Professional Documents

Culture Documents

HT Waiver - 67B-ST-52 JT-16

HT Waiver - 67B-ST-52 JT-16

Uploaded by

mohamadyusuf1989Copyright:

Available Formats

You might also like

- Hvac PM Service Checklist ContractorDocument1 pageHvac PM Service Checklist Contractorudupiganesh3069100% (2)

- 300D 310D and 315D Backhoe Loader IntroductionDocument7 pages300D 310D and 315D Backhoe Loader Introductionhenry ibañez100% (1)

- Minor Electrical Installation Works - GreenDocument2 pagesMinor Electrical Installation Works - GreenPopescuLaurentiuNo ratings yet

- 7ss - Busbar Low Imp Relay Test-1Document17 pages7ss - Busbar Low Imp Relay Test-1Ravi100% (3)

- Saudi Aramco Test ReportDocument6 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Engineering Specification: ESFU5A-8079-AADocument5 pagesEngineering Specification: ESFU5A-8079-AAjavier ortizNo ratings yet

- Senior High School: Emilio Aguinaldo College City of Dasmariñas, CaviteDocument7 pagesSenior High School: Emilio Aguinaldo College City of Dasmariñas, CaviteNicole De AsisNo ratings yet

- QCR W 2014Document3 pagesQCR W 2014Madhan KannanNo ratings yet

- Ab-083f Const Data Report Piping Sys Foreign Supplemental PagesDocument2 pagesAb-083f Const Data Report Piping Sys Foreign Supplemental Pagesmansih457No ratings yet

- Pages From 30.99.97.1612 Rev.1 SMR - Stock Material Request GuidelinesDocument1 pagePages From 30.99.97.1612 Rev.1 SMR - Stock Material Request GuidelinesPradeepNo ratings yet

- 016Document6 pages016Moinullah Khan AteeqNo ratings yet

- Ab-083f Const Data Report Piping Sys ForeignDocument1 pageAb-083f Const Data Report Piping Sys Foreignflores.john.chNo ratings yet

- Ab-083f Const Data Report Piping Sys ForeignDocument1 pageAb-083f Const Data Report Piping Sys Foreignmansih457No ratings yet

- QIP TT 307 PIPING WORK - RevisedDocument2 pagesQIP TT 307 PIPING WORK - Revisedsuria qaqcNo ratings yet

- ITP-P-001 ITP For Above Ground Piping Rev. ADocument9 pagesITP-P-001 ITP For Above Ground Piping Rev. APhong Đỗ100% (1)

- Sample Quality Assurance Plan For Welded Cs Butt Weld Fittings (Sa 234)Document2 pagesSample Quality Assurance Plan For Welded Cs Butt Weld Fittings (Sa 234)Dhrumil ChauhanNo ratings yet

- 2654 - Pipe Wall Thickness Calculation As Per ASME B31.3Document20 pages2654 - Pipe Wall Thickness Calculation As Per ASME B31.3Sridhar Vijayan100% (3)

- Ohl TestDocument5 pagesOhl TestAnonymous ExWAN2xjFJNo ratings yet

- Burj Dubai Development The Dubai Mall: Main Contract Joint Venture: Dbb/Ag&CccDocument3 pagesBurj Dubai Development The Dubai Mall: Main Contract Joint Venture: Dbb/Ag&CccJoseph DarwinNo ratings yet

- Hole Openers NS 1 A4 WatermarkedDocument13 pagesHole Openers NS 1 A4 Watermarkedislam atifNo ratings yet

- Basic Design & Fabrication of Pressure VesselDocument30 pagesBasic Design & Fabrication of Pressure VesselannisNo ratings yet

- Approved ITP 06012023 For WT6Document1 pageApproved ITP 06012023 For WT6mohamed irsath100% (1)

- 74ind 1Document2 pages74ind 1wazakifyNo ratings yet

- Saudi Aramco Test Report: Switchyard - HV Mechanical Termination Torque Testing SATR-P-3901 3-Jul-18 ElectDocument8 pagesSaudi Aramco Test Report: Switchyard - HV Mechanical Termination Torque Testing SATR-P-3901 3-Jul-18 Electkarthi51289No ratings yet

- ELECT-TIC-1.6 (Continuity and Insulation Resistance Test)Document3 pagesELECT-TIC-1.6 (Continuity and Insulation Resistance Test)Muhammad IrfanNo ratings yet

- Saic A 2010Document13 pagesSaic A 2010jerinNo ratings yet

- Itp Ec14epDocument1 pageItp Ec14epRavi ShankarNo ratings yet

- WPQ Process As Per ISO-9606-1 2013Document4 pagesWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- Qcpi 7Document2 pagesQcpi 7Hausland Const. Corp.No ratings yet

- WPS BARAM & D35 (Comment Response Sheet)Document13 pagesWPS BARAM & D35 (Comment Response Sheet)Naveen RaoNo ratings yet

- Ammeter, Voltmeter Testing Not Applicable For This PanelDocument3 pagesAmmeter, Voltmeter Testing Not Applicable For This Paneleswaran005No ratings yet

- Saudi Aramco Test Report: 30-Apr-13 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116Document5 pagesSaudi Aramco Test Report: 30-Apr-13 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116zhangNo ratings yet

- JX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - BDocument3 pagesJX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - BAmyNo ratings yet

- AB-83 (2016-07) - (ABSA) Completion of ConstructionDocument3 pagesAB-83 (2016-07) - (ABSA) Completion of ConstructionFarooqNo ratings yet

- SAIC-A-2010 Rev 8Document13 pagesSAIC-A-2010 Rev 8Syed ImranNo ratings yet

- Bourdon Tube Pressure Gauge Model 131.11, Stainless Steel VersionDocument3 pagesBourdon Tube Pressure Gauge Model 131.11, Stainless Steel VersionChau TranNo ratings yet

- CPM Coc 22 010Document16 pagesCPM Coc 22 010Mark Darrel AranasNo ratings yet

- Mhob 04-Pw Protection (Translay) RelayDocument1 pageMhob 04-Pw Protection (Translay) RelayTHILAKKUMARNo ratings yet

- Capacitor TestDocument2 pagesCapacitor TestdineshNo ratings yet

- Dayang Enterprise Sdn. BHD.: INSPECTION AND TEST PLAN (Vessel Buttering Repair)Document3 pagesDayang Enterprise Sdn. BHD.: INSPECTION AND TEST PLAN (Vessel Buttering Repair)AmyNo ratings yet

- Itp FGP 2Document21 pagesItp FGP 2fusionndtNo ratings yet

- ARAMCO UT Inspection Checklist - SAIC-UT-2001Document6 pagesARAMCO UT Inspection Checklist - SAIC-UT-2001Anonymous hBBam1n100% (1)

- Reinforcement Pad CalculationDocument5 pagesReinforcement Pad Calculationsada siva100% (1)

- Itp For Piping Fabrication and InstallationDocument10 pagesItp For Piping Fabrication and InstallationwidiNo ratings yet

- Ec-2692-220-2 - Void 4SDocument3 pagesEc-2692-220-2 - Void 4SMatheus Fabrício TeixeiraNo ratings yet

- TR007-PAT Report - 132kV SWGR CB TestDocument9 pagesTR007-PAT Report - 132kV SWGR CB TestPrabaNo ratings yet

- CHW2204-00-EL-CAL-7301 Rev1 Sizing Cable & Drop Voltage For Electrical SystemDocument9 pagesCHW2204-00-EL-CAL-7301 Rev1 Sizing Cable & Drop Voltage For Electrical SystemphongtttNo ratings yet

- Globe 0.5in Up To 1.5in-Valve Spec - YTAN5 - R1Document4 pagesGlobe 0.5in Up To 1.5in-Valve Spec - YTAN5 - R1Ammanda ErnawanNo ratings yet

- Nickel-Chromium-Molybdenum-Tungsten Alloys (UNS N06110) Pipe and TubeDocument3 pagesNickel-Chromium-Molybdenum-Tungsten Alloys (UNS N06110) Pipe and TubeNav TalukdarNo ratings yet

- ITP Sample5-2-3Document2 pagesITP Sample5-2-3Mohammed Mostafa El HaddadNo ratings yet

- Saudi Aramco Test Report: 3-Jul-18 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116Document5 pagesSaudi Aramco Test Report: 3-Jul-18 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116karthi51289No ratings yet

- Process Piping Inspection and Test PlanDocument6 pagesProcess Piping Inspection and Test Planmanoj thakkarNo ratings yet

- Ab 083 Pressure Piping Construction and Test Data ReportDocument2 pagesAb 083 Pressure Piping Construction and Test Data Reportmansih457No ratings yet

- Qcpi 4Document2 pagesQcpi 4Hausland Const. Corp.No ratings yet

- Asme b31g Level 2 A1Document27 pagesAsme b31g Level 2 A1finiteinjustice78% (9)

- Shunt Reactor TestDocument10 pagesShunt Reactor TestEngr Imtiaz Hussain GilaniNo ratings yet

- CW213623 - Sokaij - Qa-5733-00001 - Inspection and Test PlanDocument15 pagesCW213623 - Sokaij - Qa-5733-00001 - Inspection and Test PlanjeszzymenNo ratings yet

- ASME B31.3 Key ChangesDocument2 pagesASME B31.3 Key ChangessssNo ratings yet

- DataSheet For Carbon Steel LinepipesDocument17 pagesDataSheet For Carbon Steel LinepipesDaniel Dambo0% (1)

- Saudi Aramco Test ReportDocument11 pagesSaudi Aramco Test Reportkarthi51289100% (1)

- Sper 1c1 - Trip CKT SupvnDocument3 pagesSper 1c1 - Trip CKT SupvnGunta Raviteja100% (1)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Quality Supervisor Job DescriptionDocument8 pagesQuality Supervisor Job Descriptionqualitymanagement246No ratings yet

- 1 6 Assignment Classifying Polygons 1Document6 pages1 6 Assignment Classifying Polygons 1TeaNo ratings yet

- Consumer Protection Act - SeminarDocument16 pagesConsumer Protection Act - SeminarAbdul KhadeerNo ratings yet

- Development of TOSRA (Test of Science Related Attitudes) Instrument For Science Related Attitude Studies in Sindh ProvinceDocument16 pagesDevelopment of TOSRA (Test of Science Related Attitudes) Instrument For Science Related Attitude Studies in Sindh ProvinceYhann Buyan GeverolaNo ratings yet

- No Overlord Rulebook For Descent: Journeys in The Dark (2nd Edition)Document21 pagesNo Overlord Rulebook For Descent: Journeys in The Dark (2nd Edition)Jeremy ForoiNo ratings yet

- Basion Horizontal CobenDocument3 pagesBasion Horizontal CobenJegan KumarNo ratings yet

- Catalog de Produse - BTRDocument62 pagesCatalog de Produse - BTRdaliproiectareNo ratings yet

- Dsm-5 Icd-10 HandoutDocument107 pagesDsm-5 Icd-10 HandoutAakanksha Verma100% (1)

- The Material Culture of The Postsocialist CityDocument15 pagesThe Material Culture of The Postsocialist Cityjsgt1980No ratings yet

- Cvp-Analysis AbsvarcostingDocument13 pagesCvp-Analysis AbsvarcostingGwy PagdilaoNo ratings yet

- Understanding Organizational Behavior: de Castro, Donna Amor Decretales, Thea Marie Estimo, Adrian Maca-Alin, SaharaDocument41 pagesUnderstanding Organizational Behavior: de Castro, Donna Amor Decretales, Thea Marie Estimo, Adrian Maca-Alin, SaharaAnna Marie RevisadoNo ratings yet

- Statement of Purpose Name: Krishna Teja SwarnaDocument2 pagesStatement of Purpose Name: Krishna Teja SwarnaMohammadRahemanNo ratings yet

- Name:: Nyoman Gede Abhyasa Class: X Mipa 2 Absent: 25 AnswersDocument2 pagesName:: Nyoman Gede Abhyasa Class: X Mipa 2 Absent: 25 AnswersRetrify - Random ContentNo ratings yet

- GDPR ReportDocument84 pagesGDPR ReportKingPlaysNo ratings yet

- Natural Gas - Pipe SizingDocument6 pagesNatural Gas - Pipe SizinglekakasNo ratings yet

- HUAWEI - SUN2000-20-40KTL-M3-UserManual GCADocument102 pagesHUAWEI - SUN2000-20-40KTL-M3-UserManual GCAReardon MetalsNo ratings yet

- Taylor Swift LyricsDocument2 pagesTaylor Swift LyricsElsie DomeNo ratings yet

- Oma TS MLP V3 - 2 20110719 ADocument128 pagesOma TS MLP V3 - 2 20110719 AkennychanklNo ratings yet

- STEWART Briony Kumiko and The Dragon FINAL2010Document8 pagesSTEWART Briony Kumiko and The Dragon FINAL2010Tahnee HallNo ratings yet

- Bayley ReviewDocument12 pagesBayley ReviewagNo ratings yet

- Linx Enterprise: Getting Results GuideDocument56 pagesLinx Enterprise: Getting Results GuideSaadullah SiddiquiNo ratings yet

- Scholastic Instant Practice Packets Numbers - CountingDocument128 pagesScholastic Instant Practice Packets Numbers - CountingcaliscaNo ratings yet

- Service Manual - NEC Versa 2700 Series LaptopDocument130 pagesService Manual - NEC Versa 2700 Series LaptopToan NguyenNo ratings yet

- IRP ReportDocument13 pagesIRP ReportAnkit JajooNo ratings yet

- Forms PensionersDocument15 pagesForms PensionersAnimesh DasNo ratings yet

- US Gasification DatabaseDocument9 pagesUS Gasification DatabaseAhmad DaoodNo ratings yet

- FermentationDocument23 pagesFermentationr_bharathi100% (2)

HT Waiver - 67B-ST-52 JT-16

HT Waiver - 67B-ST-52 JT-16

Uploaded by

mohamadyusuf1989Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HT Waiver - 67B-ST-52 JT-16

HT Waiver - 67B-ST-52 JT-16

Uploaded by

mohamadyusuf1989Copyright:

Available Formats

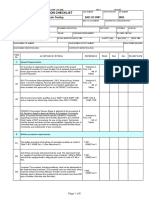

MALAYSIAN REFINING COMPANY SDN BHD

PRESSURE TESTING WAIVER CONCESSION (06_01_01-L3 AIM-L3-06-01-01-011-Pressure Test Waiver Management System)

FORM 2: INSPECTION AND SITE VERIFICATION REPORT

Equipment Tag / Line No. 67B-ST-52 Tie-in/Field Weld No. JT-16

Drawing / ISO Drawing No. AS PER ATTACHED LIST PEFS Drawing No.

Materials of Construction CARBON STEEL O.D, Thk or Height 3/4" SCH 80 (26.7 & 3.91)

Contractor / Repairer PIONEER RANEX SDN BHD WPS No. PRSB-P1-G-02 REV.0

Welder No. PRSB-038 Joint Type SOCKET WELD

Field Welding Inspection and Site Verification

Witness, check and verify each step - specify accept or reject result (with remark) based upon specified criteria and indicate acceptance with initial

Inspection and Site Verification Checklist Accept. Criteria / Recorded Accept/Reject/Remark Initial/Date

Data

Verify that all pre-fabricated spools have been examined and ASME B31.3

hydrostatically tested in accordance with design Code.

Verify WPS acceptability and compliance for scope of work. ASME IX, ASME B31.3,

PTS 12.30.05 ,PTS 12.30.02

Verify welder qualification acceptability and compliance for scope ASME IX, ASME B31.3,

of work (record actual Welder No.) PTS 12.30.05 ,PTS 12.30.02

Welder No : PRSB-038

Existing piping materials has been checked or positively identified ASME IX, ASME B31.3,

to material specification and grade PTS 12.30.05 ,PTS 12.30.02

UTTM measurement on existing piping has been verified where the Thickness =

tie-in is to be made (record actual value)1 N/A N/A N/A

Conduct Visual Inspection during cutting and beveling. Verify no ASME B31.3

defect and foreign material on or inside the pipe that would affect

the quality of the weld (paint, slag, etc..)

100% NDE on bevel of existing pipe:1 MPT or DPT ASME B31.3

Conduct fit-up inspection (record actual value) Root Gap = 2MM

- Root Gap Misalignment = ACCEPT

- Misalignment (Internal or External)

Verify storage and distribution of welding consumable compliance Welding consumable handling

with consumable handling procedure or manufacturer's procedure.

specifications Baking Temperature: N/A

Quiver Temperature: N/A

Verify correct welding consumable is used (record actual welding Root pass = Fill and cap =

consumable used) ER70S-G

Verify preheat or interpass temperature (record actual value) Preheat =

Interpass = 250 DEG MAX

Conduct Visual Inspection on the root pass ASME B31.3

100% NDE on the completed root pass:1 MPT or DPT ASME B31.3

Conduct Visual Inspection between weld passes - Each weld pass Total number of passes =

shall be inspected & any defects found shall be satisfactorily 3 PASSES

removed before welding the next pass.

Monitoring & record WPS parameters (as per WPS, including heat Approved WPS

input) Current: 90 Voltage: 12

Conduct Visual Inspection on the completed weld ASME B31.3

100% NDE on the completed weld:1,2 ASME B31.3

- MPT or DPT

- RT or UT

PWHT on the completed weld2 ASME B31.3,

PTS 12.30.05 ,PTS 12.30.02 N/A N/A

3

Hardness test on the final weld ASME B31.3,

PTS 12.30.05 ,PTS 12.30.02 N/A N/A

Inspected by: Reviewed by: Approved by:

Signature Signature Signature

Date & Stamp Date & Stamp Date & Stamp

Note :

1

All NDE shall be performed and interpreted by PCN level II operator or approved equivalent. 2Subjected to piping class requirement (NDE performed before or after PWHT)

3

Only for piping class with PWHT requirement

You might also like

- Hvac PM Service Checklist ContractorDocument1 pageHvac PM Service Checklist Contractorudupiganesh3069100% (2)

- 300D 310D and 315D Backhoe Loader IntroductionDocument7 pages300D 310D and 315D Backhoe Loader Introductionhenry ibañez100% (1)

- Minor Electrical Installation Works - GreenDocument2 pagesMinor Electrical Installation Works - GreenPopescuLaurentiuNo ratings yet

- 7ss - Busbar Low Imp Relay Test-1Document17 pages7ss - Busbar Low Imp Relay Test-1Ravi100% (3)

- Saudi Aramco Test ReportDocument6 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Engineering Specification: ESFU5A-8079-AADocument5 pagesEngineering Specification: ESFU5A-8079-AAjavier ortizNo ratings yet

- Senior High School: Emilio Aguinaldo College City of Dasmariñas, CaviteDocument7 pagesSenior High School: Emilio Aguinaldo College City of Dasmariñas, CaviteNicole De AsisNo ratings yet

- QCR W 2014Document3 pagesQCR W 2014Madhan KannanNo ratings yet

- Ab-083f Const Data Report Piping Sys Foreign Supplemental PagesDocument2 pagesAb-083f Const Data Report Piping Sys Foreign Supplemental Pagesmansih457No ratings yet

- Pages From 30.99.97.1612 Rev.1 SMR - Stock Material Request GuidelinesDocument1 pagePages From 30.99.97.1612 Rev.1 SMR - Stock Material Request GuidelinesPradeepNo ratings yet

- 016Document6 pages016Moinullah Khan AteeqNo ratings yet

- Ab-083f Const Data Report Piping Sys ForeignDocument1 pageAb-083f Const Data Report Piping Sys Foreignflores.john.chNo ratings yet

- Ab-083f Const Data Report Piping Sys ForeignDocument1 pageAb-083f Const Data Report Piping Sys Foreignmansih457No ratings yet

- QIP TT 307 PIPING WORK - RevisedDocument2 pagesQIP TT 307 PIPING WORK - Revisedsuria qaqcNo ratings yet

- ITP-P-001 ITP For Above Ground Piping Rev. ADocument9 pagesITP-P-001 ITP For Above Ground Piping Rev. APhong Đỗ100% (1)

- Sample Quality Assurance Plan For Welded Cs Butt Weld Fittings (Sa 234)Document2 pagesSample Quality Assurance Plan For Welded Cs Butt Weld Fittings (Sa 234)Dhrumil ChauhanNo ratings yet

- 2654 - Pipe Wall Thickness Calculation As Per ASME B31.3Document20 pages2654 - Pipe Wall Thickness Calculation As Per ASME B31.3Sridhar Vijayan100% (3)

- Ohl TestDocument5 pagesOhl TestAnonymous ExWAN2xjFJNo ratings yet

- Burj Dubai Development The Dubai Mall: Main Contract Joint Venture: Dbb/Ag&CccDocument3 pagesBurj Dubai Development The Dubai Mall: Main Contract Joint Venture: Dbb/Ag&CccJoseph DarwinNo ratings yet

- Hole Openers NS 1 A4 WatermarkedDocument13 pagesHole Openers NS 1 A4 Watermarkedislam atifNo ratings yet

- Basic Design & Fabrication of Pressure VesselDocument30 pagesBasic Design & Fabrication of Pressure VesselannisNo ratings yet

- Approved ITP 06012023 For WT6Document1 pageApproved ITP 06012023 For WT6mohamed irsath100% (1)

- 74ind 1Document2 pages74ind 1wazakifyNo ratings yet

- Saudi Aramco Test Report: Switchyard - HV Mechanical Termination Torque Testing SATR-P-3901 3-Jul-18 ElectDocument8 pagesSaudi Aramco Test Report: Switchyard - HV Mechanical Termination Torque Testing SATR-P-3901 3-Jul-18 Electkarthi51289No ratings yet

- ELECT-TIC-1.6 (Continuity and Insulation Resistance Test)Document3 pagesELECT-TIC-1.6 (Continuity and Insulation Resistance Test)Muhammad IrfanNo ratings yet

- Saic A 2010Document13 pagesSaic A 2010jerinNo ratings yet

- Itp Ec14epDocument1 pageItp Ec14epRavi ShankarNo ratings yet

- WPQ Process As Per ISO-9606-1 2013Document4 pagesWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- Qcpi 7Document2 pagesQcpi 7Hausland Const. Corp.No ratings yet

- WPS BARAM & D35 (Comment Response Sheet)Document13 pagesWPS BARAM & D35 (Comment Response Sheet)Naveen RaoNo ratings yet

- Ammeter, Voltmeter Testing Not Applicable For This PanelDocument3 pagesAmmeter, Voltmeter Testing Not Applicable For This Paneleswaran005No ratings yet

- Saudi Aramco Test Report: 30-Apr-13 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116Document5 pagesSaudi Aramco Test Report: 30-Apr-13 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116zhangNo ratings yet

- JX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - BDocument3 pagesJX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - BAmyNo ratings yet

- AB-83 (2016-07) - (ABSA) Completion of ConstructionDocument3 pagesAB-83 (2016-07) - (ABSA) Completion of ConstructionFarooqNo ratings yet

- SAIC-A-2010 Rev 8Document13 pagesSAIC-A-2010 Rev 8Syed ImranNo ratings yet

- Bourdon Tube Pressure Gauge Model 131.11, Stainless Steel VersionDocument3 pagesBourdon Tube Pressure Gauge Model 131.11, Stainless Steel VersionChau TranNo ratings yet

- CPM Coc 22 010Document16 pagesCPM Coc 22 010Mark Darrel AranasNo ratings yet

- Mhob 04-Pw Protection (Translay) RelayDocument1 pageMhob 04-Pw Protection (Translay) RelayTHILAKKUMARNo ratings yet

- Capacitor TestDocument2 pagesCapacitor TestdineshNo ratings yet

- Dayang Enterprise Sdn. BHD.: INSPECTION AND TEST PLAN (Vessel Buttering Repair)Document3 pagesDayang Enterprise Sdn. BHD.: INSPECTION AND TEST PLAN (Vessel Buttering Repair)AmyNo ratings yet

- Itp FGP 2Document21 pagesItp FGP 2fusionndtNo ratings yet

- ARAMCO UT Inspection Checklist - SAIC-UT-2001Document6 pagesARAMCO UT Inspection Checklist - SAIC-UT-2001Anonymous hBBam1n100% (1)

- Reinforcement Pad CalculationDocument5 pagesReinforcement Pad Calculationsada siva100% (1)

- Itp For Piping Fabrication and InstallationDocument10 pagesItp For Piping Fabrication and InstallationwidiNo ratings yet

- Ec-2692-220-2 - Void 4SDocument3 pagesEc-2692-220-2 - Void 4SMatheus Fabrício TeixeiraNo ratings yet

- TR007-PAT Report - 132kV SWGR CB TestDocument9 pagesTR007-PAT Report - 132kV SWGR CB TestPrabaNo ratings yet

- CHW2204-00-EL-CAL-7301 Rev1 Sizing Cable & Drop Voltage For Electrical SystemDocument9 pagesCHW2204-00-EL-CAL-7301 Rev1 Sizing Cable & Drop Voltage For Electrical SystemphongtttNo ratings yet

- Globe 0.5in Up To 1.5in-Valve Spec - YTAN5 - R1Document4 pagesGlobe 0.5in Up To 1.5in-Valve Spec - YTAN5 - R1Ammanda ErnawanNo ratings yet

- Nickel-Chromium-Molybdenum-Tungsten Alloys (UNS N06110) Pipe and TubeDocument3 pagesNickel-Chromium-Molybdenum-Tungsten Alloys (UNS N06110) Pipe and TubeNav TalukdarNo ratings yet

- ITP Sample5-2-3Document2 pagesITP Sample5-2-3Mohammed Mostafa El HaddadNo ratings yet

- Saudi Aramco Test Report: 3-Jul-18 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116Document5 pagesSaudi Aramco Test Report: 3-Jul-18 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116karthi51289No ratings yet

- Process Piping Inspection and Test PlanDocument6 pagesProcess Piping Inspection and Test Planmanoj thakkarNo ratings yet

- Ab 083 Pressure Piping Construction and Test Data ReportDocument2 pagesAb 083 Pressure Piping Construction and Test Data Reportmansih457No ratings yet

- Qcpi 4Document2 pagesQcpi 4Hausland Const. Corp.No ratings yet

- Asme b31g Level 2 A1Document27 pagesAsme b31g Level 2 A1finiteinjustice78% (9)

- Shunt Reactor TestDocument10 pagesShunt Reactor TestEngr Imtiaz Hussain GilaniNo ratings yet

- CW213623 - Sokaij - Qa-5733-00001 - Inspection and Test PlanDocument15 pagesCW213623 - Sokaij - Qa-5733-00001 - Inspection and Test PlanjeszzymenNo ratings yet

- ASME B31.3 Key ChangesDocument2 pagesASME B31.3 Key ChangessssNo ratings yet

- DataSheet For Carbon Steel LinepipesDocument17 pagesDataSheet For Carbon Steel LinepipesDaniel Dambo0% (1)

- Saudi Aramco Test ReportDocument11 pagesSaudi Aramco Test Reportkarthi51289100% (1)

- Sper 1c1 - Trip CKT SupvnDocument3 pagesSper 1c1 - Trip CKT SupvnGunta Raviteja100% (1)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Quality Supervisor Job DescriptionDocument8 pagesQuality Supervisor Job Descriptionqualitymanagement246No ratings yet

- 1 6 Assignment Classifying Polygons 1Document6 pages1 6 Assignment Classifying Polygons 1TeaNo ratings yet

- Consumer Protection Act - SeminarDocument16 pagesConsumer Protection Act - SeminarAbdul KhadeerNo ratings yet

- Development of TOSRA (Test of Science Related Attitudes) Instrument For Science Related Attitude Studies in Sindh ProvinceDocument16 pagesDevelopment of TOSRA (Test of Science Related Attitudes) Instrument For Science Related Attitude Studies in Sindh ProvinceYhann Buyan GeverolaNo ratings yet

- No Overlord Rulebook For Descent: Journeys in The Dark (2nd Edition)Document21 pagesNo Overlord Rulebook For Descent: Journeys in The Dark (2nd Edition)Jeremy ForoiNo ratings yet

- Basion Horizontal CobenDocument3 pagesBasion Horizontal CobenJegan KumarNo ratings yet

- Catalog de Produse - BTRDocument62 pagesCatalog de Produse - BTRdaliproiectareNo ratings yet

- Dsm-5 Icd-10 HandoutDocument107 pagesDsm-5 Icd-10 HandoutAakanksha Verma100% (1)

- The Material Culture of The Postsocialist CityDocument15 pagesThe Material Culture of The Postsocialist Cityjsgt1980No ratings yet

- Cvp-Analysis AbsvarcostingDocument13 pagesCvp-Analysis AbsvarcostingGwy PagdilaoNo ratings yet

- Understanding Organizational Behavior: de Castro, Donna Amor Decretales, Thea Marie Estimo, Adrian Maca-Alin, SaharaDocument41 pagesUnderstanding Organizational Behavior: de Castro, Donna Amor Decretales, Thea Marie Estimo, Adrian Maca-Alin, SaharaAnna Marie RevisadoNo ratings yet

- Statement of Purpose Name: Krishna Teja SwarnaDocument2 pagesStatement of Purpose Name: Krishna Teja SwarnaMohammadRahemanNo ratings yet

- Name:: Nyoman Gede Abhyasa Class: X Mipa 2 Absent: 25 AnswersDocument2 pagesName:: Nyoman Gede Abhyasa Class: X Mipa 2 Absent: 25 AnswersRetrify - Random ContentNo ratings yet

- GDPR ReportDocument84 pagesGDPR ReportKingPlaysNo ratings yet

- Natural Gas - Pipe SizingDocument6 pagesNatural Gas - Pipe SizinglekakasNo ratings yet

- HUAWEI - SUN2000-20-40KTL-M3-UserManual GCADocument102 pagesHUAWEI - SUN2000-20-40KTL-M3-UserManual GCAReardon MetalsNo ratings yet

- Taylor Swift LyricsDocument2 pagesTaylor Swift LyricsElsie DomeNo ratings yet

- Oma TS MLP V3 - 2 20110719 ADocument128 pagesOma TS MLP V3 - 2 20110719 AkennychanklNo ratings yet

- STEWART Briony Kumiko and The Dragon FINAL2010Document8 pagesSTEWART Briony Kumiko and The Dragon FINAL2010Tahnee HallNo ratings yet

- Bayley ReviewDocument12 pagesBayley ReviewagNo ratings yet

- Linx Enterprise: Getting Results GuideDocument56 pagesLinx Enterprise: Getting Results GuideSaadullah SiddiquiNo ratings yet

- Scholastic Instant Practice Packets Numbers - CountingDocument128 pagesScholastic Instant Practice Packets Numbers - CountingcaliscaNo ratings yet

- Service Manual - NEC Versa 2700 Series LaptopDocument130 pagesService Manual - NEC Versa 2700 Series LaptopToan NguyenNo ratings yet

- IRP ReportDocument13 pagesIRP ReportAnkit JajooNo ratings yet

- Forms PensionersDocument15 pagesForms PensionersAnimesh DasNo ratings yet

- US Gasification DatabaseDocument9 pagesUS Gasification DatabaseAhmad DaoodNo ratings yet

- FermentationDocument23 pagesFermentationr_bharathi100% (2)