Professional Documents

Culture Documents

1714802 2

1714802 2

Uploaded by

hassan awadallaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1714802 2

1714802 2

Uploaded by

hassan awadallaCopyright:

Available Formats

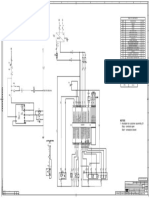

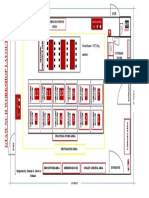

Unit Arrangement Concrete Fill-Up

Basic requirements for Anchoring 1:5

Structural concrete Concrete filling Separate reinforced concrete

9 13

1 3 1 2 3

2 5 5

1 10

2 5 3

25

25

Pb 2mm Lead lining for all walls,frames and doors 4

in accordance to the national regulation . 11

95

10 11 8

400 88 35 35 166 4

7 14

≥ 140

12

≥ 140

18

1.05 Pb 6

1.03 ≥ 140

6

60

6

80

Pb

1.02

30 20 30

134

SID = 115

1 Base plate of unit 2 Shim(s) 3 Floor covering 4 tfix-mark

25

5 Seal all around with hygienic-grad silicon

Structural concrete (=reinforced concrete) of grade min. C20/25;

6

min. thickness 140 mm for 11 / 12 below t fix mark

567

Examination room Concrete filling with reinforcement of grade min. C20/25, with force-fit connection to 6 if there is

170

1.04 7

a risk of tilting; min. thickness 140 mm for 11 below t fix mark

Pb

8 Concrete filling/bonded screed of grade min. C20/25 9 Screed 10 Insulation

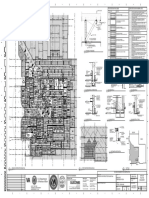

1.01 Examination Room 52

In Shipment: Mungo HL-B M10 / 25 expansion bolts with t fix= 25 mm (maximum thickness for fixing parts)

50 80 202 11

Please observe the manufacturer's installation instructions.

Alternative: Mungo HL-B M10 / 95 expansion bolts (with t fix= 95 mm); not in shipment

16 12 Please observe the manufacturer's installation instructions.

185

13 Tiles of raised floor 14 Subconstruction of raised floor / free space

Pb

Statics / Installation notes

37 100 51 150 41 The floor slab must ensure sufficient transverse distribution of the load (e.g. steel-reinforced concrete) and be

1.06 designed for an evenly distributed live load with at least 3.5 kN/m² for component installation on the floor.

1.07

199

1.08 Solid surface with sufficient load capacity is required, e.g. structural concrete/reinforced concrete.

Control Room The concrete quality in the setup and installation area of the units must be at least C20/25 with a characteristic

Control Room cylinder compressive strength of 2.0 kN/cm².

Other floor types without sufficient load bearing capacity and floor coverings must be removed first.

A floor unevenness of max. 5 mm/m is permitted in the footprint area of all components.

188 Min. thickness of structural concrete slab = 140 mm plus remaining thickness of fixture.

In shipment: Mungo HL-B M10 / 25 expansion bolts

With the heavy duty anchor in shipment only parts with thickness up to 25 mm can be fixed in structural ceiling

concrete. Therefore anchors in shipment are applicable only in case the fixation is realized directly on structural

concrete ceiling.

For other conditions the fixation requires other solutions as exemplarily described:

- Fixation on concrete filling with thickness up to 80 mm → Mungo HL-B M10 / 95 - not in shipment

- Fixation on concrete filling as replacement of raised floor, thickness > 160 mm → Concrete filling need to be

executed as reinforced concrete member with grade C20/25 and this member - if there is a risk of tilting - needs

to be fixed force-fit to the structural concrete ceiling below. Then the heavy duty anchor in shipment can be used.

For this example a structural engineer is mandatory!

The supplied drilling templates must be used.

Please observe the manufacturer's installation instructions.

Mounting table base not to scale Concrete fill-up min. C20/25 1:20 Conrete fill-up min. C20/25 not to scale

800

2500

1397 400 400

668 668

1 613 613 1

500

850

2 2

252

241

550

100

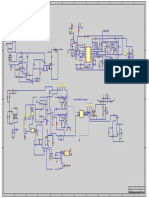

Radiation protection in doors

1700

Milled lead inlay in doors

Room height finished floor to

65

241

252

2 The radiation protection must be well overlapped, especially Location Concrete Suspending Ceiling Suspended required, min.

2 on doors and windows. door leaf

600

EXAMINATION ROOM 325 cm. N.A 250 cm.

850

milled lead door frame

1 1

3

250

1

1 Fixing holes, max. tensile force per anchor 1.5 kN; max. compressive force 4.2 kN

Basics of Planning

2 No. Document No. from Document

2 Alternative fixing holes 3 User side

01 XPB1-200.891.01.01.02 01 / 2019 PG Multix Impact

300 200 300

Mounting Bucky Wall Stand 1:10 1 Recess for cable duct, width depending on cable duct 2 Cable duct 200x60 mm NOTE : ALL DOORS SYMBOLS MEAN CLEAR DOOR OPENING

NOT WALL OPENING

468 Site preparations

50 368 50 Technical details - Floor Mounting

2 2

45

1

102

1 Abdelrahman Gamal Karem Zakaria Abdelrahman Gamal

5/1/2024 5/1/2024 5/1/2024

168

311

Edited Checked Released

168

2 2 Siemens Healthcare GmbH

98

Planning department

41

Hartmannstrasse 16

1 1

62.5 343 62.5 D-91052 Erlangen

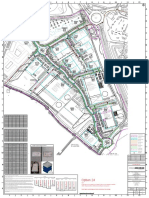

DELTA UNIVERSITY HOSPITAL

International Coastal Rd,

Fixation holes, max. tensile force per anchor 1.34 kN

Al Hafir WA Al Amal

1

RADIOLOGY

2 Alternative fixation holes

GROUND FLOOR

0m 1m 2m

Multi Modality

MULTIX Impact VA20/VA21

Project File Revision Page Size Scale

112332 1714802 01 02 of 03 A1 1:50

© Siemens Healthcare GmbH created by Sales CAD

You might also like

- Reflection: Gennady Lukinykh Геннадий ЛукиныхDocument3 pagesReflection: Gennady Lukinykh Геннадий ЛукиныхVasilescuLucian100% (4)

- Nezukos ThemeDocument4 pagesNezukos ThemeVKZ cuberNo ratings yet

- Bridge Design Sample Autocad-2Document1 pageBridge Design Sample Autocad-2DINESHNo ratings yet

- One - Piece - Overtaken - Full ScoreDocument2 pagesOne - Piece - Overtaken - Full Scorelanguagelearner451No ratings yet

- Shanghai Tower Construction MaterialsDocument25 pagesShanghai Tower Construction Materialskingashish67% (6)

- Partitura PianoDocument1 pagePartitura PianoEmilyRabeloNo ratings yet

- Conn 4 Conn 34: MTR BatDocument1 pageConn 4 Conn 34: MTR BatKevinCollenNo ratings yet

- Aoc Le32w254dDocument4 pagesAoc Le32w254dVenícius SetubalNo ratings yet

- AOC LE32W164 Diagrama Power Board - K-75L2 - K-75L1 - OB2273Document33 pagesAOC LE32W164 Diagrama Power Board - K-75L2 - K-75L1 - OB2273Angel ArebaloNo ratings yet

- Master Plan PHASE 1pdfDocument1 pageMaster Plan PHASE 1pdfNaimuddinNo ratings yet

- Sec C Ió N: Vicepresidenciadeproyectos Minachuquicamatasubterránea IngenieríadedetalleDocument1 pageSec C Ió N: Vicepresidenciadeproyectos Minachuquicamatasubterránea IngenieríadedetalleCR ConductorNo ratings yet

- KA2 KA3 S1a: NotesDocument1 pageKA2 KA3 S1a: NotescristianNo ratings yet

- Fur Elise - Easy: Mihu Piano - 0911117495Document1 pageFur Elise - Easy: Mihu Piano - 0911117495Huynh Dang Han33% (3)

- Shut Down - BLACKPINK EASYDocument5 pagesShut Down - BLACKPINK EASYMaoNo ratings yet

- 11 Game For Two GurlittDocument1 page11 Game For Two GurlitteddyeNo ratings yet

- Gershwin The Glory of GershwinDocument2 pagesGershwin The Glory of GershwinTESSIERNo ratings yet

- Jingo Christopher NortonDocument3 pagesJingo Christopher NortonEvelyn SoonNo ratings yet

- Rikos Theme Made in Abyss OST Rui Ruii The Seal Pianist Full SheetsDocument4 pagesRikos Theme Made in Abyss OST Rui Ruii The Seal Pianist Full SheetsLud WingNo ratings yet

- SWR 1404SDocument1 pageSWR 1404SMarcos Lima Audiomarc SoluçõesNo ratings yet

- Pump Room & Hot and Cold Water Sump Codination Dwg.01.08.23-A1Document1 pagePump Room & Hot and Cold Water Sump Codination Dwg.01.08.23-A1Tanzil HassanNo ratings yet

- Slk07 04 Fe Igoms Pgf Lay 001 Project Location 12-06-2024Document1 pageSlk07 04 Fe Igoms Pgf Lay 001 Project Location 12-06-2024Agung MaulanaNo ratings yet

- My - Life - Is - Going - On CifraDocument2 pagesMy - Life - Is - Going - On CifraAndressa GomesNo ratings yet

- 3516 S2X1 - Up - RUMDocument2 pages3516 S2X1 - Up - RUMHamza AbuRayyaNo ratings yet

- 3516 s2x1 - Up - Petra & RumDocument2 pages3516 s2x1 - Up - Petra & RumHamza AbuRayyaNo ratings yet

- 3516 S2X1 - UpDocument2 pages3516 S2X1 - UpHamza AbuRayyaNo ratings yet

- T17m202-02300-205mi-00002 (Im8-65519-4)Document1 pageT17m202-02300-205mi-00002 (Im8-65519-4)Rodrigo RaddatzNo ratings yet

- Paul de Senneville - Mariage D'amourDocument6 pagesPaul de Senneville - Mariage D'amourNguyễnKhoaMaiAnhNo ratings yet

- Rp6s - Master For Idc - 8-Oct-2021 Printed PDFDocument25 pagesRp6s - Master For Idc - 8-Oct-2021 Printed PDFItz GyyyNo ratings yet

- Melody of The Night Shi JinDocument5 pagesMelody of The Night Shi JinYara N MeirellesNo ratings yet

- Praeludium - XII Johann Sebastian BachDocument2 pagesPraeludium - XII Johann Sebastian BachDiegoNo ratings yet

- 쇼팽왈츠15번Document4 pages쇼팽왈츠15번hryu7422No ratings yet

- Architect/Engineers: #117 Office of Facilities Management 100% Bid Documents For Construction Ground Floor Reflected Ceiling Plan 626A4-15-103 Renovate Emergency RoomDocument11 pagesArchitect/Engineers: #117 Office of Facilities Management 100% Bid Documents For Construction Ground Floor Reflected Ceiling Plan 626A4-15-103 Renovate Emergency RoomAlexNo ratings yet

- Red Face - Trombita DuettDocument1 pageRed Face - Trombita DuettSándor GáspárNo ratings yet

- Partitura TotoroDocument2 pagesPartitura TotoroBeto DrumondNo ratings yet

- Street 25M Street 25M: 02 GF - F.F.L +1.90 1Document1 pageStreet 25M Street 25M: 02 GF - F.F.L +1.90 1Khaled AshrafNo ratings yet

- Road From Palugaswewa To HabaranaDocument2 pagesRoad From Palugaswewa To HabaranaRenga Ramanujan CNo ratings yet

- 车尔尼练习曲No.50 g小调 世界末日Document6 pages车尔尼练习曲No.50 g小调 世界末日ygyxc114514No ratings yet

- Je_veux_de_ZazDocument3 pagesJe_veux_de_ZazMargareta ClaeysNo ratings yet

- No.32 - Gland Steam PipingDocument1 pageNo.32 - Gland Steam PipingAdetunji Babatunde TaiwoNo ratings yet

- 220 M6 0310 00001r001Document1 page220 M6 0310 00001r001Luis BernedoNo ratings yet

- Ornstein Cello Sonata 2 PDFDocument39 pagesOrnstein Cello Sonata 2 PDFemilyNo ratings yet

- Another Love: by Tom OdellDocument8 pagesAnother Love: by Tom OdellGraceNo ratings yet

- Éramos Mortosnas Obras Más ADocument1 pageÉramos Mortosnas Obras Más AGUSTAVO santosNo ratings yet

- Fire Safety Control PlanDocument1 pageFire Safety Control PlanALPHA OMEGANo ratings yet

- Key Notes: A B D CDocument1 pageKey Notes: A B D CCristo BglezNo ratings yet

- Allegretto en Re MayorDocument1 pageAllegretto en Re MayorGisel PauletteNo ratings yet

- O Mia Bela MaduninaDocument2 pagesO Mia Bela MaduninaJutta Von KospothNo ratings yet

- Hvac Fan Location DWGDocument1 pageHvac Fan Location DWGNitish BhardwajNo ratings yet

- Queen's GardenDocument3 pagesQueen's GardenJonah ProudFoot PhilibertNo ratings yet

- G Minor Bach by Luo NiDocument5 pagesG Minor Bach by Luo NighidimandavidNo ratings yet

- Sweet Dreams Cello DuoDocument2 pagesSweet Dreams Cello DuoFernando ÁlvarezNo ratings yet

- Face A FaceDocument1 pageFace A FaceCíntia Santos de MenezesNo ratings yet

- Sanyo LCD PsuDocument1 pageSanyo LCD Psuroca9oNo ratings yet

- 099b Passamezzo+saltarello Lute 2 AnonDocument2 pages099b Passamezzo+saltarello Lute 2 AnonLuis Angel Oviedo BermúdezNo ratings yet

- Fly MetothemoonscoreDocument2 pagesFly MetothemoonscoreMichael DobkinNo ratings yet

- Fuga 5Document2 pagesFuga 5Deyan DenchevNo ratings yet

- Guldan K QareebDocument88 pagesGuldan K QareebRafi RazaNo ratings yet

- P2021262-110-Rev0 CSD - Option 24 (06 Nov)Document1 pageP2021262-110-Rev0 CSD - Option 24 (06 Nov)yusufuNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: MathFrom EverandInstant Assessments for Data Tracking, Grade 1: MathRating: 4 out of 5 stars4/5 (1)

- Absolute VEXL VEXXL H13-H14Document1 pageAbsolute VEXL VEXXL H13-H14Khemmou AmokraneNo ratings yet

- Manufacturing and Application of Stainless Steels: Andrea Di SchinoDocument262 pagesManufacturing and Application of Stainless Steels: Andrea Di SchinoJohanes DarmawanNo ratings yet

- RCC - Gupta & Gupta.Document803 pagesRCC - Gupta & Gupta.Rajat Rathore100% (1)

- CBF & Pultrusion Basalt Composite Materials Production Project in ArmeniaDocument16 pagesCBF & Pultrusion Basalt Composite Materials Production Project in ArmeniaAnonymous LhmiGjONo ratings yet

- Spinor A20: Product Data SheetDocument2 pagesSpinor A20: Product Data SheetKhin Sandi KoNo ratings yet

- Study and Analysis On Heat Treatment Process and Microstructure of Low Carbon SteelDocument6 pagesStudy and Analysis On Heat Treatment Process and Microstructure of Low Carbon SteelIJARTESNo ratings yet

- Comdiflex Spiral Wound Gaskets Technical CatalogueDocument7 pagesComdiflex Spiral Wound Gaskets Technical CatalogueSugianto BarusNo ratings yet

- Removal of Corrosion ProductDocument3 pagesRemoval of Corrosion ProductAlan NipNo ratings yet

- Research and Project Work On The Rate of Evaporation of Different LiquidsDocument24 pagesResearch and Project Work On The Rate of Evaporation of Different LiquidsSamuelNo ratings yet

- Pompa Siram Tanaman pst-1 2x3 m3h @35mDocument3 pagesPompa Siram Tanaman pst-1 2x3 m3h @35mAndreas B KresnawanNo ratings yet

- 1 Sheet Fundamentals of Heat TransferDocument3 pages1 Sheet Fundamentals of Heat TransferManju MuruhanNo ratings yet

- 41xx SteelDocument2 pages41xx Steelkumar rajaNo ratings yet

- Molecularly Oriented Polyvinyl Chloride (Pvco) Pressure Pipe, 4 In. Through 12 In. (100 MM Through 300 MM), For Water DistributionDocument24 pagesMolecularly Oriented Polyvinyl Chloride (Pvco) Pressure Pipe, 4 In. Through 12 In. (100 MM Through 300 MM), For Water DistributionJORGE LOPEZ100% (1)

- MatterDocument44 pagesMatterkaren sadiaNo ratings yet

- SCH4U1 Course ReviewDocument7 pagesSCH4U1 Course ReviewTest EmailNo ratings yet

- Total Area 272 Sq. Meters: Waste DisposalDocument1 pageTotal Area 272 Sq. Meters: Waste DisposalMANPOWER ORMOCNo ratings yet

- Proconnect H05 - H07-BQ-FDocument1 pageProconnect H05 - H07-BQ-FPaul ScottNo ratings yet

- To Study Strength Characteristics of Concrete With Rice Husk AshDocument6 pagesTo Study Strength Characteristics of Concrete With Rice Husk Ashabdulshkur muridNo ratings yet

- MDSReport 942254230Document183 pagesMDSReport 942254230javier ortizNo ratings yet

- Case Study Alcoa Reynobond (R) With EcoCleanT Jay KahnDocument30 pagesCase Study Alcoa Reynobond (R) With EcoCleanT Jay KahnsrowbothamNo ratings yet

- Kalmetall W Kalpraxis GBDocument12 pagesKalmetall W Kalpraxis GBkaniappan sakthivelNo ratings yet

- Catalogo-Valvula-De-Bloqueo STEALDocument4 pagesCatalogo-Valvula-De-Bloqueo STEALToty Ainol ValeroNo ratings yet

- Kaleesuwari - Palani - Project Report 2018Document62 pagesKaleesuwari - Palani - Project Report 2018Raja' s100% (1)

- Plastic LimitDocument3 pagesPlastic LimitthuaiyaalhinaiNo ratings yet

- Types of Additive Manufacturing TechnologyDocument7 pagesTypes of Additive Manufacturing Technologydeekamittal100% (1)

- Overview Data LOCTITE HB S PURBOND-Line July 2015 - 2Document1 pageOverview Data LOCTITE HB S PURBOND-Line July 2015 - 2frankNo ratings yet

- TMCX DiametrosDocument1 pageTMCX DiametrosalbertoNo ratings yet

- Piping JointsDocument2 pagesPiping JointsWaleed ShafiqNo ratings yet

- He Design Report Group 2Document29 pagesHe Design Report Group 2Aji PratamaNo ratings yet