Professional Documents

Culture Documents

sea2d34en

sea2d34en

Uploaded by

asstepCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

sea2d34en

sea2d34en

Uploaded by

asstepCopyright:

Available Formats

Instar Electrical Instar Electrical

SEA2D34

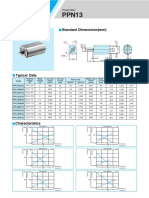

Installation dimensions Driver Connection

25

12.5 41 10

Features Division Setting Table

0.0

0.1

0.5

0.8

PWR TM

Pu/rev D4 D3

1.2 1.5 2.0

O.H O.C

High performance, low noise, affordable price, high speed and torque, excellent stability.

CURRENT(Im)

1600 ON ON

3200 OFF ON IM

4 selections of uniform angle and constant torque subdivisions, the max resolution up to 12800 steps / rev. 6400 ON OFF

D1

ON O FF

ON

1 2 3 4

12800 OFF OFF D2

2.8

2.5

2.3

3.0

Adoption of 6-wires-control circuit greatly reduces noise and increases the rotation stability. D3

D4

The max response frequency up to 200Kpps. +(5V) +

PU PU

Once the pulse stops for more than 100ms, the coil current will be halved automatically, to prevent the overheating. DR

136

127

136

DR

Bipolar constant current chopper control improves the output speed and power of the motor. MF MF

+V +V

Optically isolated signal I / O DC12-40V

-V

61.2

-V

Current range: 0.1A 3.0A AC

+A BC

AC -

Single power input, voltage range: DC12 40V ( the optimal voltage is DC36V ) A Phase -A +A

M +B -A

Error Protection: Overheating Overcurrent Low voltage B Phase BC

SEA2D34 -B +B

Size: 136 92 25mm, Net weight: 0.3kg -B

http://www.instar.com.cn

Introduction

SEA2D34 is a microstep motor driver with uniform angle and constant torque subdivisions, voltage range is DC12 40V ( the optimal 4.5 82

voltage is DC36V ), single power supply. It matches 2 phase hybrid stepper motors which rated current under 3.0A, external diameter 42mm

60mm, and outlets 6 or 8.

Bipolar constant current chopper control makes the motor run smoothly with lower noise and higher stability, The increase of the voltage

greatly improves the drive capability. and speed, The coil current will be halved automatically onece the pulse stops for more than 100ms, it Pin Functions

reduces the heat of driver by 50%, reduces the heat of motor as well. Users can choose low speed high subdivision which up to 12800steps

Mark Function Instruction

/ rev, it improves the precision, reduces the vibration and noise.

POWER Power indicator Power on, the green indicator normally on.

When the pulse frequency is low, the green indicator flashes, when the pulse

Applications TM Working indicator light

frequency is high, the green indicator normally on.

Carpentry engracing machine, Laser engraving machine, Labelling machine, Die bonder, Inkjrt printer, Embroiderer, Dispenser, BGA repair O.H Overheat indicator The Temperature rise exceeds the red indicator normally on.

machine, Laminating machine Wire-stripping machine, Winding machine,Hot-press machine, PCB drilling machine, Non-standard equipment The current exceeds rated value or the voltage is lower than rated value, the red

O.C Overcurrent / Low voltage indicator

STEPPING MOTOR

STEPPING MOTOR

indicator normally on.

SIMPLE 2 PHASE

SIMPLE 2 PHASE

XYZ gauge, Connctors assemble machine, Medical equipments, Semiconductor Equipment, Blast furnace, etc.

Im Phase current setting adjuster Set the phase current, clockwise it increases, anticlockwise it dereases.

DRVIER

DRVIER

Microstep Setting List Pulse signal power supply should in the range of +5V +24V, if higher than +5V

+ Input signal positive side

, needs to add a resistor on PU-, DR- FM- ( do not add on + sides )

Microstep 800 3200 6400 12800 When the falling edge is valid, the motor moves a step as the pulse become

D4 ON OFF ON OFF PU Pulse signal lower, input resistance is 220Ω. Requires: low level +0V +0.5V, high level +4V

HASE

+5V, pulse width >2.5 μs.

D3 ON ON OFF OFF

D2 NULL For changing the direction, input resistance is 220Ω. Requires: low level +0V

DR Direction control signal

+0.5V, high level +4V +5V, pulse width >2.5 μs.

D1 NULL

Motor free signal When the low electrical level is valid, it cuts off the motor current, the driver

MF

stops working and motor will be in a free state.

Running current setting DIP Switch Function setting Input signal timing diagram

+V Power+

DC12 40V ( the optimal voltage is DC36V )

-V Power-

AC BC

+A -A Connect to the motor Please refer to the motor connections

+B -B

Attantion

F 1 Please do not reverse the power supply, input voltage not more than DC40V

2 The input control signal level is +5V, if higher than +5V, needs to add a resistor on PU-, DR-, FM- ( do not add on + sides

3 This model of the driver uses a special control circuit, so it matches stepper motor of 6 or 8 outlets only

4 The driver will automatically stop working when the temperature exceeds 70 degrees, the O.H indicator light normally on, temperature drops to 50

degrees it automatic recovers to work, please install radiator when it's in overheating protection

5 When the current exceeds rated value or the voltage is lower than rated value, the O.C indicator light normally on, please check the connections

and other short troubles needs to re-up power after the faults cleared, or if the power voltage is too low

6 The PWR green indicator light normally on when the driver is powered on

7 The TM indicator light comes on when the pulse input go crossing the zero point

You might also like

- Transformer Sizing CalculationDocument10 pagesTransformer Sizing CalculationArunava BasakNo ratings yet

- Addams Family Values Pinball Service ManualDocument70 pagesAddams Family Values Pinball Service ManualabalwayzNo ratings yet

- Red Digsilent VPPDocument1 pageRed Digsilent VPPSANTIAGO ANDRES OSORIO HUERTASNo ratings yet

- Smith2 PDFDocument1 pageSmith2 PDFwilber123456No ratings yet

- Normalized Impedance and Admittance Coordinates: Name Title Dwg. NoDocument1 pageNormalized Impedance and Admittance Coordinates: Name Title Dwg. Nohuy doanNo ratings yet

- Carta de Smith PDFDocument1 pageCarta de Smith PDFLuis SanchezNo ratings yet

- Carta de Inmitancia de SmithDocument1 pageCarta de Inmitancia de SmithEddy Santiago Neira SisaNo ratings yet

- Colored Smith Chart PDFDocument1 pageColored Smith Chart PDFvoltagecrapNo ratings yet

- Normalized Impedance and Admittance Coordinates: Name Title Dwg. NoDocument1 pageNormalized Impedance and Admittance Coordinates: Name Title Dwg. Nohuy doanNo ratings yet

- Normalized Impedance and Admittance Coordinates: Name Title Dwg. NoDocument1 pageNormalized Impedance and Admittance Coordinates: Name Title Dwg. NoNick CohechaNo ratings yet

- Carta de SmithDocument1 pageCarta de SmithRui AlmeidaNo ratings yet

- Admit Smithchart PDFDocument1 pageAdmit Smithchart PDFDanny AlonsoNo ratings yet

- Carta de SmithDocument1 pageCarta de SmithJuan DavidNo ratings yet

- Impedance Admittance SmithchartDocument1 pageImpedance Admittance SmithchartWolfNo ratings yet

- Imped Admit SmithChartDocument1 pageImped Admit SmithChartjoseNo ratings yet

- Normalized Impedance and Admittance Coordinates: ZI Y 0.3 + j0.5Document1 pageNormalized Impedance and Admittance Coordinates: ZI Y 0.3 + j0.5huy doanNo ratings yet

- Normalized Impedance and Admittance Coordinates: ZI Y 0.1+0.2jDocument1 pageNormalized Impedance and Admittance Coordinates: ZI Y 0.1+0.2jhuy doanNo ratings yet

- DIgSILENT PEA System - 115kV - 3Document1 pageDIgSILENT PEA System - 115kV - 3Noptana TummasitNo ratings yet

- Normalized Impedance and Admittance Coordinates: Name Title Dwg. NoDocument1 pageNormalized Impedance and Admittance Coordinates: Name Title Dwg. NoFrogstyNo ratings yet

- Gear Insert-3 Mix 9000 PDFDocument1 pageGear Insert-3 Mix 9000 PDFNathan KamNo ratings yet

- Smith Chart - Z Y QDocument1 pageSmith Chart - Z Y QmanuelNo ratings yet

- Smith Chart - Z Y QDocument1 pageSmith Chart - Z Y QYon LopezNo ratings yet

- CM100RX-24A NDocument8 pagesCM100RX-24A NLITMAS TECHNOLOGYNo ratings yet

- Experimental Research Into Whirl Flutter Aeroelastic PhenomenonDocument2 pagesExperimental Research Into Whirl Flutter Aeroelastic Phenomenonaodabai1999No ratings yet

- History MatchingDocument20 pagesHistory MatchingAamir LokhandwalaNo ratings yet

- Normalized Impedance and Admittance Coordinates: Name Title Dwg. NoDocument1 pageNormalized Impedance and Admittance Coordinates: Name Title Dwg. NoTrần MinhNo ratings yet

- Power Transistor ( 40V, 2A) : 2SB1183 / 2SB1239Document1 pagePower Transistor ( 40V, 2A) : 2SB1183 / 2SB1239Angel Simo MoralesNo ratings yet

- Addition Alteration 2Document1 pageAddition Alteration 2Kscsiddhant KscsiddhantNo ratings yet

- SD en 201803Document2 pagesSD en 201803Benjamín Varela UmbralNo ratings yet

- Lambda 0.088: Normalized Impedance and Admittance CoordinatesDocument1 pageLambda 0.088: Normalized Impedance and Admittance CoordinatesAndrés VallejoNo ratings yet

- RE1 - SmithChartDocument1 pageRE1 - SmithChartDinaj AttanayakaNo ratings yet

- Smith ChartDocument1 pageSmith Chartsumra.batool876No ratings yet

- PDF CropDocument1 pagePDF CropAditiNo ratings yet

- Digital Transistors (Built-In Resistor) : DTC115GUA / DTC115GKA / DTC115GSADocument3 pagesDigital Transistors (Built-In Resistor) : DTC115GUA / DTC115GKA / DTC115GSACube7 GeronimoNo ratings yet

- Cube 480Document2 pagesCube 480Saul AguilarNo ratings yet

- SampleDocument1 pageSampleGokul VenugopalNo ratings yet

- Additional Slides On Latent Heat PhenomenaDocument2 pagesAdditional Slides On Latent Heat PhenomenaChester FengNo ratings yet

- PC929 - Ic On Line - CNDocument6 pagesPC929 - Ic On Line - CNOrgil-erdene YadamsurenNo ratings yet

- ESCALA 1:160: Detalle Baño ESCALA 1:20Document1 pageESCALA 1:160: Detalle Baño ESCALA 1:20ArtuRo HuillcaNo ratings yet

- Smith Chart in Color - 2Document1 pageSmith Chart in Color - 2Andro Elnatan HarianjaNo ratings yet

- Smith Chart in Color - 2Document1 pageSmith Chart in Color - 2Andro Elnatan HarianjaNo ratings yet

- Transcending Conventional Log Interpretation-A More Effective Approach For Spraberry ReservoirDocument34 pagesTranscending Conventional Log Interpretation-A More Effective Approach For Spraberry ReservoirWahyu Indra NugrohoNo ratings yet

- Vježba 1: Osnove RELEX-a I Određivanje Pouzdanosti SustavaDocument17 pagesVježba 1: Osnove RELEX-a I Određivanje Pouzdanosti SustavaMajaNo ratings yet

- Product Catalog: CAT. No.129EDocument45 pagesProduct Catalog: CAT. No.129EOmar Hops Elizondo MartinezNo ratings yet

- T - S Diagram For Water: Plotted By: J P M TruslerDocument1 pageT - S Diagram For Water: Plotted By: J P M TruslerMuhammed Shameem N EdavannapparaNo ratings yet

- RS-540RH/SH: Output: 5.0W 90W (Approx)Document1 pageRS-540RH/SH: Output: 5.0W 90W (Approx)Onur GençoğluNo ratings yet

- 4422 107 05473 - LFC7710-CodedMains - sh-460 - 20170222 - V3FinLRDocument2 pages4422 107 05473 - LFC7710-CodedMains - sh-460 - 20170222 - V3FinLRJo HydeNo ratings yet

- LCM1602A Display LCD16x2 PDFDocument1 pageLCM1602A Display LCD16x2 PDFhenriquezrsNo ratings yet

- Partplans (Cinema)Document1 pagePartplans (Cinema)Nage AbdalazezNo ratings yet

- Fuad Clinte G+4 AR-4Document1 pageFuad Clinte G+4 AR-4mohammednasruNo ratings yet

- Value Sheet - Precicontrol ClinChem Multi 1.05117003190.Lot-564978.Exp-2024!10!31.V87.EnDocument19 pagesValue Sheet - Precicontrol ClinChem Multi 1.05117003190.Lot-564978.Exp-2024!10!31.V87.EnDanielIvanGuerreroNo ratings yet

- Technical Characteristics:: Product CMR 1al CMR 1Ml CMR 5al CMR 5Ml CMR 5ap CMR 5Mp CMR 5ag CMR 5MgDocument2 pagesTechnical Characteristics:: Product CMR 1al CMR 1Ml CMR 5al CMR 5Ml CMR 5ap CMR 5Mp CMR 5ag CMR 5MgSudheerKumarNo ratings yet

- Datasheet Motor VideoDocument1 pageDatasheet Motor VideoDocente Fede TecnologicoNo ratings yet

- Working Drawing Floor Plan-Dimensions and Center-Line Plan: Subject Name: Sheet Title: Mid Term ExaminationDocument2 pagesWorking Drawing Floor Plan-Dimensions and Center-Line Plan: Subject Name: Sheet Title: Mid Term ExaminationSHASHWAT GUPTANo ratings yet

- Joel Rest HouseDocument1 pageJoel Rest HousejsacurNo ratings yet

- мотор PPN-13KADocument1 pageмотор PPN-13KAServiceVNo ratings yet

- Applied Time Series Econometrics: A Practical Guide for Macroeconomic Researchers with a Focus on AfricaFrom EverandApplied Time Series Econometrics: A Practical Guide for Macroeconomic Researchers with a Focus on AfricaRating: 3 out of 5 stars3/5 (1)

- 2013 Catalog KabeldonCA 1-420 KV CSEP-A 12-42 KV Pages 3-22 To 3-24 EnglishDocument3 pages2013 Catalog KabeldonCA 1-420 KV CSEP-A 12-42 KV Pages 3-22 To 3-24 Englishiyilmaz1No ratings yet

- HWC - O&M ManualDocument16 pagesHWC - O&M ManualAONLANo ratings yet

- Lecture 5 - Climper and Clamper CircuitDocument22 pagesLecture 5 - Climper and Clamper CircuitArifah HamidunNo ratings yet

- Thyristor Switch ApplicationsDocument7 pagesThyristor Switch ApplicationsPathum SudasingheNo ratings yet

- Shanghai CO., LTDDocument32 pagesShanghai CO., LTDJose Rodrigo Ramirez Ordoñez100% (1)

- Extinguishing Panel 8010, Series 4, W/o Operating Unit: Part-No. 788012.40Document1 pageExtinguishing Panel 8010, Series 4, W/o Operating Unit: Part-No. 788012.40Nelutu LapadatuNo ratings yet

- 100N50P IXFB Power Mosfet PDFDocument5 pages100N50P IXFB Power Mosfet PDFHưng HQNo ratings yet

- Equivalent Circuits and Parameters of Power System PlantDocument32 pagesEquivalent Circuits and Parameters of Power System Plantcontact_amit_010% (2)

- PROTEK SRS InstructionsDocument7 pagesPROTEK SRS InstructionsTom BeanNo ratings yet

- Question BankDocument15 pagesQuestion BankSyamala JothyNo ratings yet

- Introductory: Capacity They Momentarily Interrupt TheyDocument19 pagesIntroductory: Capacity They Momentarily Interrupt Theysravani dhulipallaNo ratings yet

- Transformer Technical Data Sheet CTMP 7 H - 1600-500: Speed 1.0.0 ###Document4 pagesTransformer Technical Data Sheet CTMP 7 H - 1600-500: Speed 1.0.0 ###prdpks2000No ratings yet

- Introduction To Grounding System Design - Pt.1Document8 pagesIntroduction To Grounding System Design - Pt.1dedeerlandNo ratings yet

- Electrical Matrial Purchasing ListDocument9 pagesElectrical Matrial Purchasing ListBilla PraveenNo ratings yet

- 19EE10076 Machinelab Expt1Document11 pages19EE10076 Machinelab Expt1temp tempNo ratings yet

- 15 BC547Document4 pages15 BC547Niranjan ReddyNo ratings yet

- API Source Inspector Electrical Equipment Exam: Publications Effectivity SheetDocument2 pagesAPI Source Inspector Electrical Equipment Exam: Publications Effectivity SheetHatem HusseinNo ratings yet

- Catalog Power Ind Oct-11Document44 pagesCatalog Power Ind Oct-11Suraj MohapatraNo ratings yet

- Motor HP Voltage To Amp ChartDocument1 pageMotor HP Voltage To Amp ChartjituplanojrNo ratings yet

- Building UtilitiesDocument2 pagesBuilding UtilitiesMarla MendozaNo ratings yet

- Mosfet As A Switch: G G V GDocument34 pagesMosfet As A Switch: G G V GswaeroNo ratings yet

- Steady-State Analysis of DC MotorsDocument24 pagesSteady-State Analysis of DC MotorsUsama RaoNo ratings yet

- For Ringmaster: VIP 300 Protection RelayDocument19 pagesFor Ringmaster: VIP 300 Protection Relaymuhamed MuneerNo ratings yet

- Digitron Semiconductors: MBR2060CT-MBR20100CT 20A Schottky RectifiersDocument2 pagesDigitron Semiconductors: MBR2060CT-MBR20100CT 20A Schottky RectifiersShawn ClearNo ratings yet

- Radial Feeder ProtectionDocument5 pagesRadial Feeder ProtectionNirmal mehta100% (1)

- Sony Crt-01 CRT Troubleshooting Training ManualDocument44 pagesSony Crt-01 CRT Troubleshooting Training ManualoxmanamouNo ratings yet