Professional Documents

Culture Documents

ENGINE PMS June 2023

ENGINE PMS June 2023

Uploaded by

GustinussinagaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ENGINE PMS June 2023

ENGINE PMS June 2023

Uploaded by

GustinussinagaCopyright:

Available Formats

Document Number :

Revision Number :

Effective Date :

LIMIN MARINE OFFSHORE Page :

1 Place & Date of Report at LAMONGAN - ANCHORAGE., 30-06-2023 Second Engineer Chief Engineer Superintendent/Tech.Manager

2 Name Of vessel AHTS DP1 HAILEY PRINCESS

3 Type Of Vessel AHTS DP1

4 Class / Register No. ABS

5 Owner LIMIN MARINE & OFFSHORE

6 Ship Management LIMIN MARINE & OFFSHORE GUGUR RADITYA ARIEF ROHANI

MAINTENANCE LAST RUNNING LAST MAINTENANCE YEARS : 2023

NO. DESCRIPTION

PERIODE

HOURS (dd/mm/yy) JAN FEB MARCH APRIL MAY JUNE JULY AUGUS SEPT OCT NOV DEC REMARKS

ENGINE DEPARTERMENT

MAIN ENGINE PORT ( CATERPILLAR 3516 C/ 2550 BHP)

Clean, Adjust, Lubricate or Replace if necessary for ( LO

1 carter,Governor) 1500 hrs 21182 2/7/2023 31 4 4 29 12

1.1 Check wiring control panel ME Daily 25482:30 10/16/2023 31 4 5 4 29 12

1.2 Check Fresh water expansion tank Daily 25482:30 10/16/2023 31 4 5 4 29 12

1.3 Check LO pressure, SW pressure, FW pressure Daily 25482:30 10/16/2023 31 4 5 4 29 12

1.4 Check FW temeprature, Exhuast gas temp. Daily 25482:30 10/16/2023 31 4 5 4 29 12

1st Service Inspection, after 50~100 running hours &

periodicly with Clean, Adjust, Lubricate or Replace if

2.0 necessary for : Daily 25482:30 10/16/2023 31 4 4 29 12

2.1 Coolant Level 1 100 Hours

st

25482:30 10/16/2023 18 28 4 28 16 9

2.2 Clean/repalce air filetr cover (kain kasa) 1st 100 Hours 25482:30 10/16/2023 18 28 4 28 16 9

2.3 Reverse gear, oil level and filter 1st 100 Hours 25482:30 10/16/2023 18 25 4 25 16 9

2.4 Reverse gear, oil strainer 1st 100 Hours 25482:30 10/16/2023 18 24 4 24 16 9

2.5 Fault codes (if any) *1 1st 100 Hours 25482:30 10/16/2023 18 24 4 24 16 9

2.6 Engine & reverse gear,oil/fuel/water leak *1 1st 100 Hours 25482:30 10/16/2023 18 23 4 23 16 9

2.7 Engine & reverse gear, noises* 1

1 100 Hours

st

25482:30 10/16/2023 18 23 4 23 16 9

2.8 Check Engine alarm device Monthly 25482:30 10/16/2023 4 13 7 13 4 2

2.9 Oil pressure / oil leakage*3 Monthly 25482:30 10/16/2023 4 13 7 13 4 2

*1 Start & Warming up Engine Monthly 25482:30 10/16/2023 4 22 7 22 4 2

*2 Stop Engine ( Emergency stop) Monthly 25482:30 10/16/2023 4 13 7 13 4 2

*3 Restart engine Monthly 25482:30 10/16/2023 4 24 7 24 4 2

2.10 Solenoid valve clean Monthly 25482:30 10/16/2023 4 13 7 13 4 2

2.11 Seawater filter Sea chest strainer 6 Monthly 25482:30 10/16/2023 17 4 4 17

2.12 Engine Oil filetrs (if used wire fiilter type) 12 Monthly 10/16/2023

Continue Periodicly 10/16/2023

3 Clean Engine Block and Engine Room 300 Hourly 25482:30 10/16/2023

4 Renewal Lube Oil Engine carter 1500 Hourly 25482:30 10/16/2023

5 Renewal or clean Lube Oil Filter and by pass 300 Hourly 25482:30 10/16/2023

6 Renewal or clean Fuel Oil Filter 300 Hourly 25482:30 10/16/2023 19 19

7 Renewal Fuel Filter Racor 300 Hourly 25482:30 10/16/2023 19 19

8 Check and Air Filter and Indikator 300 Hourly 19 19

9 Check and clean coolant filter 300 Hourly 19 19

10 Check & Tightening Van Belt 300 Hourly 19 19

11 Check & Tightening Air strating connection 300 Hourly

12 Check & Cleaning Strainer of sea charge & Cooler 500 Hourly 15876 3/22/2023 13 4 4 13

13 Check or clean Impeller seawater Pump 500 Hourly

14 Clean Turbo charger blower side 1000 Hoursly

15 Check and Cleaning Fuel tank (daily tank) 1500 Hourly 3/22/2023

Clean, Adjust, Lubricate or Replace if necessary for

16 1500 Hoursly

Seawater pump impeller

17 Clean, Adjust, Lubricate or Replace if necessary for Zink 1500 Hoursly 15876 3/22/2023

anodes

18 Inspection with VODIA (Diagnostic Tool) if any 1500 Hoursly

19 Clean, Adjust, Lubricate or Replace if necessary for 1500 Hoursly

Drive Belts

Clean, Adjust, Lubricate or Replace if necessery for

20 1500 Hoursly NA NA NA NA NA

distribution starting valve

21 Check and adjust clearnce Ex.V/V & intake V/V 2000 Hoursly 17055 3/22/2023

22 Check and calibration fuel injector 2000 Hoursly 17055 3/22/2023

1 maintenance not applicable on board

1.the Item have been done in this maintenance plan should shown in the monthly maintrenance reports accordingly2.Please mark N/A or leave blank if the

23 Check and adjust timing fuel pump 2000 Hoursly 12561 3/22/2023

Clean, Adjust, Lubricate or Replace dynamo air starting

24 valve 2000 Hoursly NA NA NA NA NA

Check Stern tube lub oil system and sea water cooling

25 line and intermediate shaft 2000 Hoursly 16300 3/22/2023

26 Check and clean Fresh water impeller 2000 Hoursly

27 Replace Seawater pump impeller 2000 Hoursly

28 Check clearance rotor Turbocharger 2500 Hoursly

29 Check All Engine and equipment 2500 Hoursly

30 Replace Drive Belts R if any 4000 Hoursly

31 Replace Coolant chemical 4000 Hoursly

32 Crank shaft deflection 4000 Hoursly

33 Electric control panel system Calibration 4000 Hoursly

34 Safety device calibrationty device alarm system 4000 Hoursly

35 Top Overhoul 8000 Hoursly

36 General Overhaul 12000 Hoursly

Gear Box system

37 Replace lub oil gear box 2000 Hoursly 12579 4/26/2023

38 Clean and Replace LO filter 2000 Hoursly 12679 4/26/2023

39 Check and calibration eletric control system 4000 Hoursly

40 Check clearence clutch and gear 4000 hoursly

41 Check and overhaul hudraulic pump 8000 hoursly

42 General overhaul Gear box 12000 hoursly

MAIN ENGINE STATRBOARD ( CATERPILLAR 3516 C/ 2550 BHP)

Clean, Adjust, Lubricate or Replace if necessary for ( LO

1 Daily 24591:42 2/7/2023

carter,Governor)

1.1 Check wiring control panel ME Daily 21119 2/7/2023 5

1.2 Check Fresh water expansion tank Daily 21119 2/7/2023 9 11 5 11 9 16

1.3 Check LO pressure, SW pressure, FW pressure Daily 21119 2/7/2023 9 11 5 11 9 16

1.4 Check FW temeprature, Exhuast gas temp. Daily 21119 2/7/2023 9 11 5 11 9 16

16

1st Service Inspection, after 50~100 running hours &

2 periodicly with Clean, Adjust, Lubricate or Replace if 21119 44964 9 11 11 9 16

necessary for :

16

2.1 Coolant Level level 1st 100 Hours 2 10 3 10 2 23

2.2 Clean/repalce air filetr cover (kain kasa) 1st 100 Hours 21009 2/7/2023 2 10 18 10 2 23

2.3 Reverse gear, oil level and filter 1st 100 Hours 2 10 10 2 23

2.4 Reverse gear, oil strainer 1st 100 Hours 2 10 10 2 23

2.5 Fault codes (if any) * 1

1 100 Hours

st

2 10 10 2 23

2.6 Engine & reverse gear,oil/fuel/water leak *1 1st 100 Hours 2 10 10 2 23

2.7 Engine & reverse gear, noises*1 1st 100 Hours 2 10 10 2 23

2.8 Check Engine alarm device Monthly 6 11 7 11 6 15

2.9 Oil pressure / oil leakage*3 6 11 7 11 6 15

*1 Start & Warming up Engine Monthly 21119 2/7/2023 6 11 7 11 6 15

*2 Stop Engine ( Emergency stop) Monthly 21119 2/7/2023 6 11 7 11 6 15

* Restart engine

3

Monthly 6 11 7 11 6 15

2.10 Solenoid valve clean Monthly 6 11 11 6 15

2.11 Seawater filter Sea chest strainer 6 Monthly 19513 4/23/2023 6 4 4 6

2.12 Engine Oil filetrs (if used wire fiilter type) 12 Monthly NA NA NA NA NA

Continue Periodicly

3 Clean Engine Block and Engine Room 300 Hourly 19225 5/16/2023

4 Renewal Lube Oil Engine carter 750 Hourly 24591:42 6/16/2022

5 Renewal or clean Lube Oil Filter and by pass 300 Hourly 21009 6/16/2022

6 Renewal or clean Fuel Oil Filter 300 Hourly 21009 6/16/2022 18 18

7 Renewal Fuel Filter Racor 300 Hourly 21009 4/13/2023 18 18

8 Check and Air Filter and Indikator 300 Hourly 18 18

9 Check and clean coolant filter 300 Hourly 5/15/2023 18 18

10 Check & Tightening Van Belt 300 Hourly 5/15/2023 18 18

11 Check & Tightening Air strating connection 300 Hourly 5/15/2023

12 Check & Cleaning Strainer of sea charge & Cooler 500 Hourly 16176 5/15/2023 18 18

13 Check or clean Impeller seawater Pump 500 Hourly 5/15/2023

14 Clean Turbo charger blower side 1000 Hoursly 5/15/2023

15 Check and Cleaning Fuel tank (daily tank) 1500 Hourly 5/15/2023

Clean, Adjust, Lubricate or Replace if necessary for

16 Seawater pump impeller 1500 Hoursly 5/15/2023

2 maintenance not applicable on board

1.the Item have been done in this maintenance plan should shown in the monthly maintrenance reports accordingly2.Please mark N/A or leave blank if the

Clean, Adjust, Lubricate or Replace if necessary for Zink

17 1500 Hoursly 15190 7/3/2018

anodes

18 Inspection with VODIA (Diagnostic Tool) if any 1500 Hoursly

19 Clean, Adjust, Lubricate or Replace if necessary for 1500 Hoursly

Drive Belts

Clean, Adjust, Lubricate or Replace if necessery for

20 distribution starting valve 1500 Hoursly NA NA

21 Check and adjust clearnce Ex.V/V & intake V/V 2000 Hoursly 12579 9/5/2017

22 Check and calibration fuel injector 2000 Hoursly 12580 9/6/2017

23 Check and adjust timing fuel pump 2000 Hoursly 12581 9/7/2017

24 Clean, Adjust, Lubricate or Replace dynamo electrical 2000 Hoursly

starting

Check Stern tube lub oil system and sea water cooling

25 line and intermediate shaft 2000 Hoursly 16301 29/12/2018 check water contaminate

26 Check and clean Fresh water impeller 2000 Hoursly

27 Replace Seawater pump impeller 2000 Hoursly

28 Check clearance rotor Turbocharger 2500 Hoursly 12561

29 Check All Engine and equipment 2500 Hoursly

30 Replace Drive Belts R if any 4000 Hoursly

31 Replace Coolant chemical 4000 Hoursly

32 Crank shaft deflection 4000 Hoursly

34 Safety device calibrationty device alarm system 4000 Hoursly

35 Top Overhoul 8000 Hoursly 12520 6/1/2017

36 General Overhaul 12000 Hoursly

Gear Box system

37 Replace lub oil gear box 2000 Hoursly 12520 4/26/2023

38 Clean and Replace LO filter 2000 Hoursly 12520 4/26/2023

39 Check and calibration eletric control system 4000 Hoursly

40 Check clearence clutch and gear 4000 hoursly

41 Check and overhaul hudraulic pump 8000 hoursly

42 General overhaul Gear box 12000 hoursly

GENERATOR ENGINE AND ALTENATOR No.1 ( CATERPILLAR C 18)

1 Check wiring and elctirc control panel component Daily 30254:30 4/26/2023 25 8 9 8 25 24

2 Check battery connection Daily 30254:30 4/26/2023 25 8 9 8 25 24

3 Check the batteries fluid level Daily 30254:30 4/26/2023 25 8 12 8 25 24

4 Check engine oil for abnormal smell / water,leakage Weekly 30254:30 4/26/2023 25 8 12 8 25 24

5 Check Noise and Vibration Weekly 30254:30 4/26/2023 25 8 9 8 25 24

6 Clean Engine Block and Engine Room Weekly 30254:30 4/26/2023 25 6 9 6 25 24

7 Renewal Lube Oil Engine 500 Hourly 30030 4/26/2023 3 20 3 12

8 Renewal Lube Oil Filter 500 Hourly 30030 4/26/2023 3 20 3 12

9 Renewal Fuel Oil Filter 300 Hourly 25448 4/26/2023 25 20 25 21

10 Renewal Filter Racor 300 Hourly 25448 4/26/2023 29 20 29 21

11 Check or clean Air Filter and Indikator 300 Hourly 25448 29 15 15 15 29 21

12 Check & Tightening Hose pipe Conection 300 Hourly 25448 25 15 15 15 25 21

13 Check Governor control actuator control 300 Hourly 25448 15 21

14 Check & Tightening bolt nut coupling 300 Hourly 25448 25 7 12 7 25 21

15 Check & Tightening Accu & Cable Conection 300 Hourly 25448 25 7 12 7 25 21

16 Check & Cleaning Strainer of sea charge & Cooler 500 Hourly 25648 4/26/2023 25 4 4 25

17 Check & or replace Impeller seawater Pump 500 Hourly 25648 4/26/2023

18 Check and Cleaning Fuel tank 500 Hourly 4/26/2023 3

19 Check and or renewal Zing Anode 500 Hoursly 25648 4/26/2023 25 25

20 Check or Renewal Air Filter and Indikator 500 Hoursly 24648 4/26/2023 25 20 25

21 Check dynamo starting valve 1000 Hoursly

22 Inspect Clean, Adjust, Lubricate or Replace if necessary 1000 Hoursly

for Engine & revers gear, inspection for leakage

Clean, Adjust, Lubricate or Replace if necessary for

23 Engine and reverse gear, inspect hoses and cable 1000 Hoursly 23 23

clamping

Clean, Adjust, Lubricate or Replace if necessary for

24 500 Hoursly 23 23

Engine and revers gear, cleaning / painting

25 Flush pump / Bilge pump, impeller 1000 Hoursly

26 Check alignment Coupling and rotor 1000 Hoursly 20 20

27 Valve clearance intake & exhuast 2000 Hoursly 14383 5/31/2017 20 20

3 maintenance not applicable on board

1.the Item have been done in this maintenance plan should shown in the monthly maintrenance reports accordingly2.Please mark N/A or leave blank if the

Clean, Adjust, Lubricate or Replace if necessary for

28 Turbocharge 2000 Hoursly 28 28

Clean, Adjust, Lubricate or Replace if necessary for

29 Drive Belts4) I 2000 Hoursly

30 Clean or repair Fresh water pump 2000 Hoursly

31 Replace Seawater pump impeller 2000 Hoursly

32 Check and calibration fuel Injector 2500 Hoursly

33 Check clearance rotor Turbocharger 2500 Hoursly

34 Electric control panel system Calibration 4000 Hoursly

35 Safety decive control system calibration 4000 Hoursly

36 Replace Drive Belts R 4000 Hoursly

37 Replace Coolant 4000 Hoursly 14862 4/15/2023 28 28

38 Crank shaft deflection 4000 Hoursly

39 Altenator merger Test 4000 Hoursly

40 Top Overhaul 6000 Hoursly 30254:30 8/10/2022 6/1/2017

41 General Overhoul 12000 Hoursly

42 Renew Battery starter 2 years

GENERATOR ENGINE AND ALTENATOR No.2 ( CATERPILLAR C 18)

1 Check wiring and elctirc control panel component Daily 30286:30 5/11/2023 4 8 5 8 4 3

2 Check battery connection Daily 30286:30 5/11/2023 4 8 5 8 4 3

3 Check the batteries fluid level Daily 30286:30 5/11/2023 4 8 5 8 4 3

4 Check engine oil for abnormal smell / water,leakage Weekly 30286:30 5/11/2023 18 5 18 27

5 Check Noise and Vibration Weekly 30286:30 5/11/2023 4 5 4 27

6 Clean Engine Block and Engine Room Weekly 30286:30 5/11/2023 4 27 5 27 4 27

7 Renewal Lube Oil Engine 500 Hourly 30042 5/11/2023 3

8 Renewal Lube Oil Filter 500 Hourly 30042 5/11/2023 3

9 Renewal Fuel Oil Filter 300 Hourly 30042 5/11/2023 3

10 Renewal Filter Racor 300 Hourly 30042 5/11/2023 3

11 Check or clean Air Filter and Indikator 300 Hourly 30042 5/11/2023 19 14 19 16

12 Check & Tightening Hose pipe Conection 300 Hourly 30042 5/11/2023 19 19 16

13 Check Governor control actuator control 300 Hourly 19 19 16

14 Check & Tightening bolt nut coupling 300 Hourly 25802 19 19 16

15 Check & Tightening Accu & Cable Conection 300 Hourly 25802 23/12/2020 19 21 27 21 19 16

16 Check & Cleaning Strainer of sea charge & Cooler 500 Hourly 26002 3/9/2019 19 4 27 4 19 16

17 Check & or replace Impeller seawater Pump 500 Hourly 15 15

18 Check and Cleaning Fuel tank 500 Hourly

19 Check and or renewal Zing Anode 500 Hoursly 26002 3/9/2019 19 19

20 Check or Renewal Air Filter and Indikator 500 Hoursly 26002

21 Check dynamo starting valve 1000 Hoursly 26502

22 Inspect Clean, Adjust, Lubricate or Replace if necessary 1000 Hoursly

for Engine & revers gear, inspection for leakage

Clean, Adjust, Lubricate or Replace if necessary for

23 Engine and reverse gear, inspect hoses and cable 1000 Hoursly

clamping

24 Clean, Adjust, Lubricate or Replace if necessary for 500 Hoursly

Engine and revers gear, cleaning / painting

25 Flush pump / Bilge pump, impeller 1000 Hoursly

26 Check alignment Coupling and rotor 1000 Hoursly 18 18

27 Valve clearance intake & exhuast 2000 Hoursly 18 18

Clean, Adjust, Lubricate or Replace if necessary for

28 Turbocharge 2000 Hoursly

Clean, Adjust, Lubricate or Replace if necessary for

29 2000 Hoursly N/A

Drive Belts4) I

30 Clean or repair Fresh water pump 2000 Hoursly

31 Replace Seawater pump impeller 2000 Hoursly

32 Check and calibration fuel Injector 2500 Hoursly

33 Check clearance rotor Turbocharger 2500 Hoursly

34 Electric control panel system Calibration 4000 Hoursly

35 Safety decive control system calibration 4000 Hoursly

36 Replace Drive Belts R 4000 Hoursly

4 maintenance not applicable on board

1.the Item have been done in this maintenance plan should shown in the monthly maintrenance reports accordingly2.Please mark N/A or leave blank if the

37 Replace Coolant 4000 Hoursly 24388 5/1/2020 19 19

38 Crank shaft deflection 4000 Hoursly

39 Altenator merger Test 4000 Hoursly

40 Top Overhaul 6000 Hoursly 13964 6/1/2017 6/1/2017

41 General Overhoul 12000 Hoursly

42 Renew Battery starter 2 years

EMERGENCY GENERATOR ENGINE AND ALTENATOR (CATERPILLAR C 4)

1 Check wiring and elctirc control panel component Daily 24/12/2020 15 5 10 5 15 22

2 Check battery connection Daily 24/12/200 15 5 10 5 15 22

3 Check the batteries fluid level Daily 24/12/2020 15 5 10 5 15 22

4 Check engine oil for abnormal smell / water,leakage Weekly 24/12/2020 15 5 5 15 22

5 Check Noise and Vibration Weekly 24/12/2020 15 5 5 15 22

6 Clean Engine Block and Engine Room Weekly 27/12/2020 15 5 5 15 22

7 Renewal Lube Oil Engine 500 Hourly

8 Renewal Lube Oil Filter 500 Hourly

9 Renewal Fuel Oil Filter 300 Hourly

10 Renewal Filter Racor 300 Hourly

11 Check or clean Air Filter and Indikator 300 Hourly

12 Check & Tightening Hose pipe Conection 300 Hourly

13 Check Governor control actuator control 300 Hourly

14 Check & Tightening bolt nut coupling 300 Hourly

15 Check & Tightening Accu & Cable Conection 300 Hourly

16 Check & Cleaning Strainer of sea charge & Cooler 500 Hourly

17 Check & or replace Impeller seawater Pump 500 Hourly

18 Check and Cleaning Fuel tank 500 Hourly

19 Check and or renewal Zing Anode 500 Hoursly

20 Check or Renewal Air Filter and Indikator 500 Hoursly

21 Check dynamo starting valve 1000 Hoursly

Inspect Clean, Adjust, Lubricate or Replace if necessary

22 for Engine & revers gear, inspection for leakage 1000 Hoursly

Clean, Adjust, Lubricate or Replace if necessary for

23 Engine and reverse gear, inspect hoses and cable 1000 Hoursly

clamping

24 Clean, Adjust, Lubricate or Replace if necessary for 500 Hoursly

Engine and revers gear, cleaning / painting

25 Flush pump / Bilge pump, impeller 1000 Hoursly

26 Check alignment Coupling and rotor 1000 Hoursly

27 Valve clearance intake & exhuast 2000 Hoursly

Clean, Adjust, Lubricate or Replace if necessary for

28 Turbocharge 2000 Hoursly

29 Clean, Adjust, Lubricate or Replace if necessary for 2000 Hoursly

Drive Belts4) I

30 Clean or repair Fresh water pump 2000 Hoursly

31 Replace Seawater pump impeller 2000 Hoursly

32 Check and calibration fuel Injector 2500 Hoursly

33 Check clearance rotor Turbocharger 2500 Hoursly

34 Electric control panel system Calibration 4000 Hoursly

35 Safety decive control system calibration 4000 Hoursly

36 Replace Drive Belts R 4000 Hoursly

37 Replace Coolant 4000 Hoursly

38 Crank shaft deflection 4000 Hoursly

39 Altenator merger Test 4000 Hoursly

40 Top Overhaul 6000 Hoursly

41 General Overhoul 12000 Hoursly

42 Renew Battery starter 2 years

STEERING GEAR SYSTEM NO.1 & 2

1 Check Leakage & Lubricate / Cek kebocoran & beri Weekly 20/12/2020 27 3 19 3 27 20

pelumas

2 Test Control System manual and automatic Monthly 20/12/2020 27 3 19 3 27 20

5 maintenance not applicable on board

1.the Item have been done in this maintenance plan should shown in the monthly maintrenance reports accordingly2.Please mark N/A or leave blank if the

3 Test emergency steering gear system Monthly 20/12/2020 27 3 19 3 27 20

4 Inspection Hydraulic Oil system 12 month 20/12/2020 27 27

5 Overhaul Steering Pump / Overhaul pompa steering 30 month

BOW TRHUSTER SYSTEM NO.1 & 2

1 Chek Lub oil tank for Bearing Daily 19/12/2020 31 14 19 14 31 24

2 Check Lub oil pipe line system Daily 19/12/2020 31 14 19 14 31 24

Check Main phanel control electric system, relay,

3 fuse,Magnetcic contactor, PLC amphere Weekly 19/12/2020 25 14 19 14 25 27

Check ECU (engine control unit panel control system ,

4 check fuse, relay, and PCB condition Weekly 19/12/2020 25 14 19 14 25 27

5 Check display monitor on the bridge after and forward Weekly 19/12/2020 21 14 15 14 21 14

side

6 Clean LO cooler for hydraulic LO system Monthly 21 14 15 14 21 14

7 Greasing eletric motor bearing Monthly

8 Clean LO hydraulic filter formbow trhuster Monthly

9 Test solenoid eletric valve for hydraulic pump Monthly

10 Megger test system and electric motor 3 year

11 Overhaul Bow trhuster 5 year

12 Overhaul Hydraulic pump no.1 & 2 5 years

CPP Hydraulic system no.1 & 2

1 Check Leakage & Lubricate / Cek kebocoran & beri Weekly 17/12/2020 27 26 19 26 27 23

pelumas

2 Test Control System manual and automatic Monthly 17/12/2020 27 26 13 26 27 23

3 Test emergency CPP pump system Monthly 17/12/2020 27 26 13 26 27 23

4 Clean LO cooler for CPP Monthly 13 23

5 Clean and inspect LO Hydraulic expansion tank Monthly 9/7/2019 13 23

6 Check CPP oil seal system Monthly 13 23

7 Inspection Hydraulic Oil system 12 month

8 Overhaul CPP Pump / Overhaul pompa CPP 30 month

9 Overhaul CPP propeller and renewed seal 60 month

AIR COMPRESSOR FOR CEMENT SYSTEM NO.1 & 2

1 Clean air filter Weekly 21/09/2019 18 22 22 18 16

2 Clean solenoid filter Monthly 21/09/2019 18 22 22 18 16

3 Replace LO carter Monthly 26

4 Clean and lapping LP and HP valve 1500 Hoursly

5 water cooler clean 1500 Hoursly

6 Top Overhaul 3 Year

7 Complete overhaul 5 Year

PURIFIER FO

1 Clean filter Strainer Weekly 11/7/2019 27

2 Clean sensor discharge pressure Weekly 11/7/2019 27

Cek eletrci control panel system ( Relay, fuse , MCB

3 joint cable) Monthly

4 Clean purifier disc and bowl ( renew seal ring, o-ring 1000 Hours

and etc)

5 Megger test eletric motor 30 Mothly

6 General Overhaul 5 Year

OILY WATER SEPARATOR

1 Clean suction filter Weekly 19/12/2020 1 1 3

2 General check for control panel, solenoid, alarm, sensor Monthly 19/12/2020 1 1 3

and pressure switch

3 Clean solenoid valve, sensor alarm Yearly 19/12/2020 1 1

4 overhaul OWS (clean filter and tank) 30 Monthy

SEWAGE SYSTEM

1 Clean suction filter, added tablet or chemical Monthly 25 19 19 25 17

2 Flushing the system used sea water Monthly 25 19 19 25 17

2 General check control panel (( relay, fuse, MCB) Monthly 24/12/2020 25 19 19 25 17

3 Megger test eletric motor 3 Month

4 Overhaul sewage pump 5 Year

5 Clean Sewage tank 5 Year

6 maintenance not applicable on board

1.the Item have been done in this maintenance plan should shown in the monthly maintrenance reports accordingly2.Please mark N/A or leave blank if the

AIR CONDITIONER CENTRAL SYSTEM NO.1 & 2

1 Clean suction air filter Weekly 29/02/2020 25 18 8 18 25 21

2 Clean Sea water suction strainer Monthly 29/02/2020 25 18 8 18 25 21

3 Clean / Brushed tube condenser, evaporator Monthly 29/02/2020 25 18 8 18 25 21

4 Charging freon R 404 to system, and leaking test 3 Monthly 8/9/2019 25 25

General inspection eletric control panel ( fuse, relay,

5 MCB, pressure switch, temperature switch, solenoid , 3 Monthly

expansionn valve)

6 Megger test eletric motor 30 month

7 Overhaul compressor 5 Year

FREZEER REFRIGERATION SYSTEM

1 Clean suction air filter Weekly 29/02/2020 6 17 28 17 6 4

2 Clean Sea water suction strainer Monthly 29/02/2020 6 17 28 17 6 4

3 Clean / Brushed tube condenser, evaporator Monthly 29/02/2020 6 17 28 17 6 4

4 Charging freon R 404 to system, and leaking test 3 Monthly 23/12/2020

General inspection eletric control panel ( fuse, relay,

5 MCB, pressure switch, temperature switch, solenoid , 3 Monthly 11/9/2019 6 17 17 6

expansionn valve)

6 Megger test eletric motor 30 month

7 Overhaul compressor 5 Year

CHILLER REFRIGERERATION SYSTEM

1 Clean suction air filter Weekly 11/9/2019 6 23 28 23 6 7

2 Clean Sea water suction strainer Monthly 11/9/2019 6 23 28 23 6 7

3 Clean / Brushed tube condenser, evaporator Monthly 11/9/2019 6 23 28 23 6 7

4 Charging freon R 404 to system, and leaking test 3 Monthly 20/12/2020

General inspection eletric control panel ( fuse, relay,

5 MCB, pressure switch, temperature switch, solenoid , 3 Monthly 11/9/2019

expansionn valve)

6 Megger test eletric motor 30 month

7 Overhaul compressor 5 Year

FRESH WATER GENERATOR SYSTEM (FRESH WATER MAKER)

1 Clean sea water suction filter Weekly 11

2 Clean omega Filter Monthly 11

3 Repalce fine filter Monthly 11

4 Clean condenser system Monthly 11

5 General inspection control panel system Monthly 11

6 Megger test electric motor 3 Year

7 Overhaul sea water supply pump 3 Year

8 Overhaul condensat pump 3 Year

FIRE HYDRANT SYSTEM ( GS PUMP SYSTEM)

1 Greasing and Painting Routine 19/9/2019 12 5

2 Check and tihgtening bolt and nut Monthly 19/9/2019 12 5

3 Check water battery starter Monthly 5

4 Check lub oil carter Monthly 5

5 Check fresh water cooling tank Monthly 5

6 Check Noise and vibration Routine 5

7 Check or renewal packing and leakage point Monthly 5

8 Check or renewal Rubber Coupling Monthly 5

9 Check and renewal Ball Bearing 30 Monthly

10 Check or renew FO filter, LO filter and carter 3 Monthly

10 Check Alignment pump and electro motor 3 Monthly

11 Merger Test Electro Motor 30 Monthly

12 Check impeller condition 5 Year

SANITARY FRESH WATER PUMP NO.1 & 2

1 Greasing and Painting Routine 18/09/2019 23 26 19 26 23 21

2 Check and tihgtening bolt and nut Weekly 18/09/2019 23 26 19 26 23 21

3 Check Noise and vibration Weekly 18/09/2019 23 26 19 26 23 21

4 Check or renewal packing and leakage point Monthly 6 26 26 6 21

5 Check or renewal Rubber Coubling Monthly 23/12/2020 6 26 26 6 21

6 Check clean pressure switch 3 Monthly 23 26 7 26 23

7 Check and clean safety valve hydrofor tank 3 Monthly 24/12/2020 7

7 maintenance not applicable on board

1.the Item have been done in this maintenance plan should shown in the monthly maintrenance reports accordingly2.Please mark N/A or leave blank if the

8 Check and renewal Ball Bearing 3 0 Monthly

9 Check Alignment pump and electro motor 3 Monthly

10 Merger Test Electro Motor 30 Monthly

11 Check impeller condition 30 Monthly

12 Clean Hydrofor tank 30 Monthly

SANITARY SEA WATER PUMP

1 Greasing and Painting Routine 18/02/2020 21 24 7 24 21 24

2 Check and tihgtening bolt and nut Weekly 18/02/2020 21 24 7 24 21 24

3 Check Noise and vibration Weekly 18/02/2020 21 24 7 24 21 24

4 Check or renewal packing and leakage point Monthly 18/02/2020 7 24

5 Check or renewal Rubber Coubling Monthly 18/02/2020 7 7 24

6 Check clean pressure switch 3 Monthly 18/02/2020 2 7 2

Check and clean safety valve hydrofor tank 3 Monthly 18/02/2020 2 2

8 Check and renewal Ball Bearing 30 Monthly 2 2

9 Check Alignment pump and electro motor 3 Monthly 18/02/2020 2 2

10 Merger Test Electro Motor 30 Monthly 2 2

11 Check impeller condition 30 Monthly overhaul 2

12 Clean Hydrofor tank 30 Monthly

FUEL OIL CARGO PUMP

1 Greasing and Painting Routine 17/9/2019 29 23 25 23 29 12

2 Check and tihgtening bolt and nut Weekly 17/9/2019 29 23 25 23 29 12

3 Check Noise and vibration Weekly 17/9/2019 29 23 25 23 29 12

4 Check or renewal packing and leakage point Monthly 10/18/2017 25 12

5 Check and renewal Rubber Coubling Monthly 10/18/2017 12

6 Check and renewal Ball Bearing 30 Monthly

7 Check Alignment pump and electro motor 3 Monthly 10/18/2017 25

8 Merger Test Electro Motor 30 Monthly 10/18/2017 25

9 Check gear condition 30 Monthly

10 Check and clean flow meter system 6 Monthly

MUD PUMP NO.1 AND 2

1 Greasing and Painting Routine 21/09/2019 15 23 25 23 15 11 Overhoul Pump 10/4/16

2 Check and tihgtening bolt and nut Weekly 21/09/2019 15 23 25 23 15 11

3 Check Noise and vibration Weekly 21/09/2019 15 23 25 23 15 11

4 Check or renewal packing and leakage point Monthly 19-Oct-17 25 11

5 Check and renewal Rubber Coubling Monthly 19-Oct-17 11

6 Check and renewal Ball Bearing 30 Monthly

7 Check Alignment pump and electro motor 3 Monthly 19-Oct-17

8 Merger Test Electro Motor 30 Monthly 10/20/2017

9 Check gear condition 30 Monthly

10 Check and clean flow meter system 6 Monthly NA NA

FUEL OIL TRANSFER PUMP

1 Greasing and Painting Routine 28/12/2020 15 5 12 5 15 9

2 Check and tihgtening bolt and nut Weekly 28/12/2020 15 5 12 5 15 9

3 Check Noise and vibration Weekly 28/12/2020 15 5 12 5 15 9

4 Check or renewal packing and leakage point Monthly 28/12/2020 12 9

5 Check and renewal Rubber Coubling Monthly 28/12/2020 9

6 Check and clean stariner 3 Monthly 12

7 Check Alignment pump and electro motor 3 Monthly

8 Merger Test Electro Motor 30 Monthly 10/30/2017

9 Check Gear pump condition 30 Monthly

BALLAST / BALLAST PUMP

1 Greasing and Painting Routine 19/12/2020 15 13 12 13 15 8

2 Check and tihgtening bolt and nut Weekly 19/12/2020 15 13 12 13 15 8

3 Check and clean strainer Monthly 19/12/2020 15 13 12 13 15 8

4 Check or renewal packing and leakage point Monthly 19/12/2020 12 8

5 Check and renewal Rubber Coubling Monthly 19/12/2020 12 8

6 Check and renewal Ball Bearing 30 Monthly 2/10/2021

7 Check Alignment pump and electro motor 3 Monthly

8 Merger Test Electro Motor 30 Monthly 18.10.17

9 Check impeller condition 30 Monthly

8 maintenance not applicable on board

1.the Item have been done in this maintenance plan should shown in the monthly maintrenance reports accordingly2.Please mark N/A or leave blank if the

GENERAL SERVICE PUMP

1 Greasing and Painting Routine 16/9/2019 15 26 13 26 15 2

2 Check and tihgtening bolt and nut Weekly 16/9/2019 15 26 13 26 15 2

3 Check and clean strainer Monthly 16/9/2019 15 26 13 26 15 2

4 Check or renewal packing and leakage point Monthly 23/07/2019 2

5 Check and renewal Rubber Coubling Monthly 12/18/2017 2

6 Check and renewal Ball Bearing 30 Monthly

7 Check Alignment pump and electro motor 3 Monthly

8 Merger Test Electro Motor 30 Monthly 10/18/2017

9 Check impeller condition 30 Monthly

FRESH WATER CARGO PUMP

25/12/22 renewed rubber

1 Greasing and Painting Routine 25/09/2019 15 22 19 22 15 11 coupling

2 Check and tihgtening bolt and nut Weekly 25/09/2019 15 22 19 22 15 11

3 Clean strainer Monthly 27/02/2018 15 22 19 22 15 11

4 Check or renewal packing and leakage point Monthly 12/18/2017 11

5 Check and renewal Rubber Coubling Monthly 12/18/2017 11

6 Check and renewal Ball Bearing 30 Monthly

7 Check Alignment pump and electro motor 3 Monthly 10/20/2017

8 Merger Test Electro Motor 30 Monthly 10/18/2017

9 Check impeller condition 30Monthly

CEMENT COMPRESOR SYSTEM NO.1 AND 2

1 Cleaning air filter Routine 21/09/2019 18 23 23 18 15

2 Check and tihgtening bolt and nut Weekly 21/09/2019 18 23 23 18 15

3 Clean strainer LO Monthly 18 23 23 18 15

4 Check and cleaning air dryer Monthly 21/09/2019 15

5 Check and clean sea water cooler & strainer Monthly 21/09/2019 18 23 23 18 15

6 Check and renewal LO carter 30 Monthly

7 Check Alignment compressor electro motor 3 Monthly 10/17/2017

8 Merger Test Electro Motor 30 Monthly 10/30/2017

9 Test safety valve 30Monthly

10 overhaul compressor 60 monthly

ANCHOR MOORING WINDLASS SYSTEM

1 Greasing and painting Routine 14/9/2019 4 26 9 26 4 3

2 Check and thigtwen bolt and nut Weekly 14/9/2019 4 26 9 26 4 3

General check panel control ( MCB, fuse, relay, joint

3 Monthly 9 3

cable)

4 Charging LO hydraulic system 3 Monthly 14/9/2019 4 26 9 26 4

5 Clean Lo strainer 3 Monthly 14/9/2019 4 26 26 4

6 Clean 3 way valve and solenoid valve 6 Monthly

7 Megger test eletric motor 30 Monthly

8 Overhaul hydraulic pump 5 Year

9 Clean hydraulic Lo tank 5 Year

TOWING WINCH AND TUGGER WINCH SYSWTEM

1 Greasing and painting Routine 10/9/2019 11 18 11 18 11 14

2 Check and thigtwen bolt and nut Weekly 10/9/2019 11 18 11 18 11 14

General check panel control ( MCB, fuse, relay, joint

3 cable) Monthly 11 18 11 18 11 14

4 Charging LO hydraulic system 3 Monthly 10/9/2019

5 Clean Lo strainer 3 Monthly 10/9/2019 11 11

6 Clean 3 way valve and solenoid valve 6 Monthly

7 Megger test eletric motor 30 Monthly

8 Overhaul hydraulic pump 5 Year

9 Clean hydraulic Lo tank 5 Year

SHARK JAW TOWING PIN

1 Greasing and painting Routine 23/12/2020 11 16 11 16 11 14

2 Check and thigtwen bolt and nut Weekly 23/12/2020 11 16 11 16 11 14

General check panel control ( MCB, fuse, relay, joint

3 cable, limit switch) Monthly 10/24/2017 11 11 14

9 maintenance not applicable on board

1.the Item have been done in this maintenance plan should shown in the monthly maintrenance reports accordingly2.Please mark N/A or leave blank if the

4 Charging LO hydraulic system 3 Monthly

5 Clean Lo strainer 3 Monthly

6 Clean 3 way valve and solenoid valve 6 Monthly 10/24/2017

7 Megger test eletric motor 30 Monthly 10/20/2017

8 Overhaul hydraulic pump 5 Year

9 Clean hydraulic Lo tank 5 Year

DAVID CRANE

1 Greasing and painting Routine 28/09/2019 18 17 17 18 12

2 Check and thigtwen bolt and nut Weekly 28/09/2019 18 17 17 18 12

General check panel control ( MCB, fuse, relay, joint

3 Monthly 10/26/2017 12

cable, limit switch)

4 Charging LO hydraulic system 3 Monthly 10/26/2017

5 Clean Lo strainer 3 Monthly 10/26/2017

6 Clean 3 way valve and solenoid valve 6 Monthly

7 Megger test eletric motor 30 Monthly 10/30/2017

8 Overhaul hydraulic pump 5 Year

9 Clean hydraulic Lo tank 5 Year

RESCUE BOAT CRANE

1 Greasing and painting Routine 28/09/2019 11 29 19 29 11 7

2 Check and thigtwen bolt and nut Weekly 28/09/2019 11 29 19 29 11 7

General check panel control ( MCB, fuse, relay, joint

3 cable, limit switch) Monthly 28/09/2019 19 7

4 Charging LO hydraulic system 3 Monthly 10/26/2017

5 Clean Lo strainer 3 Monthly 10/26/2017

6 Clean 3 way valve and solenoid valve 6 Monthly 9/26/2017

7 Megger test eletric motor 30 Monthly

8 Overhaul hydraulic pump 5 Year

9 Clean hydraulic Lo tank 5 Year

GALLEY EXHAUST FAN BLOWER

1 Clean air filet Monthly 11/9/2019 11 16 19 16 11 17

2 Check and greasing exhaust manifold valve Monthly 11/9/2019 11 16 19 16 11

3 General check control panel ( MCB, fuse, relay, joint Monthly 11/9/2019 11 16 16 11 17

cable )

4 Megger test eletric motor 30 Month

5 Overhaul 5 year

GALLEY ELECTRIC COCKING RANGE

1 Clean plate area Routine 11/9/2019 10 17

2 General check control panel (MCB,Fuse, relay socket, Monthly 10/6/2017 10 17

element heater)

3 Clean element heater Monthly 10/6/2017 7 17

4 Megger test 30 Month

5 Repalce element heater 30 Month

SHAFT AND STERN TUBE , INTERMEDIATE SHAFT BEARING AND PROPLEER

1 Greasing and painting Routine 10/9/2017 18 9 19 9 18 22

2 Check packing and leakage point Routine 12/9/2019 18 9 19 9 18 22

3 Charging LO gear system Routine 10/9/2017 19 22

4 Check and tightening Routine 10/9/2017 19 22

5 Check seal and alignment ( clearence shaft) 30 Monthly

6 Balancing Propeller 30 Monthly

7 Polishing blade, balancing and repair 5 Year

8 Polishing shaft propeller and check clearence 5 Year

OVER BOARD VALVE

1 Painting an greasing Routine 20/12/2020 25 30 17 30 25 22

2 Test open and close Routine 20/12/2020 25 30 17 30 25 22

3 Chek and tightening Bolt and nut Routine 20/12/2020 25 30 17 30 25 22

4 Check packing and leakage point 30 Monthly

5 Renew gland packing 30 Monthly

CHECK VALVE SEA WATER

1 Painting an greasing Routine 17/12/2020 25 7 19 7 25 22

10 maintenance not applicable on board

1.the Item have been done in this maintenance plan should shown in the monthly maintrenance reports accordingly2.Please mark N/A or leave blank if the

2 Test open and close Routine 17/12/2020 25 7 19 7 25 22

3 Chek and tightening Bolt and nut Routine 17/12/2020 25 7 19 7 25 22

4 Check packing and leakage point 30 Monthly

5 Renew gland packing 30 Monthly

SEA WATER BALLAST VALVE

1 Painting an greasing Routine 11/12/2020 25 17 14 17 25 22

2 Test open and close Routine 11/12/2020 25 17 14 17 25 22

3 Chek and tightening Bolt and nut Routine 11/12/2020 25 17 14 17 25 22

4 Check packing and leakage point 30 Monthly

5 Renew gland packing 30 Monthly

FUEL OIL TRANSFER VALVE

1 Painting an greasing Routine 27/12/2020 25 17 7 17 25 22

2 Test open and close Routine 27/12/2020 25 17 7 17 25 22

3 Chek and tightening Bolt and nut Routine 27/12/2020 25 17 7 17 25 22

4 Check packing and leakage point 30 Monthly

5 Renew gland packing 30 Monthly

BYPASS VALVE

1 Painting an greasing Routine 22/12/2020 25 17 19 17 25 22

2 Test open and close Routine 22/12/2020 25 17 19 17 25 22

3 Chek and tightening Bolt and nut Routine 22/12/2020 25 17 19 17 25 22 BYPASS valve MUD tank

4 Check packing and leakage point 30 Monthly 22/12/2020 BYPASS valve MUD tank

5 Renew gland packing 30 Monthly

BILGES VALVE

1 Painting an greasing Routine 26/12/2020 25 17 19 17 25 22

2 Test open and close Routine 26/12/2020 25 17 19 17 25 22

3 Chek and tightening Bolt and nut Routine 26/12/2020 25 17 19 17 25 22

4 Check packing and leakage point 30 Monthly

5 Renew gland packing 30 Monthly

PIPING SYSTEM

1 Maintenance & Inspection Sea Water System 6 Monthly 29/7/2018 15

2 Maintenance & Inspection Fresh Water System 6 Monthly 29/7/2018 15

3 Maintenance & Inspection Bilge & Ballast System 6 Monthly 29/7/2018 15

4 Maintenance & Inspection FO & LO System 6 Monthly 8/4/2017

ELECTRIC EQUIPMENT

1 Checking Liquid Density Emergency Battery System Monthly 23/12/2020 18 22 19 22 18 21

2 Clean Battery Supply power 24 volt Monthly 23/12/2020 18 22 22 18 21

3 Inspection Electric Circuits/Cable AC and DC Monthly 23/12/2020 18 22 22 18 21

4 Check Main Breaker Monthly 23/12/2020 18 22 22 18 21

5 Check Contactor/Fuse Monthly 23/12/2020 21

6 Emergency Lamp Function Test Monthly 23/12/2020 21

7 Inspection Main Switch Board 6 Monthly

8 Inspection Transformer 6 Monthly

9 Merger Test Main Switch Board 30 Monthly

ALARM AND SAFETY DEVICE

1 Function Test Fire Alarm Monthly 12/12/2020 4 20 19 20 4 7

2 Function Test General Alarm Monthly 12/12/2020 4 20 19 20 4 7

3 Function Test ME Alarm 3 Monthly 12/12/2020 4 20 19 20 4

4 Function Test AE Alarm 3 Monthly 12/12/2020 4 20 19 20 4

5 Function Test Towing Winch Alarm 3 Monthly 19

6 Function Test Steering Gear Alarm 3 Monthly 26/04/2019 19

7 Function Test ME Emergency Stop 3 Monthly 19

8 Function Test Overspeed Trip 3 Monthly 19

9 Function Test Main Switchboard Trip 3 Monthly 19

10 Function Test FO Tank High Level 3 Monthly

OTHERS

1 Check Installation Emergency Shutdown System Monthly 17/12/2020

11 maintenance not applicable on board

1.the Item have been done in this maintenance plan should shown in the monthly maintrenance reports accordingly2.Please mark N/A or leave blank if the

Quick Closing Valve To Be Tested Monthly 17/12/2020 14 20 19 20 14 7

2 Check Ventilation Flap (rubber packing & hinge) Monthly 17/12/2020 14 20 19 20 14 7

3 Emergency Stopped For Fan & Pump To Test Monthly 17/12/2020 14 20 20 14 7

Main Sea Chect Valve To Shut & Close Manually, Clean

4 strainer P/S 3 Monthly 17/12/2020

5 Check, Test & Activate Ship Air Horn Monthly 28/09/2019 14 20 17 20 14 7

6 CO2 system to be test Monthly 12/16/2017

Fuel Oil tank no.1 P/S

1 Visual Inspection inside Tank B/O Observation

2 Sounding Quantity Routine 24/12/2020 31 7 13 7 31 29

3 Test discharge and check Valve Routine 24/12/2020 31 7 13 7 31 29

4 Man hole and cover Greasing & Painting Monthly 31 7 13 7 31 29

5 Rubber Packing Condition 3 Monthly

6 Renewal Zinc Anode 24 Monthly

7 Tank Cleaning 24 Monthly

8 Pressure Tank Test 48 Monthly

9 Internal Painting 48 Monthly

Fuel Oil tank no.2 P/S

1 Visual Inspection inside Tank B/O Observation

2 Sounding Quantity Routine 23/12/2020 31 7 13 7 31 29

3 Test discharge and check Valve Routine 23/12/2020 31 7 13 7 31 29

4 Man hole and cover Greasing & Painting Monthly 31 7 11 7 31 29

5 Rubber Packing Condition 3 Monthly 31 7 11 7 31

6 Renewal Zinc Anode 24 Monthly

7 Tank Cleaning 24 Monthly

8 Pressure Tank Test 48 Monthly

9 Internal Painting 48 Monthly

Fuel Oil tank no.3 P/S

1 Visual Inspection inside Tank Conditional 31 7 7 31 29

2 Sounding Quantity Routine 23/12/2020 31 7 13 7 31 29

3 Test discharge and check Valve Routine 23/12/2020 31 7 13 7 31 29

4 Man hole and cover Greasing & Painting Monthly 31 7 13 7 31 29

5 Rubber Packing Condition 3 Monthly 13

6 Renewal Zinc Anode 24 Monthly

7 Tank Cleaning 24 Monthly

8 Pressure Tank Test 48 Monthly

9 Internal Painting 48 Monthly

Fuel Oil tank no.4 P/S

1 Visual Inspection inside Tank Conditional 31 7 7 31 29

2 Sounding Quantity Routine 9/30/2022 31 7 13 7 31 29

3 Test discharge and check Valve Routine 12/30/2022 31 7 13 7 31 29

4 Man hole and cover Greasing & Painting Monthly 31 7 7 31 29

5 Rubber Packing Condition 3 Monthly

6 Renewal Zinc Anode 24 Monthly

7 Tank Cleaning 24 Monthly

8 Pressure Tank Test 48 Monthly

9 Internal Painting 48 Monthly

MUD tanks no.1 P/S

1 Visual Inspection inside Tank Conditional 23/12/2020 3 Cleaned TK 10/5/17

2 Sounding Quantity Routine 23/12/2020

3 Test discharge and check Valve Routine 23/12/2020

4 Man hole and cover Greasing & Painting Monthly 23/12/2020

5 Rubber Packing Condition 3 Monthly 23/12/2020

6 Renewal Zinc Anode 24 Monthly

7 Tank Cleaning 24 Monthly

8 Pressure Tank Test 48 Monthly

9 Internal Painting 48 Monthly

MUD tank no.2 P/S

12 maintenance not applicable on board

1.the Item have been done in this maintenance plan should shown in the monthly maintrenance reports accordingly2.Please mark N/A or leave blank if the

1 Visual Inspection inside Tank Conditional 21/09/2019 22 4 3 4 22 24

2 Sounding Quantity Routine 21/09/2019 22 4 4 22 24

3 Test discharge and check Valve Routine 18/07/2019 22 4 4 22 24

4 Man hole and cover Greasing & Painting Monthly 18/07/2019

5 Rubber Packing Condition 3 Monthly 18/07/2019

6 Renewal Zinc Anode 24 Monthly

7 Tank Cleaning 24 Monthly

8 Pressure Tank Test 48 Monthly

9 Internal Painting 48 Monthly

Fuel Oil Daily tank P/S

1 Visual Inspection inside Tank Conditional 11

2 Sounding Quantity Routine 12/12/2022 everyday 18 13 18 everyday 7

3 Test discharge and check Valve Routine 12/12/2022 6 18 13 18 6 7

4 Man hole and cover Greasing & Painting Monthly 12/12/2022 13 7

5 Rubber Packing Condition 3 Monthly 12/12/2022

6 Renewal Zinc Anode 24 Monthly

7 Tank Cleaning 24 Monthly

8 Pressure Tank Test 48 Monthly

9 Internal Painting 48 Monthly

Bilge Holding tank (P)

1 Visual Inspection inside Tank Conditional

2 Sounding Quantity Routine 30/09/2019 31 13 11 13 31 29

3 Test discharge and check Valve Routine 10/10/2017 31 13 11 13 31 29

4 Man hole and cover Greasing & Painting Monthly 10/10/2022

5 Rubber Packing Condition 3 Monthly 10/10/2022

6 Renewal Zinc Anode 24 Monthly

7 Tank Cleaning 24 Monthly

8 Pressure Tank Test 48 Monthly

9 Internal Painting 48 Monthly

Dirty Oil tank (S)

1 Visual Inspection inside Tank Conditional

2 Sounding Quantity Routine 9/30/2022 31 28 11 28 31 29

3 Test discharge and check Valve Routine 10/10/2022 31 28 11 28 31 29

4 Man hole and cover Greasing & Painting Monthly 10/10/2022 11

5 Rubber Packing Condition 3 Monthly 10/10/2022 11

6 Renewal Zinc Anode 24 Monthly

7 Tank Cleaning 24 Monthly

8 Pressure Tank Test 48 Monthly

9 Internal Painting 48 Monthly

Foam tank (P)

1 Visual Inspection inside Tank Conditional 11/19/2022

2 Sounding Quantity Routine 10/10/2017 7 11 7 9

3 Test discharge and check Valve Routine 11/19/2022 7 11 7 9

4 Man hole and cover Greasing & Painting Monthly 11/19/2022 9

5 Rubber Packing Condition 3 Monthly 11/19/2022

6 Renewal Zinc Anode 24 Monthly

7 Tank Cleaning 24 Monthly

8 Pressure Tank Test 48 Monthly

9 Internal Painting 48 Monthly

Detergent tank (S)

1 Visual Inspection inside Tank Conditional 31/07/2019

2 Sounding Quantity Routine 31/07/2019 10 5 11 5 10 11

3 Test discharge and check Valve Routine 31/07/2019 10 5 11 5 10 11

4 Man hole and cover Greasing & Painting Monthly 31/07/2019 11

5 Rubber Packing Condition 3 Monthly 10/10/2017

6 Renewal Zinc Anode 24 Monthly

7 Tank Cleaning 24 Monthly

8 Pressure Tank Test 48 Monthly

9 Internal Painting 48 Monthly

13 maintenance not applicable on board

1.the Item have been done in this maintenance plan should shown in the monthly maintrenance reports accordingly2.Please mark N/A or leave blank if the

Hydraulic oil tank (P)

1 Visual Inspection inside Tank Conditional 12

2 Sounding Quantity Routine 11/12/2022 31 18 12 18 31 28

3 Test discharge and check Valve Routine 1/12/2023 31 18 12 18 31 28

4 Man hole and cover Greasing & Painting Monthly 12/10/2022 12

5 Rubber Packing Condition 3 Monthly 10/10/2017

6 Renewal Zinc Anode 24 Monthly

7 Tank Cleaning 24 Monthly

8 Pressure Tank Test 48 Monthly

9 Internal Painting 48 Monthly

Hydraulic oil tank (S)

1 Visual Inspection inside Tank Conditional

2 Sounding Quantity Routine 12/12/2022 31 18 13 18 31 28

3 Test discharge and check Valve Routine 12/12/2022 31 18 13 18 31 28

4 Man hole and cover Greasing & Painting Monthly 10/10/2022 13

5 Rubber Packing Condition 3 Monthly 10/10/2022 13

6 Renewal Zinc Anode 24 Monthly

7 Tank Cleaning 24 Monthly

8 Pressure Tank Test 48 Monthly

9 Internal Painting 48 Monthly

Cement Tk no.1

1 Visual Inspection inside Tank Conditional 31 17 17 31

2 Sounding Quantity Routine 31 17 17 31 28

3 Test discharge and check Valve Routine 31 17 17 31 28

4 Man hole and cover Greasing & Painting Monthly 31 17 17 31 28

5 Rubber Packing Condition 3 Monthly 31 17 17 31

6 Renewal Zinc Anode 24 Monthly

7 Tank Cleaning 24 Monthly 15/11/2019

8 Pressure Tank Test 48 Monthly

9 Internal Painting 48 Monthly

Cement Tk no.2

Cement TkVisual Inspection inside Tank Conditional 31 16 16 31

Cement TkSounding Quantity Routine 31 16 16 31 28

Cement TkTest discharge and check Valve Routine 31 16 16 31 28

Cement TkMan hole and cover Greasing & Painting Monthly 31 16 16 31 28

Cement TkRubber Packing Condition 3 Monthly 31 16 16 31

Cement TkRenewal Zinc Anode 24 Monthly

Cement TkTank Cleaning 24 Monthly 15/11/2019

Cement TkPressure Tank Test 48 Monthly

Cement TkInternal Painting 48 Monthly

Cement Tk No.3

1 Visual Inspection inside Tank Conditional 31 16 16 31

2 Sounding Quantity Routine 31 16 16 31 28

3 Test discharge and check Valve Routine 31 16 16 31 28

4 Man hole and cover Greasing & Painting Monthly 31 16 16 31 28

5 Rubber Packing Condition 3 Monthly 31 16 16 31

6 Renewal Zinc Anode 24 Monthly

7 Tank Cleaning 24 Monthly 15/11/2019

8 Pressure Tank Test 48 Monthly

9 Internal Painting 48 Monthly

Cement Tk No.4

1 Visual Inspection inside Tank Conditional 31 16 16 31

2 Sounding Quantity Routine 31 16 16 31 28

3 Test discharge and check Valve Routine 31 16 16 31 28

4 Man hole and cover Greasing & Painting Monthly 31 16 16 31 28

5 Rubber Packing Condition 3 Monthly 31 16 16 31

6 Renewal Zinc Anode 24 Monthly

7 Tank Cleaning 24 Monthly 15/11/2019

8 Pressure Tank Test 48 Monthly

9 Internal Painting 48 Monthly

14 maintenance not applicable on board

1.the Item have been done in this maintenance plan should shown in the monthly maintrenance reports accordingly2.Please mark N/A or leave blank if the

You might also like

- F-IMP-007 Monthly Planned Work Schedule and Progress Monitoring ReportDocument1 pageF-IMP-007 Monthly Planned Work Schedule and Progress Monitoring ReportTrisha TanNo ratings yet

- Drew Marine Tank Cleaning ManualDocument102 pagesDrew Marine Tank Cleaning ManualStasio8091% (11)

- Laporan Dialy Pica, 29 April 2023, MalamDocument2 pagesLaporan Dialy Pica, 29 April 2023, MalamJaelani MalikNo ratings yet

- Ship Particular MBDocument2 pagesShip Particular MBromi.arvNo ratings yet

- Wallem: To Whomsoever It May ConcernDocument3 pagesWallem: To Whomsoever It May Concernshubham purohitNo ratings yet

- Non Mobile Equip Pre Mainten - Jan-24Document1 pageNon Mobile Equip Pre Mainten - Jan-24QADEER SHANNo ratings yet

- Checklist 08 Ship Equipment Maintenance Plan S-8917-MD Main Engine Performance DataDocument1 pageChecklist 08 Ship Equipment Maintenance Plan S-8917-MD Main Engine Performance DataJezrell JaravataNo ratings yet

- ES1745 Installation Instructions Rev - CDocument12 pagesES1745 Installation Instructions Rev - CIfran Sierra100% (1)

- Certificate of Bollard Pull - TRICAHUE IDocument2 pagesCertificate of Bollard Pull - TRICAHUE IRuben Rodriguez100% (1)

- 40 - Anchor Handling Procedure - 230705 - 171155Document44 pages40 - Anchor Handling Procedure - 230705 - 171155Tao HienNo ratings yet

- 006 CPP Shafting-Rudder 20-21Document2 pages006 CPP Shafting-Rudder 20-21AlagesanNo ratings yet

- DRL Atk 2010 - ReviewDocument5 pagesDRL Atk 2010 - ReviewDaniel Fr SinagaNo ratings yet

- 0370-AGA-0005 - I&MM Rev. Agosto 99Document44 pages0370-AGA-0005 - I&MM Rev. Agosto 99Carlos Rafael Uriarte VasquezNo ratings yet

- n19 Grey WaterDocument2 pagesn19 Grey WaterJames CKNo ratings yet

- 2024-04-13 & 14 FCO Daily Report - Day 11 & 12 WSDocument7 pages2024-04-13 & 14 FCO Daily Report - Day 11 & 12 WSAnggelo P.D.No ratings yet

- Form Check List Maintenance: Activity 250 500 1000 2000 RemarksDocument1 pageForm Check List Maintenance: Activity 250 500 1000 2000 Remarksferry saputra100% (2)

- SAIPEM MS Grounding & Lightning ProtectionDocument20 pagesSAIPEM MS Grounding & Lightning Protectionsyam prasad50% (2)

- eqtryqetrDocument3 pageseqtryqetrRé Marc TathyNo ratings yet

- BGL - Pms Crane LibherrDocument6 pagesBGL - Pms Crane LibherrAbdul BasitNo ratings yet

- Unloading Arm Datasheet: Crude Oil Unloading and Pumping ProjectDocument2 pagesUnloading Arm Datasheet: Crude Oil Unloading and Pumping Projectbecpavan0% (1)

- Vessel CategorisationDocument12 pagesVessel CategorisationbenNo ratings yet

- Full Plant Survey MAY 14, 2014 Minera Cerro Bayo: July 9, 2014Document49 pagesFull Plant Survey MAY 14, 2014 Minera Cerro Bayo: July 9, 2014ZeleinhoNo ratings yet

- Rachit Marine CVDocument4 pagesRachit Marine CVnaiko.No ratings yet

- Synthetic-Based Mud Report No. 39: LLOG ExplorationDocument1 pageSynthetic-Based Mud Report No. 39: LLOG Explorationadvantage025No ratings yet

- 2.TSR Finish041cv - Energy Baru Riau703700 (Main Pump Leak)Document9 pages2.TSR Finish041cv - Energy Baru Riau703700 (Main Pump Leak)Adhe Sanjaya KusumaNo ratings yet

- Unloading Arm DatasheetDocument2 pagesUnloading Arm DatasheetbecpavanNo ratings yet

- ghn,dxghjdxDocument3 pagesghn,dxghjdxRé Marc TathyNo ratings yet

- Jms Demolishing RGTP p20220019 Esb Con Jms 9243 0002 ADocument14 pagesJms Demolishing RGTP p20220019 Esb Con Jms 9243 0002 Aamir hakimNo ratings yet

- Work Order: VN 23515383 6 - MiscellaneousDocument2 pagesWork Order: VN 23515383 6 - MiscellaneoushungphanNo ratings yet

- Certificate: Cv. Solas Marine IndonesiaDocument8 pagesCertificate: Cv. Solas Marine Indonesiamasyithah fadhaniNo ratings yet

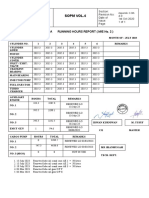

- CO 1 # 4 - SOPM V4 APP 2.24A Running Hours Report (No. 2)Document1 pageCO 1 # 4 - SOPM V4 APP 2.24A Running Hours Report (No. 2)sukhaidir suripnoNo ratings yet

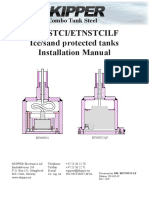

- Etnstci/Etnstcilf Ice/sand Protected Tanks Installation ManualDocument14 pagesEtnstci/Etnstcilf Ice/sand Protected Tanks Installation ManualRafael ReisNo ratings yet

- se(ty(ty(reDocument3 pagesse(ty(ty(reRé Marc TathyNo ratings yet

- Pressure Vessel Design CalculationsDocument127 pagesPressure Vessel Design Calculationsajayghosh314086% (22)

- Pressure Vessel Design Calculations - by Abdel Halim Galala PDFDocument127 pagesPressure Vessel Design Calculations - by Abdel Halim Galala PDFsizmaru100% (1)

- E-021 Auxiliary Engine Performance.04Document2 pagesE-021 Auxiliary Engine Performance.04Rizky Sapugungdo100% (1)

- Du1438 - 1010 - Final Intact Stability Booklet - Rev 2Document492 pagesDu1438 - 1010 - Final Intact Stability Booklet - Rev 2Amr AbdelkafyNo ratings yet

- Laporan Dialy Pica, 27 April 2023, SiangDocument2 pagesLaporan Dialy Pica, 27 April 2023, SiangJaelani MalikNo ratings yet

- S-111003-02FRM (OIL SPIIL ) Drill Record_113315Document5 pagesS-111003-02FRM (OIL SPIIL ) Drill Record_113315yo binNo ratings yet

- A/C Model: SAAB 340B+: C&L Aerospace - Aircraft SpecificationsDocument4 pagesA/C Model: SAAB 340B+: C&L Aerospace - Aircraft SpecificationsHiroKoNo ratings yet

- 1.appendix 25.32 - Vessel Pre-Mobilization Inspection Checklist (Rev.02 - 2022) - 18.02.2023Document14 pages1.appendix 25.32 - Vessel Pre-Mobilization Inspection Checklist (Rev.02 - 2022) - 18.02.2023mohamed hathilNo ratings yet

- Arabian Fal Limited Company: 6600036109 RPO Line# 6510966428 Service Line Item# TK 103b Direct / Part of L.I. DescriptionDocument4 pagesArabian Fal Limited Company: 6600036109 RPO Line# 6510966428 Service Line Item# TK 103b Direct / Part of L.I. DescriptionGurumoorthy RajavijayanNo ratings yet

- NO.: D-2-01-03-01-04: Testing Kit Details Test Perfo Rmed Make Rating / Measu Ring Range Date of Last CalibrationDocument39 pagesNO.: D-2-01-03-01-04: Testing Kit Details Test Perfo Rmed Make Rating / Measu Ring Range Date of Last Calibrationmayur dhandeNo ratings yet

- Pipe, Ma Sec To FR BK Hose, R 51410-67L40Document4 pagesPipe, Ma Sec To FR BK Hose, R 51410-67L40majidNo ratings yet

- 3rd Engineer ANKUSH VERMA CV.-1222-1Document4 pages3rd Engineer ANKUSH VERMA CV.-1222-1Anshu VermaNo ratings yet

- C22-Yb60-M-4763 - 0 Sa3-Ps2, Butterfly Valve, Operating ManualsDocument173 pagesC22-Yb60-M-4763 - 0 Sa3-Ps2, Butterfly Valve, Operating ManualssartajNo ratings yet

- #Operating Manual r1Document274 pages#Operating Manual r1tri arwindaNo ratings yet

- Stability Design of Articulated Concrete Mattress-Revision 5-Eil Approved in Code1Document87 pagesStability Design of Articulated Concrete Mattress-Revision 5-Eil Approved in Code1SAUGAT DUTTANo ratings yet

- WK231207 Mill CertificateDocument1 pageWK231207 Mill CertificatemrwolveringNo ratings yet

- qreg ergDocument3 pagesqreg ergRé Marc TathyNo ratings yet

- COS Oil Analysis Sample ReportDocument2 pagesCOS Oil Analysis Sample ReportpuryadianatiNo ratings yet

- UntitledDocument1 pageUntitledCLAUDE BIRIKUNZIRANo ratings yet

- DHL30291 C 0Document1 pageDHL30291 C 0Joel MinafiNo ratings yet

- EMX 00 E 122b - ET99 CL 003-en-A-Acid Cleaning Procedure and Supporting DocumentsDocument235 pagesEMX 00 E 122b - ET99 CL 003-en-A-Acid Cleaning Procedure and Supporting DocumentsRichardLemusNo ratings yet

- Oil Spill Remediation: Colloid Chemistry-Based Principles and SolutionsFrom EverandOil Spill Remediation: Colloid Chemistry-Based Principles and SolutionsNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Wear: Materials, Mechanisms and PracticeFrom EverandWear: Materials, Mechanisms and PracticeGwidon W. StachowiakNo ratings yet

- Time Line Cost Perusahaan Pelayaran revisedDocument45 pagesTime Line Cost Perusahaan Pelayaran revisedGustinussinagaNo ratings yet

- FM-S-TECH-03.01A PMS Deck AHTSDocument7 pagesFM-S-TECH-03.01A PMS Deck AHTSGustinussinagaNo ratings yet

- Cargo Out Jamut to ISP Report (35)Document3 pagesCargo Out Jamut to ISP Report (35)GustinussinagaNo ratings yet

- Denah FurnitureDocument1 pageDenah FurnitureGustinussinagaNo ratings yet

- Time SheetDocument4 pagesTime SheetGustinussinagaNo ratings yet

- Pod Kargo 31 Mei 2022Document6 pagesPod Kargo 31 Mei 2022GustinussinagaNo ratings yet

- Po 21701050 - TB P 112 - PST Grogot-Jetty Tanah MerahDocument1 pagePo 21701050 - TB P 112 - PST Grogot-Jetty Tanah MerahGustinussinagaNo ratings yet

- Gi General Information PDFDocument9 pagesGi General Information PDFGustinussinagaNo ratings yet

- Design of Hose Reel System: - Nozzle: P 200 Kpa 0.4 L/SDocument36 pagesDesign of Hose Reel System: - Nozzle: P 200 Kpa 0.4 L/Sمحمد القدومي100% (2)

- Omm Wa380-3Document235 pagesOmm Wa380-3tania fajarwatiNo ratings yet

- Fuel Supply Agreement - LNG - UI 2021 (407769612.1)Document54 pagesFuel Supply Agreement - LNG - UI 2021 (407769612.1)Edmund KhoveyNo ratings yet

- Childe Master SpreadsheetDocument33 pagesChilde Master SpreadsheetSelino CruzNo ratings yet

- MF52D-103f-3950 NTC ThermistorDocument3 pagesMF52D-103f-3950 NTC ThermistorROHAN DARVENo ratings yet

- Theoretical and Conceptual Framework To Design Efficient Dye-Sensitized Solar Cells (DSSCS) : Molecular Engineering by DFT MethodDocument11 pagesTheoretical and Conceptual Framework To Design Efficient Dye-Sensitized Solar Cells (DSSCS) : Molecular Engineering by DFT MethodTomas Delgado MontielNo ratings yet

- Unit - 2 Developing Life Skills Study Material Culture and CommunicationDocument8 pagesUnit - 2 Developing Life Skills Study Material Culture and CommunicationLakshita NainNo ratings yet

- Technical Data PM50-6ADocument3 pagesTechnical Data PM50-6ADodi HermawanNo ratings yet

- National Maritime Center: U.S.C.G. Merchant Marine Exam First Assistant Engineer Q514 Motor Plants (Sample Examination)Document35 pagesNational Maritime Center: U.S.C.G. Merchant Marine Exam First Assistant Engineer Q514 Motor Plants (Sample Examination)Flo MarineNo ratings yet

- Kuliah 2 Perancangan KapalDocument21 pagesKuliah 2 Perancangan KapalJusmaWahidahNo ratings yet

- PrEN 50530-The New European Standard For PerformanDocument6 pagesPrEN 50530-The New European Standard For PerformanJEY KEYNo ratings yet

- Inter 56632 Oil Soft Offer FobDocument8 pagesInter 56632 Oil Soft Offer Fobisam mansouriNo ratings yet

- Flashcards - 2.3 Domestic Uses and Safety - AQA Physics GCSEDocument25 pagesFlashcards - 2.3 Domestic Uses and Safety - AQA Physics GCSEakio haruNo ratings yet

- Case Study Metals Use of AlloysDocument8 pagesCase Study Metals Use of AlloysNamrata MaheshwariNo ratings yet

- NETL Life Cycle Inventory Data - Detailed Spreadsheet Documentation DS Sheet InformationDocument28 pagesNETL Life Cycle Inventory Data - Detailed Spreadsheet Documentation DS Sheet InformationParveen SalariaNo ratings yet

- Magazine Research PaperDocument4 pagesMagazine Research Papercam3tckm100% (1)

- Engineering Utilities Midterm NotesDocument4 pagesEngineering Utilities Midterm NotesMarycorNo ratings yet

- Chris - Electrician CVDocument1 pageChris - Electrician CVchris_dalzellNo ratings yet

- Fotis - SP220004 - 12W Spike LightDocument2 pagesFotis - SP220004 - 12W Spike Lightmohd1996No ratings yet

- 2017.04.17 Bidding Documents For Dist - HanguDocument40 pages2017.04.17 Bidding Documents For Dist - HanguYasir ShahzadNo ratings yet

- Máquinas Pra DLCDocument43 pagesMáquinas Pra DLCrenatoeliegeNo ratings yet

- ADDC System Safety RulesDocument166 pagesADDC System Safety RulesksarawanNo ratings yet

- 2018 Lift Station Cover-Spec-Drawings 07162018 FINALDocument41 pages2018 Lift Station Cover-Spec-Drawings 07162018 FINALRyanNo ratings yet

- Konark SolarDocument7 pagesKonark SolarAdedotun OlanrewajuNo ratings yet

- Commander SK Technical Manual DataDocument122 pagesCommander SK Technical Manual DataBlelebNo ratings yet

- Bushong: Radiologic Science For Technologists, 11th EditionDocument4 pagesBushong: Radiologic Science For Technologists, 11th Editiongasai gasaiNo ratings yet

- Annual LNG Transport, Handling & Storage Forum, Chairani Rachmatullah - PLNDocument17 pagesAnnual LNG Transport, Handling & Storage Forum, Chairani Rachmatullah - PLNShah Reza DwiputraNo ratings yet

- AR-053 Rooftop Air Conditioner (EN) 12-2022Document2 pagesAR-053 Rooftop Air Conditioner (EN) 12-2022Blog TeknisiNo ratings yet

- Mass Combi Ultra: Multi Purpose Charger InverterDocument32 pagesMass Combi Ultra: Multi Purpose Charger InverterPr. Samuel CostaNo ratings yet

- Gas HydrateDocument54 pagesGas Hydratefatma belkacemiNo ratings yet