Professional Documents

Culture Documents

mos3

mos3

Uploaded by

Smart EngineerCopyright:

Available Formats

You might also like

- Final ExamDocument2 pagesFinal ExamJisoo Eric LeeNo ratings yet

- Chapter 1Document14 pagesChapter 1Manish JaiswalNo ratings yet

- UTM - Lab ReportDocument5 pagesUTM - Lab Reportshubhradiproy2003No ratings yet

- CEN206Document10 pagesCEN206shiaondo543No ratings yet

- Strength of Materials LabDocument30 pagesStrength of Materials LabDipesh GugaleNo ratings yet

- Experiment No 10 Tension TestDocument6 pagesExperiment No 10 Tension TestrashmarsvNo ratings yet

- Direct Rubber Shear Test PDFDocument9 pagesDirect Rubber Shear Test PDFMohammad ShehabNo ratings yet

- Tensile Test For Steel SpecimenDocument12 pagesTensile Test For Steel SpecimenEddie BowokuNo ratings yet

- Papua New Guinea University of Technology CE 261-Engineering Materials Test 2 - Tensile Test of A Steel SpecimenDocument4 pagesPapua New Guinea University of Technology CE 261-Engineering Materials Test 2 - Tensile Test of A Steel SpecimenIsrael PopeNo ratings yet

- Strength of Materials Lab Manual: 1. Tension Test On MS Bar and HYSD BarsDocument61 pagesStrength of Materials Lab Manual: 1. Tension Test On MS Bar and HYSD Barsswe_maniNo ratings yet

- Lab Manual: Sant Longowal Institute of Engineering & Technology Longowal-148106Document4 pagesLab Manual: Sant Longowal Institute of Engineering & Technology Longowal-148106Vivek JhaNo ratings yet

- MosDocument42 pagesMosSajjan Kumar100% (2)

- Stress and StrainDocument38 pagesStress and StrainNandi ?No ratings yet

- Design Failure AnalysisDocument8 pagesDesign Failure AnalysisHamzaNo ratings yet

- Mos Lab Manual PDFDocument34 pagesMos Lab Manual PDFs.rihanaNo ratings yet

- Mechanics of Solid Lab ManualDocument32 pagesMechanics of Solid Lab ManualPrithvijeet SahooNo ratings yet

- Exp 1 ErianeDocument20 pagesExp 1 ErianeEriane GarciaNo ratings yet

- Strength of MaterialDocument18 pagesStrength of MaterialMamta SinghNo ratings yet

- Design of Machine Elements 2 6Document25 pagesDesign of Machine Elements 2 6sasikskNo ratings yet

- Aumar AlMeshhadany - Experiment 2 - Lab DI-XDocument20 pagesAumar AlMeshhadany - Experiment 2 - Lab DI-XTonyFalconeNo ratings yet

- Full Report Solid MechDocument19 pagesFull Report Solid MechMUHAMMAD ARIFF DYAMIMNo ratings yet

- Strength of Materials: Machine Design 1Document28 pagesStrength of Materials: Machine Design 1John ReyNo ratings yet

- Tensile TestDocument6 pagesTensile Testkinwai5557100% (1)

- Torsion Final ReportDocument24 pagesTorsion Final ReportHanis FarinaNo ratings yet

- Som Manual-2013 RegDocument26 pagesSom Manual-2013 RegsugunavidiyadarNo ratings yet

- SOM-BMT Lab Manual FinalDocument48 pagesSOM-BMT Lab Manual FinalHarish T S Gowda100% (1)

- Strength of Materia Lab Manual UET, LahoreDocument14 pagesStrength of Materia Lab Manual UET, LahoreRizwan Khurram100% (3)

- Part 1: Tension Test Objective: Experiment 1: Tension and Torsion TestsDocument20 pagesPart 1: Tension Test Objective: Experiment 1: Tension and Torsion TestsOngNo ratings yet

- Ex 1Document8 pagesEx 1arindamckbtNo ratings yet

- Universiti Tun Hussein Onn Malaysia Department of Mechanical EngineeringDocument12 pagesUniversiti Tun Hussein Onn Malaysia Department of Mechanical EngineeringAriff ShasteraNo ratings yet

- L4 - Design Against Fluctucaing LoadsDocument26 pagesL4 - Design Against Fluctucaing LoadsDhyan PatelNo ratings yet

- Youngs Modulus ExperimentDocument4 pagesYoungs Modulus ExperimentAsif Ur Rahman AdibNo ratings yet

- Material Testing LabDocument79 pagesMaterial Testing LabBrijesh VermaNo ratings yet

- MoM Lab Manual - 2021Document15 pagesMoM Lab Manual - 2021huzaifa sarwarNo ratings yet

- Design of Machine Elements PageDocument203 pagesDesign of Machine Elements PageKrishnan P MNo ratings yet

- Experiment 1 Tensile and Torsion TestDocument27 pagesExperiment 1 Tensile and Torsion TestMuhd Fauzan Ibrahim100% (1)

- Som Lab RawDocument10 pagesSom Lab RawAbhishek singh (abhi.03)No ratings yet

- Scissor Jack DesignDocument66 pagesScissor Jack DesignTewodros DereseNo ratings yet

- Reaction On BeamDocument10 pagesReaction On BeamNurul NadhirahNo ratings yet

- Design QPDocument57 pagesDesign QPJegan ParamasivamNo ratings yet

- Som ExperimentsDocument17 pagesSom ExperimentsAnudeex ShettyNo ratings yet

- Strength of Materials Laboratory ExperimentsDocument20 pagesStrength of Materials Laboratory Experimentskenneth iyahenNo ratings yet

- Mechanical Engineering Interview Questions With AnswersDocument5 pagesMechanical Engineering Interview Questions With Answersbrpnaidu2157100% (1)

- btech3rd-CE SOM LAB MANUALDocument21 pagesbtech3rd-CE SOM LAB MANUALvkmstp2005No ratings yet

- Tensile TestDocument11 pagesTensile TestOsura GunasenaNo ratings yet

- Design of Machine Elements: Unit - I Steady Stresses and Variable Stress in Machine MembesDocument53 pagesDesign of Machine Elements: Unit - I Steady Stresses and Variable Stress in Machine MembesDinesh PatilNo ratings yet

- As Physics Practical Set 1 Updated April 2014Document99 pagesAs Physics Practical Set 1 Updated April 2014Pathmanathan Nadeson33% (3)

- MSC Structural Integrity Academic Year 2017-2018: College of Engineering, Design and Physical SciencesDocument14 pagesMSC Structural Integrity Academic Year 2017-2018: College of Engineering, Design and Physical Sciencesshafahat aliNo ratings yet

- Laboratory Manual of Tensile TestDocument12 pagesLaboratory Manual of Tensile TestVIPAN KUMARNo ratings yet

- Group 6 - Exp 6Document32 pagesGroup 6 - Exp 6Arrianna PeterNo ratings yet

- Deflection of BeamDocument4 pagesDeflection of BeamRampukar SahNo ratings yet

- MEC 222 EXP-Lab-SOMDocument69 pagesMEC 222 EXP-Lab-SOMAbhijeeth NagarajNo ratings yet

- Experiment No. - 1: Material Testing Lab (MOM Lab) 1of 4 PagesDocument4 pagesExperiment No. - 1: Material Testing Lab (MOM Lab) 1of 4 PagesKirtismita TalukdarNo ratings yet

- Laboratory Manual of Tensile TestDocument11 pagesLaboratory Manual of Tensile TestVIPAN KUMARNo ratings yet

- Lab Report (Torsion) - Mohd Syazwan Bin Sarudin - 2021836538Document19 pagesLab Report (Torsion) - Mohd Syazwan Bin Sarudin - 2021836538Wanz SkylineNo ratings yet

- Experiment 1Document7 pagesExperiment 1waseemjuttNo ratings yet

- Part - ADocument20 pagesPart - AKumar SubramanianNo ratings yet

- Design of Machine Elements Two MarksDocument23 pagesDesign of Machine Elements Two MarksManivannan JeevaNo ratings yet

- Tensile Test - UTMDocument4 pagesTensile Test - UTMmjayrajsharma19No ratings yet

- Statistical Tolerance Regions: Theory, Applications, and ComputationFrom EverandStatistical Tolerance Regions: Theory, Applications, and ComputationNo ratings yet

- Spectral method for fatigue damage estimation with non-zero mean stressFrom EverandSpectral method for fatigue damage estimation with non-zero mean stressNo ratings yet

- Liquefaction Analysis of Earthen DamDocument15 pagesLiquefaction Analysis of Earthen DamSmart EngineerNo ratings yet

- SHEAR TESTDocument7 pagesSHEAR TESTSmart EngineerNo ratings yet

- 1Document5 pages1Smart EngineerNo ratings yet

- torsionDocument6 pagestorsionSmart EngineerNo ratings yet

- IZODDocument6 pagesIZODSmart EngineerNo ratings yet

- SPRING TESTDocument9 pagesSPRING TESTSmart EngineerNo ratings yet

- Certificate NewDocument1 pageCertificate NewSmart EngineerNo ratings yet

- CANTILEVER BEAMDocument7 pagesCANTILEVER BEAMSmart EngineerNo ratings yet

- ROCKWELLDocument5 pagesROCKWELLSmart EngineerNo ratings yet

- SIMPLY SUPPORTED BEAMDocument7 pagesSIMPLY SUPPORTED BEAMSmart EngineerNo ratings yet

- Muta Scholarship 2023Document1 pageMuta Scholarship 2023Smart EngineerNo ratings yet

- Hasiholan 2023 IOP Conf. Ser. Earth Environ. Sci. 1184 012003Document15 pagesHasiholan 2023 IOP Conf. Ser. Earth Environ. Sci. 1184 012003Smart EngineerNo ratings yet

- Awarness Seminar of PEC Price Adjustment Formula 19Document1 pageAwarness Seminar of PEC Price Adjustment Formula 19Smart EngineerNo ratings yet

- Submitted Note of ViscometerDocument1 pageSubmitted Note of ViscometerSmart EngineerNo ratings yet

- List of Items of H&TE LabDocument1 pageList of Items of H&TE LabSmart EngineerNo ratings yet

- ASTM E-11 Sieves DesignationDocument1 pageASTM E-11 Sieves DesignationSmart EngineerNo ratings yet

- 9644 ExamplesDocument5 pages9644 ExamplesSmart EngineerNo ratings yet

- Submitted Note of High Shear MixerDocument1 pageSubmitted Note of High Shear MixerSmart EngineerNo ratings yet

- UntitledDocument196 pagesUntitledSmart EngineerNo ratings yet

- Certificate NewDocument1 pageCertificate NewSmart EngineerNo ratings yet

- 37th Mock Test Municipal & Town OfficerDocument5 pages37th Mock Test Municipal & Town OfficerSmart Engineer100% (1)

- Mehran University of Engineering and Technology, Jamshoro: List of All Eligible / Candidates of Master & PH.D StduiesDocument29 pagesMehran University of Engineering and Technology, Jamshoro: List of All Eligible / Candidates of Master & PH.D StduiesSmart EngineerNo ratings yet

- Provisional List of Class Attendance Directorate of Postgraduate StudiesDocument2 pagesProvisional List of Class Attendance Directorate of Postgraduate StudiesSmart EngineerNo ratings yet

- RI AdvertisementDocument1 pageRI AdvertisementSmart EngineerNo ratings yet

- Job Opportunities: Directorate of Human ResourcesDocument11 pagesJob Opportunities: Directorate of Human ResourcesSmart EngineerNo ratings yet

- Advertisement of Vacant Post in MoITDocument1 pageAdvertisement of Vacant Post in MoITSmart EngineerNo ratings yet

- AEN RailwayDocument16 pagesAEN RailwaySmart EngineerNo ratings yet

- Pavement The Pavement Is The Structure Which Separates The Tires of Vehicles From The Underlying Foundation MaterialDocument23 pagesPavement The Pavement Is The Structure Which Separates The Tires of Vehicles From The Underlying Foundation MaterialSmart EngineerNo ratings yet

- Soil For Highway ConstructionDocument22 pagesSoil For Highway ConstructionSmart EngineerNo ratings yet

- Cholin BaseDocument5 pagesCholin Basex_aav3No ratings yet

- Antioxidant and AntiozonantDocument10 pagesAntioxidant and AntiozonantMaggie VillacortaNo ratings yet

- Sensors SyllabusDocument2 pagesSensors Syllabusdirector.sportssrmistNo ratings yet

- 2000-Solution Properties of Hsian-Tsao (Mesona Procumbens Hemsl) Leaf GumDocument8 pages2000-Solution Properties of Hsian-Tsao (Mesona Procumbens Hemsl) Leaf GumhasbullahNo ratings yet

- T014108e PDFDocument5 pagesT014108e PDFSilvester KolicNo ratings yet

- II PUC Chemistry Short Notes-2024 (Other)Document63 pagesII PUC Chemistry Short Notes-2024 (Other)preitaphilena80% (5)

- Problems 1Document3 pagesProblems 1Pablo AlejandroNo ratings yet

- 4696 7938 1 PB DikonversiDocument8 pages4696 7938 1 PB Dikonversiadrian perdanaNo ratings yet

- Physicochemical Properties of Palm Kernel OilDocument3 pagesPhysicochemical Properties of Palm Kernel OilJames UgbesNo ratings yet

- Experiment 6 ProteinsDocument6 pagesExperiment 6 Proteinsjayco sonNo ratings yet

- 12 Rotational EquilibriumDocument6 pages12 Rotational EquilibriumAlba ArjunNo ratings yet

- Analysis of 15 Simple Salts Xi STD-1 PDFDocument38 pagesAnalysis of 15 Simple Salts Xi STD-1 PDFAnisha Fathima Begum100% (1)

- Final Print - Report On Critical Minerals For India - May 2023 - 24!06!23Document48 pagesFinal Print - Report On Critical Minerals For India - May 2023 - 24!06!23sonia raj gill100% (1)

- Physical Science Acid Plan PDF FreeDocument19 pagesPhysical Science Acid Plan PDF Freegigi meiNo ratings yet

- WaterDocument26 pagesWaterRahulNo ratings yet

- Port Land Cement: Manufacture of Portland CementDocument24 pagesPort Land Cement: Manufacture of Portland Cementtesfalem kiros100% (1)

- Shelf Life DRYDocument2 pagesShelf Life DRYSai KiranNo ratings yet

- AU2700 SpecDocument1 pageAU2700 SpecMaduraiveeran cNo ratings yet

- 2013 Theory of Antirelativity Eric DollardDocument13 pages2013 Theory of Antirelativity Eric DollardJR2017100% (3)

- Chemical Incompatibility ListDocument11 pagesChemical Incompatibility ListWONG TSNo ratings yet

- Chinasa Ihediwa 2021Document52 pagesChinasa Ihediwa 2021salim salimNo ratings yet

- General Polyurea Questions (Versaflex)Document6 pagesGeneral Polyurea Questions (Versaflex)thinesNo ratings yet

- Electron Spin ResonanceDocument28 pagesElectron Spin ResonanceDonaNo ratings yet

- Chromium Compounds: Historical. Chrome Iron Ore (Chromite) WasDocument15 pagesChromium Compounds: Historical. Chrome Iron Ore (Chromite) WasYusufNo ratings yet

- Material Safety Data Sheet: Distributed byDocument2 pagesMaterial Safety Data Sheet: Distributed byRC VilledaNo ratings yet

- Cat FAODocument2 pagesCat FAOemmanuel kyunduNo ratings yet

- A Recycling Hydrogen Supply System of NaBH4Document12 pagesA Recycling Hydrogen Supply System of NaBH4hunggiang2887No ratings yet

- Machine Learning in 2D Materials Science 1St Edition Parvathi Chundi Online Ebook Texxtbook Full Chapter PDFDocument69 pagesMachine Learning in 2D Materials Science 1St Edition Parvathi Chundi Online Ebook Texxtbook Full Chapter PDFrussell.gould295100% (11)

mos3

mos3

Uploaded by

Smart EngineerCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

mos3

mos3

Uploaded by

Smart EngineerCopyright:

Available Formats

EXPERIMENT No.

1

AIM: Determine tensile Strength of a given specimen using UTM.

OBJECT: To conduct a tensile test on a mild steel specimen and determine the following:

(i) Limit of proportionality

(ii) (ii) Elastic limit

(iii) (iii) Yield strength

(iv) (iv) Ultimate strength

(v) (v) Young’s modulus of elasticity

(vi) (vi) Percentage elongation

(vii) (vii) Percentage reduction in area.

APPARATUS:

(i) Universal Testing Machine (UTM)

(ii) (ii) Mild steel specimens

(iii) (iii) Graph paper

(iv) (iv) Scale

(v) (v) Vernier Caliper

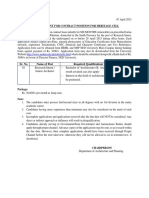

DIAGRAM:

DEPARTMENT OF MECHANICAL ENGINEERING Page 1

THEORY:

The tensile test is most applied one, of all mechanical tests. In this test ends of test piece are fixed

into grips connected to a straining device and to a load measuring device. If the applied load is

small enough, the deformation of any solid body is entirely elastic. An elastically deformed solid

will return to its original form as soon as load is removed. However, if the load is too large, the

material can be deformed permanently. The initial part of the tension curve which is recoverable

immediately after unloading is termed. As elastic and the rest of the curve which represents the

manner in which solid undergoes plastic deformation is termed plastic. The stress below which the

deformations essentially entirely elastic is known as the yield strength of material. In some

material the onset of plastic deformation is denoted by a sudden drop in load indicating both an

upper and a lower yield point. However, some materials do not exhibit a sharp yield point. During

plastic deformation, at larger extensions strain hardening cannot compensate for the decrease in

section and thus the load passes through a maximum and then begins to decrease. This stage the

“ultimate strength”’ which is defined as the ratio of the load on the specimen to original cross-

sectional area, reaches a maximum value. Further loading will eventually cause ‘neck’ formation

and rupture.

DEPARTMENT OF MECHANICAL ENGINEERING Page 2

About of UTM

The tensile test is conducted on UTM. It is hydraulically operates a pump, oil in oil sump, load dial

indicator and central buttons. The left has upper, middle and lower cross heads i.e; specimen grips

(or jaws). Idle cross head can be moved up and down for adjustment. The pipes connecting the lift

and right parts are oil pipes through which the pumped oil under pressure flows on left parts to

more the cross-heads.

SPECIFICATIONS:

1. Load capacity = 0-40 Tones.

2. Least count = 8 kgf.

3. Overall dimension. =

4. Power supply = 440 V

PROCEDURE:

1. Measure the original length and diameter of the specimen. The length may either be length of

gauge section which is marked on the specimen with a preset punch or the total length of the

specimen

2. Insert the specimen into grips of the test machine and attach strain-measuring device to it

3. Begin the load application and record load versus elongation data.

4. Take readings more frequently as yield point is approached.

5. Measure elongation values with the help of dividers and a ruler.

6. Continue the test till Fracture occurs.

7. By joining the two broken halves of the specimen together, measure the final length and

diameter of specimen.

OBSEVATION:

(a) Initial diameter of specimen d1 =

(b) Initial gauge length of specimen L1 =

(c) Initial cross-section area of specimen A1 =

(d) Load of yield point Ft =

(e) Ultimate load after specimen breaking F=

(f) Final length after specimen breaking L2 =

(g) Diameter of specimen at breaking place d2 =

DEPARTMENT OF MECHANICAL ENGINEERING Page 3

About of UTM

(h) Cross section area at breaking place A2 =

DEPARTMENT OF MECHANICAL ENGINEERING Page 4

OBESERVATION TABLE:

S.No Load (N) Original Extension Stress Strain

Gauge (mm) (N/mm2)

Length

CALCULATION:

Ultimate tensile strength =.................... 𝑁

𝑚𝑚2

𝐿𝑜𝑎𝑑 𝑎𝑡 𝑒𝑙𝑎𝑠𝑡𝑖𝑐 𝑙𝑖𝑚𝑖𝑡 = …………… 𝑁

Elastic limit = 𝑜𝑟𝑖𝑔𝑖𝑛𝑎𝑙 𝑎𝑟𝑒𝑎 𝑜𝑓 𝑐𝑟𝑜𝑠 𝑠 𝑠𝑒𝑐𝑡𝑖𝑜𝑛 𝑚𝑚2

(iii) Modulus of Elasticity (E) = 𝑠𝑡𝑟𝑒𝑠𝑠 𝑏𝑒𝑙𝑜𝑤 𝑝𝑟𝑜𝑝𝑜𝑟𝑡𝑖𝑜𝑛𝑎𝑙 𝑙𝑖𝑚𝑖𝑡 𝑁

𝑐𝑜𝑟𝑟𝑠𝑝𝑜𝑛𝑑𝑖𝑛𝑔 𝑠𝑡𝑟𝑎𝑖𝑛 =…….………

𝑚𝑚2

(iv) Yield Strength = 𝑦𝑖𝑒𝑙𝑑 𝑙𝑜𝑎𝑑

=…………….

𝑁

𝑜𝑟𝑖𝑔𝑖𝑛𝑎𝑙 𝑐𝑟𝑜𝑠𝑠 𝑠𝑒𝑐𝑡𝑖𝑜𝑛𝑎𝑙 𝑎𝑟𝑒𝑎

𝑚𝑚2

𝐴𝑓−𝐴𝑖

% Reduction in area = × 100 =....................%

𝐴𝑖

𝑙𝑖−𝑙𝑓

Percentage of elongation = × 100 =.....................%

𝑙𝑓

𝐿𝑜𝑎𝑑 𝑎𝑡 𝑙𝑖𝑚𝑖𝑡 𝑜𝑓 𝑝𝑟𝑜𝑝𝑟𝑡𝑖𝑜𝑛𝑎𝑙𝑖𝑡𝑦

Limit of Propagation = 𝑜𝑟𝑖𝑔𝑖𝑛𝑎𝑙 𝑐𝑟𝑜𝑠𝑠 𝑠𝑒𝑐𝑡𝑖𝑜𝑛𝑎𝑙 𝑎𝑟𝑒𝑎

Stress = 𝜎 𝐿𝑜𝑎𝑑

= 𝑃 ………………….. 𝑁

=

𝐴𝑟𝑒𝑎 𝐴 𝑚𝑚2

𝑐ℎ𝑎𝑛𝑔𝑒 𝑖𝑛 𝑙𝑒𝑛𝑔𝑡ℎ

Strain = 𝜖 = = …………..

𝑜𝑟𝑖𝑔𝑖𝑛𝑎𝑙 𝑙𝑒𝑛𝑔𝑡ℎ

𝑠𝑡𝑟𝑠𝑠

Young’s modulus= E = …………. 𝑁

𝑠𝑡𝑟𝑎𝑖𝑛 𝑚𝑚2

PRECAUTIONS:

1. The specimen should be prepared in proper dimensions.

2. The specimen should be properly to get between the jaws.

DEPARTMENT OF MECHANICAL ENGINEERING Page 5

OBESERVATION TABLE:

3. Take reading carefully.

DEPARTMENT OF MECHANICAL ENGINEERING Page 6

4. After breaking specimen stop to m/c.

RESULT:

( i) Average Breaking Stress =

(ii) Ultimate Stress =

(iii) Average % Elongation =

VIVA-QUESTIONS

1. Which steel have you tested? What is its carbon content?

2. What general information is obtained from tensile test regarding the properties of a material?

3. Which stress have you calculated: nominal stress or true stress?

4. What kind of fracture has occurred in the tensile specimen and why?

5. Which is the most ductile metal? How much is its elongation

APPLICATIONS:

1. In Aerospace

2. Automotive

3. Packaging

4. sports

DEPARTMENT OF MECHANICAL ENGINEERING Page 7

OBSERVATIONS

DEPARTMENT OF MECHANICAL ENGINEERING Page 8

OBSERVATIONS

DEPARTMENT OF MECHANICAL ENGINEERING Page 9

OBSERVATIONS

DEPARTMENT OF MECHANICAL ENGINEERING Page 10

You might also like

- Final ExamDocument2 pagesFinal ExamJisoo Eric LeeNo ratings yet

- Chapter 1Document14 pagesChapter 1Manish JaiswalNo ratings yet

- UTM - Lab ReportDocument5 pagesUTM - Lab Reportshubhradiproy2003No ratings yet

- CEN206Document10 pagesCEN206shiaondo543No ratings yet

- Strength of Materials LabDocument30 pagesStrength of Materials LabDipesh GugaleNo ratings yet

- Experiment No 10 Tension TestDocument6 pagesExperiment No 10 Tension TestrashmarsvNo ratings yet

- Direct Rubber Shear Test PDFDocument9 pagesDirect Rubber Shear Test PDFMohammad ShehabNo ratings yet

- Tensile Test For Steel SpecimenDocument12 pagesTensile Test For Steel SpecimenEddie BowokuNo ratings yet

- Papua New Guinea University of Technology CE 261-Engineering Materials Test 2 - Tensile Test of A Steel SpecimenDocument4 pagesPapua New Guinea University of Technology CE 261-Engineering Materials Test 2 - Tensile Test of A Steel SpecimenIsrael PopeNo ratings yet

- Strength of Materials Lab Manual: 1. Tension Test On MS Bar and HYSD BarsDocument61 pagesStrength of Materials Lab Manual: 1. Tension Test On MS Bar and HYSD Barsswe_maniNo ratings yet

- Lab Manual: Sant Longowal Institute of Engineering & Technology Longowal-148106Document4 pagesLab Manual: Sant Longowal Institute of Engineering & Technology Longowal-148106Vivek JhaNo ratings yet

- MosDocument42 pagesMosSajjan Kumar100% (2)

- Stress and StrainDocument38 pagesStress and StrainNandi ?No ratings yet

- Design Failure AnalysisDocument8 pagesDesign Failure AnalysisHamzaNo ratings yet

- Mos Lab Manual PDFDocument34 pagesMos Lab Manual PDFs.rihanaNo ratings yet

- Mechanics of Solid Lab ManualDocument32 pagesMechanics of Solid Lab ManualPrithvijeet SahooNo ratings yet

- Exp 1 ErianeDocument20 pagesExp 1 ErianeEriane GarciaNo ratings yet

- Strength of MaterialDocument18 pagesStrength of MaterialMamta SinghNo ratings yet

- Design of Machine Elements 2 6Document25 pagesDesign of Machine Elements 2 6sasikskNo ratings yet

- Aumar AlMeshhadany - Experiment 2 - Lab DI-XDocument20 pagesAumar AlMeshhadany - Experiment 2 - Lab DI-XTonyFalconeNo ratings yet

- Full Report Solid MechDocument19 pagesFull Report Solid MechMUHAMMAD ARIFF DYAMIMNo ratings yet

- Strength of Materials: Machine Design 1Document28 pagesStrength of Materials: Machine Design 1John ReyNo ratings yet

- Tensile TestDocument6 pagesTensile Testkinwai5557100% (1)

- Torsion Final ReportDocument24 pagesTorsion Final ReportHanis FarinaNo ratings yet

- Som Manual-2013 RegDocument26 pagesSom Manual-2013 RegsugunavidiyadarNo ratings yet

- SOM-BMT Lab Manual FinalDocument48 pagesSOM-BMT Lab Manual FinalHarish T S Gowda100% (1)

- Strength of Materia Lab Manual UET, LahoreDocument14 pagesStrength of Materia Lab Manual UET, LahoreRizwan Khurram100% (3)

- Part 1: Tension Test Objective: Experiment 1: Tension and Torsion TestsDocument20 pagesPart 1: Tension Test Objective: Experiment 1: Tension and Torsion TestsOngNo ratings yet

- Ex 1Document8 pagesEx 1arindamckbtNo ratings yet

- Universiti Tun Hussein Onn Malaysia Department of Mechanical EngineeringDocument12 pagesUniversiti Tun Hussein Onn Malaysia Department of Mechanical EngineeringAriff ShasteraNo ratings yet

- L4 - Design Against Fluctucaing LoadsDocument26 pagesL4 - Design Against Fluctucaing LoadsDhyan PatelNo ratings yet

- Youngs Modulus ExperimentDocument4 pagesYoungs Modulus ExperimentAsif Ur Rahman AdibNo ratings yet

- Material Testing LabDocument79 pagesMaterial Testing LabBrijesh VermaNo ratings yet

- MoM Lab Manual - 2021Document15 pagesMoM Lab Manual - 2021huzaifa sarwarNo ratings yet

- Design of Machine Elements PageDocument203 pagesDesign of Machine Elements PageKrishnan P MNo ratings yet

- Experiment 1 Tensile and Torsion TestDocument27 pagesExperiment 1 Tensile and Torsion TestMuhd Fauzan Ibrahim100% (1)

- Som Lab RawDocument10 pagesSom Lab RawAbhishek singh (abhi.03)No ratings yet

- Scissor Jack DesignDocument66 pagesScissor Jack DesignTewodros DereseNo ratings yet

- Reaction On BeamDocument10 pagesReaction On BeamNurul NadhirahNo ratings yet

- Design QPDocument57 pagesDesign QPJegan ParamasivamNo ratings yet

- Som ExperimentsDocument17 pagesSom ExperimentsAnudeex ShettyNo ratings yet

- Strength of Materials Laboratory ExperimentsDocument20 pagesStrength of Materials Laboratory Experimentskenneth iyahenNo ratings yet

- Mechanical Engineering Interview Questions With AnswersDocument5 pagesMechanical Engineering Interview Questions With Answersbrpnaidu2157100% (1)

- btech3rd-CE SOM LAB MANUALDocument21 pagesbtech3rd-CE SOM LAB MANUALvkmstp2005No ratings yet

- Tensile TestDocument11 pagesTensile TestOsura GunasenaNo ratings yet

- Design of Machine Elements: Unit - I Steady Stresses and Variable Stress in Machine MembesDocument53 pagesDesign of Machine Elements: Unit - I Steady Stresses and Variable Stress in Machine MembesDinesh PatilNo ratings yet

- As Physics Practical Set 1 Updated April 2014Document99 pagesAs Physics Practical Set 1 Updated April 2014Pathmanathan Nadeson33% (3)

- MSC Structural Integrity Academic Year 2017-2018: College of Engineering, Design and Physical SciencesDocument14 pagesMSC Structural Integrity Academic Year 2017-2018: College of Engineering, Design and Physical Sciencesshafahat aliNo ratings yet

- Laboratory Manual of Tensile TestDocument12 pagesLaboratory Manual of Tensile TestVIPAN KUMARNo ratings yet

- Group 6 - Exp 6Document32 pagesGroup 6 - Exp 6Arrianna PeterNo ratings yet

- Deflection of BeamDocument4 pagesDeflection of BeamRampukar SahNo ratings yet

- MEC 222 EXP-Lab-SOMDocument69 pagesMEC 222 EXP-Lab-SOMAbhijeeth NagarajNo ratings yet

- Experiment No. - 1: Material Testing Lab (MOM Lab) 1of 4 PagesDocument4 pagesExperiment No. - 1: Material Testing Lab (MOM Lab) 1of 4 PagesKirtismita TalukdarNo ratings yet

- Laboratory Manual of Tensile TestDocument11 pagesLaboratory Manual of Tensile TestVIPAN KUMARNo ratings yet

- Lab Report (Torsion) - Mohd Syazwan Bin Sarudin - 2021836538Document19 pagesLab Report (Torsion) - Mohd Syazwan Bin Sarudin - 2021836538Wanz SkylineNo ratings yet

- Experiment 1Document7 pagesExperiment 1waseemjuttNo ratings yet

- Part - ADocument20 pagesPart - AKumar SubramanianNo ratings yet

- Design of Machine Elements Two MarksDocument23 pagesDesign of Machine Elements Two MarksManivannan JeevaNo ratings yet

- Tensile Test - UTMDocument4 pagesTensile Test - UTMmjayrajsharma19No ratings yet

- Statistical Tolerance Regions: Theory, Applications, and ComputationFrom EverandStatistical Tolerance Regions: Theory, Applications, and ComputationNo ratings yet

- Spectral method for fatigue damage estimation with non-zero mean stressFrom EverandSpectral method for fatigue damage estimation with non-zero mean stressNo ratings yet

- Liquefaction Analysis of Earthen DamDocument15 pagesLiquefaction Analysis of Earthen DamSmart EngineerNo ratings yet

- SHEAR TESTDocument7 pagesSHEAR TESTSmart EngineerNo ratings yet

- 1Document5 pages1Smart EngineerNo ratings yet

- torsionDocument6 pagestorsionSmart EngineerNo ratings yet

- IZODDocument6 pagesIZODSmart EngineerNo ratings yet

- SPRING TESTDocument9 pagesSPRING TESTSmart EngineerNo ratings yet

- Certificate NewDocument1 pageCertificate NewSmart EngineerNo ratings yet

- CANTILEVER BEAMDocument7 pagesCANTILEVER BEAMSmart EngineerNo ratings yet

- ROCKWELLDocument5 pagesROCKWELLSmart EngineerNo ratings yet

- SIMPLY SUPPORTED BEAMDocument7 pagesSIMPLY SUPPORTED BEAMSmart EngineerNo ratings yet

- Muta Scholarship 2023Document1 pageMuta Scholarship 2023Smart EngineerNo ratings yet

- Hasiholan 2023 IOP Conf. Ser. Earth Environ. Sci. 1184 012003Document15 pagesHasiholan 2023 IOP Conf. Ser. Earth Environ. Sci. 1184 012003Smart EngineerNo ratings yet

- Awarness Seminar of PEC Price Adjustment Formula 19Document1 pageAwarness Seminar of PEC Price Adjustment Formula 19Smart EngineerNo ratings yet

- Submitted Note of ViscometerDocument1 pageSubmitted Note of ViscometerSmart EngineerNo ratings yet

- List of Items of H&TE LabDocument1 pageList of Items of H&TE LabSmart EngineerNo ratings yet

- ASTM E-11 Sieves DesignationDocument1 pageASTM E-11 Sieves DesignationSmart EngineerNo ratings yet

- 9644 ExamplesDocument5 pages9644 ExamplesSmart EngineerNo ratings yet

- Submitted Note of High Shear MixerDocument1 pageSubmitted Note of High Shear MixerSmart EngineerNo ratings yet

- UntitledDocument196 pagesUntitledSmart EngineerNo ratings yet

- Certificate NewDocument1 pageCertificate NewSmart EngineerNo ratings yet

- 37th Mock Test Municipal & Town OfficerDocument5 pages37th Mock Test Municipal & Town OfficerSmart Engineer100% (1)

- Mehran University of Engineering and Technology, Jamshoro: List of All Eligible / Candidates of Master & PH.D StduiesDocument29 pagesMehran University of Engineering and Technology, Jamshoro: List of All Eligible / Candidates of Master & PH.D StduiesSmart EngineerNo ratings yet

- Provisional List of Class Attendance Directorate of Postgraduate StudiesDocument2 pagesProvisional List of Class Attendance Directorate of Postgraduate StudiesSmart EngineerNo ratings yet

- RI AdvertisementDocument1 pageRI AdvertisementSmart EngineerNo ratings yet

- Job Opportunities: Directorate of Human ResourcesDocument11 pagesJob Opportunities: Directorate of Human ResourcesSmart EngineerNo ratings yet

- Advertisement of Vacant Post in MoITDocument1 pageAdvertisement of Vacant Post in MoITSmart EngineerNo ratings yet

- AEN RailwayDocument16 pagesAEN RailwaySmart EngineerNo ratings yet

- Pavement The Pavement Is The Structure Which Separates The Tires of Vehicles From The Underlying Foundation MaterialDocument23 pagesPavement The Pavement Is The Structure Which Separates The Tires of Vehicles From The Underlying Foundation MaterialSmart EngineerNo ratings yet

- Soil For Highway ConstructionDocument22 pagesSoil For Highway ConstructionSmart EngineerNo ratings yet

- Cholin BaseDocument5 pagesCholin Basex_aav3No ratings yet

- Antioxidant and AntiozonantDocument10 pagesAntioxidant and AntiozonantMaggie VillacortaNo ratings yet

- Sensors SyllabusDocument2 pagesSensors Syllabusdirector.sportssrmistNo ratings yet

- 2000-Solution Properties of Hsian-Tsao (Mesona Procumbens Hemsl) Leaf GumDocument8 pages2000-Solution Properties of Hsian-Tsao (Mesona Procumbens Hemsl) Leaf GumhasbullahNo ratings yet

- T014108e PDFDocument5 pagesT014108e PDFSilvester KolicNo ratings yet

- II PUC Chemistry Short Notes-2024 (Other)Document63 pagesII PUC Chemistry Short Notes-2024 (Other)preitaphilena80% (5)

- Problems 1Document3 pagesProblems 1Pablo AlejandroNo ratings yet

- 4696 7938 1 PB DikonversiDocument8 pages4696 7938 1 PB Dikonversiadrian perdanaNo ratings yet

- Physicochemical Properties of Palm Kernel OilDocument3 pagesPhysicochemical Properties of Palm Kernel OilJames UgbesNo ratings yet

- Experiment 6 ProteinsDocument6 pagesExperiment 6 Proteinsjayco sonNo ratings yet

- 12 Rotational EquilibriumDocument6 pages12 Rotational EquilibriumAlba ArjunNo ratings yet

- Analysis of 15 Simple Salts Xi STD-1 PDFDocument38 pagesAnalysis of 15 Simple Salts Xi STD-1 PDFAnisha Fathima Begum100% (1)

- Final Print - Report On Critical Minerals For India - May 2023 - 24!06!23Document48 pagesFinal Print - Report On Critical Minerals For India - May 2023 - 24!06!23sonia raj gill100% (1)

- Physical Science Acid Plan PDF FreeDocument19 pagesPhysical Science Acid Plan PDF Freegigi meiNo ratings yet

- WaterDocument26 pagesWaterRahulNo ratings yet

- Port Land Cement: Manufacture of Portland CementDocument24 pagesPort Land Cement: Manufacture of Portland Cementtesfalem kiros100% (1)

- Shelf Life DRYDocument2 pagesShelf Life DRYSai KiranNo ratings yet

- AU2700 SpecDocument1 pageAU2700 SpecMaduraiveeran cNo ratings yet

- 2013 Theory of Antirelativity Eric DollardDocument13 pages2013 Theory of Antirelativity Eric DollardJR2017100% (3)

- Chemical Incompatibility ListDocument11 pagesChemical Incompatibility ListWONG TSNo ratings yet

- Chinasa Ihediwa 2021Document52 pagesChinasa Ihediwa 2021salim salimNo ratings yet

- General Polyurea Questions (Versaflex)Document6 pagesGeneral Polyurea Questions (Versaflex)thinesNo ratings yet

- Electron Spin ResonanceDocument28 pagesElectron Spin ResonanceDonaNo ratings yet

- Chromium Compounds: Historical. Chrome Iron Ore (Chromite) WasDocument15 pagesChromium Compounds: Historical. Chrome Iron Ore (Chromite) WasYusufNo ratings yet

- Material Safety Data Sheet: Distributed byDocument2 pagesMaterial Safety Data Sheet: Distributed byRC VilledaNo ratings yet

- Cat FAODocument2 pagesCat FAOemmanuel kyunduNo ratings yet

- A Recycling Hydrogen Supply System of NaBH4Document12 pagesA Recycling Hydrogen Supply System of NaBH4hunggiang2887No ratings yet

- Machine Learning in 2D Materials Science 1St Edition Parvathi Chundi Online Ebook Texxtbook Full Chapter PDFDocument69 pagesMachine Learning in 2D Materials Science 1St Edition Parvathi Chundi Online Ebook Texxtbook Full Chapter PDFrussell.gould295100% (11)