Professional Documents

Culture Documents

SPRING TEST

SPRING TEST

Uploaded by

Smart EngineerCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SPRING TEST

SPRING TEST

Uploaded by

Smart EngineerCopyright:

Available Formats

SPRING TEST

AIM: Determine the stiffness of the spring and modulus of rigidity of the spring wire

OBJECT: To determine the stiffness of the spring and modulus of rigidity of the spring

APPARATUS:

i) Spring testing machine.

ii) A spring iii) Vernier caliper,

iii) Scale.

iv) Micrometer.

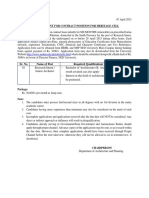

DIAGRAM:

THEORY:

Springs are elastic member which distort under load and regain their original shape when load is

removed. They are used in railway carriages, motor cars, scooters, motorcycles, rickshaws,

Governors etc. According to their uses the springs perform the following Functions:

1) To absorb shock or impact loading as in carriage springs.

2) To store energy as in clock springs.

3) To apply forces to and to control motions as in brakes and clutches.

4) To measure forces as in spring balances.

5) To change the variations characteristic of a member as in flexible mounting of motors.

DEPARTMENT OF MECHANICAL ENGINEERING Page 1

The spring is usually made of either high carbon steel (0.7 to 1.0%) or medium carbon alloy steels.

Phosphor bronze, brass, 18/8 stainless steel and Monel and other metal alloys are used for

Corrosion resistance spring. Several types of spring are available for different application. Springs

may classify as helical springs, leaf springs and flat spring depending upon their shape. They are

fabricated of high shear strength materials such as high carbon alloy steels spring form elements of

not only mechanical system but also structural system. In several cases it is essential to idealize

Complex structural systems by suitable spring.

PROCEDURE:

1) Measure the diameter of the wire of the spring by using the micrometer.

2) Measure the diameter of spring coils by using the vernier caliper

3) Count the number of turns.

4) Insert the spring in the spring testing machine and load the spring by a suitable weight and note

the corresponding axial deflection in tension or compression.

5) Increase the load and take the corresponding axial deflection readings.

6) Plot a curve between load and deflection. The shape of the curve gives the stiffness of

the Spring.

OBESERVATION

Least count of micrometer = ………mm

Diameter of the spring wire, d =……… mm (Mean of three

readings) Least count of vernier caliper = ………mm

Diameter of the spring coil, D = ………mm (Mean of three

readings) Mean coil diameter, Dm = D – d =……… mm

Number of turns, n =………

TABLE:

S.No Load W (in N) Deflection ( 𝛿) Stiffness Modulus

mm K=𝑊 of

𝛿 𝑁

Rigidity(C)

𝑚𝑚2

DEPARTMENT OF MECHANICAL ENGINEERING Page 2

Mean k = ……

DEPARTMENT OF MECHANICAL ENGINEERING Page 3

8𝑊𝐷3𝑛

Modulus of rigidity C

4

= 𝛿𝐷𝑚

𝐷𝑚

Spring Index =

𝐷

PRECAUTIONS:

1) The dimension of spring was measured accurately.

2) Deflection obtained in spring was measured accurately

ADVANTAGES:

1. To apply forces and to control motions as in brakes and clutches.

2. To store energy as in clock springs.

3. This test is conducted to find the material properties of the spring like modulus of rigidity.

This can be obtained by observing the values of deflections of the spring with the application of

Different amounts of the load applied along the axis of the spring. The observed Values of

deflections are compared with the theoretical value for the deflection of the spring under the load

and shear modulus is to be obtained.

4. To reduce the effect of shock or impact loading as in carriage springs

RESULT:

The value of spring constant k of closely coiled helical spring is found to be_

N/ mm

VIVA QUESTIONS:

1. What is meant by stiffness

2. Define deflection

3. What are different types of springs

4. Define helical spring

5. What is the strain energy stored in the springs

DEPARTMENT OF MECHANICAL ENGINEERING Page 4

APPLICATIONS:

1. To apply forces and controlling motion, as in brakes and clutches.

DEPARTMENT OF MECHANICAL ENGINEERING Page 5

2. Used in suspension system

DEPARTMENT OF MECHANICAL ENGINEERING Page 6

OBSERVATIONS

DEPARTMENT OF MECHANICAL ENGINEERING Page 7

OBSERVATIONS

DEPARTMENT OF MECHANICAL ENGINEERING Page 8

OBSERVATIONS

DEPARTMENT OF MECHANICAL ENGINEERING Page 9

You might also like

- Lab ReportDocument20 pagesLab ReportJoshua Reynolds67% (3)

- Spring TestDocument5 pagesSpring Testmohanadymt50% (2)

- Latihan Soal Pas Bahasa Inggris Kelas 8Document5 pagesLatihan Soal Pas Bahasa Inggris Kelas 8Surati Ibu FattahNo ratings yet

- The Titmar Motor Company Is Considering The Production of ADocument1 pageThe Titmar Motor Company Is Considering The Production of ATaimour HassanNo ratings yet

- torsionDocument6 pagestorsionSmart EngineerNo ratings yet

- 2 3 Wheeler Lab ManualDocument21 pages2 3 Wheeler Lab ManualAmitesh ShrivastavaNo ratings yet

- Dme Model Key 2019Document25 pagesDme Model Key 2019Siva RamanNo ratings yet

- Spring TestDocument3 pagesSpring TestSaiman SaysNo ratings yet

- Design Analysis and Fabrication of Hydra PDFDocument9 pagesDesign Analysis and Fabrication of Hydra PDFMac NyandoroNo ratings yet

- Assignment 1Document7 pagesAssignment 1Rikko Putra YouliaNo ratings yet

- Design and Analysis of Fixture For Heavy Shell TiltingDocument5 pagesDesign and Analysis of Fixture For Heavy Shell Tiltinggkdora574No ratings yet

- Design Procedure For Crane Runway Girders - bk105 PDFDocument7 pagesDesign Procedure For Crane Runway Girders - bk105 PDFFWICIPNo ratings yet

- Mechanic & Mechanical DesignDocument5 pagesMechanic & Mechanical DesignreezmanNo ratings yet

- Design Procedure of An Electrohydraulic Drive: Srishti Sharma, Ramesh R. Lekurwale, Amith MasadeDocument6 pagesDesign Procedure of An Electrohydraulic Drive: Srishti Sharma, Ramesh R. Lekurwale, Amith MasadeAshishNo ratings yet

- Irjet V3i7146 PDFDocument6 pagesIrjet V3i7146 PDFatulnarkhede2002No ratings yet

- Kinematics of Machine Lab ManualDocument29 pagesKinematics of Machine Lab ManualNottaAmandeepSingh100% (1)

- Ex#01 MomDocument11 pagesEx#01 MomEntertainment , Enjoyment InformativeNo ratings yet

- "Spring" Tafila Technical UniversityDocument7 pages"Spring" Tafila Technical Universityعبد الرحمن أبوخاطر, أبو رزقNo ratings yet

- Important Short Questions DYNAMICS AND DESIGN OF MACHINERYDocument32 pagesImportant Short Questions DYNAMICS AND DESIGN OF MACHINERYramos mingoNo ratings yet

- Design Analysis of Spring and Cam Follower Mechanism: June 2020Document5 pagesDesign Analysis of Spring and Cam Follower Mechanism: June 2020Abiola AjayiNo ratings yet

- Experiment Five (Cam Analysis Apparatus)Document3 pagesExperiment Five (Cam Analysis Apparatus)J SNo ratings yet

- Cam Mechanisms PackDocument28 pagesCam Mechanisms PackRongguang HanNo ratings yet

- Dme (Unit 1)Document11 pagesDme (Unit 1)RajeshKumarNo ratings yet

- Laboratory Report 1 - ME415Document10 pagesLaboratory Report 1 - ME415Lester Alfred OlasimanNo ratings yet

- Buckling Analysis of Connecting Rod ..Document4 pagesBuckling Analysis of Connecting Rod ..redwan al-mustafaNo ratings yet

- Validation of Use of Fem (Ansys) For Structural Analysis of Tower Crane Jib and Static and Dynamic Analysis of Tower Crane Jib Using AnsysDocument7 pagesValidation of Use of Fem (Ansys) For Structural Analysis of Tower Crane Jib and Static and Dynamic Analysis of Tower Crane Jib Using AnsysKaique CavalcanteNo ratings yet

- Experimental Analysis of Helical Compression Spring Used in Two Wheeler Suspension System Ijariie6023Document6 pagesExperimental Analysis of Helical Compression Spring Used in Two Wheeler Suspension System Ijariie6023Jacks Test MailNo ratings yet

- Design and Analysis of Cyclone Separator: Chittamplly Mahender A.PraveenaDocument9 pagesDesign and Analysis of Cyclone Separator: Chittamplly Mahender A.PraveenaugandaNo ratings yet

- MOS Lab Manual - NewDocument41 pagesMOS Lab Manual - NewPavan Kalyan SuryavamshiNo ratings yet

- Design of Machine Elements: Project ReportDocument12 pagesDesign of Machine Elements: Project ReportMuhammad BilalNo ratings yet

- Cam Analysis ManualDocument4 pagesCam Analysis ManualNishant B MayekarNo ratings yet

- 2 67 1573883164 148.ijmperdaug2019148Document11 pages2 67 1573883164 148.ijmperdaug2019148pad abtNo ratings yet

- MEC322 Chapter 7 - TORQUE & POWER MEASUREMENTDocument19 pagesMEC322 Chapter 7 - TORQUE & POWER MEASUREMENTAiman ArhamNo ratings yet

- Engineering Dynamics Lab ReportDocument36 pagesEngineering Dynamics Lab Reportabdul rehmanNo ratings yet

- Design of Machine Elements: Chapter 1: Steady Stresses and Variable Stresses in Machine MemberDocument9 pagesDesign of Machine Elements: Chapter 1: Steady Stresses and Variable Stresses in Machine MemberusernameqwertNo ratings yet

- Helical SpringDocument7 pagesHelical SpringSalam Albaradie100% (4)

- Som Lab Exp4Document5 pagesSom Lab Exp4Amisha SharonNo ratings yet

- Staff College Hyderabad - 2Document38 pagesStaff College Hyderabad - 2Om PrakashNo ratings yet

- Torsional Vibration DamperDocument5 pagesTorsional Vibration DamperSatbir SinghNo ratings yet

- Suherman 2016Document5 pagesSuherman 2016PatrickNo ratings yet

- TruptiDocument7 pagesTruptidebanshushekharNo ratings yet

- Modified Dme-II (r20)Question Bank - AnswersDocument74 pagesModified Dme-II (r20)Question Bank - Answerslayakishor63No ratings yet

- Design and Analysis of Column Mounted JIDocument21 pagesDesign and Analysis of Column Mounted JIEpure GabrielNo ratings yet

- 668-Article Text-1216-1-10-20171231Document7 pages668-Article Text-1216-1-10-20171231galataataaddesaaNo ratings yet

- Fatigue Analysis and Life Predictions of Forged Steel and Powder Metal Connecting RodsDocument5 pagesFatigue Analysis and Life Predictions of Forged Steel and Powder Metal Connecting Rodsethiopian art2020No ratings yet

- Laboratory Manual: MEC259 Unified Mechanical Engineering IIDocument35 pagesLaboratory Manual: MEC259 Unified Mechanical Engineering IIHimanshu Kumar Raut100% (2)

- Limit States Design of Crane Runway Girders: Research Report R967Document17 pagesLimit States Design of Crane Runway Girders: Research Report R967Rabin SedighPourNo ratings yet

- System Simulation of Belt ConveyorsDocument9 pagesSystem Simulation of Belt Conveyorsharishkumar.ravichandranNo ratings yet

- Final Major PDFDocument7 pagesFinal Major PDFArnav AnanyaNo ratings yet

- Me6601 QB 4 PDFDocument15 pagesMe6601 QB 4 PDFpremgmech762No ratings yet

- Cam and FollowerDocument12 pagesCam and FollowerAjay HadaNo ratings yet

- 7structural Analysis of Crane Hook PDFDocument4 pages7structural Analysis of Crane Hook PDFMohankumarNo ratings yet

- Vibration Analysis in Reciprocating Compressors - Vassillaq Kacani, Ernst HuttarDocument8 pagesVibration Analysis in Reciprocating Compressors - Vassillaq Kacani, Ernst HuttarConradodaMatta0% (1)

- Effect of Bearing Housing On Centrifugal Pump RotordynamicDocument6 pagesEffect of Bearing Housing On Centrifugal Pump Rotordynamicmsh16000No ratings yet

- Lec01-Springs (Ch10)Document32 pagesLec01-Springs (Ch10)Kiril AckovskiNo ratings yet

- Design and Analysis of Hose ClampDocument3 pagesDesign and Analysis of Hose Clampahmed maghrabyNo ratings yet

- Exp 10,11Document22 pagesExp 10,11Fida khanNo ratings yet

- Damper 2Document18 pagesDamper 2takalkars2511No ratings yet

- Torque Measurements MetrologyDocument20 pagesTorque Measurements MetrologymukhilNo ratings yet

- Liquefaction Analysis of Earthen DamDocument15 pagesLiquefaction Analysis of Earthen DamSmart EngineerNo ratings yet

- ROCKWELLDocument5 pagesROCKWELLSmart EngineerNo ratings yet

- 1Document5 pages1Smart EngineerNo ratings yet

- torsionDocument6 pagestorsionSmart EngineerNo ratings yet

- IZODDocument6 pagesIZODSmart EngineerNo ratings yet

- SHEAR TESTDocument7 pagesSHEAR TESTSmart EngineerNo ratings yet

- Certificate NewDocument1 pageCertificate NewSmart EngineerNo ratings yet

- CANTILEVER BEAMDocument7 pagesCANTILEVER BEAMSmart EngineerNo ratings yet

- mos3Document10 pagesmos3Smart EngineerNo ratings yet

- SIMPLY SUPPORTED BEAMDocument7 pagesSIMPLY SUPPORTED BEAMSmart EngineerNo ratings yet

- Muta Scholarship 2023Document1 pageMuta Scholarship 2023Smart EngineerNo ratings yet

- Hasiholan 2023 IOP Conf. Ser. Earth Environ. Sci. 1184 012003Document15 pagesHasiholan 2023 IOP Conf. Ser. Earth Environ. Sci. 1184 012003Smart EngineerNo ratings yet

- Awarness Seminar of PEC Price Adjustment Formula 19Document1 pageAwarness Seminar of PEC Price Adjustment Formula 19Smart EngineerNo ratings yet

- Submitted Note of ViscometerDocument1 pageSubmitted Note of ViscometerSmart EngineerNo ratings yet

- List of Items of H&TE LabDocument1 pageList of Items of H&TE LabSmart EngineerNo ratings yet

- ASTM E-11 Sieves DesignationDocument1 pageASTM E-11 Sieves DesignationSmart EngineerNo ratings yet

- 9644 ExamplesDocument5 pages9644 ExamplesSmart EngineerNo ratings yet

- Submitted Note of High Shear MixerDocument1 pageSubmitted Note of High Shear MixerSmart EngineerNo ratings yet

- UntitledDocument196 pagesUntitledSmart EngineerNo ratings yet

- Certificate NewDocument1 pageCertificate NewSmart EngineerNo ratings yet

- 37th Mock Test Municipal & Town OfficerDocument5 pages37th Mock Test Municipal & Town OfficerSmart Engineer100% (1)

- Mehran University of Engineering and Technology, Jamshoro: List of All Eligible / Candidates of Master & PH.D StduiesDocument29 pagesMehran University of Engineering and Technology, Jamshoro: List of All Eligible / Candidates of Master & PH.D StduiesSmart EngineerNo ratings yet

- Provisional List of Class Attendance Directorate of Postgraduate StudiesDocument2 pagesProvisional List of Class Attendance Directorate of Postgraduate StudiesSmart EngineerNo ratings yet

- RI AdvertisementDocument1 pageRI AdvertisementSmart EngineerNo ratings yet

- Job Opportunities: Directorate of Human ResourcesDocument11 pagesJob Opportunities: Directorate of Human ResourcesSmart EngineerNo ratings yet

- Advertisement of Vacant Post in MoITDocument1 pageAdvertisement of Vacant Post in MoITSmart EngineerNo ratings yet

- AEN RailwayDocument16 pagesAEN RailwaySmart EngineerNo ratings yet

- Pavement The Pavement Is The Structure Which Separates The Tires of Vehicles From The Underlying Foundation MaterialDocument23 pagesPavement The Pavement Is The Structure Which Separates The Tires of Vehicles From The Underlying Foundation MaterialSmart EngineerNo ratings yet

- Soil For Highway ConstructionDocument22 pagesSoil For Highway ConstructionSmart EngineerNo ratings yet

- Service Manual KTM Adventure 1190Document226 pagesService Manual KTM Adventure 1190Tim BlockxNo ratings yet

- Doas - MotorcycleDocument2 pagesDoas - MotorcycleNaojNo ratings yet

- Learner'S Licence PB17 /0003892/2023: SDM, Baba BakalaDocument1 pageLearner'S Licence PB17 /0003892/2023: SDM, Baba Bakalaravikaran623No ratings yet

- Jeep - World War II DatabaseDocument15 pagesJeep - World War II DatabaseMarlin ZamoraNo ratings yet

- Angket Pemilihan Kegiatan Ekstrakurikuler Peserta Didik SMPN 2 Tengaran Tahun Ajar 2023 - 2024 (Jawaban)Document106 pagesAngket Pemilihan Kegiatan Ekstrakurikuler Peserta Didik SMPN 2 Tengaran Tahun Ajar 2023 - 2024 (Jawaban)Wahyu RizkyNo ratings yet

- Learning Driving A Semi-Manual MotorcycleDocument3 pagesLearning Driving A Semi-Manual MotorcycleVonna Cristalyn VeluzNo ratings yet

- Kawasaki Barako - WikipediaDocument4 pagesKawasaki Barako - WikipediaJas SajNo ratings yet

- Spo3 Cardo Dalisay ReportDocument2 pagesSpo3 Cardo Dalisay ReportJessy FrancisNo ratings yet

- Project 2 Rhetorical Analysis of Field ArtifactsDocument8 pagesProject 2 Rhetorical Analysis of Field Artifactsapi-675896910No ratings yet

- Research Paper On Royal EnfieldDocument7 pagesResearch Paper On Royal Enfieldsacjvhbkf100% (1)

- Current Status and Traits of The Auto Parts Industry in VN 2017Document26 pagesCurrent Status and Traits of The Auto Parts Industry in VN 2017haihien98livlyNo ratings yet

- Elective - I Automobile EngineeringDocument74 pagesElective - I Automobile Engineeringarulmurugu100% (1)

- Dell Verbal Ability Test PlacementClassesDocument5 pagesDell Verbal Ability Test PlacementClassesRoshan VaradharajanNo ratings yet

- ????? ??????? - ?? ??? ? - ? ? ? & ? (??????? ?????)Document4 pages????? ??????? - ?? ??? ? - ? ? ? & ? (??????? ?????)Jon AkimNo ratings yet

- Keeway Website Spec Sheet V302C 20240215 1Document1 pageKeeway Website Spec Sheet V302C 20240215 1kovacs456No ratings yet

- Rto, Moradabad Transport Department: Form 3 (See Rule 3 (A) and 13)Document1 pageRto, Moradabad Transport Department: Form 3 (See Rule 3 (A) and 13)TURK SARFRAZNo ratings yet

- Tejaswi Project Final Draft PDFDocument111 pagesTejaswi Project Final Draft PDFHemasri ChinnuNo ratings yet

- Tuning For Speed PDFDocument152 pagesTuning For Speed PDFSimon Tudor100% (1)

- Design Analysis E-Kart PDFDocument9 pagesDesign Analysis E-Kart PDFSIDHARTH MISHRANo ratings yet

- VIẾT LẠI CÂU- ADVANCEDocument118 pagesVIẾT LẠI CÂU- ADVANCEMai AnhNo ratings yet

- Es350 BurroescooterDocument32 pagesEs350 Burroescooterswtdczj2c2No ratings yet

- Electric Go Kart in Retro Style For KidsDocument7 pagesElectric Go Kart in Retro Style For KidsPaul MerrickNo ratings yet

- Gixxer SF Fi l8 p10Document115 pagesGixxer SF Fi l8 p10Cesar SalasNo ratings yet

- B Tech Question Paper 4Document2 pagesB Tech Question Paper 4Darshan UghadeNo ratings yet

- CGO600 English ManualDocument34 pagesCGO600 English ManualMrAlexsa57No ratings yet

- BMW f800r Riders ManualDocument201 pagesBMW f800r Riders ManualVictor Gutiérrez MarcoletaNo ratings yet

- Motor Vehicle Make Abbreviation List: Updated As of June 21, 2012Document29 pagesMotor Vehicle Make Abbreviation List: Updated As of June 21, 2012Sourabh Samanta0% (1)

- Traffic ManagementDocument174 pagesTraffic ManagementArahbela Dane Simangan AgustinNo ratings yet