Professional Documents

Culture Documents

Failure.of.Lifting.Learning.Event

Failure.of.Lifting.Learning.Event

Uploaded by

Ayodele AdebolaCopyright:

Available Formats

You might also like

- Rigging & Lifting HandbookDocument7 pagesRigging & Lifting HandbookRachmadKurniadi33% (6)

- JSA Transformer Installations, Testing, Commissioning.Document6 pagesJSA Transformer Installations, Testing, Commissioning.Kiran Bhatt75% (4)

- SOP Gantry Crane or HoistDocument5 pagesSOP Gantry Crane or Hoistrizki hsb100% (2)

- Mythic RacesDocument173 pagesMythic RacesRobert Howell100% (9)

- Overhead Crane Study 1Document12 pagesOverhead Crane Study 1shahrilmr6934No ratings yet

- Iso 18295 1 2017Document11 pagesIso 18295 1 2017Duilio HomarNo ratings yet

- General Crane SafetyDocument4 pagesGeneral Crane SafetyEhab Mostafa AliNo ratings yet

- Job Safety Analysis MDC Cylinder ReplacementDocument2 pagesJob Safety Analysis MDC Cylinder ReplacementMaxi Pro100% (2)

- BPO Management SystemDocument39 pagesBPO Management SystemSachin Manjunath67% (3)

- Slewing Jib Cranes SI 18.3Document2 pagesSlewing Jib Cranes SI 18.3reda mesbahNo ratings yet

- A97 A98 Lifting OperationsDocument4 pagesA97 A98 Lifting OperationsDavidNo ratings yet

- SEOT JSA For Installation of Project Sign BoardDocument3 pagesSEOT JSA For Installation of Project Sign BoardArchana SoorajNo ratings yet

- SafeuseofliftingequipmentDocument6 pagesSafeuseofliftingequipmentDjole GeorgeNo ratings yet

- 11-Lifting OperationsDocument73 pages11-Lifting OperationsElavarasan Pavan100% (1)

- Material Handling by CraneDocument16 pagesMaterial Handling by Cranenitin369100% (1)

- Lifting With Cranes and Hoists: Knowing The LoadDocument1 pageLifting With Cranes and Hoists: Knowing The LoadWahid AkramNo ratings yet

- Safeuseofliftingequipment PDFDocument5 pagesSafeuseofliftingequipment PDFAutumn Assirem TrefoilNo ratings yet

- Lifting PlanDocument5 pagesLifting Planmariyappanparamasivam61No ratings yet

- Title: 9801 High-Impact Crane Safety: Length: 18 Minutes Production Year: 1998 Program SynopsisDocument2 pagesTitle: 9801 High-Impact Crane Safety: Length: 18 Minutes Production Year: 1998 Program Synopsisg665013No ratings yet

- DTXkA3YUXA18hIrR - FXoZ9U5aIKPV-8BH-Scissor Lift Table Safe Operating Procedure v1Document2 pagesDTXkA3YUXA18hIrR - FXoZ9U5aIKPV-8BH-Scissor Lift Table Safe Operating Procedure v1robinNo ratings yet

- 039 G HSE Bulletin Safe Crane OperationsDocument1 page039 G HSE Bulletin Safe Crane OperationsOws AnishNo ratings yet

- Crane/lifting Operations Supervisor: Planning and Regulatory RequirementsDocument5 pagesCrane/lifting Operations Supervisor: Planning and Regulatory RequirementssurendraNo ratings yet

- RiggingDocument2 pagesRiggingpruncu.alianmNo ratings yet

- Instructions For The Safe Use Of: Jacks: AlwaysDocument1 pageInstructions For The Safe Use Of: Jacks: Alwaysreda mesbahNo ratings yet

- Beam ClampsDocument2 pagesBeam ClampsMateen KhanNo ratings yet

- Lifting Plan AgcDocument8 pagesLifting Plan Agcragesh p rNo ratings yet

- 2019 02 - SAFETY ALERT - Bending Machine LiftingDocument1 page2019 02 - SAFETY ALERT - Bending Machine LiftingzaimNo ratings yet

- Driving A Forklift - SOPDocument2 pagesDriving A Forklift - SOPivansNo ratings yet

- Job Safety Analysis Sheet: Activity Potential Hazard Likely Causes Control MeasureDocument2 pagesJob Safety Analysis Sheet: Activity Potential Hazard Likely Causes Control MeasureM Waqas HabibNo ratings yet

- Safe Crane Operations: Zero Harm - Only Safe ProductionDocument1 pageSafe Crane Operations: Zero Harm - Only Safe ProductionKushNo ratings yet

- LCC Docs 12144732 v1 Gantry Crane PfsDocument2 pagesLCC Docs 12144732 v1 Gantry Crane PfsShaiju NarayananNo ratings yet

- WinchesusedforliftingDocument2 pagesWinchesusedforliftingdavemcgrath17No ratings yet

- Forklift Jha Move Pallets Loads Around YardDocument5 pagesForklift Jha Move Pallets Loads Around Yardjacobpm2010No ratings yet

- Operating & Safety GuideDocument2 pagesOperating & Safety Guidelalit PatilNo ratings yet

- Job Safety Analysis (Jsa) FormDocument4 pagesJob Safety Analysis (Jsa) FormNaukhez A. KashifNo ratings yet

- Liftingoperationsafetyppt 230220111908 487c851eDocument39 pagesLiftingoperationsafetyppt 230220111908 487c851emamuNo ratings yet

- OS-NTP-WI-Truck 777D Transmission Remove & InstallDocument16 pagesOS-NTP-WI-Truck 777D Transmission Remove & Installconnor.millsNo ratings yet

- TBT BULLETIN - Safe Operation of Dump Trucks - English PDFDocument1 pageTBT BULLETIN - Safe Operation of Dump Trucks - English PDF孔超100% (1)

- SWMS Forklift CNGDocument2 pagesSWMS Forklift CNGAkano OluwasolaNo ratings yet

- Shifting and Loading Unloading of MaterialDocument4 pagesShifting and Loading Unloading of MaterialAdilMunirNo ratings yet

- Solar PV Modules Loading On Roof Top: Project: Seaworld Abu Dhabi - 8.368Mwp Solar PV Project OperationDocument3 pagesSolar PV Modules Loading On Roof Top: Project: Seaworld Abu Dhabi - 8.368Mwp Solar PV Project OperationKarimo KilaniNo ratings yet

- Ei0Pz71R3efC3jFh - rYavs5iKWZl6SQiL-Pallet Jack Safe Operating Procedure v1Document2 pagesEi0Pz71R3efC3jFh - rYavs5iKWZl6SQiL-Pallet Jack Safe Operating Procedure v1robinNo ratings yet

- Offloading SWP - 045.1 Unloading of Solar PV Modules With Telehandler - Rev0...Document11 pagesOffloading SWP - 045.1 Unloading of Solar PV Modules With Telehandler - Rev0...Babel THIAMNo ratings yet

- Gabion Risk AssessmentDocument2 pagesGabion Risk Assessmentmark jayson yabesNo ratings yet

- Health and Safety On Construction Sites: Safe Operation of LiftsDocument9 pagesHealth and Safety On Construction Sites: Safe Operation of Liftsmichael.cotugnoNo ratings yet

- LSA - Lifting & Hoisting - EN - ARDocument2 pagesLSA - Lifting & Hoisting - EN - ARmuatazNo ratings yet

- Instructions For The Safe Use Of: Hand Operated Chain Lever HoistsDocument2 pagesInstructions For The Safe Use Of: Hand Operated Chain Lever HoistsMontadhar SaeedNo ratings yet

- Lifting Supervisors Guidebook Revised 2014Document15 pagesLifting Supervisors Guidebook Revised 2014Abn BK100% (1)

- JSA Transformer InstallationDocument1 pageJSA Transformer Installationpushpanath reddyNo ratings yet

- Windows-1256 - Hand Operated Chain Lever HoistsDocument2 pagesWindows-1256 - Hand Operated Chain Lever HoistsFenner ElectromechanicalNo ratings yet

- Stype Hoist Manual E PDFDocument33 pagesStype Hoist Manual E PDFabdillahrulyNo ratings yet

- 960C-SOP-407-R2 - Crane Operation-Rubber Tire Gantry Crane_2022-05-26Document6 pages960C-SOP-407-R2 - Crane Operation-Rubber Tire Gantry Crane_2022-05-26amonNo ratings yet

- Crane and Rigging OperationDocument94 pagesCrane and Rigging OperationJust singingNo ratings yet

- Donald BG 2011 09 14 DROPS Forum PresentationDocument6 pagesDonald BG 2011 09 14 DROPS Forum PresentationHelp Tubestar CrewNo ratings yet

- 新75安全手册译稿SDocument37 pages新75安全手册译稿SSamuelOliveiraNo ratings yet

- Job Hazard Analysis PDFDocument8 pagesJob Hazard Analysis PDFashok KumarNo ratings yet

- Lift Plan RequirementsDocument37 pagesLift Plan RequirementsBathija DevendraNo ratings yet

- Maxon Telecom wl7 Users Manual 554065Document29 pagesMaxon Telecom wl7 Users Manual 554065Nicolas BerguecioNo ratings yet

- Mobile Gantries SI 20.3Document2 pagesMobile Gantries SI 20.3reda mesbahNo ratings yet

- Safe Work Practices - CraneDocument22 pagesSafe Work Practices - CranepentianNo ratings yet

- LEB Vessel ContactDocument1 pageLEB Vessel ContactAyodele AdebolaNo ratings yet

- LEB Lifting-Failure Of EquipmentDocument1 pageLEB Lifting-Failure Of EquipmentAyodele AdebolaNo ratings yet

- DNV - Enhancing organizational resilience through integrated risk managementDocument7 pagesDNV - Enhancing organizational resilience through integrated risk managementAyodele AdebolaNo ratings yet

- Iosh Training Courses BrochureDocument32 pagesIosh Training Courses BrochureAyodele AdebolaNo ratings yet

- Leopard 2A4M CANDocument1 pageLeopard 2A4M CANMobil BoyNo ratings yet

- Common Law Pleading Regarding Name ChangesDocument54 pagesCommon Law Pleading Regarding Name ChangesgmsapiensNo ratings yet

- Petroleum & Petrochemicals Test Method Capabilities: Intertek Caleb Brett 1Document18 pagesPetroleum & Petrochemicals Test Method Capabilities: Intertek Caleb Brett 1Eng-sadeq HesseinNo ratings yet

- 3374 PDFDocument10 pages3374 PDFCornel DumitruNo ratings yet

- Customer Service AssignmentDocument2 pagesCustomer Service AssignmentJoe Kau Zi YaoNo ratings yet

- WMA12 01 Que 20211013Document32 pagesWMA12 01 Que 20211013Md Shahidul Islam IslamNo ratings yet

- Bushman and Smith 2001Document97 pagesBushman and Smith 2001Rajesh VijayaraghavanNo ratings yet

- Simatic ManagerDocument19 pagesSimatic ManagerNabilBouabana100% (2)

- Chi-Square and Related DistributionDocument7 pagesChi-Square and Related DistributionMohammedseid AhmedinNo ratings yet

- 99 Ways To Be A Better MusicianDocument14 pages99 Ways To Be A Better Musiciangunter_wepplerNo ratings yet

- Toro CCR3650 SnowBlowerDocument24 pagesToro CCR3650 SnowBlowerRupertPupkin74No ratings yet

- Marinediesels - Co.uk - Members Section Starting and Reversing MAN B&W Air Start Distributor OperationDocument2 pagesMarinediesels - Co.uk - Members Section Starting and Reversing MAN B&W Air Start Distributor OperationArun SNo ratings yet

- Investment in GoldDocument4 pagesInvestment in GoldERIN KRISTINo ratings yet

- Assg1 200501Document7 pagesAssg1 200501SHARIFAH NURIN ZAHIRAH BINTI SYED ZAINAL ABIDINNo ratings yet

- Why Critical Thinking Is ImportantDocument3 pagesWhy Critical Thinking Is ImportantMehreen KandaanNo ratings yet

- Monica Ward ThesisDocument7 pagesMonica Ward Thesiscandacedaiglelafayette100% (2)

- Word PartsDocument15 pagesWord PartsDr. Zakir HorizontalNo ratings yet

- KTM ContentsDocument4 pagesKTM Contentstahaqureshi123No ratings yet

- Clat Mock Prime 10Document49 pagesClat Mock Prime 10Ritvikh RajputNo ratings yet

- Seedless FruitsDocument14 pagesSeedless FruitsManjrekar RohanNo ratings yet

- The KilnDocument43 pagesThe Kilnraja ghoshNo ratings yet

- Apr 30 23:59:59 IST 2023 Sunil Kumar Bhardwaj: 3rd Floor, No - 165 Megh Towers PH Road Maduravoyal Chennai - 600095Document1 pageApr 30 23:59:59 IST 2023 Sunil Kumar Bhardwaj: 3rd Floor, No - 165 Megh Towers PH Road Maduravoyal Chennai - 600095amanNo ratings yet

- Seligram, IncDocument5 pagesSeligram, IncAto SumartoNo ratings yet

- Gradsaleh PDFDocument257 pagesGradsaleh PDFميرفت بكرى نمرNo ratings yet

- Build Tight RangeDocument8 pagesBuild Tight RangeMihai MunteanuNo ratings yet

- Priinciples of Statistics PDFDocument62 pagesPriinciples of Statistics PDFkaroNo ratings yet

- Appendix-1 Piping Isometric With Node Numbers: Saudi Arabian Oil CompanyDocument1 pageAppendix-1 Piping Isometric With Node Numbers: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

Failure.of.Lifting.Learning.Event

Failure.of.Lifting.Learning.Event

Uploaded by

Ayodele AdebolaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Failure.of.Lifting.Learning.Event

Failure.of.Lifting.Learning.Event

Uploaded by

Ayodele AdebolaCopyright:

Available Formats

!

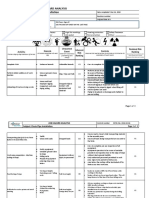

Learning Event

Failure of Lifting Equipment

Hazard Unwanted Event

Lifting / Loading / Unloading

led to Failure of Lifting Equipment

Description

When lifting a Frac Valve from the wellhead, one of the top lifting

eyes sheared at the bolt causing the valve to swing sideways

slightly. The valve stayed suspended held by the remaining 3

chains and was lowered to the ground in a controlled manner.

Nobody was injured. The only resulting damage was the sheared

bolt on the lifting eye.

The lifting operation used the blocks of the rig with 10mm 4-leg

chain attached to the top of the valve. A loader was also used

with a chain and soft sling attached to the bottom of the valve.

The intention was to lower the valve to the ground horizontally.

Risk Event Statement Habits Learnings

Due to deficiencies in lift ✔ Exclusion zones properly defined • Rigging angles were not maintained

planning or equipment and maintained. within prescribed angles for the type

inspection, failure of lifting ✔ Plan in place to ensure no need of lifting eyes being used.

equipment may occur which to walk/work under suspended • Chain hooks were connected

could lead to personnel load. directly onto lifting eyes (adequate

being exposed to ✔ Lifting gear carefully checked by shackles not used) resulting in lifting

dropped/uncontrolled crew on site prior to lifting. points being pulled in the wrong

suspended loads potentially ✔ Job stopped when identified that direction/plane.

causing serious injuries or a current tags were not available.

fatality. • When the two ends of the load (top

✗ Inspection tags not current on

original lifting eyes. & bottom) are simultaneously lifted/

pulled by separate equipment (rig &

!

✗ Replacement lifting eyes of

different style than original loader) the SWL of

- lifting plan not revised individual lifting points

accordingly. may be exceeded.

✗ Equal load distribution

not maintained across

all lifting points.

Considerations

• Verify all equipment to be used for lifting & hoisting has been inspected, maintained & certified by a competent person & in

accordance with the corresponding asset management procedure.

• Ensure that a specific lift plan is developed for all non-routine lifts, including complex & heavy lifts. When developing lift plans,

all relevant parties must be involved/consulted including not only supervisors & operators, but also equipment supplier/owner.

Could this happen to you?

• Are you & your crew in charge of, or involved with, any lifting operations at your work site? What are they?

• What resources & controls are available at your site to ensure that all lifting equipment is properly inspected, maintained & certified?

• Are you & your team members trained on, & familiar with, how to prepare & develop adequate lift plans?

• What resources & controls are available at your site to make sure that people understand & comply with exclusion zones?

February 2018 Was this Bulletin useful? Click here to provide your feedback safertogether.com.au

You might also like

- Rigging & Lifting HandbookDocument7 pagesRigging & Lifting HandbookRachmadKurniadi33% (6)

- JSA Transformer Installations, Testing, Commissioning.Document6 pagesJSA Transformer Installations, Testing, Commissioning.Kiran Bhatt75% (4)

- SOP Gantry Crane or HoistDocument5 pagesSOP Gantry Crane or Hoistrizki hsb100% (2)

- Mythic RacesDocument173 pagesMythic RacesRobert Howell100% (9)

- Overhead Crane Study 1Document12 pagesOverhead Crane Study 1shahrilmr6934No ratings yet

- Iso 18295 1 2017Document11 pagesIso 18295 1 2017Duilio HomarNo ratings yet

- General Crane SafetyDocument4 pagesGeneral Crane SafetyEhab Mostafa AliNo ratings yet

- Job Safety Analysis MDC Cylinder ReplacementDocument2 pagesJob Safety Analysis MDC Cylinder ReplacementMaxi Pro100% (2)

- BPO Management SystemDocument39 pagesBPO Management SystemSachin Manjunath67% (3)

- Slewing Jib Cranes SI 18.3Document2 pagesSlewing Jib Cranes SI 18.3reda mesbahNo ratings yet

- A97 A98 Lifting OperationsDocument4 pagesA97 A98 Lifting OperationsDavidNo ratings yet

- SEOT JSA For Installation of Project Sign BoardDocument3 pagesSEOT JSA For Installation of Project Sign BoardArchana SoorajNo ratings yet

- SafeuseofliftingequipmentDocument6 pagesSafeuseofliftingequipmentDjole GeorgeNo ratings yet

- 11-Lifting OperationsDocument73 pages11-Lifting OperationsElavarasan Pavan100% (1)

- Material Handling by CraneDocument16 pagesMaterial Handling by Cranenitin369100% (1)

- Lifting With Cranes and Hoists: Knowing The LoadDocument1 pageLifting With Cranes and Hoists: Knowing The LoadWahid AkramNo ratings yet

- Safeuseofliftingequipment PDFDocument5 pagesSafeuseofliftingequipment PDFAutumn Assirem TrefoilNo ratings yet

- Lifting PlanDocument5 pagesLifting Planmariyappanparamasivam61No ratings yet

- Title: 9801 High-Impact Crane Safety: Length: 18 Minutes Production Year: 1998 Program SynopsisDocument2 pagesTitle: 9801 High-Impact Crane Safety: Length: 18 Minutes Production Year: 1998 Program Synopsisg665013No ratings yet

- DTXkA3YUXA18hIrR - FXoZ9U5aIKPV-8BH-Scissor Lift Table Safe Operating Procedure v1Document2 pagesDTXkA3YUXA18hIrR - FXoZ9U5aIKPV-8BH-Scissor Lift Table Safe Operating Procedure v1robinNo ratings yet

- 039 G HSE Bulletin Safe Crane OperationsDocument1 page039 G HSE Bulletin Safe Crane OperationsOws AnishNo ratings yet

- Crane/lifting Operations Supervisor: Planning and Regulatory RequirementsDocument5 pagesCrane/lifting Operations Supervisor: Planning and Regulatory RequirementssurendraNo ratings yet

- RiggingDocument2 pagesRiggingpruncu.alianmNo ratings yet

- Instructions For The Safe Use Of: Jacks: AlwaysDocument1 pageInstructions For The Safe Use Of: Jacks: Alwaysreda mesbahNo ratings yet

- Beam ClampsDocument2 pagesBeam ClampsMateen KhanNo ratings yet

- Lifting Plan AgcDocument8 pagesLifting Plan Agcragesh p rNo ratings yet

- 2019 02 - SAFETY ALERT - Bending Machine LiftingDocument1 page2019 02 - SAFETY ALERT - Bending Machine LiftingzaimNo ratings yet

- Driving A Forklift - SOPDocument2 pagesDriving A Forklift - SOPivansNo ratings yet

- Job Safety Analysis Sheet: Activity Potential Hazard Likely Causes Control MeasureDocument2 pagesJob Safety Analysis Sheet: Activity Potential Hazard Likely Causes Control MeasureM Waqas HabibNo ratings yet

- Safe Crane Operations: Zero Harm - Only Safe ProductionDocument1 pageSafe Crane Operations: Zero Harm - Only Safe ProductionKushNo ratings yet

- LCC Docs 12144732 v1 Gantry Crane PfsDocument2 pagesLCC Docs 12144732 v1 Gantry Crane PfsShaiju NarayananNo ratings yet

- WinchesusedforliftingDocument2 pagesWinchesusedforliftingdavemcgrath17No ratings yet

- Forklift Jha Move Pallets Loads Around YardDocument5 pagesForklift Jha Move Pallets Loads Around Yardjacobpm2010No ratings yet

- Operating & Safety GuideDocument2 pagesOperating & Safety Guidelalit PatilNo ratings yet

- Job Safety Analysis (Jsa) FormDocument4 pagesJob Safety Analysis (Jsa) FormNaukhez A. KashifNo ratings yet

- Liftingoperationsafetyppt 230220111908 487c851eDocument39 pagesLiftingoperationsafetyppt 230220111908 487c851emamuNo ratings yet

- OS-NTP-WI-Truck 777D Transmission Remove & InstallDocument16 pagesOS-NTP-WI-Truck 777D Transmission Remove & Installconnor.millsNo ratings yet

- TBT BULLETIN - Safe Operation of Dump Trucks - English PDFDocument1 pageTBT BULLETIN - Safe Operation of Dump Trucks - English PDF孔超100% (1)

- SWMS Forklift CNGDocument2 pagesSWMS Forklift CNGAkano OluwasolaNo ratings yet

- Shifting and Loading Unloading of MaterialDocument4 pagesShifting and Loading Unloading of MaterialAdilMunirNo ratings yet

- Solar PV Modules Loading On Roof Top: Project: Seaworld Abu Dhabi - 8.368Mwp Solar PV Project OperationDocument3 pagesSolar PV Modules Loading On Roof Top: Project: Seaworld Abu Dhabi - 8.368Mwp Solar PV Project OperationKarimo KilaniNo ratings yet

- Ei0Pz71R3efC3jFh - rYavs5iKWZl6SQiL-Pallet Jack Safe Operating Procedure v1Document2 pagesEi0Pz71R3efC3jFh - rYavs5iKWZl6SQiL-Pallet Jack Safe Operating Procedure v1robinNo ratings yet

- Offloading SWP - 045.1 Unloading of Solar PV Modules With Telehandler - Rev0...Document11 pagesOffloading SWP - 045.1 Unloading of Solar PV Modules With Telehandler - Rev0...Babel THIAMNo ratings yet

- Gabion Risk AssessmentDocument2 pagesGabion Risk Assessmentmark jayson yabesNo ratings yet

- Health and Safety On Construction Sites: Safe Operation of LiftsDocument9 pagesHealth and Safety On Construction Sites: Safe Operation of Liftsmichael.cotugnoNo ratings yet

- LSA - Lifting & Hoisting - EN - ARDocument2 pagesLSA - Lifting & Hoisting - EN - ARmuatazNo ratings yet

- Instructions For The Safe Use Of: Hand Operated Chain Lever HoistsDocument2 pagesInstructions For The Safe Use Of: Hand Operated Chain Lever HoistsMontadhar SaeedNo ratings yet

- Lifting Supervisors Guidebook Revised 2014Document15 pagesLifting Supervisors Guidebook Revised 2014Abn BK100% (1)

- JSA Transformer InstallationDocument1 pageJSA Transformer Installationpushpanath reddyNo ratings yet

- Windows-1256 - Hand Operated Chain Lever HoistsDocument2 pagesWindows-1256 - Hand Operated Chain Lever HoistsFenner ElectromechanicalNo ratings yet

- Stype Hoist Manual E PDFDocument33 pagesStype Hoist Manual E PDFabdillahrulyNo ratings yet

- 960C-SOP-407-R2 - Crane Operation-Rubber Tire Gantry Crane_2022-05-26Document6 pages960C-SOP-407-R2 - Crane Operation-Rubber Tire Gantry Crane_2022-05-26amonNo ratings yet

- Crane and Rigging OperationDocument94 pagesCrane and Rigging OperationJust singingNo ratings yet

- Donald BG 2011 09 14 DROPS Forum PresentationDocument6 pagesDonald BG 2011 09 14 DROPS Forum PresentationHelp Tubestar CrewNo ratings yet

- 新75安全手册译稿SDocument37 pages新75安全手册译稿SSamuelOliveiraNo ratings yet

- Job Hazard Analysis PDFDocument8 pagesJob Hazard Analysis PDFashok KumarNo ratings yet

- Lift Plan RequirementsDocument37 pagesLift Plan RequirementsBathija DevendraNo ratings yet

- Maxon Telecom wl7 Users Manual 554065Document29 pagesMaxon Telecom wl7 Users Manual 554065Nicolas BerguecioNo ratings yet

- Mobile Gantries SI 20.3Document2 pagesMobile Gantries SI 20.3reda mesbahNo ratings yet

- Safe Work Practices - CraneDocument22 pagesSafe Work Practices - CranepentianNo ratings yet

- LEB Vessel ContactDocument1 pageLEB Vessel ContactAyodele AdebolaNo ratings yet

- LEB Lifting-Failure Of EquipmentDocument1 pageLEB Lifting-Failure Of EquipmentAyodele AdebolaNo ratings yet

- DNV - Enhancing organizational resilience through integrated risk managementDocument7 pagesDNV - Enhancing organizational resilience through integrated risk managementAyodele AdebolaNo ratings yet

- Iosh Training Courses BrochureDocument32 pagesIosh Training Courses BrochureAyodele AdebolaNo ratings yet

- Leopard 2A4M CANDocument1 pageLeopard 2A4M CANMobil BoyNo ratings yet

- Common Law Pleading Regarding Name ChangesDocument54 pagesCommon Law Pleading Regarding Name ChangesgmsapiensNo ratings yet

- Petroleum & Petrochemicals Test Method Capabilities: Intertek Caleb Brett 1Document18 pagesPetroleum & Petrochemicals Test Method Capabilities: Intertek Caleb Brett 1Eng-sadeq HesseinNo ratings yet

- 3374 PDFDocument10 pages3374 PDFCornel DumitruNo ratings yet

- Customer Service AssignmentDocument2 pagesCustomer Service AssignmentJoe Kau Zi YaoNo ratings yet

- WMA12 01 Que 20211013Document32 pagesWMA12 01 Que 20211013Md Shahidul Islam IslamNo ratings yet

- Bushman and Smith 2001Document97 pagesBushman and Smith 2001Rajesh VijayaraghavanNo ratings yet

- Simatic ManagerDocument19 pagesSimatic ManagerNabilBouabana100% (2)

- Chi-Square and Related DistributionDocument7 pagesChi-Square and Related DistributionMohammedseid AhmedinNo ratings yet

- 99 Ways To Be A Better MusicianDocument14 pages99 Ways To Be A Better Musiciangunter_wepplerNo ratings yet

- Toro CCR3650 SnowBlowerDocument24 pagesToro CCR3650 SnowBlowerRupertPupkin74No ratings yet

- Marinediesels - Co.uk - Members Section Starting and Reversing MAN B&W Air Start Distributor OperationDocument2 pagesMarinediesels - Co.uk - Members Section Starting and Reversing MAN B&W Air Start Distributor OperationArun SNo ratings yet

- Investment in GoldDocument4 pagesInvestment in GoldERIN KRISTINo ratings yet

- Assg1 200501Document7 pagesAssg1 200501SHARIFAH NURIN ZAHIRAH BINTI SYED ZAINAL ABIDINNo ratings yet

- Why Critical Thinking Is ImportantDocument3 pagesWhy Critical Thinking Is ImportantMehreen KandaanNo ratings yet

- Monica Ward ThesisDocument7 pagesMonica Ward Thesiscandacedaiglelafayette100% (2)

- Word PartsDocument15 pagesWord PartsDr. Zakir HorizontalNo ratings yet

- KTM ContentsDocument4 pagesKTM Contentstahaqureshi123No ratings yet

- Clat Mock Prime 10Document49 pagesClat Mock Prime 10Ritvikh RajputNo ratings yet

- Seedless FruitsDocument14 pagesSeedless FruitsManjrekar RohanNo ratings yet

- The KilnDocument43 pagesThe Kilnraja ghoshNo ratings yet

- Apr 30 23:59:59 IST 2023 Sunil Kumar Bhardwaj: 3rd Floor, No - 165 Megh Towers PH Road Maduravoyal Chennai - 600095Document1 pageApr 30 23:59:59 IST 2023 Sunil Kumar Bhardwaj: 3rd Floor, No - 165 Megh Towers PH Road Maduravoyal Chennai - 600095amanNo ratings yet

- Seligram, IncDocument5 pagesSeligram, IncAto SumartoNo ratings yet

- Gradsaleh PDFDocument257 pagesGradsaleh PDFميرفت بكرى نمرNo ratings yet

- Build Tight RangeDocument8 pagesBuild Tight RangeMihai MunteanuNo ratings yet

- Priinciples of Statistics PDFDocument62 pagesPriinciples of Statistics PDFkaroNo ratings yet

- Appendix-1 Piping Isometric With Node Numbers: Saudi Arabian Oil CompanyDocument1 pageAppendix-1 Piping Isometric With Node Numbers: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet