Professional Documents

Culture Documents

RFQ_Eng590

RFQ_Eng590

Uploaded by

Ershad SCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RFQ_Eng590

RFQ_Eng590

Uploaded by

Ershad SCopyright:

Available Formats

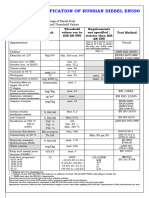

Request for Quotation (R O Q).

- Product details:

Destination:

COMMODITY/PRODUCT: ENG590 10PPM

ORIGIN Kazakhstan

TOTAL/ CONTRACT QUANTITY: 3.600.000 Tons

CONTRACT PERIOD: One year

MONTHLY DELIVERY 300,000 MT

DURATOIN OF THE CONTRACT One year

DELIVERY/SHIPMENT: San Paolo- Brazil

PACKAGING As buyer request

PRICE: MT

VALUE OF THE CONTRACT IN TOTAL $

VALUE OF THE MONTHLY CONTRACT $

SHIPPING TERMS CIF

PAYMENT TERMS: LC/ SBLC

- Product Specifications

COMPONENT METHOD OF ANALYSIS UNIT RESULT

Min. Max.

Aspect Visual Clear

Color inspection 2,0

ASTM D 1500

Density @ 15° EN ISO 3675:98/ ENISO Kg/m3 845,0~LK835

12185:96 820,0~LK815

/C1:2001

Flash Point EN 1SO 2719:2002 C° 55(1)~LK40

Distillation: 2,0

- Recovered @ 150℃ % vol

- Recovered @ 250 °C EN ISO 3405:2000 % vol 65,0(2)~LK85(2)

- Recovered @ 350 ℃ % vol

- Recovered at 95% ℃ 85,0(2) 360,0

C.F.P.P. (summer)(3) EN 116:1997 ℃ -2

C.F.P.P. (winter)(3) ℃ 50,0 -12

CLOUD Point (summer) EN 23015:1994 ℃ Report

CLOUD Point (winter) ℃ 0

Cetane number EN ISO 5165:1998 n° 51,0

Cetane index EN ISO 4264:1996 Index 46,0~LK52

Viscosity @ 40 °℃ EN ISO 3104:1996 mm2/s 2,00~LK1.9 4,50~LK5.5

Water content EN ISO 12937:2000 mg/kg 200

Total contamination EN ISO 12662:2002 mg/kg 15

mg/kg~LK

EN ISO 20884:2004 %WEIGHT 10,0

Sulfur content

Copper strip corrosion

(3 hr at 50 ℃)~LK:Copper strip

EN ISO 2160:1998 Indice

corrosion (3 hr at 100 °C)

1st Class

Carbon residue EN ISO 10370:1995 % weight 0,15

(on 10% distillation residue)

Total acidity ASTM D 974:2002 mgKOH/g 0,3

Ash content EN ISO 6245:2002 % weight 0,01~LK0.02

Lubricity, correct wear scar ENISO 12156-1:2000 μm 460~LK400

Oxidation stability EN ISO 12205:1996 g/m3 20

Electrical conductivity (4) IP 274;ASTM 2624;IS06297 p₅/m 50

Polyciclic aromatic hydrocarbons EN 12916:2001 %m/m 11,0(6)~LK5.0

Biodiesel content (5) EN 14078:2003 % vol 4,5 7,0

Standard operating procedures

1. Buyer accepts seller working procedure and issue ICPO .

2. Seller issues commercial invoice (CI), Buyer signs and returns back commercial invoice.

3. Seller issue TSR with GPS coordinate to Buyer Company,

4. Buyer contacts the Seller's storage facility for tank extension to enable Buyer approval to gain access to the facility

and execute the Quality & Quantity Inspection in Seller Tank Farm for FRESH Analytical Report/Result by SGS.

5. After successful DIP test, (NCNDA/IMFPA) will be signed by all parties.

6. Seller injects product into Buyer’s vessel or injects into Buyer’s tanks Buyer or buyer take over the storage tanks,

within maximum 48 hours Buyer pays via MT 103/TT for the spot transaction and seller issues all export documents to

buyer.

7. Upon conclusion of first lift transaction seller pays all intermediaries involved in the Transaction and proceed with

the signing of contract with Buyer

You might also like

- Full Corporate Offer Diesel En590 (10 PPM)Document7 pagesFull Corporate Offer Diesel En590 (10 PPM)Patricia LeahDalyNo ratings yet

- CEPE - Printable BDSM Checklist. August 2014Document41 pagesCEPE - Printable BDSM Checklist. August 2014hollywoodbear999990% (10)

- Cec Vogo Fco 20230811-1-1Document4 pagesCec Vogo Fco 20230811-1-1kangwm21No ratings yet

- Icpo NG En590 2704231111Document3 pagesIcpo NG En590 2704231111Nikita Novikov100% (1)

- Louis Hardan Mobile Dental Photography Part I ViaDocument9 pagesLouis Hardan Mobile Dental Photography Part I ViaMuchlis Fauzi ENo ratings yet

- Bio Diesel b20, En590-Biodiesel b5 SpecsDocument1 pageBio Diesel b20, En590-Biodiesel b5 Specsmohammed wajid100% (1)

- Kraus & Naimer C Switches PDFDocument56 pagesKraus & Naimer C Switches PDFJefMur100% (1)

- Diesel EN590 - Looking For SupplyDocument2 pagesDiesel EN590 - Looking For Supplydandy.baratetaNo ratings yet

- SCO Diesel EN590 10PPM Apr 23 200K MT Monthly MR Abess To End BuyerDocument4 pagesSCO Diesel EN590 10PPM Apr 23 200K MT Monthly MR Abess To End BuyerJoel SEMONNo ratings yet

- EN590 10ppm SPECIFICATIONS PEGASUS OILDocument1 pageEN590 10ppm SPECIFICATIONS PEGASUS OILSephiwe Mafilika100% (1)

- Kubera-Petroleum Product PassportDocument2 pagesKubera-Petroleum Product Passportptintimaritimsekawan100% (1)

- Hxh En590 Jurong Fob Icpo 富吉拉港口Document4 pagesHxh En590 Jurong Fob Icpo 富吉拉港口tsng812No ratings yet

- Screenshot 2019-12-28 at 4.13.33 PMDocument10 pagesScreenshot 2019-12-28 at 4.13.33 PMDave Acang100% (1)

- Sop FobDocument3 pagesSop FobAdnan IsmailNo ratings yet

- Document 4Document1 pageDocument 4albert.mamuevNo ratings yet

- Document 4Document1 pageDocument 4albert.mamuevNo ratings yet

- SF-43 Standard DieselDocument2 pagesSF-43 Standard DieselClaudiu PanaNo ratings yet

- Attn: Mr. Theodore Kolozian, CEO: Letter of Intent (Loi) (Purchase of Ago)Document4 pagesAttn: Mr. Theodore Kolozian, CEO: Letter of Intent (Loi) (Purchase of Ago)Даниил ЛебенNo ratings yet

- Fco Ulsd 10PPM BLM - Mep 200K TtoDocument6 pagesFco Ulsd 10PPM BLM - Mep 200K TtoAnugerah KalimantanNo ratings yet

- Technical Specs DieselDocument1 pageTechnical Specs Dieselalbert.mamuevNo ratings yet

- 0121-Sco En590-Espo-Urea-Petcoke-Lng-Ejb To BuyerDocument8 pages0121-Sco En590-Espo-Urea-Petcoke-Lng-Ejb To Buyerdimas100% (1)

- 10ppm Sulphur GasoilDocument1 page10ppm Sulphur GasoilRos Neftegaz TransitNo ratings yet

- Messrs. Petrobras Global Trading B.V / Eni Trading & Shipping S.P.A Certificate of Quality JOB MA 007/16Document1 pageMessrs. Petrobras Global Trading B.V / Eni Trading & Shipping S.P.A Certificate of Quality JOB MA 007/16Marcones SáNo ratings yet

- Crown Oil HVODocument1 pageCrown Oil HVOLuca CarazzoloNo ratings yet

- 2 Specification Russian EN590Document1 page2 Specification Russian EN590Sephiwe MafilikaNo ratings yet

- RxqLAqoza7pbNi3pvz1GfRieVcYTaAbfFuel Specifications EN590-10PPMDocument1 pageRxqLAqoza7pbNi3pvz1GfRieVcYTaAbfFuel Specifications EN590-10PPMalbert.mamuevNo ratings yet

- En 590Document1 pageEn 590anil divveNo ratings yet

- En 590Document1 pageEn 590osmankoc812No ratings yet

- 18 Apr 20 AFRICAN FLAMINGO (9802322) IFO 380 (RMG 380) : Report Date Vessel Fuel GradeDocument4 pages18 Apr 20 AFRICAN FLAMINGO (9802322) IFO 380 (RMG 380) : Report Date Vessel Fuel GradeNguyễn Hữu DũngNo ratings yet

- Bio Diesel b20, En590 b5 SpecificationsDocument1 pageBio Diesel b20, En590 b5 Specificationsmohammed wajidNo ratings yet

- Fuel Analysis ReportDocument3 pagesFuel Analysis ReportRichardson P.A.No ratings yet

- Uls DieselDocument1 pageUls DieselHUYQUYENNo ratings yet

- Trafigura Kazakhstan Spot Trail Invoice For En590 To Sirus Petroleum Products Trading LLCDocument2 pagesTrafigura Kazakhstan Spot Trail Invoice For En590 To Sirus Petroleum Products Trading LLCHermes Trismegistos0% (1)

- 18ee En590, Euro 5, Gost R52368 - 2005 - WW ..Document1 page18ee En590, Euro 5, Gost R52368 - 2005 - WW ..JZ HuangNo ratings yet

- Shellsol T q7412 PDFDocument3 pagesShellsol T q7412 PDFmeNo ratings yet

- ASTM D 770 FOR ISOPRANAOLDocument3 pagesASTM D 770 FOR ISOPRANAOLdaya vashishtNo ratings yet

- ANKRAL R1 Zement ISO PTDocument1 pageANKRAL R1 Zement ISO PTWalysson JohnathasNo ratings yet

- Methyl Ethyl Ketone: Shell ChemicalsDocument3 pagesMethyl Ethyl Ketone: Shell ChemicalssyamlokNo ratings yet

- 22 Jan 21 AFRICAN FLAMINGO (9802322) IFO 180 (RMG 180) : Report Date Vessel Fuel GradeDocument4 pages22 Jan 21 AFRICAN FLAMINGO (9802322) IFO 180 (RMG 180) : Report Date Vessel Fuel GradeNguyễn Hữu DũngNo ratings yet

- Datasheet Isoparaffinsshellsoltdeurope PDFDocument3 pagesDatasheet Isoparaffinsshellsoltdeurope PDFmeNo ratings yet

- Acetone: Shell ChemicalsDocument3 pagesAcetone: Shell ChemicalsUzair BukhariNo ratings yet

- Colpoly 7160 TDSDocument2 pagesColpoly 7160 TDSKristjan PosavecNo ratings yet

- Shellsol A150 q7493 Eu 18042016Document3 pagesShellsol A150 q7493 Eu 18042016Henry FloresNo ratings yet

- Benzin Spec Antetli - EN 92e9085b 8eaa 4025 A4d4 98c610fa9a28Document2 pagesBenzin Spec Antetli - EN 92e9085b 8eaa 4025 A4d4 98c610fa9a28AdelNo ratings yet

- MS HSD Bs-Vi SpecsDocument3 pagesMS HSD Bs-Vi SpecsKusunuru SandeepNo ratings yet

- Shellsol T q7412 AmDocument3 pagesShellsol T q7412 AmRagavendra Prabu GovindarajuNo ratings yet

- Ficha Tecnica Diesel En590Document1 pageFicha Tecnica Diesel En590Alfred Peyrot Eyssautier100% (1)

- Comprit 185H 0 6Document1 pageComprit 185H 0 6Ahmed AbdelhamidNo ratings yet

- Hexane Polymerisation: Data SheetDocument3 pagesHexane Polymerisation: Data SheetHamid Vahedi LarijaniNo ratings yet

- Skikda Training CDU (Goal Content)Document26 pagesSkikda Training CDU (Goal Content)Mohamed OuichaouiNo ratings yet

- Product Passport (Quantity & Quality Dip Test Analysis Report)Document1 pageProduct Passport (Quantity & Quality Dip Test Analysis Report)spetsoilgroupNo ratings yet

- Indian Standard Specification For Petroleum Products-2019Document15 pagesIndian Standard Specification For Petroleum Products-2019Ganesh BhandaryNo ratings yet

- Base OIL SN-650: CharacteristicsDocument1 pageBase OIL SN-650: CharacteristicsAlzahraa TradingNo ratings yet

- Isopentane Shell ChemicalsDocument3 pagesIsopentane Shell Chemicalsazrim02No ratings yet

- Shellsol A150 ND q7497 Eu 18042016Document3 pagesShellsol A150 ND q7497 Eu 18042016sizmaruNo ratings yet

- Fobas Bunker Sample ResultDocument6 pagesFobas Bunker Sample ResultRiskyMaulanaNo ratings yet

- Spec - Diesel S10Document1 pageSpec - Diesel S10Dylson ValenteNo ratings yet

- Isoparaffins Shellsolt EuropeDocument3 pagesIsoparaffins Shellsolt EuropeSaman ZehraNo ratings yet

- Transformer Oil TestingDocument8 pagesTransformer Oil TestingAndrei HoNo ratings yet

- Port 5709 Sampleanalysedreport 2016 02 05 17 04 0001543Document3 pagesPort 5709 Sampleanalysedreport 2016 02 05 17 04 0001543trongthemai_80475818No ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Hydrogen Production TechnologiesFrom EverandHydrogen Production TechnologiesMehmet SankirNo ratings yet

- RFQ-IBRU-WS-0474 Hyundai Tractor F42-1079 Chassis Spare PartsDocument1 pageRFQ-IBRU-WS-0474 Hyundai Tractor F42-1079 Chassis Spare PartsErshad SNo ratings yet

- Sample COADocument2 pagesSample COAErshad SNo ratings yet

- Sales & Purchase Agreement Draft_compressedDocument14 pagesSales & Purchase Agreement Draft_compressedErshad SNo ratings yet

- HRUM_AR_2014Document202 pagesHRUM_AR_2014Ershad SNo ratings yet

- HMSP - Public Expose - 3Q2020Document19 pagesHMSP - Public Expose - 3Q2020Ershad SNo ratings yet

- Talent Search Recruitment - Company ProfileDocument10 pagesTalent Search Recruitment - Company ProfileErshad SNo ratings yet

- Edith Stein: Women, Social-Political Philosophy, Theology, Metaphysics and Public HistoryDocument281 pagesEdith Stein: Women, Social-Political Philosophy, Theology, Metaphysics and Public HistorySantiago GarciaNo ratings yet

- SCHOOL YEAR 2017 - 2018: 1. Informational DataDocument8 pagesSCHOOL YEAR 2017 - 2018: 1. Informational Datadamyan_salazarNo ratings yet

- HYPACK ECHO Brochure 2022 Nautilus OceanicaDocument2 pagesHYPACK ECHO Brochure 2022 Nautilus OceanicaADOUKONo ratings yet

- 04 What Is Easement Distinguish Easement From Usufruct 2 Can There Be A An - Course HeroDocument9 pages04 What Is Easement Distinguish Easement From Usufruct 2 Can There Be A An - Course HerojrstockholmNo ratings yet

- Safar Ki Dua - Travel SupplicationinvocationDocument1 pageSafar Ki Dua - Travel SupplicationinvocationShamshad Begum ShaikNo ratings yet

- Jadual Waktu Kelas PKPP PDFDocument18 pagesJadual Waktu Kelas PKPP PDFAidda SuriNo ratings yet

- HCR5 Leaflet E 1102 Sheet PDFDocument8 pagesHCR5 Leaflet E 1102 Sheet PDFAmilcar CoutoNo ratings yet

- Case 1Document2 pagesCase 1Wanda Marie SingletaryNo ratings yet

- Detergent Powder: Project Report ofDocument15 pagesDetergent Powder: Project Report ofOSG Chemical Industry LLP 'A Cause For Cleanliness'67% (3)

- Errata Sheet 1.7 - Dropzone Commander Official Update: NEW ADDITIONS/ CHANGES FROM VERSION 1.6 Highlighted in RedDocument2 pagesErrata Sheet 1.7 - Dropzone Commander Official Update: NEW ADDITIONS/ CHANGES FROM VERSION 1.6 Highlighted in RedTecnocastoroNo ratings yet

- The Process of Expository Preaching Sermon Study and Development 1 PDFDocument19 pagesThe Process of Expository Preaching Sermon Study and Development 1 PDFjNo ratings yet

- NutriSmart - Food Products Recommendation SystemDocument3 pagesNutriSmart - Food Products Recommendation SystemAnonymous izrFWiQNo ratings yet

- Specification For BMW POLYBAGSDocument3 pagesSpecification For BMW POLYBAGSDarpan BhattNo ratings yet

- Structure and PoetryDocument13 pagesStructure and PoetrySherwinNo ratings yet

- Denture Base MaterialsDocument65 pagesDenture Base MaterialsGitanjali Sharma33% (3)

- Blog Profile: Activity A. " ". Complete El Perfil Con Su Información Personal en Los Espacios Indicados "Document5 pagesBlog Profile: Activity A. " ". Complete El Perfil Con Su Información Personal en Los Espacios Indicados "El dominadorNo ratings yet

- DIGITAL MARKETING (Unit 4)Document9 pagesDIGITAL MARKETING (Unit 4)sharmapranav780No ratings yet

- Chapter 13 Lecture 1 Career OptionsDocument24 pagesChapter 13 Lecture 1 Career OptionseltpgroupNo ratings yet

- PD 477Document21 pagesPD 477Rak Nopel Taro100% (1)

- Acts 13 New 2Document8 pagesActs 13 New 2fitsum tesfayeNo ratings yet

- Pertemuan Kedua-Narrative TextDocument22 pagesPertemuan Kedua-Narrative TextLilik YuliyantiNo ratings yet

- Topic 06 - Introduction To Differential Calculus - Cake TinDocument4 pagesTopic 06 - Introduction To Differential Calculus - Cake Tinmmi0% (1)

- Anth 133 - HUNTERS AND GATHERERS PDFDocument15 pagesAnth 133 - HUNTERS AND GATHERERS PDFAnjelica Pearl NazarenoNo ratings yet

- 1.socio Economic Determinants of HealthDocument64 pages1.socio Economic Determinants of HealthdenekeNo ratings yet

- Literature Book: The Poem Dulce Et Decorum Est by Wilfred Owen PDFDocument8 pagesLiterature Book: The Poem Dulce Et Decorum Est by Wilfred Owen PDFIRFAN TANHANo ratings yet

- ATV930 950 Installation Manual EN NHA80932 01Document129 pagesATV930 950 Installation Manual EN NHA80932 01ahilsergeyNo ratings yet

- Modul EFB Unit 7Document18 pagesModul EFB Unit 7Muhammad IlhamNo ratings yet