Professional Documents

Culture Documents

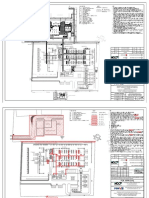

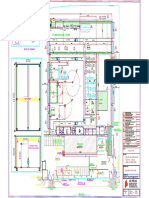

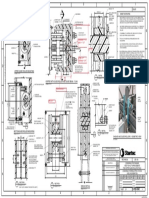

GA DRG FOR WOOD SAWDUST BLOCKS MAKING INLINE SYSTEM

GA DRG FOR WOOD SAWDUST BLOCKS MAKING INLINE SYSTEM

Uploaded by

ronaldcajaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GA DRG FOR WOOD SAWDUST BLOCKS MAKING INLINE SYSTEM

GA DRG FOR WOOD SAWDUST BLOCKS MAKING INLINE SYSTEM

Uploaded by

ronaldcajaCopyright:

Available Formats

SPACE REQUIRED (TENTATIVE) GEARBOX

O/P RPM 15

MOTOR-5HP,

3PH,1440RPM

BLOWER

HEATER

25MTR(L) X 6MTR(W) X 6MTR(H) BRACKET

DUMPING SILO AGITATOR

CAP- 700KG ASSEMBLY

(SAWDUST) (LOW SPEED)

MAINS INPUT SUPPLY- MOTOR- 3HP, CONVEYER 3

LOAD CELL

CAP - 1 TON = 4TON

3430 RPM 4NOS.

440V,2PH,60HZ WITH OUT NEUTRAL

CYCLONE

CAP - 300KG/HR

DUST

PIPE

START PROCESS

ROTARY

VALVE-2

1HP,3PH

MAGNETIC MOTOR-2HP,

ROLLER 3PH,1430RPM

CONVEYER-2 OUTLET PIPE

WOOD SHREDDER GEARBOX MOTOR-20HP, MIXING TANK

CAP-300 KG/HR 40 RPM CAP- 40KG/HR (WORKING)

960RPM (SAWDUST)

ROTARY GLUE TANK

COLLECTION TANK

CAP- 200LTR

VALVE-1 (VOLUMETRIC)

CAP- 40KG/HR

MOTOR-15HP,

1HP,3PH. (SAWDUST)

3PH,975RPM

MOTOR-10HP,

WITH BELT

PUSHER GB

2.4 RPM MOTOR-2HP,

NAIL WOOD CRUSHER LOAD CELL

CAP-300 KG/HR LEGS 3PH,1430RPM

COLLECTOR - 2 CAP - 1 TON = 4TON

4NOS.

4NOS.

LOBE PUMP

CAP- 30 LPM

NAIL

TRANSFER SCREW TRANSFER SCREW

COLLECTOR - 1

FEEDER-LHS PIPELINE FEEDER-RHS PIPELINE

HOPPER-LHS HOPPER-RHS

CAP-200LTR CAP-200LTR

UP AND DOWN UP AND DOWN

HYDRAULIC PRESS

STROCKE LENGTH 150MM (FOUR HEADED) STROCKE LENGTH 150MM

HYD PRESS HOPPER-LHS MOTOR-12.5HP,1440RPM

HEATER-25.6KW

HYD PRESS HOPPER-RHS

BLOCK CUTTING BLOCK CUTTING

MOTOR -1HP WITH HYD PRESS OUTLET

TEMP SENSOR- PT100

MOTOR -1HP WITH

GB-O/P RPM-30 GB-O/P RPM-30

FINISH FINISH

PROCESS BLOCK TILTING TABLE BLOCK TILTING TABLE PROCESS

DUST

MOTOR-2HP,WITH COLLECTOR

MOTOR-2HP,WITH GB- O/P RPM-48 GLUE TANK MOTOR-2HP,WITH

MOTOR- 3HP,

GB - O/P RPM-48 MAGNETIC MAGNETIC CAP- 200LTR GB- O/P RPM-48

ROLLER 1440RPM

ROLLER

CONVEYER-1 CONVEYER-2

DUMPING

CRUSHER

SILO TANK

CONVEYER 3

CYCLONE

SCREW FEEDER-2

SCREW FEEDER-1 MOTOR -2HP

MOTOR -2HP WITH GB-O/P RPM-48

WOOD SHREDDER WITH GB-O/P RPM-48

CAP-300 KG/HR

POWER PACK

FINISH FINISH

PROCESS BLOCK TILTING TABLE PROCESS

BLOCK TILTING TABLE

REVERSE AND FORWARD REVERSE AND FORWARD

STROCKE LENGTH - 300MM STROCKE LENGTH - 300MM

Procetech Engineers

Nashik-India

D.C.RN. RIVISION DETAIL DT BY

DRN. K.S.A TITLE:-

Note:- NO.

M/Cg Tole. other than specified.

CHD. S.D.

1) Plant Equipment arrangement to be Placed on Ground Floor. DIM. OVER mm. 0 6 30 120 315

APPD. D.R.B.

2) Drawing shows only overall placement of equipment. TOL. UPTO mm. 6 30 120 315 1000

SCALE N.T.S. DRG.NO.:NPE/21/GA/WSB/MIS

3) Not to scale. TOLERANCE ± 0.1 ± 0.2 ± 0.3 ± 0.5 ± 0.8 DATE 20/03/2023 REV- 0 ISUUE NO -01

You might also like

- CT660 2012Document58 pagesCT660 2012Eduardo Alvarez100% (2)

- 2015 Jeep Grand Cherokee 3.0L Eng VIN M LimitedDocument149 pages2015 Jeep Grand Cherokee 3.0L Eng VIN M LimitedData Técnica100% (2)

- DOPPLER Series Cabin Assembly SerialsDocument1 pageDOPPLER Series Cabin Assembly Serialsfirasalthiyaby100% (1)

- Drawing and TC SDocument42 pagesDrawing and TC Sshadab ahmadNo ratings yet

- Electrical Schematic 750L and 850L CRAWLER: V M P TDocument1 pageElectrical Schematic 750L and 850L CRAWLER: V M P TfeliizzNo ratings yet

- Power House Lighting Outside Lighting Battery Charger Power Point Unit 2 Power Point Unit 1 16A DPDocument24 pagesPower House Lighting Outside Lighting Battery Charger Power Point Unit 2 Power Point Unit 1 16A DPPritam SinghNo ratings yet

- King Air 350: Operation LimitationsDocument2 pagesKing Air 350: Operation LimitationsjuandiegobetNo ratings yet

- 3500 and 3500B Generator With MUI and EUI Engines Electrical SystemDocument4 pages3500 and 3500B Generator With MUI and EUI Engines Electrical Systemkrisari90% (1)

- Start of Taper End of Taper km.74+980: ROW ROW ROW ROW ROW ROW ROWDocument2 pagesStart of Taper End of Taper km.74+980: ROW ROW ROW ROW ROW ROW ROWs.s engineering and knowledge developed worksNo ratings yet

- HVAC LAYOUT at AB'S L&T MALL HYDERABAD (2022-01-06) - ModelDocument1 pageHVAC LAYOUT at AB'S L&T MALL HYDERABAD (2022-01-06) - ModelRohan RohanNo ratings yet

- Esr - Section - R0 - 24.04.23Document1 pageEsr - Section - R0 - 24.04.23Kalika RigsarNo ratings yet

- Doosan DX225LCA Electric Circuit 110705 PDFDocument1 pageDoosan DX225LCA Electric Circuit 110705 PDFDaniel Ardila100% (1)

- The Generator Industrial Diesel Generator Range WEBDocument8 pagesThe Generator Industrial Diesel Generator Range WEBaselabollegalaNo ratings yet

- 23.00m Non DOT TugDocument1 page23.00m Non DOT TugrafetguzelsoyNo ratings yet

- B350 Panel Art PDFDocument2 pagesB350 Panel Art PDFAyrton NobileNo ratings yet

- Layout FinalDocument1 pageLayout FinalrasoolasnNo ratings yet

- Rly. Platform DrawingDocument1 pageRly. Platform DrawingAtul Kumar MishraNo ratings yet

- GBC TextDocument1 pageGBC TextkeshavaNo ratings yet

- 69Kv Control Pob FDR SST BreakerDocument1 page69Kv Control Pob FDR SST BreakerJEFFREY BAUTISTANo ratings yet

- Ward 36 PDFDocument1 pageWard 36 PDFManish SharmaNo ratings yet

- Battery: Exhaust Gas Sensor (RH)Document3 pagesBattery: Exhaust Gas Sensor (RH)Joakin BcNo ratings yet

- SLD FOR 33 11kV METERING PROTECTION SS 2-ModelDocument1 pageSLD FOR 33 11kV METERING PROTECTION SS 2-ModelManasNo ratings yet

- Navistar Manual de Taller DT466 Amp I530eDocument1 pageNavistar Manual de Taller DT466 Amp I530eAnonymous 7t2BOJb100% (2)

- Ac Cabin Connection ParallelDocument1 pageAc Cabin Connection ParallelSamir Ben RomdhaneNo ratings yet

- Jambu Lochan Hall - ArchitectureDocument11 pagesJambu Lochan Hall - ArchitectureSherry HutNo ratings yet

- 408 Nagamin SDP (Approved)Document2 pages408 Nagamin SDP (Approved)REY PAMELO NAVARRONo ratings yet

- Technology Overview: SPV - Stable Platform ValveDocument2 pagesTechnology Overview: SPV - Stable Platform ValveJonah HexNo ratings yet

- E1Document1 pageE1Peter John Lozada LangitNo ratings yet

- B737NG - 49 00 A3 01 PDFDocument1 pageB737NG - 49 00 A3 01 PDFMuhammed MudassirNo ratings yet

- B737NG - 49 00 A3 01 PDFDocument1 pageB737NG - 49 00 A3 01 PDFMuhammed MudassirNo ratings yet

- B737NG - 49 00 A3 01 PDFDocument1 pageB737NG - 49 00 A3 01 PDFMuhammed MudassirNo ratings yet

- IRP 20 Generic Site Plan Example Stages 1 8Document8 pagesIRP 20 Generic Site Plan Example Stages 1 8Ralf JonesNo ratings yet

- Details of Water MeterDocument1 pageDetails of Water MeterKlausmene AveriaNo ratings yet

- Daily Progress Report P-132 August - 07 2022 Rev-00Document1 pageDaily Progress Report P-132 August - 07 2022 Rev-00arockiajijinsNo ratings yet

- New IPCamDocument1 pageNew IPCamChandra KiranaNo ratings yet

- Ground Floor Plan - Rev 6Document1 pageGround Floor Plan - Rev 6PRASHANT KANTENo ratings yet

- R1 10363 20 - 10T Cap, 35M Span, 10M HolDocument1 pageR1 10363 20 - 10T Cap, 35M Span, 10M HolsatyajitNo ratings yet

- Cross Section at Ch.8700 M: EXST. RAIL LEVEL 163.669Document1 pageCross Section at Ch.8700 M: EXST. RAIL LEVEL 163.669Atul Kumar MishraNo ratings yet

- 8997 0846 00 DrawingsDocument41 pages8997 0846 00 Drawingsedduami montoya neyraNo ratings yet

- F51 170 VTF Accessories Typical InstallationDocument1 pageF51 170 VTF Accessories Typical InstallationkimcucspktNo ratings yet

- Important Information: Naphtha Fractionation UnitDocument1 pageImportant Information: Naphtha Fractionation UnitTouseef HaiderNo ratings yet

- Hotel FIRE Model2Document1 pageHotel FIRE Model2Anonymous zrPBiglNo ratings yet

- Site PlanDocument1 pageSite PlanreshapalepiNo ratings yet

- Plano 336d2lDocument2 pagesPlano 336d2lAdonaí MoralesNo ratings yet

- Cat 336D2 Hydr.&Elect - DiagramDocument10 pagesCat 336D2 Hydr.&Elect - DiagrammanuelNo ratings yet

- Hopper Guide Plate DWG - RDDocument1 pageHopper Guide Plate DWG - RDRaj KumarNo ratings yet

- LEAP-1A - A3 - Modular Design - Rev1.3Document1 pageLEAP-1A - A3 - Modular Design - Rev1.3zeyadNo ratings yet

- Transition Between EW2 Viaduct (P-254) and EW2 UG (Shahpur) Plinth Details Are Missing and Will Be Published After Inputs AvailableDocument1 pageTransition Between EW2 Viaduct (P-254) and EW2 UG (Shahpur) Plinth Details Are Missing and Will Be Published After Inputs AvailablePawanNo ratings yet

- 6904132-ELE (1) 11-06 LRDocument8 pages6904132-ELE (1) 11-06 LRЭрнест БекировNo ratings yet

- 2020 I30 G 1.4 Mpi-DiagramDocument1 page2020 I30 G 1.4 Mpi-DiagramcarsexpressNo ratings yet

- Plot Plan Wellpad E - SUPERIMPOSE RIG (E31P, E56P) (WI)Document1 pagePlot Plan Wellpad E - SUPERIMPOSE RIG (E31P, E56P) (WI)Xiang JintaoNo ratings yet

- RENR2343Document4 pagesRENR2343ReymartinNo ratings yet

- Bedroom-01: Type E1 Unit No Key PlanDocument1 pageBedroom-01: Type E1 Unit No Key Plankaushik vijayendraNo ratings yet

- Multi-Coil / 2-Way Valve: Fan Detail Roof Mounted Exhaust Coil Piping Diagram Chilled Water PipingDocument2 pagesMulti-Coil / 2-Way Valve: Fan Detail Roof Mounted Exhaust Coil Piping Diagram Chilled Water PipingChristian TaboadaNo ratings yet

- Level D Full Flight Simulator Beechcraft Kingair 350: or Raining Urposes NlyDocument1 pageLevel D Full Flight Simulator Beechcraft Kingair 350: or Raining Urposes NlyAlejandro Gómez Buenaventura100% (1)

- Antipolo-Teresa-Morong Hi-Way (Zigzag RD.)Document1 pageAntipolo-Teresa-Morong Hi-Way (Zigzag RD.)Freddie MendezNo ratings yet

- Basement Floor Plan Water Supply Layout: 18C R O A D 18.29Document1 pageBasement Floor Plan Water Supply Layout: 18C R O A D 18.29abdullah amanullahNo ratings yet

- VERSA 2016 Engine Control System (Powertrain Management) - ALLDATA RepairDocument3 pagesVERSA 2016 Engine Control System (Powertrain Management) - ALLDATA RepairMarcos Ortega LeonNo ratings yet

- Week 3 Laminar and Turbulent FlowDocument80 pagesWeek 3 Laminar and Turbulent FlowRohit TomarNo ratings yet

- AC Plus: O N FR EQDocument40 pagesAC Plus: O N FR EQIgnacioNo ratings yet

- VSG 411 FordDocument124 pagesVSG 411 FordMARCO ANTONIO BOJORQUEZ FELIXNo ratings yet

- PT. Giwang Kanaka Company ProfileDocument5 pagesPT. Giwang Kanaka Company Profilealan.giwangkanakaNo ratings yet

- Maintenance Manual Austro E4 SeriesDocument739 pagesMaintenance Manual Austro E4 Serieskeneilwe budaniNo ratings yet

- LABTECTA BrochureDocument12 pagesLABTECTA BrochureSulaiman Kadher KNo ratings yet

- Mass Combi Ultra: Multi Purpose Charger InverterDocument32 pagesMass Combi Ultra: Multi Purpose Charger InverterPr. Samuel CostaNo ratings yet

- Dynamic FM&C Profile 2023Document8 pagesDynamic FM&C Profile 2023Hasan Al khooriNo ratings yet

- VersaJet Series Manual 06-13 WebDocument36 pagesVersaJet Series Manual 06-13 WebJOSE LUIS HERNANDEZ CHAVEZNo ratings yet

- Tutorial Week 11 - Non-Isothermal CSTR - System ABDocument25 pagesTutorial Week 11 - Non-Isothermal CSTR - System ABsiti azilaNo ratings yet

- 3RN10131BW10 Datasheet enDocument3 pages3RN10131BW10 Datasheet enXuân Kiên VũNo ratings yet

- Energy Profile of MalaysiaDocument7 pagesEnergy Profile of MalaysiaMohd HafizNo ratings yet

- LedaFlow Tutorial LedaFlow Tutorial. Study of Severe Slugging Effects in A Pipeline - Riser GeometryDocument26 pagesLedaFlow Tutorial LedaFlow Tutorial. Study of Severe Slugging Effects in A Pipeline - Riser GeometryericNo ratings yet

- Eaton 10858691 NZMN4 AE1000 en - GBDocument4 pagesEaton 10858691 NZMN4 AE1000 en - GBPeter UhuleNo ratings yet

- 6.section C - ElectricsDocument225 pages6.section C - ElectricsKo Zay100% (5)

- Reliance GT-FRAME-9-MANUALDocument97 pagesReliance GT-FRAME-9-MANUALkishoremarNo ratings yet

- 01 - Quiz-1 OIC B1 & B2 Gen 3 To 8) PCM (5357)Document8 pages01 - Quiz-1 OIC B1 & B2 Gen 3 To 8) PCM (5357)PhantomAssaulterNo ratings yet

- D2 S3 P4 Klaus MeyersieckDocument14 pagesD2 S3 P4 Klaus MeyersieckLelosPinelos123No ratings yet

- Utilities AssignmentDocument9 pagesUtilities Assignmentbint e bilalNo ratings yet

- Circuit Electrique SR20 G3Document34 pagesCircuit Electrique SR20 G3Bruno BrazNo ratings yet

- Arunima Shandilya Scienc e 10 BDocument22 pagesArunima Shandilya Scienc e 10 BHOWE CHENG TENGNo ratings yet

- 2309 Catalog-Hysincere BatteryDocument19 pages2309 Catalog-Hysincere BatterydtechsarlNo ratings yet

- Internship Report: BVM Engineering CollegeDocument14 pagesInternship Report: BVM Engineering CollegeJaykumar SentaNo ratings yet

- 402-91-EL-LIS-00003 Rev A1Document3 pages402-91-EL-LIS-00003 Rev A1Krishnan KrishNo ratings yet

- Ficha Tecnicas Controlador de Carga MPPT-150-70Document1 pageFicha Tecnicas Controlador de Carga MPPT-150-70Mathías Huillca CameronNo ratings yet

- Activity 4 ME LABDocument11 pagesActivity 4 ME LABAlan Jade de LeonNo ratings yet

- Brochure NGR HilkarDocument4 pagesBrochure NGR HilkarCandra BaswardaniNo ratings yet

- 218alecturenotes - 6 07 12Document441 pages218alecturenotes - 6 07 12Raja Muda Raja NgahNo ratings yet

- W5 Source Models ULearnDocument46 pagesW5 Source Models ULearnFakhrulShahrilEzanieNo ratings yet

- SHM 3Document27 pagesSHM 3THE PHYSICS TEACHERNo ratings yet