Professional Documents

Culture Documents

Flo-Grout EP215 star

Flo-Grout EP215 star

Uploaded by

Ahmed AbdallahCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flo-Grout EP215 star

Flo-Grout EP215 star

Uploaded by

Ahmed AbdallahCopyright:

Available Formats

215*

Flo-Grout EP270

High strength pourable epoxy resin grout

Description

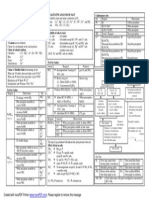

Technical Properties @ 25 C:

Flo-Grout EP270

215*is a three component, high strength, free

Compressive strength:

EP270*is suitable for

ßowing, epoxy resin grout. Flo-Grout EP215 ! 100 MPa @ 7 days

BS6319, Part 2 : 1983

grou#ng gaps with thicknesses between 10 – 150100 mm at

ambient temperatures between 10 - 40oC. Flexural strength:

! 28 MPa @ 7 days

BS6319, Part 3 : 1990

Applications

Fresh wet density: 2.00 ± 0.05 g/cm"

Flo-Grout EP215*

EP270 is ideally designed for use in the Tensile strength:

following applica#ons: ! 15 MPa @ 7 days

BS6319, Part 7 : 1985

Machine base plates. Recommended work-

Heavy crane rails. ing ambient tempera- 10 - 40oC

Pile top waterprooÞng. ture:

Bearing plinths. Crack forma#on @

High speed turbines. No cracks or bleeding

150mm and 40oC:

Grou#ng areas where occasional chemical spillage

may occur. Peak exothermic tem-

perature @ 40oC: 50oC

Advantages ASTM D2471

Peak exothermic #me

Resistant to dynamic loading. @ 40oC: 40 min

Non-shrink and low creep characteris#cs under ASTM D2471

con#nuous loading.

Excep#onally high compressive, ßexural and tensile Water absorp#on:

< 0.15%

strengths. ASTM C413

Extremely dense. 80 - 100 min @ 25 C

Excep#onal bond to concrete and steel surfaces. Working life:

40 - 60 min @ 35 C

Good chemical resistance.

High early strength development allowing for rapid VOC: < 10 g/ltr

installa#on. ASTM D2369 (complies with LEED)

Method of Use Mixing

Substrate Preparation To ensure proper mixing, a mechanically powered mixer

or drill Þ$ed with suitable paddle should be used.

The Substrate should be sound, clean and free from

contamina#on. Surface laitance should be removed by The en#re content of the Hardener pack should be added

scabbling or grit blas#ng. to the Base pack. Care should be taken to ensure that the

bo$om and the product sides are thoroughly scraped and

Steel surfaces should be grit blasted to remove all rust used. Mix the two components for 2 minutes. The Þller

and scale. should be gradually added while mixing. Mixing should

con#nue for 3 minutes or un#l a uniform consistency

Concrete surfaces should be dry. obtained.

Holes drilled for anchor bolts should be thoroughly

cleaned from dust and lose debris using suitable brush or

compressed air.

Flo-Grout EP270

EP215*

Placing and Finishing Yield

Under Base plate: Approximately 10 litre/20 kg pack.

Enough materials should be available to achieve

con#nuous Þll and to complete the work. Pouring of the Storage

mixed grout should be started from one side only to avoid

air entrapment. EP215*has a shelf life of 12 months from date of

Flo-Grout EP270

manufacture if stored at temperatures between 5°C and

To obtain maximum ßow distance, a side shu$er feed 35°C.

100 mm height should be erected and used to build

the required head. At 100 mm of head, a ßow distance If these condi#ons are exceeded, DCP Technical

of 1800 mm and 3000 mm can be achieved at gap Department should be contacted for advise.

thicknesses of 40 mm to 75 mm respec#vely @ 25°C

ambient temperatures. Cautions

Formwork: Health and Safety

As the mixed grout possesses high ßuid characteris#cs, all

formwork and shu$ers should be water #ght. This can be EP215*is irritant to the eyes, skin and respiratory

Flo-Grout EP270

achieved by sealing underneath the formwork and at the system. Wear suitable gloves and eye protec#on.

joints by using an appropriate mas#c.

For further informa#on refer to the Material Safety Data

Notes: Sheet.

If applica#on is done under high temperatures, care

should be done because the working #me will be Fire

reduced signiÞcantly.

To reduce the e%ect of this problem, try to store the EP215*is nonßammable.

Flo-Grout EP270

unmixed materials in a cool environment, avoiding the

direct sunlight. Also, try not to make the applica#on in More from Don Construction Products

the middle of the day or direct sunlight.

A wide range of construc#on chemicals products are

Cleaning manufactured by DCP which include:

All tools should be cleaned immediately a&er Þnishing Concrete admixtures.

using a suitable epoxy thinner. Hardened materials Surface treatments

should be cleaned mechanically. Grouts and anchors.

Concrete repair.

Packaging Flooring systems.

Protec#ve coa#ngs.

EP215*is available in 20 kg packs.

Flo-Grout EP270 Sealants.

WaterprooÞng.

Thicknesses and Size Limitations Adhesives.

Tile adhesives and grouts.

EP215* can be applied in a single layer at

Flo-Grout EP270 Building products.

thicknesses between 10 - 150

100 mm. For thicknesses Structural strengthening.

greater than 100

150mm:

Mul#ple layers can be applied a&er ini#al curing of the

previous layer.

Flo-Grout EP330 can be used instead.

03-0024-A-2013

Note:

!"!#$!%&'()"*'"!#+()!"*,%*"%#-".#/')0%1'#2"%$&.3!"')")!3'00!#$%1'#"4!"0%-"5.&!".#"

6)'$(3*" 7.*!)%*()!" .+" %33()%*!" %#$" 3'))!3*8" 9'4!&!)2" :!3%(+!" 4!" ,%&!" #'" 3'#*)'7" '&!)"

4,!)!"%#$",'4"6)'$(3*+"%)!"%667.!$2"4!"3%##'*"%33!6*"%#-"7.%:.7.*-"%).+.#5"/)'0"*,!"(+!"'/"

*,!"6)'$(3*+8

You might also like

- Full Download PDF of The Cell: A Molecular Approach 7th Edition (Ebook PDF) All ChapterDocument41 pagesFull Download PDF of The Cell: A Molecular Approach 7th Edition (Ebook PDF) All Chapterkutsisanouh100% (14)

- UC1.docx ACP iNSTITUTIONAL aSSESWSMENTDocument5 pagesUC1.docx ACP iNSTITUTIONAL aSSESWSMENTDanny R. Salvador100% (2)

- Disease Detection Using Bio RoboticsDocument11 pagesDisease Detection Using Bio RoboticsGorby C. Ulanday50% (2)

- Pipelining Liquefied Petroleum GasDocument8 pagesPipelining Liquefied Petroleum GasSaurabh Sengar100% (1)

- The British Pharmacopoeia 2015Document4 pagesThe British Pharmacopoeia 2015sesilia dyah novitrianiNo ratings yet

- Flo-Grout EP270Document2 pagesFlo-Grout EP270Ahmed AbdallahNo ratings yet

- Flo-Grout EP260Document2 pagesFlo-Grout EP260Ahmed AbdallahNo ratings yet

- Flo-Grout EP280Document2 pagesFlo-Grout EP280Ahmed AbdallahNo ratings yet

- Flo-Grout EP215Document4 pagesFlo-Grout EP215Ahmed AbdallahNo ratings yet

- Flo Grout EP330Document2 pagesFlo Grout EP330Ahmed AbdallahNo ratings yet

- Flo Grout EPCGDocument4 pagesFlo Grout EPCGosama mohNo ratings yet

- TDS Nitobond EP India4Document3 pagesTDS Nitobond EP India4SHIVANSHUNo ratings yet

- Chesterton 860 Moldable Polymer Gasketing Datasheet PDFDocument2 pagesChesterton 860 Moldable Polymer Gasketing Datasheet PDFHumberto ParisNo ratings yet

- MasterEmaco - S650 v1 PDFDocument2 pagesMasterEmaco - S650 v1 PDFPuneet AggarwalNo ratings yet

- Ep 300Document2 pagesEp 300mathewsujith31No ratings yet

- Flo-Grout PC100 - TDSDocument2 pagesFlo-Grout PC100 - TDSAhmed AbuoelnagaNo ratings yet

- Conbextra Ep40Document3 pagesConbextra Ep40talatzahoorNo ratings yet

- Weberep 360 FFRDocument2 pagesWeberep 360 FFRBasemNo ratings yet

- Strongcoat PE350Document48 pagesStrongcoat PE350Ahmad ElghazolyNo ratings yet

- Mea Polybit Tds Polybit Polygrout Ey 3000 PH en MeaDocument2 pagesMea Polybit Tds Polybit Polygrout Ey 3000 PH en MeaMuhammad hussainNo ratings yet

- 860 Moldable Polymer GasketingDocument2 pages860 Moldable Polymer GasketingprajanegaraNo ratings yet

- Fosroc Conbextra EP40: Free Flowing, Epoxy Resin GroutDocument2 pagesFosroc Conbextra EP40: Free Flowing, Epoxy Resin GroutVincent JavateNo ratings yet

- Nitobond EP: Epoxy Resin Concrete Bonding AgentDocument3 pagesNitobond EP: Epoxy Resin Concrete Bonding AgentDinesh HastakNo ratings yet

- Concresive Fluido: Two-Pack Solvent-Free Fluid Epoxy Adhesive For Fixings, Construction Joints and AnchoragesDocument3 pagesConcresive Fluido: Two-Pack Solvent-Free Fluid Epoxy Adhesive For Fixings, Construction Joints and AnchoragesKarl FarrugiaNo ratings yet

- Conbextra EP10: High Strength, Epoxy Resin GroutDocument3 pagesConbextra EP10: High Strength, Epoxy Resin GroutR.ThangarajNo ratings yet

- Carboguard 690: Selection & Specification Data Selection & Specification DataDocument2 pagesCarboguard 690: Selection & Specification Data Selection & Specification DataImran AhmadNo ratings yet

- Masteremaco S 650: Fast Setting High Strength Thixotropic Roadway Patching MortarDocument2 pagesMasteremaco S 650: Fast Setting High Strength Thixotropic Roadway Patching MortarRavi kumarNo ratings yet

- AJ220335-LCV-CVL-MTL-0001 - Cement & Civil Repair MaterialsDocument8 pagesAJ220335-LCV-CVL-MTL-0001 - Cement & Civil Repair Materialsmohammed mustafaNo ratings yet

- Conbextra EP300Document4 pagesConbextra EP300m.basim.technitalNo ratings yet

- Fosroc Conbextra EP10: Constructive SolutionsDocument2 pagesFosroc Conbextra EP10: Constructive SolutionsVincent JavateNo ratings yet

- CONCRESIVE 2200 - v1Document2 pagesCONCRESIVE 2200 - v1VaishamNo ratings yet

- Flexane HP PuttyDocument2 pagesFlexane HP PuttyDivyanshu GuptaNo ratings yet

- Conbextra EP40 UAEDocument2 pagesConbextra EP40 UAEjasonNo ratings yet

- Masteremaco S 5410 Ci Tds PDFDocument3 pagesMasteremaco S 5410 Ci Tds PDFSolomon AhimbisibweNo ratings yet

- Weberep 331 TXDocument2 pagesWeberep 331 TXmelvinkorahNo ratings yet

- TDS CONBEXTRA EP300 Saudi ArabiaDocument3 pagesTDS CONBEXTRA EP300 Saudi ArabiaShaikhRizwanNo ratings yet

- Weberep 331 TXDocument2 pagesWeberep 331 TXmoizm53No ratings yet

- Concrete Repair - Pinhole and Reprofile 1-5mm 20mpa SodamcoDocument2 pagesConcrete Repair - Pinhole and Reprofile 1-5mm 20mpa SodamcoVincent JavateNo ratings yet

- Solvent-Free, Low Viscosity Epoxy ResinDocument2 pagesSolvent-Free, Low Viscosity Epoxy ResinYASHICA VAITTIANATHANNo ratings yet

- Conbextra EP120: High Strength, Epoxy Resin GroutDocument2 pagesConbextra EP120: High Strength, Epoxy Resin GroutzulfikarNo ratings yet

- Semstone 145 SL: Selection & Specification DataDocument3 pagesSemstone 145 SL: Selection & Specification DataSHAIK ASIMUDDINNo ratings yet

- Flo-Grout 60 - TDSDocument2 pagesFlo-Grout 60 - TDSOption HunterNo ratings yet

- ST171EN24081906 Diathonite ThermoStep.047Document5 pagesST171EN24081906 Diathonite ThermoStep.047NoraPetreNo ratings yet

- iKOTE CM 30R (TDS) 02-APRIL-2024Document2 pagesiKOTE CM 30R (TDS) 02-APRIL-2024nguyen hoang AnhNo ratings yet

- Epoxy Grout E33 PDFDocument2 pagesEpoxy Grout E33 PDFUa AnyanhunNo ratings yet

- MasterEmaco - S 348 v2Document2 pagesMasterEmaco - S 348 v2Umeshchandra PatilNo ratings yet

- Bitumastic 300M: Selection & Specification DataDocument4 pagesBitumastic 300M: Selection & Specification DataSHAIK ASIMUDDINNo ratings yet

- Polygrout EY 3000(HF)Document2 pagesPolygrout EY 3000(HF)Alexi ALfred H. TagoNo ratings yet

- Smarter Building Systems SBS-R30 Insulating Paint InstructionsDocument5 pagesSmarter Building Systems SBS-R30 Insulating Paint InstructionsJJ Sherem MoraNo ratings yet

- Conbextra EP75 PDFDocument3 pagesConbextra EP75 PDFKhaerul SidikNo ratings yet

- Ep37 3flfaoDocument3 pagesEp37 3flfaostahlmob5657No ratings yet

- Thermaline 450 EP PDSDocument3 pagesThermaline 450 EP PDSNguyễn Duy BiênNo ratings yet

- Passive Fire Protection Solutions: Presented by International IpsDocument20 pagesPassive Fire Protection Solutions: Presented by International IpsTung Doan ThanhNo ratings yet

- Devcon Flexane-High-Performance-Putty - 15330Document2 pagesDevcon Flexane-High-Performance-Putty - 15330Yajaira ValdezNo ratings yet

- Flo-Grout 2Document2 pagesFlo-Grout 2Ahmed SamyNo ratings yet

- Conbextra EP150 UAEDocument4 pagesConbextra EP150 UAEjasonNo ratings yet

- Nitobond EP: Epoxy Resin Concrete Bonding AgentDocument2 pagesNitobond EP: Epoxy Resin Concrete Bonding AgentjitendraNo ratings yet

- Non Toxic EpoxyDocument36 pagesNon Toxic EpoxyAhmed FahmyNo ratings yet

- Sikalastic®-8440: Product Data SheetDocument3 pagesSikalastic®-8440: Product Data SheetGeorge EnescuNo ratings yet

- PRIMER COAT-Zinc Anode 304 MZV - PDSDocument2 pagesPRIMER COAT-Zinc Anode 304 MZV - PDSMANIMARAN QCNo ratings yet

- Conbextra EP10Document2 pagesConbextra EP10m.elsanee.cubicNo ratings yet

- Sikagrout - 215: Pumpable Shrinkage Compensated Cementitious GroutDocument2 pagesSikagrout - 215: Pumpable Shrinkage Compensated Cementitious GroutKent BasigaNo ratings yet

- PDS Sikacrete 113 PPDocument4 pagesPDS Sikacrete 113 PPKoh HanNo ratings yet

- Conbextra EP75Document4 pagesConbextra EP75Venkata Raju KalidindiNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Flo Grout EP330Document2 pagesFlo Grout EP330Ahmed AbdallahNo ratings yet

- Flo-Grout EP215Document4 pagesFlo-Grout EP215Ahmed AbdallahNo ratings yet

- Flo-Grout EP260Document2 pagesFlo-Grout EP260Ahmed AbdallahNo ratings yet

- Flo-Grout EP270Document2 pagesFlo-Grout EP270Ahmed AbdallahNo ratings yet

- Flo-Grout EP280Document2 pagesFlo-Grout EP280Ahmed AbdallahNo ratings yet

- Mobile Potentiostat IoT CompatibleDocument6 pagesMobile Potentiostat IoT CompatibleJoão CostaNo ratings yet

- Hospital ReservesDocument84 pagesHospital ReservesThe Boston GlobeNo ratings yet

- Comparative Study of HerzbergDocument2 pagesComparative Study of HerzbergRoy Peter DelizoNo ratings yet

- Phase Transfer CatalysisDocument15 pagesPhase Transfer CatalysisUnnati SinariNo ratings yet

- Bio Psychology Lecture Notes Chapter 6 The Visual SystemDocument7 pagesBio Psychology Lecture Notes Chapter 6 The Visual SystemGeneric_Persona50% (2)

- 3 - Le Chateliers Principle Experiment Chemistry LibreTextsDocument11 pages3 - Le Chateliers Principle Experiment Chemistry LibreTextsReynee Shaira Lamprea MatulacNo ratings yet

- DRUG-STUDY Piptaz ClindamycinDocument2 pagesDRUG-STUDY Piptaz ClindamycinJAYMIE ROSE M. MANUELNo ratings yet

- Cardiomyopathy: Restrictive Heart DiseaseDocument18 pagesCardiomyopathy: Restrictive Heart DiseaseMitch GabuyaNo ratings yet

- VG 70 Data Sheet - 201901Document3 pagesVG 70 Data Sheet - 201901Cláudio Fernando OliveiraNo ratings yet

- Np4 np5Document71 pagesNp4 np5Erika SapieraNo ratings yet

- Sociology Final ProjectDocument16 pagesSociology Final Projectabt09No ratings yet

- HydrationDocument1 pageHydrationfidaauddinNo ratings yet

- 3blocks - IFRS 17 PDFDocument131 pages3blocks - IFRS 17 PDFDurgaprasad VelamalaNo ratings yet

- SCIENCE-10 Q4 MOD1 Behavior-of-Gases BookletDocument12 pagesSCIENCE-10 Q4 MOD1 Behavior-of-Gases BookletRetep Aren50% (2)

- Microbial CarcinogensDocument33 pagesMicrobial CarcinogensJacob ThomasNo ratings yet

- ICP and TIADocument4 pagesICP and TIANurse AmbassadorsNo ratings yet

- Volume Changes of ConcreteDocument17 pagesVolume Changes of ConcreteAljawhara AlnadiraNo ratings yet

- 1NU04 - MICROPARA - INITIAL TRANSES - Viruses PrionsDocument9 pages1NU04 - MICROPARA - INITIAL TRANSES - Viruses Prionssammydels98No ratings yet

- Compensation and BenefitsDocument4 pagesCompensation and BenefitsNiño Sismoan BenigayNo ratings yet

- Usg Sheetrock® Brand Mold Tough® Firecode® XDocument3 pagesUsg Sheetrock® Brand Mold Tough® Firecode® XHoracio PadillaNo ratings yet

- Factor Affecting Quality of TimberDocument3 pagesFactor Affecting Quality of TimberJitesh AnejaNo ratings yet

- Physics MidtermDocument14 pagesPhysics MidtermPrecious015100% (1)

- SPK Manual 2007-2009Document26 pagesSPK Manual 2007-2009jlhood65No ratings yet

- Analisis Kualitatif GaramDocument1 pageAnalisis Kualitatif GaramAbu AimanNo ratings yet

- Danika Sanders Student Teacher ResumeDocument2 pagesDanika Sanders Student Teacher Resumeapi-496485131No ratings yet