Professional Documents

Culture Documents

Annexure 2 - RCC Encasement Reinf Calculation-P1

Annexure 2 - RCC Encasement Reinf Calculation-P1

Uploaded by

marameez7886Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Annexure 2 - RCC Encasement Reinf Calculation-P1

Annexure 2 - RCC Encasement Reinf Calculation-P1

Uploaded by

marameez7886Copyright:

Available Formats

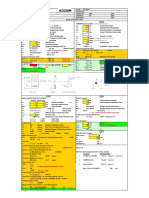

BY: RKS TATA CONSULTING ENGINEERS LIMITED JOB NO.: TCE.

12556A

DATE: dd-mm-yyyy

30-04-2024 CLIENT: GREENKO MP01 IREP PRIVATE LIMITED SUBJECT: ENCASEMENT

CHD.: SP PROJECT: MP30 Gandhisagar Pumped Storage Project DOC. NO.: 03-REP-20

DATE: dd-mm-yyyy

30-04-2024 BU: PBC DC: BLR DISC.: CIVIL SH. 1 OF 4 REV. NO.: P1

SECTION 3-3_ CONCRETE CASING

TOP OF CONCRETE CASING

Tension face = 1.2866 N/mm2 Comp. strength Check

2

Compression face = 2.7898 N/mm Design Comp. sterngth

2 2

Grade of steel = 550 N/mm 0.45fck = 11.15 N/mm

2

Charachteristic strength of concrete = 25 Mpa > 2.7898 N/mm

Thickness of the section = 0.60 m OK

Width of the section assumed = 1.00 m

Section exerts tension = 0.189 m 0.876708

Force (Tensile force in concrete) = 121.8 kN (Considerd triangular

2

Area of steel required to resist tensile force on tension face = 254.6 mm variation)

Minimum reinforcemnt for required for tension = 0.12% *bd

Minimum area of reinforcemnt required = 360.00 mm2 (On each face)

2

Therefore required area of the steel = 360.00 mm

Hoop reinforcement

Diameter of bar used = 16 mm

Spacing of the steel provided = 200 mm

Area of steel provided = 1206.37 mm2

Area of the steel provided is sufficient

Outer face reinforcement

Diameter of bar used = 16 mm

Spacing of the steel provided = 200 mm

Area of steel provided = 1206.37 mm2

Area of the steel provided is sufficient

1.2866

Compressive stress

Tensile stress

2.7898

FILE NAME: F010R3.XLSX TCE FORM NO. 010 R3

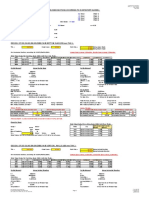

BY: RKS TATA CONSULTING ENGINEERS LIMITED JOB NO.: TCE. 12556A

DATE: dd-mm-yyyy

30-04-2024 CLIENT: GREENKO MP01 IREP PRIVATE LIMITED SUBJECT: ENCASEMENT

CHD.: SP PROJECT: MP30 Gandhisagar Pumped Storage Project DOC. NO.: 03-REP-20

DATE: dd-mm-yyyy

30-04-2024 BU: PBC DC: BLR DISC.: CIVIL SH. 2 OF 4 REV. NO.: P1

BOTTOM OF CONCRETE CASING

2

Tension face = 1.925 N/mm Comp. strength Check

Compression face = 3.6154 N/mm2 Design Comp. sterngth

2 2

Grade of steel = 550 N/mm 0.45fck = 11.25 N/mm

2

Charachteristic strength of concrete = 25 Mpa > 3.6154 N/mm

Thickness of the section = 0.60 m OK

Width of the section assumed = 1.00 m

Section exerts tension = 0.208 m

Force (Tensile force in concrete) = 200.6 kN (Considerd triangular

2

Area of steel required to resist tensile force on tension face = 419.2 mm variation)

Minimum reinforcemnt for bars = 0.12% *bd

Minimum area of reinforcemnt required = 360.00 mm2 (On each face)

2

Therefore required area of the steel = 419.23 mm

Hoop Reinforcement

Diameter of bar used = 16 mm

Spacing of the steel provided = 200 mm

Area of steel provided = 1206.37 mm2

Area of the steel provided is sufficient

Outer face Reinforcement

Diameter of bar used = 16 mm

Spacing of the steel provided = 200 mm

Area of steel provided = 1206.37 mm2

Area of the steel provided is sufficient

1.9247 3.6154

Tensile stress

Compressive stress

FILE NAME: F010R3.XLSX TCE FORM NO. 010 R3

BY: RKS TATA CONSULTING ENGINEERS LIMITED JOB NO.: TCE. 12556A

DATE: dd-mm-yyyy

30-04-2024 CLIENT: GREENKO MP01 IREP PRIVATE LIMITED SUBJECT: ENCASEMENT

CHD.: SP PROJECT: MP30 Gandhisagar Pumped Storage Project DOC. NO.: 03-REP-20

DATE: dd-mm-yyyy

30-04-2024 BU: PBC DC: BLR DISC.: CIVIL SH. 3 OF 4 REV. NO.: P1

SIDE FACE OF CONCRETE CASING

2

Compression face = 3.0152 N/mm Comp. strength Check

Compression face = 1.849 N/mm2 Design Comp. sterngth

2 2

Grade of steel = 550 N/mm 0.45fck = 11.25 N/mm

2

Charachteristic strength of concrete = 25 Mpa > 1.849 N/mm

Thickness of the section = 0.60 m OK

Width of the section assumed = 1.00 m

Section exerts tension = 0.372 m

Force (Tensile force in concrete) = 560.7 kN (Considerd triangular

2

Area of steel required to resist tensile force on tension face = 1171.8 mm variation)

Minimum reinforcemnt for bars = 0.12% *bd

Minimum area of reinforcemnt required = 360.00 mm2 (On each face)

2

Therefore required area of the steel = 1171.82 mm

Outer face Reinforcement

Diameter of bar used = 16 mm

Spacing of the steel provided = 200 mm

Area of steel provided = 1206.37 mm2

Area of the steel provided is sufficient

3.0152

1.849

Tensile stress

Compressive stress

FILE NAME: F010R3.XLSX TCE FORM NO. 010 R3

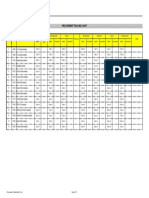

BY: RKS TATA CONSULTING ENGINEERS LIMITED JOB NO.: TCE. 12556A

DATE: dd-mm-yyyy

30-04-2024 CLIENT: GREENKO MP01 IREP PRIVATE LIMITED SUBJECT: ENCASEMENT

CHD.: SP PROJECT: MP30 Gandhisagar Pumped Storage Project DOC. NO.: 03-REP-20

DATE: dd-mm-yyyy

30-04-2024 BU: PBC DC: BLR DISC.: CIVIL SH. 4 OF 4 REV. NO.: P1

Distribution steel calculation

Thickness of the liner provided in top and sides of the penstock = 600 mm

Thickness of the liner provided at bottom = 600 mm

2

Minimum area od steel required = 0.12% *bd mm

Area of steel required at top of the casing = 360 mm2

2

Area of steel required at bottom of the casing = 360 mm (On each face)

Provided area of distribution steel at side and top of casing = 867.08 mm2

Diameter of the bars used = 12 mm

Spacing of the bars = 150 mm

SAFE

2

Provided area of distribution steel at side and bottom of casing = 867.08 mm

Diameter of the bars used = 12 mm

Spacing of the bars = 150 mm

SAFE

Distributed Reinforcement (SXX)

Check for Shear

2

Factored Shear Stress tve = 0.145 N/mm

% of tensile reinforcement provided at support As = 0.201

0.8xfck / ( 6.89xAs ) β = 14.437

Design shear strength of section 0.332 N/mm2

Hence the section is SAFE in Shear

FILE NAME: F010R3.XLSX TCE FORM NO. 010 R3

You might also like

- 1a Boundary Wall Design CalculationDocument9 pages1a Boundary Wall Design Calculationsanju middya67% (3)

- Cantilever Sheet Pile DesignDocument14 pagesCantilever Sheet Pile DesignMaltesh H100% (3)

- Unbraced RC Circular Column Design - Sample Calculation (AS3600)Document4 pagesUnbraced RC Circular Column Design - Sample Calculation (AS3600)Tiam MarapeNo ratings yet

- Case Study On: Burj Al Arab: Wayne Reuben Dsouza 4NM18CV112 Department of Civil EngineeringDocument22 pagesCase Study On: Burj Al Arab: Wayne Reuben Dsouza 4NM18CV112 Department of Civil Engineering4NM18CV112 WAYNE REUBEN DSOUZANo ratings yet

- Pow 17J00077Document47 pagesPow 17J00077Joseph MontalesNo ratings yet

- BS5400-R-C-Design-With-Crack-Width SampleDocument1 pageBS5400-R-C-Design-With-Crack-Width SampleAlden CayagaNo ratings yet

- Imps - Short Wall (My - Vertical) : Calculation of SteelDocument12 pagesImps - Short Wall (My - Vertical) : Calculation of Steelpearl kachhawahNo ratings yet

- Aisc 14 Edition (Asd) : 0 1 18/jan/16 13/jun/16 SN SN AN ANDocument5 pagesAisc 14 Edition (Asd) : 0 1 18/jan/16 13/jun/16 SN SN AN ANGousePeerzadeNo ratings yet

- CN 05Document3 pagesCN 05GousePeerzadeNo ratings yet

- Aisc 14 Edition (Asd) : 14/jan/16 SN SN 0 1Document2 pagesAisc 14 Edition (Asd) : 14/jan/16 SN SN 0 1GousePeerzadeNo ratings yet

- Bending Axial WORKING STRESSDocument4 pagesBending Axial WORKING STRESSgade phaniNo ratings yet

- RC Beam Torsion Design BS8110Document2 pagesRC Beam Torsion Design BS8110saman2580No ratings yet

- Beam DesignDocument35 pagesBeam DesignAli Aafaaq100% (1)

- New Bearing Stopper 25mDocument2 pagesNew Bearing Stopper 25mAmit VarmaNo ratings yet

- Beam Design With Crackwidth CalculationDocument16 pagesBeam Design With Crackwidth CalculationFazilat Mohammad ZaidiNo ratings yet

- PC3 QmaxDocument1 pagePC3 QmaxCuong TranNo ratings yet

- Short Wall - Vertical: Plate No.-961 L/C No. - 10Document12 pagesShort Wall - Vertical: Plate No.-961 L/C No. - 10pearl kachhawahNo ratings yet

- Calculation For Crack WidthDocument48 pagesCalculation For Crack Widthpearl kachhawahNo ratings yet

- C7CH20050 - Wall - Reinforcement - WR2Document20 pagesC7CH20050 - Wall - Reinforcement - WR2Mahadev Sastry100% (1)

- RB8 1200x1200 PDFDocument6 pagesRB8 1200x1200 PDFsallysel90No ratings yet

- Calculations: Project: of Section: File/ref No: Designed: Date: Checked: DateDocument6 pagesCalculations: Project: of Section: File/ref No: Designed: Date: Checked: DateWintun73No ratings yet

- BeamDocument4 pagesBeamPraYush RajbhandariNo ratings yet

- B150 - Lift Roof Slab DesignDocument2 pagesB150 - Lift Roof Slab DesignGovendan GopalakrishnanNo ratings yet

- S2 - Floor / Roof: Design of Two - Way Slab With Provision For Torsion at CornersDocument2 pagesS2 - Floor / Roof: Design of Two - Way Slab With Provision For Torsion at CornersMuhammed Sabah100% (1)

- 4.10. Pier Pile Cap Design: BR - CP7-5B (KTM) CH 39+884 To CH 39+954Document3 pages4.10. Pier Pile Cap Design: BR - CP7-5B (KTM) CH 39+884 To CH 39+954saubhagya majhiNo ratings yet

- EA - Check of Punching Shear in Flat Slabs & Raft ACI 318M-14 v1.0Document2 pagesEA - Check of Punching Shear in Flat Slabs & Raft ACI 318M-14 v1.0Imaduddin KhajaNo ratings yet

- Page 1Document1 pagePage 1Edward Albert BañagaNo ratings yet

- Phytorid STPDocument4 pagesPhytorid STPsamirbendre1No ratings yet

- BS5400 R.C Design With Crack WidthDocument9 pagesBS5400 R.C Design With Crack WidthWangTF100% (4)

- Liquid Retaining Reinforced Concrete Section To BS 8007& BS 8110Document1 pageLiquid Retaining Reinforced Concrete Section To BS 8007& BS 8110James LaurentNo ratings yet

- Pier Cap DesignDocument5 pagesPier Cap DesignsanilNo ratings yet

- Triangle Beam B1Document6 pagesTriangle Beam B1sallysel90No ratings yet

- Ground Floor Slab Design CalculationsDocument7 pagesGround Floor Slab Design CalculationsArindam RoyNo ratings yet

- Corbel R C BracketDocument2 pagesCorbel R C BracketVijendra Singh SoniNo ratings yet

- Output: Pile Cap Beam Calculation For Most Critical Zone 1Document7 pagesOutput: Pile Cap Beam Calculation For Most Critical Zone 1Prakash Singh RawalNo ratings yet

- Design of Precast BeamDocument4 pagesDesign of Precast BeamMUTHUKKUMARAMNo ratings yet

- DRHFDocument1 pageDRHFdccd8801No ratings yet

- Pad FootingDocument1 pagePad FootingKingsley ChukwuNo ratings yet

- Middle Wall (All Intermediate Walls)Document3 pagesMiddle Wall (All Intermediate Walls)epe civilNo ratings yet

- Concrete Slab Design.Document5 pagesConcrete Slab Design.Johan De LangeNo ratings yet

- Beam DesignDocument4 pagesBeam DesignPraYush RajbhandariNo ratings yet

- 5.0 Design of Top Ring BeamDocument3 pages5.0 Design of Top Ring BeamJayNo ratings yet

- General Design Parameters (For Uncracked Section According To Is:3370 (Part-Ii) - 2009)Document6 pagesGeneral Design Parameters (For Uncracked Section According To Is:3370 (Part-Ii) - 2009)sumit_7285No ratings yet

- Beam DesignDocument14 pagesBeam DesignAbinash MandalNo ratings yet

- Stress Check of Box CulvertDocument2 pagesStress Check of Box CulvertBRIDGE DESIGNCELLNo ratings yet

- Lintal Beam and Wall OpeningDocument4 pagesLintal Beam and Wall Openingkc chanNo ratings yet

- Crack Width CalculationDocument7 pagesCrack Width CalculationSrinivas RegulavalasaNo ratings yet

- Grade Slab ACI 150thkDocument7 pagesGrade Slab ACI 150thkraahul_nNo ratings yet

- Beam DesignDocument4 pagesBeam DesignPrayush RajbhandariNo ratings yet

- Cantilever SlabDocument7 pagesCantilever Slabankit kadamNo ratings yet

- Confinement Reinforcement of Pier ShaftDocument2 pagesConfinement Reinforcement of Pier ShaftMayurSoniNo ratings yet

- WALL DESIGN-400mm THK.Document2 pagesWALL DESIGN-400mm THK.voilNo ratings yet

- Circular Foundation Design For PoleDocument2 pagesCircular Foundation Design For PoleJayNo ratings yet

- Liquid Retaining Reinforced Concrete Section To BS 8007& BS 8110Document1 pageLiquid Retaining Reinforced Concrete Section To BS 8007& BS 8110christopherNo ratings yet

- Beam DesignDocument2 pagesBeam DesignBilal A BarbhuiyaNo ratings yet

- Anchorbolt For Pole DesignDocument3 pagesAnchorbolt For Pole DesignJayNo ratings yet

- Slab Design Vehicle MovementDocument21 pagesSlab Design Vehicle MovementsivaNo ratings yet

- Elastomeric Bearing 21.6mDocument8 pagesElastomeric Bearing 21.6mnaresh KUMARNo ratings yet

- Crack PDFDocument22 pagesCrack PDFghansaNo ratings yet

- Typical Sample Calculation: Design Procedure FollowedDocument3 pagesTypical Sample Calculation: Design Procedure FollowedsputlekarNo ratings yet

- 1st Floor Slab Design Sample PDFDocument5 pages1st Floor Slab Design Sample PDFSanjeev SanjeevNo ratings yet

- Architectural Drawings 1Document13 pagesArchitectural Drawings 1Manish PandeyNo ratings yet

- Maharashtra Jeevan Pradhikaran Rate Analysis 2012 2013Document177 pagesMaharashtra Jeevan Pradhikaran Rate Analysis 2012 2013ulhas_nakasheNo ratings yet

- Ans To IS 800 LSM CodeDocument11 pagesAns To IS 800 LSM Codeanon_854101020% (1)

- Detailed Section of Footing 1 (C1-Fi) 1 2 3 Detailed Section of Footing 2 (C1-F2) Wall Footing DetailDocument1 pageDetailed Section of Footing 1 (C1-Fi) 1 2 3 Detailed Section of Footing 2 (C1-F2) Wall Footing DetailEdward CardenasNo ratings yet

- Prof Ashok Jain-Example On Torsion - IRC 112 PDFDocument5 pagesProf Ashok Jain-Example On Torsion - IRC 112 PDFrahuljoagNo ratings yet

- Ian 124-11 PDFDocument70 pagesIan 124-11 PDFstavros_stergNo ratings yet

- Skirt & Anchor Bolt BROWNELL & YOUNG Process Equip. DesignDocument15 pagesSkirt & Anchor Bolt BROWNELL & YOUNG Process Equip. DesignImthiyaz HNo ratings yet

- "Design of Prefabricated Modular Housing For Different Occupancies at Pancheshwar Power PlantDocument16 pages"Design of Prefabricated Modular Housing For Different Occupancies at Pancheshwar Power PlantJithesh DharmadasNo ratings yet

- Fracture Mechanics Simulation Lab: Report On Tutorial Problems Submitted in Fulfillment of The Requirements ofDocument24 pagesFracture Mechanics Simulation Lab: Report On Tutorial Problems Submitted in Fulfillment of The Requirements ofRishabh SrivastavaNo ratings yet

- RC 7 TO 9Document5 pagesRC 7 TO 9Arjie RecarialNo ratings yet

- Concrete Filled With High Strength Steel Box Column For Tall Building-Behavior & DesignDocument20 pagesConcrete Filled With High Strength Steel Box Column For Tall Building-Behavior & DesigntaosyeNo ratings yet

- INTERNSHIPDocument31 pagesINTERNSHIPStalan JonathanNo ratings yet

- Types of Caissons:: (I) Single Wall Open Caisson (Ii) Cylindrical Open Caisson (Iii) Open Caisson With Dredging WellsDocument4 pagesTypes of Caissons:: (I) Single Wall Open Caisson (Ii) Cylindrical Open Caisson (Iii) Open Caisson With Dredging WellsKeith GarridoNo ratings yet

- Procurement Tracking Chart Project Name: Woody 2000Document1 pageProcurement Tracking Chart Project Name: Woody 2000Gunawan MSNo ratings yet

- Penawaran Negosiasi Harga: Power House New VersionDocument1 pagePenawaran Negosiasi Harga: Power House New VersionSAFRUDDINNo ratings yet

- Reinforced Concrete KhmerDocument628 pagesReinforced Concrete KhmerCheng Por Eng100% (2)

- 25570929192444Document30 pages25570929192444Trần Quang LộcNo ratings yet

- 10 Multi-Storey Frames (Revised)Document100 pages10 Multi-Storey Frames (Revised)susan87No ratings yet

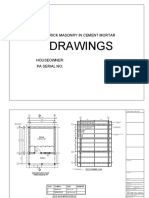

- Drawings: Brick Masonry in Cement MortarDocument5 pagesDrawings: Brick Masonry in Cement MortarSuman Resolved NeupaneNo ratings yet

- Single Cell Box Culvert Final 3x3m Gad (3m Cushion) 07-02-17Document1 pageSingle Cell Box Culvert Final 3x3m Gad (3m Cushion) 07-02-17praveenNo ratings yet

- Office of The Building Official Office of The Building OfficialDocument1 pageOffice of The Building Official Office of The Building OfficialAlvy Faith Pel-eyNo ratings yet

- Steel Hangar SampleDocument104 pagesSteel Hangar SampleFares YaredNo ratings yet

- Prokon FootingDocument58 pagesProkon Footingmbhanusagar.keynesNo ratings yet

- Conjugate Beam MethodDocument3 pagesConjugate Beam MethodBlessy Marie SottoNo ratings yet

- 6 BAA4513 Mat FoundationDocument41 pages6 BAA4513 Mat FoundationAizat HermanNo ratings yet

- Stairs Supported at The Ends of Landings: Detail 'X'Document1 pageStairs Supported at The Ends of Landings: Detail 'X'Anuja JadhavNo ratings yet

- Example of Application of AISI 360 10 and Parallel With EC3Document5 pagesExample of Application of AISI 360 10 and Parallel With EC3Aakash KhatriNo ratings yet