Professional Documents

Culture Documents

LEB Lifting-Failure Of Equipment

LEB Lifting-Failure Of Equipment

Uploaded by

Ayodele AdebolaCopyright:

Available Formats

You might also like

- Aircraft Safety: Accident Investigations, Analyses, & Applications, Second EditionFrom EverandAircraft Safety: Accident Investigations, Analyses, & Applications, Second EditionRating: 1.5 out of 5 stars1.5/5 (2)

- JSA Installation of Equipment For Electrical and InstrumentDocument3 pagesJSA Installation of Equipment For Electrical and InstrumentHong Hai Pham80% (5)

- JSA DrillingDocument4 pagesJSA DrillingAmalNo ratings yet

- Swms For Glass Partition FixingDocument6 pagesSwms For Glass Partition FixingSiddharth PNo ratings yet

- General Crane SafetyDocument4 pagesGeneral Crane SafetyEhab Mostafa AliNo ratings yet

- LB95B 110B 115B (E31)Document4 pagesLB95B 110B 115B (E31)Agro SipotNo ratings yet

- AAR Section A - Part I - 2016Document110 pagesAAR Section A - Part I - 2016GstavinNo ratings yet

- Ace Mega XLDocument2 pagesAce Mega XLBavithra75% (4)

- Truck/Tractor System Trailer System: Trucks and Truck Tractors: TrailersDocument2 pagesTruck/Tractor System Trailer System: Trucks and Truck Tractors: TrailersJuan Jose PerdomoNo ratings yet

- Zipcar CaseDocument3 pagesZipcar CasemeriemNo ratings yet

- SF 04 23Document6 pagesSF 04 23Reda MashalNo ratings yet

- Crane Safety PowerPoint PresentationDocument30 pagesCrane Safety PowerPoint Presentationhamouda hediNo ratings yet

- SF 15 23Document7 pagesSF 15 23Shivkumar JadhavNo ratings yet

- Crane Safety Training CLP. 15.11.2016 .Pps PDFDocument117 pagesCrane Safety Training CLP. 15.11.2016 .Pps PDFJSW Bellary, Project100% (1)

- Lifting-Failure of EquipmentDocument1 pageLifting-Failure of EquipmentRanjan PradhanNo ratings yet

- New Job Hazard Analysis (JHA) Hot Water Geyser InstallationDocument2 pagesNew Job Hazard Analysis (JHA) Hot Water Geyser Installationwaqar naeemNo ratings yet

- Case Study AnalysisDocument25 pagesCase Study AnalysisAmirah AkayNo ratings yet

- Jsa For LiftingDocument4 pagesJsa For Liftingshaibaz chafekarNo ratings yet

- JSA - LOAD TEST PILE No. 1Document6 pagesJSA - LOAD TEST PILE No. 1Sanjeet SinghNo ratings yet

- 016 Procedure ScaffoldingDocument13 pages016 Procedure ScaffoldingHSE CERINo ratings yet

- RAMS-Loading, Unloading and Shifting of MaterialDocument5 pagesRAMS-Loading, Unloading and Shifting of MaterialEm Niax50% (2)

- PREVENTING LIFTING POINT FAILURES IN CONSTRUCTIONv2Document3 pagesPREVENTING LIFTING POINT FAILURES IN CONSTRUCTIONv2Sandra FildesNo ratings yet

- RA58 Portable LaddersDocument2 pagesRA58 Portable LaddersRakeshKrishnanNo ratings yet

- Activity Hazard Analysis (AHA) : Risk Assessment Code (RAC) Matrix Severity ProbabilityDocument6 pagesActivity Hazard Analysis (AHA) : Risk Assessment Code (RAC) Matrix Severity ProbabilitygrandeNo ratings yet

- Material Handling by CraneDocument16 pagesMaterial Handling by Cranenitin369100% (1)

- Few Words About Crane Few Words About CraneDocument42 pagesFew Words About Crane Few Words About CraneSamuel GeorgeNo ratings yet

- 9-2016 - Fatalities Caused by Falling Trailer RampsDocument1 page9-2016 - Fatalities Caused by Falling Trailer RampsaymenmoatazNo ratings yet

- Lifting Operation (JSA)Document4 pagesLifting Operation (JSA)abdullah ashrafNo ratings yet

- Overhead CraneDocument10 pagesOverhead CraneMaryNo ratings yet

- SF 22 23Document6 pagesSF 22 23Shivkumar JadhavNo ratings yet

- Preventing Lifting Point Failures in ConstructionDocument3 pagesPreventing Lifting Point Failures in ConstructionSandra FildesNo ratings yet

- IMCASF - Sept 20Document6 pagesIMCASF - Sept 20Shivkumar JadhavNo ratings yet

- SF-10-24Document7 pagesSF-10-24Shivkumar JadhavNo ratings yet

- SF 02 24Document6 pagesSF 02 24Shivkumar JadhavNo ratings yet

- Job Safety Analysis (Jsa) FormDocument4 pagesJob Safety Analysis (Jsa) FormNaukhez A. KashifNo ratings yet

- Scaffolding Accidents On Construction SitesDocument18 pagesScaffolding Accidents On Construction SiteslucasNo ratings yet

- JSA - LOAD TEST PILE No. 1Document6 pagesJSA - LOAD TEST PILE No. 1noahlungu96No ratings yet

- Dropped Object - Fatale AccidentDocument9 pagesDropped Object - Fatale Accidentvikrant911No ratings yet

- Hoist - Folding Mobile Floor Crane HoistDocument5 pagesHoist - Folding Mobile Floor Crane HoistCharlie Dela RosaNo ratings yet

- SF 23 23Document5 pagesSF 23 23Shivkumar JadhavNo ratings yet

- Power Shovel Operation: Surface Metal and Nonmetal MinesDocument16 pagesPower Shovel Operation: Surface Metal and Nonmetal MinesHowk RiosNo ratings yet

- Job Hazard AnalysisDocument5 pagesJob Hazard AnalysisShamel Jen FacundoNo ratings yet

- SF 24 23Document5 pagesSF 24 23Shivkumar JadhavNo ratings yet

- Bucket Elevator SafetyDocument20 pagesBucket Elevator SafetyMuhammad WajidNo ratings yet

- Job Safety Analysis 14 For Cable Laying and PullingDocument4 pagesJob Safety Analysis 14 For Cable Laying and PullingBishop Ojonuguwa Ameh100% (1)

- Crane SafetyDocument8 pagesCrane SafetyRaghu Dev Hosur100% (1)

- Mines Safety Bulletin No. 123: SubjectDocument4 pagesMines Safety Bulletin No. 123: SubjectInsannulNo ratings yet

- SF 12 23Document7 pagesSF 12 23Shivkumar JadhavNo ratings yet

- Capstan (OSRV) SOPDocument7 pagesCapstan (OSRV) SOPakbar muslimNo ratings yet

- TC Nearhits April-June 2008Document3 pagesTC Nearhits April-June 2008Syuhud NurNo ratings yet

- Safe Plan of ActionDocument14 pagesSafe Plan of ActionRichard TorresNo ratings yet

- SF 29 23Document6 pagesSF 29 23Shivkumar JadhavNo ratings yet

- Imcasf 31 21Document6 pagesImcasf 31 21Paulo IsabelNo ratings yet

- Job Safety Practices Erection of Precast Columns, Beams, TT Slab, Hollow Core Slab, Insulated Wall Panels & Cladding and StairsDocument4 pagesJob Safety Practices Erection of Precast Columns, Beams, TT Slab, Hollow Core Slab, Insulated Wall Panels & Cladding and StairsBarkat UllahNo ratings yet

- Scaffolding Hazard: When Scaffolds Are Not Erected or UsedDocument2 pagesScaffolding Hazard: When Scaffolds Are Not Erected or UsedVicheeckoOrtegaNo ratings yet

- Worksafe Bulletin: Conveyor Hazards in Shake and Shingle MillsDocument4 pagesWorksafe Bulletin: Conveyor Hazards in Shake and Shingle MillsJanardhan KNo ratings yet

- IMCASF - Jun 18Document5 pagesIMCASF - Jun 18Shivkumar JadhavNo ratings yet

- 8300-0027 SK-300 Trifasica ItDocument24 pages8300-0027 SK-300 Trifasica Itankarthik11No ratings yet

- S.No Job Steps Hazards Preventative Measures Responsible PersonDocument3 pagesS.No Job Steps Hazards Preventative Measures Responsible Personmd_rehan_2No ratings yet

- Man Machine Interface 002Document6 pagesMan Machine Interface 002Anwar AhmedNo ratings yet

- Hydraulics SafetyDocument6 pagesHydraulics Safetydamith galagedaraNo ratings yet

- Emergency Plan For LiftDocument8 pagesEmergency Plan For LiftScribdTranslationsNo ratings yet

- Section A Operation & Maintenance ManualDocument20 pagesSection A Operation & Maintenance ManualManh DoanNo ratings yet

- Winching Operations in Forestry (fctg001) PDFDocument30 pagesWinching Operations in Forestry (fctg001) PDFMichael BatleyNo ratings yet

- Ast Jsa - Piping FabricationDocument3 pagesAst Jsa - Piping Fabricationmd_rehan_2No ratings yet

- LEB Vessel ContactDocument1 pageLEB Vessel ContactAyodele AdebolaNo ratings yet

- Failure.of.Lifting.Learning.EventDocument1 pageFailure.of.Lifting.Learning.EventAyodele AdebolaNo ratings yet

- DNV - Enhancing organizational resilience through integrated risk managementDocument7 pagesDNV - Enhancing organizational resilience through integrated risk managementAyodele AdebolaNo ratings yet

- Iosh Training Courses BrochureDocument32 pagesIosh Training Courses BrochureAyodele AdebolaNo ratings yet

- Linked PDFDocument400 pagesLinked PDFиван Троянов100% (1)

- 07E-1 TraXon XLRAEM4100G211062Document1 page07E-1 TraXon XLRAEM4100G211062Dtl DiagNo ratings yet

- XCMG Catalogue 2017Document14 pagesXCMG Catalogue 2017Islam AttiaNo ratings yet

- Technical Information KALMAR DCF280-500, DIESEL.: Heavy Lift Trucks 28 - 50 TonnesDocument16 pagesTechnical Information KALMAR DCF280-500, DIESEL.: Heavy Lift Trucks 28 - 50 Tonnescostinha fabio50% (2)

- RRE, 8FBRE: Introduction of New Firmware: Service Message/BSM: 0958Document4 pagesRRE, 8FBRE: Introduction of New Firmware: Service Message/BSM: 0958candra pmNo ratings yet

- SUNROOFDocument112 pagesSUNROOFJohn VNo ratings yet

- Swire Helifuel Tanks US Spec SheetDocument2 pagesSwire Helifuel Tanks US Spec SheetBruno Moreira SilvaNo ratings yet

- Specialized Lookup ExamplesDocument16 pagesSpecialized Lookup ExamplesDreamer_ShopnoNo ratings yet

- PAC10596 FebMar 017 Cat - webLRDocument16 pagesPAC10596 FebMar 017 Cat - webLRa04205No ratings yet

- Freightliner Trucks: Freightliner Trucks Is An American Semi Truck ManufacturerDocument15 pagesFreightliner Trucks: Freightliner Trucks Is An American Semi Truck ManufacturerRoberto Ortega Micalizzi33% (3)

- MRF Media PlanDocument3 pagesMRF Media PlanSaurav SharmaNo ratings yet

- You Are Managing A Small Project That Is Expected To Take 11 Weeks To CompleteDocument1 pageYou Are Managing A Small Project That Is Expected To Take 11 Weeks To CompletealokNo ratings yet

- 1736LOCTenders - MaldivesDocument55 pages1736LOCTenders - MaldivesHARENDRA SINGH BISHTNo ratings yet

- Linde N20vi, N20vliDocument4 pagesLinde N20vi, N20vliATILLANo ratings yet

- Operations and Maintenance Manual: February 2019Document16 pagesOperations and Maintenance Manual: February 2019Krishna N H100% (1)

- CASE 10.1 - Minentonka WarehouseDocument1 pageCASE 10.1 - Minentonka WarehouseKhoa KrisNo ratings yet

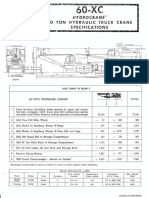

- 60-XC Bucyrus-Erie-Truck-Cranes-Spec-Ea10ccDocument5 pages60-XC Bucyrus-Erie-Truck-Cranes-Spec-Ea10ccRothsby Hoyos GomezNo ratings yet

- Col SizeDocument5 pagesCol SizeMohsin JeelaniNo ratings yet

- Spare Parts Price ListDocument14 pagesSpare Parts Price ListMassawe ENo ratings yet

- Newmodeltruckworldissue 8 Marchapril 2022Document64 pagesNewmodeltruckworldissue 8 Marchapril 2022Martijn Hinfelaar100% (1)

- Loading Unloading Checklist (07 20) - CS Energy RegisteredDocument1 pageLoading Unloading Checklist (07 20) - CS Energy RegisteredBAlaNo ratings yet

- MBA 206 - PRODUCTION MANAGEMENT - 2nd SEMDocument6 pagesMBA 206 - PRODUCTION MANAGEMENT - 2nd SEMprayas sarkarNo ratings yet

- Road Tanker Filling Flow ChartDocument1 pageRoad Tanker Filling Flow ChartKamal DeshapriyaNo ratings yet

- Lista Especial Abril 2022-1Document11 pagesLista Especial Abril 2022-1leonar eduardo montoya pinedaNo ratings yet

- Belarus 510/512: Operating ManualDocument125 pagesBelarus 510/512: Operating Manualirfan_19820% (1)

LEB Lifting-Failure Of Equipment

LEB Lifting-Failure Of Equipment

Uploaded by

Ayodele AdebolaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LEB Lifting-Failure Of Equipment

LEB Lifting-Failure Of Equipment

Uploaded by

Ayodele AdebolaCopyright:

Available Formats

Learning Event

Failure of Lifting Equipment

Hazard Unwanted Event

led to

Lifting Dropped Object

Description

A Franna Mac 25 crane was being used to position a

500kV generator in a High Voltage transformer yard. As

the generator was passing over the fence line, the crane

wire broke and the generator fell unrestrained to the

ground from a height of 3 metres.

No personnel were injured. The crane and generator

were damaged. Approximately 40-60 litres of coolant

leaked out of the generator.

For a video version of this Learning Event Bulletin go to:

www.safertogether.com.au/resources/sharing-library/xxx

Risk Event Habits Learnings

The top wear pad between the first and second extension was secured to the mounting base

Statement ✓ Exclusion by bronze screws. Stress corrosion cracking of these screws had occurred, initiated at the

Unidentified zones in thread roots. This caused the screws to fail.

mechanical place The wear pad dislodged from its normal location. It slid down on top of the second extension

failures in lifting and obeyed and was caught on the compensating sheave. This caused the C53 wire rope to ride up and

equipment can ✓ Lift plan in out of the compensating sheave (the last crane movement was telescoping out the boom). As

lead to dropped place and a result, all the lift load carried by the sheave was transferred onto the guides. The wire rope

objects during approved started cutting through the guides. This damaged strands of the wire rope, causing it to fail.

lifting which can The dislodged wear pad was not visible to the work crew and was not able to be identified

✓ Pre-start

cause prior to the incident. Catastrophic failures may still occur when all identified/planned controls

checks

equipment are in place.

conducted

damage, serious

on crane Observing Lifting Life Saving Rules (no-one was under the load when it fell) prevented

injury or fatality. possible injury.

The generator was “picked and carried” 660 metres. The flatbed truck that was used

to deliver the generator to site could have been unloaded closer to the lifting position to

eliminate the travel of the Franna crane.

Considerations

> Ensure exclusion zones are in place and observed for all lifting operations

> Inspect crane fleet. If the use of bronze screws to secure wear pads to mounting base is identified, consult the

Original Equipment Manufacturer.

> Include a section addressing safe pick and carry operations in lifting and hoisting procedures.

Could this happen to you?

> Do you put exclusion zones in place when lifting activities take place on your site? Do you observe them? Do you

make sure other people observe them?

> What equipment do you use that may have hidden faults that may pose a risk or have the potential to cause harm?

> What processes do you have in place to assess risks associated with the machinery and equipment you are using?

> What actions will you take to challenge the task at hand and ensure that you have the most appropriate equipment

and machinery available?

Was this Bulletin useful?

Please let us know your feedback at:

August 2019 https://www.surveymonkey.com/failureofliftingequipment-generator safertogether.com.au

You might also like

- Aircraft Safety: Accident Investigations, Analyses, & Applications, Second EditionFrom EverandAircraft Safety: Accident Investigations, Analyses, & Applications, Second EditionRating: 1.5 out of 5 stars1.5/5 (2)

- JSA Installation of Equipment For Electrical and InstrumentDocument3 pagesJSA Installation of Equipment For Electrical and InstrumentHong Hai Pham80% (5)

- JSA DrillingDocument4 pagesJSA DrillingAmalNo ratings yet

- Swms For Glass Partition FixingDocument6 pagesSwms For Glass Partition FixingSiddharth PNo ratings yet

- General Crane SafetyDocument4 pagesGeneral Crane SafetyEhab Mostafa AliNo ratings yet

- LB95B 110B 115B (E31)Document4 pagesLB95B 110B 115B (E31)Agro SipotNo ratings yet

- AAR Section A - Part I - 2016Document110 pagesAAR Section A - Part I - 2016GstavinNo ratings yet

- Ace Mega XLDocument2 pagesAce Mega XLBavithra75% (4)

- Truck/Tractor System Trailer System: Trucks and Truck Tractors: TrailersDocument2 pagesTruck/Tractor System Trailer System: Trucks and Truck Tractors: TrailersJuan Jose PerdomoNo ratings yet

- Zipcar CaseDocument3 pagesZipcar CasemeriemNo ratings yet

- SF 04 23Document6 pagesSF 04 23Reda MashalNo ratings yet

- Crane Safety PowerPoint PresentationDocument30 pagesCrane Safety PowerPoint Presentationhamouda hediNo ratings yet

- SF 15 23Document7 pagesSF 15 23Shivkumar JadhavNo ratings yet

- Crane Safety Training CLP. 15.11.2016 .Pps PDFDocument117 pagesCrane Safety Training CLP. 15.11.2016 .Pps PDFJSW Bellary, Project100% (1)

- Lifting-Failure of EquipmentDocument1 pageLifting-Failure of EquipmentRanjan PradhanNo ratings yet

- New Job Hazard Analysis (JHA) Hot Water Geyser InstallationDocument2 pagesNew Job Hazard Analysis (JHA) Hot Water Geyser Installationwaqar naeemNo ratings yet

- Case Study AnalysisDocument25 pagesCase Study AnalysisAmirah AkayNo ratings yet

- Jsa For LiftingDocument4 pagesJsa For Liftingshaibaz chafekarNo ratings yet

- JSA - LOAD TEST PILE No. 1Document6 pagesJSA - LOAD TEST PILE No. 1Sanjeet SinghNo ratings yet

- 016 Procedure ScaffoldingDocument13 pages016 Procedure ScaffoldingHSE CERINo ratings yet

- RAMS-Loading, Unloading and Shifting of MaterialDocument5 pagesRAMS-Loading, Unloading and Shifting of MaterialEm Niax50% (2)

- PREVENTING LIFTING POINT FAILURES IN CONSTRUCTIONv2Document3 pagesPREVENTING LIFTING POINT FAILURES IN CONSTRUCTIONv2Sandra FildesNo ratings yet

- RA58 Portable LaddersDocument2 pagesRA58 Portable LaddersRakeshKrishnanNo ratings yet

- Activity Hazard Analysis (AHA) : Risk Assessment Code (RAC) Matrix Severity ProbabilityDocument6 pagesActivity Hazard Analysis (AHA) : Risk Assessment Code (RAC) Matrix Severity ProbabilitygrandeNo ratings yet

- Material Handling by CraneDocument16 pagesMaterial Handling by Cranenitin369100% (1)

- Few Words About Crane Few Words About CraneDocument42 pagesFew Words About Crane Few Words About CraneSamuel GeorgeNo ratings yet

- 9-2016 - Fatalities Caused by Falling Trailer RampsDocument1 page9-2016 - Fatalities Caused by Falling Trailer RampsaymenmoatazNo ratings yet

- Lifting Operation (JSA)Document4 pagesLifting Operation (JSA)abdullah ashrafNo ratings yet

- Overhead CraneDocument10 pagesOverhead CraneMaryNo ratings yet

- SF 22 23Document6 pagesSF 22 23Shivkumar JadhavNo ratings yet

- Preventing Lifting Point Failures in ConstructionDocument3 pagesPreventing Lifting Point Failures in ConstructionSandra FildesNo ratings yet

- IMCASF - Sept 20Document6 pagesIMCASF - Sept 20Shivkumar JadhavNo ratings yet

- SF-10-24Document7 pagesSF-10-24Shivkumar JadhavNo ratings yet

- SF 02 24Document6 pagesSF 02 24Shivkumar JadhavNo ratings yet

- Job Safety Analysis (Jsa) FormDocument4 pagesJob Safety Analysis (Jsa) FormNaukhez A. KashifNo ratings yet

- Scaffolding Accidents On Construction SitesDocument18 pagesScaffolding Accidents On Construction SiteslucasNo ratings yet

- JSA - LOAD TEST PILE No. 1Document6 pagesJSA - LOAD TEST PILE No. 1noahlungu96No ratings yet

- Dropped Object - Fatale AccidentDocument9 pagesDropped Object - Fatale Accidentvikrant911No ratings yet

- Hoist - Folding Mobile Floor Crane HoistDocument5 pagesHoist - Folding Mobile Floor Crane HoistCharlie Dela RosaNo ratings yet

- SF 23 23Document5 pagesSF 23 23Shivkumar JadhavNo ratings yet

- Power Shovel Operation: Surface Metal and Nonmetal MinesDocument16 pagesPower Shovel Operation: Surface Metal and Nonmetal MinesHowk RiosNo ratings yet

- Job Hazard AnalysisDocument5 pagesJob Hazard AnalysisShamel Jen FacundoNo ratings yet

- SF 24 23Document5 pagesSF 24 23Shivkumar JadhavNo ratings yet

- Bucket Elevator SafetyDocument20 pagesBucket Elevator SafetyMuhammad WajidNo ratings yet

- Job Safety Analysis 14 For Cable Laying and PullingDocument4 pagesJob Safety Analysis 14 For Cable Laying and PullingBishop Ojonuguwa Ameh100% (1)

- Crane SafetyDocument8 pagesCrane SafetyRaghu Dev Hosur100% (1)

- Mines Safety Bulletin No. 123: SubjectDocument4 pagesMines Safety Bulletin No. 123: SubjectInsannulNo ratings yet

- SF 12 23Document7 pagesSF 12 23Shivkumar JadhavNo ratings yet

- Capstan (OSRV) SOPDocument7 pagesCapstan (OSRV) SOPakbar muslimNo ratings yet

- TC Nearhits April-June 2008Document3 pagesTC Nearhits April-June 2008Syuhud NurNo ratings yet

- Safe Plan of ActionDocument14 pagesSafe Plan of ActionRichard TorresNo ratings yet

- SF 29 23Document6 pagesSF 29 23Shivkumar JadhavNo ratings yet

- Imcasf 31 21Document6 pagesImcasf 31 21Paulo IsabelNo ratings yet

- Job Safety Practices Erection of Precast Columns, Beams, TT Slab, Hollow Core Slab, Insulated Wall Panels & Cladding and StairsDocument4 pagesJob Safety Practices Erection of Precast Columns, Beams, TT Slab, Hollow Core Slab, Insulated Wall Panels & Cladding and StairsBarkat UllahNo ratings yet

- Scaffolding Hazard: When Scaffolds Are Not Erected or UsedDocument2 pagesScaffolding Hazard: When Scaffolds Are Not Erected or UsedVicheeckoOrtegaNo ratings yet

- Worksafe Bulletin: Conveyor Hazards in Shake and Shingle MillsDocument4 pagesWorksafe Bulletin: Conveyor Hazards in Shake and Shingle MillsJanardhan KNo ratings yet

- IMCASF - Jun 18Document5 pagesIMCASF - Jun 18Shivkumar JadhavNo ratings yet

- 8300-0027 SK-300 Trifasica ItDocument24 pages8300-0027 SK-300 Trifasica Itankarthik11No ratings yet

- S.No Job Steps Hazards Preventative Measures Responsible PersonDocument3 pagesS.No Job Steps Hazards Preventative Measures Responsible Personmd_rehan_2No ratings yet

- Man Machine Interface 002Document6 pagesMan Machine Interface 002Anwar AhmedNo ratings yet

- Hydraulics SafetyDocument6 pagesHydraulics Safetydamith galagedaraNo ratings yet

- Emergency Plan For LiftDocument8 pagesEmergency Plan For LiftScribdTranslationsNo ratings yet

- Section A Operation & Maintenance ManualDocument20 pagesSection A Operation & Maintenance ManualManh DoanNo ratings yet

- Winching Operations in Forestry (fctg001) PDFDocument30 pagesWinching Operations in Forestry (fctg001) PDFMichael BatleyNo ratings yet

- Ast Jsa - Piping FabricationDocument3 pagesAst Jsa - Piping Fabricationmd_rehan_2No ratings yet

- LEB Vessel ContactDocument1 pageLEB Vessel ContactAyodele AdebolaNo ratings yet

- Failure.of.Lifting.Learning.EventDocument1 pageFailure.of.Lifting.Learning.EventAyodele AdebolaNo ratings yet

- DNV - Enhancing organizational resilience through integrated risk managementDocument7 pagesDNV - Enhancing organizational resilience through integrated risk managementAyodele AdebolaNo ratings yet

- Iosh Training Courses BrochureDocument32 pagesIosh Training Courses BrochureAyodele AdebolaNo ratings yet

- Linked PDFDocument400 pagesLinked PDFиван Троянов100% (1)

- 07E-1 TraXon XLRAEM4100G211062Document1 page07E-1 TraXon XLRAEM4100G211062Dtl DiagNo ratings yet

- XCMG Catalogue 2017Document14 pagesXCMG Catalogue 2017Islam AttiaNo ratings yet

- Technical Information KALMAR DCF280-500, DIESEL.: Heavy Lift Trucks 28 - 50 TonnesDocument16 pagesTechnical Information KALMAR DCF280-500, DIESEL.: Heavy Lift Trucks 28 - 50 Tonnescostinha fabio50% (2)

- RRE, 8FBRE: Introduction of New Firmware: Service Message/BSM: 0958Document4 pagesRRE, 8FBRE: Introduction of New Firmware: Service Message/BSM: 0958candra pmNo ratings yet

- SUNROOFDocument112 pagesSUNROOFJohn VNo ratings yet

- Swire Helifuel Tanks US Spec SheetDocument2 pagesSwire Helifuel Tanks US Spec SheetBruno Moreira SilvaNo ratings yet

- Specialized Lookup ExamplesDocument16 pagesSpecialized Lookup ExamplesDreamer_ShopnoNo ratings yet

- PAC10596 FebMar 017 Cat - webLRDocument16 pagesPAC10596 FebMar 017 Cat - webLRa04205No ratings yet

- Freightliner Trucks: Freightliner Trucks Is An American Semi Truck ManufacturerDocument15 pagesFreightliner Trucks: Freightliner Trucks Is An American Semi Truck ManufacturerRoberto Ortega Micalizzi33% (3)

- MRF Media PlanDocument3 pagesMRF Media PlanSaurav SharmaNo ratings yet

- You Are Managing A Small Project That Is Expected To Take 11 Weeks To CompleteDocument1 pageYou Are Managing A Small Project That Is Expected To Take 11 Weeks To CompletealokNo ratings yet

- 1736LOCTenders - MaldivesDocument55 pages1736LOCTenders - MaldivesHARENDRA SINGH BISHTNo ratings yet

- Linde N20vi, N20vliDocument4 pagesLinde N20vi, N20vliATILLANo ratings yet

- Operations and Maintenance Manual: February 2019Document16 pagesOperations and Maintenance Manual: February 2019Krishna N H100% (1)

- CASE 10.1 - Minentonka WarehouseDocument1 pageCASE 10.1 - Minentonka WarehouseKhoa KrisNo ratings yet

- 60-XC Bucyrus-Erie-Truck-Cranes-Spec-Ea10ccDocument5 pages60-XC Bucyrus-Erie-Truck-Cranes-Spec-Ea10ccRothsby Hoyos GomezNo ratings yet

- Col SizeDocument5 pagesCol SizeMohsin JeelaniNo ratings yet

- Spare Parts Price ListDocument14 pagesSpare Parts Price ListMassawe ENo ratings yet

- Newmodeltruckworldissue 8 Marchapril 2022Document64 pagesNewmodeltruckworldissue 8 Marchapril 2022Martijn Hinfelaar100% (1)

- Loading Unloading Checklist (07 20) - CS Energy RegisteredDocument1 pageLoading Unloading Checklist (07 20) - CS Energy RegisteredBAlaNo ratings yet

- MBA 206 - PRODUCTION MANAGEMENT - 2nd SEMDocument6 pagesMBA 206 - PRODUCTION MANAGEMENT - 2nd SEMprayas sarkarNo ratings yet

- Road Tanker Filling Flow ChartDocument1 pageRoad Tanker Filling Flow ChartKamal DeshapriyaNo ratings yet

- Lista Especial Abril 2022-1Document11 pagesLista Especial Abril 2022-1leonar eduardo montoya pinedaNo ratings yet

- Belarus 510/512: Operating ManualDocument125 pagesBelarus 510/512: Operating Manualirfan_19820% (1)