Professional Documents

Culture Documents

122_8_70_DATA_SHEET_COBRITHERM_ALCUP

122_8_70_DATA_SHEET_COBRITHERM_ALCUP

Uploaded by

Juan Vicente Hernandez LogytelCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

122_8_70_DATA_SHEET_COBRITHERM_ALCUP

122_8_70_DATA_SHEET_COBRITHERM_ALCUP

Uploaded by

Juan Vicente Hernandez LogytelCopyright:

Available Formats

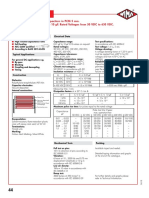

COBRITHERM

A AISMALIBAR

DATA SHEET DS_1105

COBRITHERM ALCUP (PROOF TEST 2000V)

DESCRIPTION

Insulated Metal Substrate (IMS), based on thick aluminium and clad with ED copper foil in the other side. It is

designed for a reliable thermal dissipation circuitry. With a proprietary formulated reinforced-polymer-ceramic

bonding layer with a high thermal conductivity, dielectric strength, and thermal endurance is guaranteed.

The material is supplied with a protective film on the aluminium side to protect it against wet PCB process

ROHS compliance directive 2002/95/EC and REACH Nº 1907/2006

STANDARD CONSTRUCTIONS

Aluminium thickness, µm 1000 - 1500 - 2000 - 3000 Aluminium Alloy / Treat 5052

Insulation thickness, µm 120 Dielectric thickness tolerance + 10 µm

ED copper thickness, µm 35 - 70 - 105

Other constructions available upon request

UL Approved , QMTS2 File: E47820

(1) Electrical proof test. 100% of our laminate production delivered, has been “on line” verified at 2000

Vdc: 500 V/sec. ramp // 5sec. held at 2000 Vdc.

PROPERTIES TEST TYPICAL Guaranteed

UNITS

1500 µm Al / 120 µm dielectric /70 µm Cu METHOD VALUES values

Time to blister at 288ºC, floating on solder (50 x 50 mm) IEC-61189 Sec >120 >60

Copper Peel strength, after heat shock 20 sec/288ºC IPC-TM 650-2.4.8 N/mm 2,8 >1,8

Dielectric breakdown voltage, AC (1) IPC-TM 650-2.5.6.3 kV 7 5

Proof Test, DC (2) -- V 2000 2000

Thermal conductivity (dielectric layer) ASTM-D 5470 w/m.ºK 1.80 1.60

-3 2

Thermal impedance (dielectric layer) x 10 ASTM-D 5470 ºK.m /w 0,067 0,075

5 5

Surface resistance after damp heat and recovery IEC-61189 MΩ 10 10

4 4

Volume resistivity after damp heat and recovery IEC-61189 MΩm 10 10

Relative permitivity after damp heat and recovery, 10 kHz IEC-61189 - 4,5 4,5

Dissipation factor after damp heat and recovery 10 kHz IEC-61189 - 0,02 0,02

Comparative tracking index (CTI) IEC-61112 V 600 >550

Capacitance -- pF/cm² 46 46

Flammability, according UL-94, class UL-94 class V-0 V-0

Glass transition temperature of dielectric layer ( by TMA) IPC-TM 650-2.4.24 ºC 90 90

Maximum operating temperature -- °C 150 150

(2) Dielectric Breakdown test, is a material destructive laboratory test. It is performed according the IPC-TM-650 part 2.5.6.3., under

AC voltage, raising it until electric failure, on relative small surface area of the dielectric part, and using metal electrodes. Values

should be taken as a material reference, and not as guaranteed values.

AVAILABILITY

STANDARD SHEET SIZES mm. 1220x930, 610x460, 1060x1170, 1210x1000 mm (Also available in cut panels)

Tolerance +5/-0 mm.

Squareness 3 mm max., as differential between diagonal measurements.

Standard size tolerance in panels +- 0,3 mm.

The data is based on typical values of standard production and should be considered as general information. Our company reserves the right to future

changes. It is the responsibility of the user to ensure that the product complies with his requirements.

c/Bach, 2-B Pol. Ind Poinvasa

08110 Montcada i reixac (Barcelona) SPAIN

Tel. +34 93 572 41 61 FAX +34 93 572 41 65

E. mail: e.benmayor@benmayor.com

www.benmayor.com

You might also like

- Semiconductor Device Fundamentals Solutions Manual Robert PierretDocument302 pagesSemiconductor Device Fundamentals Solutions Manual Robert Pierreteva1235x82% (11)

- Electrical Design Engineering Oil GasDocument10 pagesElectrical Design Engineering Oil GasDnyanesh MaskeNo ratings yet

- Commander 400: Parts List ForDocument38 pagesCommander 400: Parts List ForIsrael_Rivas_5442No ratings yet

- CEM Data SheetDocument1 pageCEM Data SheetBiswajit Debnath OffcNo ratings yet

- Air/Ship Microwave Material With High Performance: Excellent Dimensional Stability & Phase StabilityDocument4 pagesAir/Ship Microwave Material With High Performance: Excellent Dimensional Stability & Phase StabilityDale XiaoNo ratings yet

- HT Cable Termination Kit 14.3.22Document8 pagesHT Cable Termination Kit 14.3.22JIGSNo ratings yet

- High Performance RF Antenna Material: FeaturesDocument3 pagesHigh Performance RF Antenna Material: FeaturesDale XiaoNo ratings yet

- DZ158 CATALOGDocument3 pagesDZ158 CATALOGManoel SilvestreNo ratings yet

- Fujikura MV Power Cable CatalogueDocument94 pagesFujikura MV Power Cable Catalogueezpme0% (1)

- TC600 Laminates Data SheetDocument4 pagesTC600 Laminates Data SheetEduardo Ruiz PalominoNo ratings yet

- High Performance RF Antenna Material: FeaturesDocument3 pagesHigh Performance RF Antenna Material: FeaturesDale XiaoNo ratings yet

- Lifeline® Specialty: Fire Resistant QFCI Cable: Fire Resistant, Flame Retardant Halogen-Free Loose Tube - QFCI/O/RM-JMDocument2 pagesLifeline® Specialty: Fire Resistant QFCI Cable: Fire Resistant, Flame Retardant Halogen-Free Loose Tube - QFCI/O/RM-JMkevinwz1989No ratings yet

- Datasheet (WAZAM+HC88) V1 3Document1 pageDatasheet (WAZAM+HC88) V1 3mccornejo1617No ratings yet

- RE 2X (ST) YSWAY FL PDFDocument3 pagesRE 2X (ST) YSWAY FL PDFAnas AzzedineNo ratings yet

- RE 2X (ST) YSWAY FLDocument3 pagesRE 2X (ST) YSWAY FLandy175No ratings yet

- Interference Suppression Capacitor: MKP-X2Document2 pagesInterference Suppression Capacitor: MKP-X2gunsakNo ratings yet

- Ki XLC 09SDocument2 pagesKi XLC 09SAbhishek HiteshkumarNo ratings yet

- Instrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VDocument4 pagesInstrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VShashank SaxenaNo ratings yet

- Instrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VDocument4 pagesInstrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VShashank SaxenaNo ratings yet

- CuClad Laminates Data SheetDocument4 pagesCuClad Laminates Data SheetDenis CarlosNo ratings yet

- Commercial Microwave and RF Multilayer MaterialsDocument3 pagesCommercial Microwave and RF Multilayer MaterialsDale XiaoNo ratings yet

- RO4400 PrepregDocument2 pagesRO4400 Prepreggcohen03No ratings yet

- Thermal Insulation Systems: High Performance Heat Shield With Superior Thermal InsulationDocument2 pagesThermal Insulation Systems: High Performance Heat Shield With Superior Thermal InsulationMikeNo ratings yet

- Instrumentation Cable Gen. To EN 50288-7Document4 pagesInstrumentation Cable Gen. To EN 50288-7Shashank SaxenaNo ratings yet

- RC300C - High Performance RF Antenna MaterialDocument3 pagesRC300C - High Performance RF Antenna MaterialDale XiaoNo ratings yet

- Llaves Termicas S200 80 A y 100 ADocument8 pagesLlaves Termicas S200 80 A y 100 AabrahambarcazaNo ratings yet

- Wima FKP 4Document9 pagesWima FKP 4M-BasicNo ratings yet

- 15KW On Grid Roof Top HP STATIONDocument7 pages15KW On Grid Roof Top HP STATIONAjayNo ratings yet

- D 9045 Hensel ElectricDocument2 pagesD 9045 Hensel ElectricThuan NguyenNo ratings yet

- Technical Data Sheet: Description Technical Particulars ValuesDocument1 pageTechnical Data Sheet: Description Technical Particulars ValuesMuhammad Ali TariqNo ratings yet

- Erico Terminal Block UD2C9C1250ALDocument2 pagesErico Terminal Block UD2C9C1250ALsandesh sawateNo ratings yet

- K 9065 - Hensel - ElectricDocument2 pagesK 9065 - Hensel - ElectricThuan NguyenNo ratings yet

- E WIMA MKS 2Document9 pagesE WIMA MKS 2Guntara WigunaNo ratings yet

- Celdas PrimariasDocument24 pagesCeldas PrimariasMartin CarrascoNo ratings yet

- GoldyDocument1 pageGoldyAniket DubeNo ratings yet

- Cable Siemon-SFTP CAT7A PDFDocument2 pagesCable Siemon-SFTP CAT7A PDFRenzo GuizadoNo ratings yet

- FO UndergroundDocument2 pagesFO UndergroundReinaldo Sciliano juniorNo ratings yet

- GOLDI - 60GN - Polycrystalline Module: NOCT Irradiance of 800 W/M, Ambient Temperature of 20°C, Wind Speed 1m/secDocument1 pageGOLDI - 60GN - Polycrystalline Module: NOCT Irradiance of 800 W/M, Ambient Temperature of 20°C, Wind Speed 1m/secsuhradamNo ratings yet

- JUD407774-B9000-TECH SPEC-60-80-100-125-160kVADocument11 pagesJUD407774-B9000-TECH SPEC-60-80-100-125-160kVAalexFillNo ratings yet

- Acquex - LedDocument1 pageAcquex - LedMhmd GhanimNo ratings yet

- 92ML Data SheetDocument4 pages92ML Data SheetEduardo Ruiz PalominoNo ratings yet

- Tdf10 NewDocument2 pagesTdf10 NewSơn Lê CaoNo ratings yet

- Wima CapacitorDocument11 pagesWima Capacitorchiranjib_kNo ratings yet

- CS Al 88Document8 pagesCS Al 88mccornejo1617No ratings yet

- Test Report 800 ALDocument55 pagesTest Report 800 ALinfo.anhungsmartNo ratings yet

- Technical Data Sheet: Description Values Technical ParticularsDocument1 pageTechnical Data Sheet: Description Values Technical ParticularsMuhammad Ali TariqNo ratings yet

- 370-385W M 72-PERC-Cell REV02Document1 page370-385W M 72-PERC-Cell REV02ARAVINTHNo ratings yet

- Power and Control Cable IEC 60502-1: Flame Retardant, Sunlight Resistant 90 °C / U /U 0,6/1 KVDocument3 pagesPower and Control Cable IEC 60502-1: Flame Retardant, Sunlight Resistant 90 °C / U /U 0,6/1 KVShashank SaxenaNo ratings yet

- Product Data Sheet: EXFS 100 / EXFS 100 KU EXFS 100 (923 100)Document1 pageProduct Data Sheet: EXFS 100 / EXFS 100 KU EXFS 100 (923 100)Alessandro KawanoNo ratings yet

- 2CDS253001R0104 Miniature Circuit Breaker s200 3p C 10 AmpereDocument5 pages2CDS253001R0104 Miniature Circuit Breaker s200 3p C 10 AmperemarioNo ratings yet

- Miniature Circuit Breaker - S200 - 4P - C - 10 Ampere: Product-DetailsDocument6 pagesMiniature Circuit Breaker - S200 - 4P - C - 10 Ampere: Product-DetailsbilalNo ratings yet

- Technical Data Sheet: Description Values Technical ParticularsDocument2 pagesTechnical Data Sheet: Description Values Technical ParticularsAli ShahzadNo ratings yet

- Dielectrics For Power Electronics ApplicationsDocument17 pagesDielectrics For Power Electronics Applicationskanuni41No ratings yet

- Schrack Power PCB Relay RPII/2: General Purpose Relays PCB RelaysDocument2 pagesSchrack Power PCB Relay RPII/2: General Purpose Relays PCB RelaysCor GratNo ratings yet

- E WIMA MKP 10-1139811Document18 pagesE WIMA MKP 10-1139811Manikanta Sai KumarNo ratings yet

- E WIMA MKP 4Document11 pagesE WIMA MKP 4kmyisusNo ratings yet

- Wima MP 3-X2: Metallized Paper (MP) RFI-Capacitors Class X2 PCM 10 MM To 27.5 MMDocument4 pagesWima MP 3-X2: Metallized Paper (MP) RFI-Capacitors Class X2 PCM 10 MM To 27.5 MMFirdaus HanipahNo ratings yet

- 2CDS253001R0324Document5 pages2CDS253001R0324Alma Leon AcostaNo ratings yet

- Schrack Miniature Power PCB RYII & RYII Reflow Solderable: General Purpose Relays PCB RelaysDocument4 pagesSchrack Miniature Power PCB RYII & RYII Reflow Solderable: General Purpose Relays PCB RelaysWilson Rubiano AlfaroNo ratings yet

- Cable 3 X50Document2 pagesCable 3 X50Jalal AlbadriNo ratings yet

- Instrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VDocument4 pagesInstrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VShashank SaxenaNo ratings yet

- PanouDocument2 pagesPanouDaniel I. PopNo ratings yet

- 3966-2645-1-PBDocument9 pages3966-2645-1-PBJuan Vicente Hernandez LogytelNo ratings yet

- Automotive Fuse-Holders: ATO Sealed 30 A In-LineDocument1 pageAutomotive Fuse-Holders: ATO Sealed 30 A In-LineJuan Vicente Hernandez LogytelNo ratings yet

- 10-12916Document9 pages10-12916Juan Vicente Hernandez LogytelNo ratings yet

- 60V Two Terminal Constant Current Led Driver PowerdiDocument17 pages60V Two Terminal Constant Current Led Driver PowerdiJuan Vicente Hernandez LogytelNo ratings yet

- CC 3 - 05 05 S F - E Features Model-Naming Method: Insulation Type DC-DC ConverterDocument26 pagesCC 3 - 05 05 S F - E Features Model-Naming Method: Insulation Type DC-DC ConverterJuan Vicente Hernandez LogytelNo ratings yet

- Android Auto Quick Start GuideDocument3 pagesAndroid Auto Quick Start GuideJuan Vicente Hernandez LogytelNo ratings yet

- IDS-87 Gray ZnNiDocument2 pagesIDS-87 Gray ZnNiJuan Vicente Hernandez LogytelNo ratings yet

- Android Auto User GuideDocument15 pagesAndroid Auto User GuideJuan Vicente Hernandez LogytelNo ratings yet

- Apple Carplay User GuideDocument15 pagesApple Carplay User GuideJuan Vicente Hernandez LogytelNo ratings yet

- Exploded View Parts List (UA32H4100AKXKE)Document9 pagesExploded View Parts List (UA32H4100AKXKE)Adedeji OluwatobilobaNo ratings yet

- DIY Remote Control Car - How To Make Your Own RC Car! - DIY HackingDocument9 pagesDIY Remote Control Car - How To Make Your Own RC Car! - DIY HackingAditya ShindeNo ratings yet

- OBIS Codes - OneMeter DocumentationDocument13 pagesOBIS Codes - OneMeter Documentationsafaat rabbyNo ratings yet

- NPM pf35t SpecsheetDocument1 pageNPM pf35t SpecsheetElectromateNo ratings yet

- Protective Relay RS 2001: Operating Instructions BA59/07Document12 pagesProtective Relay RS 2001: Operating Instructions BA59/07raza239No ratings yet

- Chapter 34 PDFDocument12 pagesChapter 34 PDFJeffreyBeridaNo ratings yet

- Ka3525a PDFDocument5 pagesKa3525a PDFAsih100% (1)

- 3 Phase RectifierDocument4 pages3 Phase RectifiersyedsheryNo ratings yet

- Glasstile S: Motorized Entrance Gate For Internal InstallationDocument4 pagesGlasstile S: Motorized Entrance Gate For Internal InstallationDanNo ratings yet

- Lab Report 5Document13 pagesLab Report 5Meng Kiat TeeNo ratings yet

- TEP0011Document2 pagesTEP0011slygerNo ratings yet

- MATLAB Simscape Model of An Alkaline ElectrolyserDocument9 pagesMATLAB Simscape Model of An Alkaline ElectrolyserAbdelaziz EL GHZIZALNo ratings yet

- Technical Site Survey Report: Telenor USF ProjectDocument14 pagesTechnical Site Survey Report: Telenor USF Projecttonygrt12No ratings yet

- SHB 9300 Servo Position Controller v4-2 enDocument441 pagesSHB 9300 Servo Position Controller v4-2 enramon navaNo ratings yet

- Casio FX9700GE PC Interface Circuit Electronics SerialDocument2 pagesCasio FX9700GE PC Interface Circuit Electronics Seriallakis lalakis888No ratings yet

- 4.2V To 18V, 3A 1ch Synchronous Buck Converter With Integrated FETDocument22 pages4.2V To 18V, 3A 1ch Synchronous Buck Converter With Integrated FETDouglas BeltránNo ratings yet

- L 0976Document12 pagesL 0976g665013No ratings yet

- ABN103 CDocument1 pageABN103 CSergio FelipeNo ratings yet

- TCC V1 - JaosbDocument28 pagesTCC V1 - Jaosbjimmy_barredoNo ratings yet

- Fluke 8808A Digital MultimeterDocument8 pagesFluke 8808A Digital MultimeteriqbalNo ratings yet

- Model OR 6308 PT: PH, TempDocument2 pagesModel OR 6308 PT: PH, TempAnatech LabNo ratings yet

- AISG Cable SpecificationDocument4 pagesAISG Cable Specificationdtvt40No ratings yet

- Pembasmi Hama Serangga Menggunakan Cahaya Lampu Bertenaga Solar CellDocument7 pagesPembasmi Hama Serangga Menggunakan Cahaya Lampu Bertenaga Solar CelloctaaaaNo ratings yet

- ElectrostaticsDocument8 pagesElectrostaticsRoopak Behera0% (1)

- Burden On CTDocument4 pagesBurden On CTkapilNo ratings yet

- PF Improvement On DG SetsDocument8 pagesPF Improvement On DG SetsAnupam SharmaNo ratings yet

- Electrochemistry 1Document64 pagesElectrochemistry 1Avinash MohanNo ratings yet