBridge Model Estimate With Well Foundationsivabathy50% (6)

- Confirmation Page: Home Find Change Your Subscription Unsubscribe SubscribeDocument1 pageConfirmation Page: Home Find Change Your Subscription Unsubscribe SubscribesivabathyNo ratings yet

- Shallow Foundation: Name: Paper Name and Code: InstituteDocument32 pagesShallow Foundation: Name: Paper Name and Code: Institutesivabathy100% (1)

- Experiment 5 Relative Density Determination: PurposeDocument10 pagesExperiment 5 Relative Density Determination: PurposeAnkush AgarwalNo ratings yet

- Unnai Karam Pidithe - KCDocument144 pagesUnnai Karam Pidithe - KCsivabathy67% (3)

- Trial Pit & BoreholeDocument10 pagesTrial Pit & BoreholesivabathyNo ratings yet

- Chapter 1 Matter in Our Surroundings Question AnswersDocument25 pagesChapter 1 Matter in Our Surroundings Question Answersram.khandelwal2010No ratings yet

- Investigating The Impact of Environmental Toxicology of Heavy Metals in Fish: A Study of Rivers of PakistanDocument24 pagesInvestigating The Impact of Environmental Toxicology of Heavy Metals in Fish: A Study of Rivers of Pakistanaqsa sattarNo ratings yet

- Organic Chemistry A Modern Approach Volume Ii Nimai Tewari Full ChapterDocument67 pagesOrganic Chemistry A Modern Approach Volume Ii Nimai Tewari Full Chapterthomas.robinson634No ratings yet

- BDS 1769 2014Document16 pagesBDS 1769 2014Walton Science Research LabNo ratings yet

- Halliburton - GasStop HTDocument2 pagesHalliburton - GasStop HThasan fırat AltınyüzükNo ratings yet

- 9th Class Chemistry Notes 2024 CH 8Document35 pages9th Class Chemistry Notes 2024 CH 8Kashi MoaviaNo ratings yet

- Computational ChemistryDocument23 pagesComputational Chemistrymubashirasamadk96No ratings yet

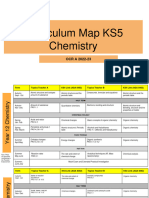

- KS5 Chemistry OCR A Curriculum Map 2022Document4 pagesKS5 Chemistry OCR A Curriculum Map 2022ghbydcqyf2No ratings yet

- Term Paper Topics ChemistryDocument8 pagesTerm Paper Topics Chemistryc5t6h1q5100% (1)

- Prep #28 - Two Phase Systems - Chalk MixtureDocument2 pagesPrep #28 - Two Phase Systems - Chalk MixtureKirsten Shayne ManingasNo ratings yet

- Kluber Kluberplex BEM 41-141 - enDocument7 pagesKluber Kluberplex BEM 41-141 - engabriela.bahamondes.pNo ratings yet

- PraktikDocument12 pagesPraktikDewi Uchsin NadiyaNo ratings yet

- 2023-24 Y12 Jan Mock ExamDocument16 pages2023-24 Y12 Jan Mock Examareejyaseen404No ratings yet

- Full Ebook of Extractive Metallurgy of Copper 6Th Edition Mark E Schlesinger Online PDF All ChapterDocument69 pagesFull Ebook of Extractive Metallurgy of Copper 6Th Edition Mark E Schlesinger Online PDF All Chaptereumaryjurcik100% (15)

- INORGANIC JAM PYQ QuestionsDocument52 pagesINORGANIC JAM PYQ QuestionsSandrapati ArunkumarNo ratings yet

- Cem Manual Pokhara UniversityDocument128 pagesCem Manual Pokhara Universitydond38480No ratings yet

- Protein JournalDocument21 pagesProtein JournalRahmadian Kahfi Zulfa KamilaNo ratings yet

- CARBON ITS COMPOUNDS ExerciseDocument14 pagesCARBON ITS COMPOUNDS ExerciseShreyanshNo ratings yet

- 111biosorption of Chromium by Termitomyces ClypeatusDocument9 pages111biosorption of Chromium by Termitomyces Clypeatuskarima majdouliNo ratings yet

- Spectrophotometric Determination of Selenium by Use of ThioninDocument4 pagesSpectrophotometric Determination of Selenium by Use of ThioninSena KulaksızNo ratings yet

- 2023 Paper 2 MS Cambridge - Checkpoint - Progression - Tests - 2023 - Science - Paper - 2 - Stage - 9 PDFDocument12 pages2023 Paper 2 MS Cambridge - Checkpoint - Progression - Tests - 2023 - Science - Paper - 2 - Stage - 9 PDFMayNo ratings yet

- Wa0007.Document2 pagesWa0007.Tonie Yanto Fanggi MbuikNo ratings yet

- Acids and Bases Lecture 1 (Grade 9)Document13 pagesAcids and Bases Lecture 1 (Grade 9)Waleed SaifNo ratings yet

- Syllabus BSC (Hons) Chemistry Semester IVDocument64 pagesSyllabus BSC (Hons) Chemistry Semester IVCHEM22028 NidhiNo ratings yet

- Electrode Electrolyte Interface Adjustment Through Adding Man - 2024 - Journal oDocument10 pagesElectrode Electrolyte Interface Adjustment Through Adding Man - 2024 - Journal omosab.backkupNo ratings yet

- Sba (Reactivity Series) 40 CopiesDocument3 pagesSba (Reactivity Series) 40 CopiesTahpehs PhiriNo ratings yet

- PH Level Research PaperDocument4 pagesPH Level Research Paperc9r5wdf5100% (1)

- Environmental Applications - Soxhlet ExtractionDocument9 pagesEnvironmental Applications - Soxhlet Extractionzineb.boussouliNo ratings yet

- 31 Atomic Structure and The Periodic Table Topic Booklet 1 CIE IGCSE ChemistryDocument15 pages31 Atomic Structure and The Periodic Table Topic Booklet 1 CIE IGCSE ChemistryMuhammad AyaanNo ratings yet