Professional Documents

Culture Documents

Valve Sizing and Selection

Valve Sizing and Selection

Uploaded by

andradedasilva.rodrigoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Valve Sizing and Selection

Valve Sizing and Selection

Uploaded by

andradedasilva.rodrigoCopyright:

Available Formats

Valve Sizing and Selection

Premium Content

Online Store

Valve Sizing and Selection

Online Job Service

Free Articles

Free Software More on Valves from Cheresources.com:

Newsletters

Message Board

FREE Resources

Link Directories Article: Using Equivalent Lengths of Valves

Physical Properties

Article: Rupture Pin Valve Technology

Submit Article

ChE Links: Search for "Valves"

Other Resources

Free Publications

Students: Ask a Question in our Forums

Advertise With Us Professionals: Ask a Question in our Forums

Contact Us Purchase / Subscription Resources

Homepage

Search Site

Book: Valve Selection Handbook

Online Store: Control Valve Flow Determination

Online Store: Control Valve Specification Sheet

Sizing flow valves is a science with many rules of thumb that few people agree on. In this article

I'll try to define a more standard procedure for sizing a valve as well as helping to select the

appropriate type of valve. **Please note that the correlation within this article are for turbulent flow

STEP #1: Define the system

The system is pumping water from one tank to another through a piping system with a total

pressure drop of 150 psi. The fluid is water at 70 0F. Design (maximum) flowrate of 150 gpm,

operating flowrate of 110 gpm, and a minimum flowrate of 25 gpm. The pipe diameter is 3 inches.

At 70 0F, water has a specific gravity of 1.0.

Key Variables: Total pressure drop, design flow, operating flow, minimum flow, pipe diameter,

specific gravity

STEP #2: Define a maximum allowable pressure drop for the valve

When defining the allowable pressure drop across the valve, you should first investigate the pump.

What is its maximum available head? Remember that the system pressure drop is limited by the

pump. Essentially the Net Positive Suction Head Available (NPSHA) minus the Net Positive

Suction Head Required (NPSHR) is the maximum available pressure drop for the valve to use and

this must not be exceeded or another pump will be needed. It's important to remember the trade off,

larger pressure drops increase the pumping cost (operating) and smaller pressure drops increase the

valve cost because a larger valve is required (capital cost). The usual rule of thumb is that a valve

should be designed to use 10-15% of the total pressure drop or 10 psi, whichever is greater. For our

system, 10% of the total pressure drop is 15 psi which is what we'll use as our allowable pressure

drop when the valve is wide open (the pump is our system is easily capable of the additional pressure

drop).

STEP #3: Calculate the valve characteristic

http://www.cheresources.com/valvezz.shtml (1 of 7)26/1/2006 19:34:25

Valve Sizing and Selection

For our system,

At this point, some people would be tempted to go to the valve charts or characteristic curves and

select a valve. Don't make this mistake, instead, proceed to Step #4!

STEP #4: Preliminary valve selection

Don't make the mistake of trying to match a valve with your calculated Cv value. The Cv value

should be used as a guide in the valve selection, not a hard and fast rule. Some other considerations

are:

a. Never use a valve that is less than half the pipe size

b. Avoid using the lower 10% and upper 20% of the valve stroke. The valve is much easier to

control in the 10-80% stroke range.

Before a valve can be selected, you have to decide what type of valve will be used (See the list of

valve types later in this article). For our case, we'll assume we're using an equal percentage, globe

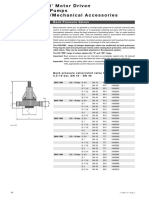

valve (equal percentage will be explained later). The valve chart for this type of valve is shown

below. This is a typical chart that will be supplied by the manufacturer (as a matter of fact, it was!)

For our case, it appears the 2 inch valve will work well for our Cv value at about 80-85% of the

stroke range. Notice that we're not trying to squeeze our Cv into the 1 1/2 valve which would need

to be at 100% stroke to handle our maximum flow. If this valve were used, two consequences

would be experienced: the pressure drop would be a little higher than 15 psi at our design (max)

flow and the valve would be difficult to control at maximum flow. Also, there would be no room for

error with this valve, but the valve we've chosen will allow for flow surges beyond the 150 gpm

range with severe headaches!

So we've selected a valve...but are we ready to order? Not yet, there are still some characteristics

to consider.

http://www.cheresources.com/valvezz.shtml (2 of 7)26/1/2006 19:34:25

Valve Sizing and Selection

STEP #5: Check the Cv and stroke percentage at the minimum flow

If the stroke percentage falls below 10% at our minimum flow, a smaller valve may have to be

used in some cases. Judgements plays role in many cases. For example, is your system more likely

to operate closer to the maximum flowrates more often than the minimum flowrates? Or is it more

likely to operate near the minimum flowrate for extended periods of time. It's difficult to find the

perfect valve, but you should find one that operates well most of the time. Let's check the valve

we've selected for our system:

Referring back to our valve chart, we see that a Cv of 6.5 would correspond to a stroke percentage of

around 35-40% which is certainly acceptable. Notice that we used the maximum pressure drop of 15

psi once again in our calculation. Although the pressure drop across the valve will be lower at

smaller flowrates, using the maximum value gives us a "worst case" scenario. If our Cv at the

minimum flow would have been around 1.5, there would not really be a problem because the valve

has a Cv of 1.66 at 10% stroke and since we use the maximum pressure drop, our estimate is

conservative. Essentially, at lower pressure drops, Cv would only increase which in this case would

be advantageous.

STEP #6: Check the gain across applicable flowrates

Gain is defined as:

Now, at our three flowrates:

Qmin = 25 gpm

Qop = 110 gpm

Qdes = 150 gpm

we have corresponding Cv values of 6.5, 28, and 39. The corresponding stroke percentages are 35%,

73%, and 85% respectively. Now we construct the following table:

Flow Stroke Change in flow

Change in Stroke (%)

(gpm) (%) (gpm)

25 35

110-25 = 85 73-35 = 38

110 73

150 85

150-110 = 40 85-73 = 12

Gain #1 = 85/38 = 2.2

Gain #2 = 40/12 = 3.3

The difference between these values should be less than 50% of the higher value.

0.5 (3.3) = 1.65

and 3.3 - 2.2 = 1.10. Since 1.10 is less than 1.65, there should be no problem in controlling the

valve. Also note that the gain should never be less than 0.50. So for our case, I believe our selected

valve will do nicely!

OTHER NOTES:

Another valve characteristic that can be examined is called the choked flow. The relation uses the FL

value found on the valve chart. I recommend checking the choked flow for vastly different

maximum and minimum flowrates. For example if the difference between the maximum and

minimum flows is above 90% of the maximum flow, you may want to check the choked flow.

Usually, the rule of thumb for determining the maximum pressure drop across the valve also helps to

http://www.cheresources.com/valvezz.shtml (3 of 7)26/1/2006 19:34:25

Valve Sizing and Selection

avoid choking flow.

SELECTING A VALVE TYPE

When speaking of valves, it's easy to get lost in the terminology. Valve types are used to describe

the mechanical characteristics and geometry (Ex/ gate, ball, globe valves). We'll use valve control to

refer to how the valve travel or stroke (openness) relates to the flow:

1. Equal Percentage: equal increments of valve travel produce an equal percentage in flow change

2. Linear: valve travel is directly proportional to the valve stoke

3. Quick opening: large increase in flow with a small change in valve stroke

So how do you decide which valve control to use? Here are some rules of thumb for each one:

1. Equal Percentage (most commonly used valve control)

a. Used in processes where large changes in pressure drop are expected

b. Used in processes where a small percentage of the total pressure drop is permitted by the valve

c. Used in temperature and pressure control loops

2. Linear

a. Used in liquid level or flow loops

b. Used in systems where the pressure drop across the valve is expected to remain fairly constant (ie.

steady state systems)

3. Quick Opening

a. Used for frequent on-off service

b. Used for processes where "instantly" large flow is needed (ie. safety systems or cooling water

systems)

Now that we've covered the various types of valve control, we'll take a look at the most common

valve types.

Gate Valves

Best Suited Control: Quick Opening

Recommended Uses:

1. Fully open/closed, non-throttling

2. Infrequent operation

3. Minimal fluid trapping in line

Applications: Oil, gas, air, slurries, heavy liquids, steam, noncondensing

gases, and corrosive liquids

Advantages: Disadvantages:

1. High capacity 1. Poor control

2. Tight shutoff 2. Cavitate at low pressure drops

3. Low cost 3. Cannot be used for throttling

4. Little resistance to flow

Globe Valves

http://www.cheresources.com/valvezz.shtml (4 of 7)26/1/2006 19:34:25

Valve Sizing and Selection

Best Suited Control: Linear and Equal percentage

Recommended Uses:

1. Throttling service/flow regulation

2. Frequent operation

Applications: Liquids, vapors, gases, corrosive substances, slurries

Advantages: Disadvantages:

1. Efficient throttling 1. High pressure drop

2. Accurate flow control 2. More expensive than other valves

3. Available in multiple ports

Ball Valves

Best Suited Control: Quick opening, linear

Recommended Uses:

1. Fully open/closed, limited-throttling

2. Higher temperature fluids

Applications: Most liquids, high

temperatures, slurries

Advantages: Disadvantages:

1. Low cost 1. Poor throttling characteristics

2. High capacity 2. Prone to cavitation

3. Low leakage and maint.

4. Tight sealing with low torque

Butterfly Valves

http://www.cheresources.com/valvezz.shtml (5 of 7)26/1/2006 19:34:25

Valve Sizing and Selection

Best Suited Control: Linear, Equal percentage

Recommended Uses:

1. Fully open/closed or throttling services

2. Frequent operation

3. Minimal fluid trapping in line

Applications: Liquids, gases, slurries, liquids with suspended

solids

Advantages: Disadvantages:

1. Low cost and maint. 1. High torque required for control

2. High capacity 2. Prone to cavitation at lower flows

3. Good flow control

4. Low pressure drop

Other Valves

Another type of valve commonly used in conjunction with other valves is called a check valve.

Check valves are designed to restrict the flow to one direction. If the flow reverses direction, the

check valve closes. Relief valves are used to regulate the operating pressure of incompressible

flow. Safety valves are used to release excess pressure in gases or compressible fluids.

References:

Rosaler, Robert C., Standard Handbook of Plant Engineering, McGraw-Hill, New York, 1995, pages

10-110 through 10-122

Purcell, Michael K., "Easily Select and Size Control Valves", Chemical Engineering Progress,

March 1999, pages 45-50

ChE Plus Subscriber - Click Here for a Printable Version

Send this Page to a Friend

Fill out your email address to

receive notification of site updates

and instantly receive five technical

questions and answers!

Email Address:

First Name:

Last Name:

State:

Not USA/CAN

Country: Choose Country

Industry:

Choose Industry

Position:

Choose Position

http://www.cheresources.com/valvezz.shtml (6 of 7)26/1/2006 19:34:25

Valve Sizing and Selection

Signup Remove

Submit

Terms of Use

Main Page

Premium Login | Signup | Learn More

Content

Engineering Software | Training Material | Continuing Education |

Online Store Maint Best Practices | Book Reviews

Free for Job Seekers

ChE Jobs

Newly Released | Popular Titles | Process Engineering | Process Design |

Free Articles Process Safety | CPI Business | Engineered Writing | As I See It | Students

Sign up for the ChE Plus Newsletter

Newsletter

Message Interact with other professionals and students on our online message baords

Boards

Free Software | Physical Properties | Submit an Aritlce | Linking to Us |

Other

Career Research | Why ChE? | Staff | Q & A's

Resources

Link ChE Links Technical Directory | Cheresources Partner Directory

Directories

Free Free Trade Publications from Cheresources

Publications

Advertise Advertise Your Company, Products, or Services

with Us

Send Us Your Feedback

Contact Us

The Chemical Engineers' Resource Page, 1442 Goswick Ridge Road, Midlothian, VA 23114, Email

All material is Copyright © 2004, www.cheresources.com

http://www.cheresources.com/valvezz.shtml (7 of 7)26/1/2006 19:34:25

You might also like

- Bomba - Weir - Curvas Warman Horizontais-Versão MetálicaDocument18 pagesBomba - Weir - Curvas Warman Horizontais-Versão MetálicaWanderson Alcantara100% (1)

- Automotive Sensor Testing and Waveform AnalysisFrom EverandAutomotive Sensor Testing and Waveform AnalysisRating: 4.5 out of 5 stars4.5/5 (13)

- Evaporator and DistillersDocument41 pagesEvaporator and DistillersPedro Oporto IIINo ratings yet

- Operator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowNo ratings yet

- Control Valve Sizing and Selection: STEP #1: Define The SystemDocument5 pagesControl Valve Sizing and Selection: STEP #1: Define The Systemprassna_kamat15730% (1)

- Siemens Valve SizingDocument32 pagesSiemens Valve SizingSteven Wei100% (2)

- Plastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1From EverandPlastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1Rating: 5 out of 5 stars5/5 (2)

- Ammonia SOPDocument51 pagesAmmonia SOPShamsul Azhar SulaimanNo ratings yet

- Batch DistillationDocument20 pagesBatch Distillationcgjp120391No ratings yet

- Valve Sizing and Selection: FREE ResourcesDocument6 pagesValve Sizing and Selection: FREE ResourcesSARATH KRISHNAKUMARNo ratings yet

- Valve Sizing and SelectionDocument6 pagesValve Sizing and SelectionZeBocaoNo ratings yet

- Valve Sizing Sample CalculationDocument6 pagesValve Sizing Sample Calculationanne_sibius100% (1)

- Control Valve SizingDocument6 pagesControl Valve SizingAlfonsus W.M.No ratings yet

- Valve Sizing and SelectionDocument7 pagesValve Sizing and SelectionCHEMNED0607No ratings yet

- Valve Sizing and SelectionDocument7 pagesValve Sizing and SelectionmanuNo ratings yet

- Flow Valves 1Document6 pagesFlow Valves 1abrahamkalilNo ratings yet

- At The Minimum Flow. in Certain Situations, A Smaller Valve May Be Needed If The StrokeDocument2 pagesAt The Minimum Flow. in Certain Situations, A Smaller Valve May Be Needed If The StrokePaula UntalanNo ratings yet

- Sizing Valve: STEP #1: Define The SystemDocument9 pagesSizing Valve: STEP #1: Define The SystemFahad RockingNo ratings yet

- Control Valve Sizing - 1Document18 pagesControl Valve Sizing - 1boy.r.indrawanNo ratings yet

- Reducers For Control ValvesDocument3 pagesReducers For Control Valveswa zaNo ratings yet

- Manual de IngenieriaDocument21 pagesManual de IngenieriaCamilo VelásquezNo ratings yet

- Valve Sizing and SelectionDocument6 pagesValve Sizing and Selectionctci17478No ratings yet

- Valve Sizing and SelectionDocument7 pagesValve Sizing and SelectionDevendra BangarNo ratings yet

- Control Valves Required DetailsDocument2 pagesControl Valves Required DetailszhangyiliNo ratings yet

- MasoneilanDocument32 pagesMasoneilanFelix AlorNo ratings yet

- PSV Sizing OrificeDocument4 pagesPSV Sizing OrificeRupak PatilNo ratings yet

- WWW Valin Com Resources Articles Size Matters Control ValveDocument12 pagesWWW Valin Com Resources Articles Size Matters Control Valvewslee0325No ratings yet

- Control Valve Question and Answer - 2Document13 pagesControl Valve Question and Answer - 2TATA STEELNo ratings yet

- Orifice Flowmeter Straight RunDocument4 pagesOrifice Flowmeter Straight RunMuhammad ImranNo ratings yet

- GroupE - Valve Presentation - SDLDocument25 pagesGroupE - Valve Presentation - SDLeng20072007No ratings yet

- Equal Percentage Control Valves and Applications - Control NotesDocument6 pagesEqual Percentage Control Valves and Applications - Control NotesShubham PisalNo ratings yet

- Control Valve Common Interview QuestionsDocument10 pagesControl Valve Common Interview QuestionsMustafa MehdiNo ratings yet

- Control Valve Sizing-Engineering DataDocument21 pagesControl Valve Sizing-Engineering Datapalindapc100% (1)

- Overcoming Control Valve Trim Selection ChallengeDocument10 pagesOvercoming Control Valve Trim Selection Challengeprasad durgaNo ratings yet

- Equal Percentage Control Valves and Applications - Control NotesDocument6 pagesEqual Percentage Control Valves and Applications - Control Notesmehdi haghdoostNo ratings yet

- Centrifugal Pump Systems TipsDocument16 pagesCentrifugal Pump Systems TipsKiran Kumar100% (1)

- Introduction To Pressure Relief Valve Design Part 3 - Sizing Orifices and Piping PDFDocument5 pagesIntroduction To Pressure Relief Valve Design Part 3 - Sizing Orifices and Piping PDFonizuka-t2263No ratings yet

- Cepde - Valve Sizing (U16ch036, U16ch037, U16ch083)Document15 pagesCepde - Valve Sizing (U16ch036, U16ch037, U16ch083)VRUSHABHNo ratings yet

- Tech. Articles About Marine & Offshore HVAC (3) Updated On 15-8-18Document165 pagesTech. Articles About Marine & Offshore HVAC (3) Updated On 15-8-18aunghtoo1No ratings yet

- Self Priming Pumps IssuesDocument5 pagesSelf Priming Pumps IssuesratheeshNo ratings yet

- Valve Sizing: Cepde AssignmentDocument15 pagesValve Sizing: Cepde AssignmentVRUSHABHNo ratings yet

- Control Valve Selection CriteriaDocument3 pagesControl Valve Selection CriteriaRamazan YaşarNo ratings yet

- Understanding Check Valves: Sizing For The Application, Not The Line SizeDocument5 pagesUnderstanding Check Valves: Sizing For The Application, Not The Line SizeSCR_010101No ratings yet

- Testing StandardDocument7 pagesTesting StandardDiego Fernando Pedroza UribeNo ratings yet

- Control Valve SizingDocument6 pagesControl Valve SizingRahul TavadareNo ratings yet

- Centrifugal Pumps TipsDocument34 pagesCentrifugal Pumps TipsFaizan AbbasiNo ratings yet

- Valve Selection for Bypass of Control ValvesDocument4 pagesValve Selection for Bypass of Control ValvesOthman Mat YamanNo ratings yet

- Control ValveDocument39 pagesControl Valveryukyu100% (1)

- FlowCon PICV Write OutDocument17 pagesFlowCon PICV Write OutmajortayNo ratings yet

- Ipc 15 Valve CharacteristicsDocument41 pagesIpc 15 Valve CharacteristicsHarsh RavalNo ratings yet

- Basic Control Valve Sizing and SelectionDocument38 pagesBasic Control Valve Sizing and SelectionmohamedNo ratings yet

- Control ValveDocument13 pagesControl ValveaimnvsNo ratings yet

- Control ValveDocument25 pagesControl ValveAsad RazaNo ratings yet

- Control Valves - EnggcyclopediaDocument8 pagesControl Valves - EnggcyclopediaazitaggNo ratings yet

- Selection and Sizing of Control Valves For Natural Gas PDFDocument3 pagesSelection and Sizing of Control Valves For Natural Gas PDFMalouk CheniouniNo ratings yet

- Valve Sizing: Cepde AssignmentDocument15 pagesValve Sizing: Cepde AssignmentVRUSHABHNo ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Automotive Actuators and EVAP System TestingFrom EverandAutomotive Actuators and EVAP System TestingRating: 4.5 out of 5 stars4.5/5 (4)

- Harvesting Rainwater for Your Home: Design, Install, and Maintain a Self-Sufficient Water Collection and Storage System in 5 Simple Steps for DIY beginner preppers, homesteaders, and environmentalistsFrom EverandHarvesting Rainwater for Your Home: Design, Install, and Maintain a Self-Sufficient Water Collection and Storage System in 5 Simple Steps for DIY beginner preppers, homesteaders, and environmentalistsNo ratings yet

- Fluid Statics. (Complete)Document49 pagesFluid Statics. (Complete)Umair AmirNo ratings yet

- ISO 14532 - 2014 (En), Natural Gas - VocabularyDocument1 pageISO 14532 - 2014 (En), Natural Gas - VocabularyDAYAMOY APLNo ratings yet

- Case Study Report On AutomobileDocument18 pagesCase Study Report On AutomobileSayaliRewaleNo ratings yet

- BrochureDocument28 pagesBrochurePapa100% (1)

- Lecture 6 - Biomass Energy Conversion Technologies and Processes - GasificationDocument20 pagesLecture 6 - Biomass Energy Conversion Technologies and Processes - GasificationBenard KalamboNo ratings yet

- Air Release Valve.Document2 pagesAir Release Valve.Shasin SolankiNo ratings yet

- Installation and Use Manual MDF-BDF-MDH-BDH 3.2 - XM670KDocument40 pagesInstallation and Use Manual MDF-BDF-MDH-BDH 3.2 - XM670KcorrolNo ratings yet

- Hy29 0035 UkDocument40 pagesHy29 0035 UkEvcol LtdaNo ratings yet

- Pipe Flow CalculationsDocument2 pagesPipe Flow CalculationsputrudeNo ratings yet

- AccBD ValvContrapresion DHV-RM en 2005Document2 pagesAccBD ValvContrapresion DHV-RM en 2005Jhonatan QuispeNo ratings yet

- Presentation 8 - LNG Firefighting ProceduresDocument9 pagesPresentation 8 - LNG Firefighting Proceduresfabio stricciNo ratings yet

- PDFDocument65 pagesPDFmurali madgundiNo ratings yet

- Oral PresentationDocument4 pagesOral PresentationAnele HadebeNo ratings yet

- Minggu 10 - Energy Analysis of Closed System - Part 2Document25 pagesMinggu 10 - Energy Analysis of Closed System - Part 2Faizal YogaNo ratings yet

- Sonda SP3200beDocument28 pagesSonda SP3200beMarcelo ArtolaNo ratings yet

- 5 Pressure MeasurementDocument28 pages5 Pressure MeasurementMorshedul IslamNo ratings yet

- Tutorial 1Document3 pagesTutorial 1nexowa9068No ratings yet

- IOCLDocument13 pagesIOCLNingSeng SingphoNo ratings yet

- 05pages From Code-291Document1 page05pages From Code-291Maged BesharaNo ratings yet

- eME4 HW3 Flores BSME-4BDocument6 pageseME4 HW3 Flores BSME-4Bjosh sanchezNo ratings yet

- Neraca Energi Asam SulfatDocument25 pagesNeraca Energi Asam SulfatMegaNo ratings yet

- CHM 101 Complete - LNDocument80 pagesCHM 101 Complete - LNSimon Adediran100% (1)

- Throttling ProcessDocument2 pagesThrottling Processsynayak100% (4)

- VCR Theory NewDocument18 pagesVCR Theory NewPranay TinkuNo ratings yet

- VecsDocument3 pagesVecsMahesh PooniaNo ratings yet

- Steam Problem SetDocument20 pagesSteam Problem SetMavrix Agustin67% (3)