Professional Documents

Culture Documents

1705135 03

1705135 03

Uploaded by

hassan awadallaCopyright:

Available Formats

You might also like

- MPM TroubleshootingDocument34 pagesMPM TroubleshootingMustafaNo ratings yet

- Renaissance Woman: Fat Loss, Muscle Growth & Performance Through Scientific EatingDocument20 pagesRenaissance Woman: Fat Loss, Muscle Growth & Performance Through Scientific EatingBenedict Ray Andhika33% (3)

- The Essentials of Psychodynamic PsychotherapyDocument6 pagesThe Essentials of Psychodynamic PsychotherapyMarthaRamirez100% (3)

- QM Hücre Kumanda Şemasi SM6-36Document15 pagesQM Hücre Kumanda Şemasi SM6-36Muhammed Demir100% (1)

- BIACS 2 - Seville Biennial: The Unhomely (Review)Document3 pagesBIACS 2 - Seville Biennial: The Unhomely (Review)foggy_notionNo ratings yet

- Acs 6t UsermanualDocument4 pagesAcs 6t UsermanualMuhammad rizkiNo ratings yet

- Sample Building Plans2 PDFDocument12 pagesSample Building Plans2 PDFAngel Lisette LaoNo ratings yet

- Ministry of Transportation: ImotkedtpDocument27 pagesMinistry of Transportation: Imotkedtpahmad kadafiNo ratings yet

- User Guide: NICE9000-V Series Integrated Villa Elevator Control CabinetDocument2 pagesUser Guide: NICE9000-V Series Integrated Villa Elevator Control Cabinetyanlay100% (1)

- AT&S Standard Scheme - Unigear ZS1 D1440Document8 pagesAT&S Standard Scheme - Unigear ZS1 D1440zhang1988No ratings yet

- Distance Sensor Dx35 Quickstart: Set KeyDocument2 pagesDistance Sensor Dx35 Quickstart: Set KeyNassNo ratings yet

- A 420 BBC WFC Stair SystemDetailsDocument1 pageA 420 BBC WFC Stair SystemDetailsEnfal AhmedogluNo ratings yet

- Operation Manual: Fieldbus DeviceDocument1 pageOperation Manual: Fieldbus DeviceRodrigo CostaNo ratings yet

- L950 Electrical SchematicsDocument64 pagesL950 Electrical Schematicsts5xxsw2m9No ratings yet

- 3048 (PIPE - 1-1/2'' - SCH. - 40 X 2515) : For ConstructionDocument1 page3048 (PIPE - 1-1/2'' - SCH. - 40 X 2515) : For ConstructionGHULAM NABINo ratings yet

- Rev-1Document8 pagesRev-1anwar sadatNo ratings yet

- Quickstart Dx35 de en FR Es PT ZH Ja It Ru Im0044955Document2 pagesQuickstart Dx35 de en FR Es PT ZH Ja It Ru Im0044955ROSSNo ratings yet

- Quickstart Dx35 de en FR Es PT ZH Ja It Ru Im0044955Document2 pagesQuickstart Dx35 de en FR Es PT ZH Ja It Ru Im0044955ROSSNo ratings yet

- Schéma Électrique 923043Document1 pageSchéma Électrique 923043ChriskvaNo ratings yet

- Ministry of Transportation: ImotkedtpDocument25 pagesMinistry of Transportation: Imotkedtpahmad kadafiNo ratings yet

- ST-1474 105 SteelDocument1 pageST-1474 105 Steelrazvan bossNo ratings yet

- NV3 - GFRC or UHPC (Concealed Fixing) : Thermally Broken Cladding Support SystemDocument16 pagesNV3 - GFRC or UHPC (Concealed Fixing) : Thermally Broken Cladding Support Systemart cafeNo ratings yet

- DD2050 LT704Document8 pagesDD2050 LT704vilmaNo ratings yet

- 1705135 02Document1 page1705135 02hassan awadallaNo ratings yet

- KT-302H Series: Instruction ManualDocument1 pageKT-302H Series: Instruction ManualputrastevanofyNo ratings yet

- Structural Design ResumeDocument15 pagesStructural Design Resumenkurunzizaapollinaire202No ratings yet

- DSGN DRWN CHKD Appd AG CB CCS CB: GMR Goa International Airport LimitedDocument10 pagesDSGN DRWN CHKD Appd AG CB CCS CB: GMR Goa International Airport LimitedAditya KNo ratings yet

- Layout Design of Base, Cable Entry & Terminals For Drive StandardDocument7 pagesLayout Design of Base, Cable Entry & Terminals For Drive Standardrizal arifinNo ratings yet

- Cmit 220046 000 SCW 15.01 0005 0Document5 pagesCmit 220046 000 SCW 15.01 0005 0Ali SalehNo ratings yet

- Rre Je Je1 A01 NSP Acm CH RDS A0 DWG 00563Document1 pageRre Je Je1 A01 NSP Acm CH RDS A0 DWG 00563BEN BENNo ratings yet

- Quick Start Atys QS 800 3200A-EnDocument1 pageQuick Start Atys QS 800 3200A-EnRofik NNo ratings yet

- Yamazumi Process Modeling Tool AdaptiveBMSDocument3 pagesYamazumi Process Modeling Tool AdaptiveBMSLaser MachineNo ratings yet

- Tidrqm7 PDFDocument11 pagesTidrqm7 PDFzizouhicheNo ratings yet

- G-102-01 (790DBBC) Al-Shahaniya: AR-SF-103-01Document1 pageG-102-01 (790DBBC) Al-Shahaniya: AR-SF-103-01AslamNo ratings yet

- Drawing DM1Document22 pagesDrawing DM1slamet haryadiNo ratings yet

- Piping Isometric - 9Document1 pagePiping Isometric - 9CosminMarianNo ratings yet

- Friend of KimDocument1 pageFriend of KimBernie QuepNo ratings yet

- JFN01 05 033 ADocument1 pageJFN01 05 033 Aluca.laniNo ratings yet

- Intake - Out Chamber Rev.01 SDR CombinedPDFDocument9 pagesIntake - Out Chamber Rev.01 SDR CombinedPDFJhonnel PunzalanNo ratings yet

- Epcc05 MDR 421 STR DWG 000 0072 05Document1 pageEpcc05 MDR 421 STR DWG 000 0072 05RANJEET PRATAP SINGHNo ratings yet

- 《NICE9000 V别墅梯一体化控制柜简易手册》 英文20181130 A01 19010649Document2 pages《NICE9000 V别墅梯一体化控制柜简易手册》 英文20181130 A01 19010649Zion LingNo ratings yet

- Sectiune 1-1: SCARA 1:50Document1 pageSectiune 1-1: SCARA 1:50George EnacheNo ratings yet

- BC-5600&5800 NewDocument2 pagesBC-5600&5800 Newsamuel debebeNo ratings yet

- Pvi Usb RS232 - 485Document2 pagesPvi Usb RS232 - 485Lucas CostaNo ratings yet

- Module 1 AssessmentDocument4 pagesModule 1 AssessmentSheela AliNo ratings yet

- DBU 10EDDocument2 pagesDBU 10EDDũng Nguyễn ViệtNo ratings yet

- Deepborewell - Ishwar House - Kichto PanchayatDocument13 pagesDeepborewell - Ishwar House - Kichto PanchayatShubham SinghNo ratings yet

- L L L L: Section Section SectionDocument1 pageL L L L: Section Section SectionajmainNo ratings yet

- Note Generale: Key NotesDocument1 pageNote Generale: Key NotesPablo BenedettoNo ratings yet

- FINETEK MAN PT76 TemperatureController enDocument2 pagesFINETEK MAN PT76 TemperatureController enMahmoud Abd-Elhamid Abu EyadNo ratings yet

- Rogers Wright-22.06.2020Document11 pagesRogers Wright-22.06.2020best essaysNo ratings yet

- D250E & D300E Series II Articulated Trucks Electrical SchematicDocument2 pagesD250E & D300E Series II Articulated Trucks Electrical SchematicOscar Tello Huaripata0% (1)

- INSPECTION AND TEST PLAN FOR INSTALLATION & TESTING FOR ACOUSTIC FALSE CEILING & GYPSUM BOARD FRAMING SYSTEMSDocument8 pagesINSPECTION AND TEST PLAN FOR INSTALLATION & TESTING FOR ACOUSTIC FALSE CEILING & GYPSUM BOARD FRAMING SYSTEMSMaqsood ChannaNo ratings yet

- ITP Ceiling worksDocument1 pageITP Ceiling worksMaqsood ChannaNo ratings yet

- Logan DelphiDocument5 pagesLogan Delphieugeh11No ratings yet

- H500i - H500 Manual Ver5 021119 - WebDocument2 pagesH500i - H500 Manual Ver5 021119 - WebBagaskara NurNo ratings yet

- Fire Door Details Black and WhiteDocument1 pageFire Door Details Black and WhiteFRANKLYN SPENCERNo ratings yet

- Disassembly and Assembly Procedures For Rollers With Inverted Duo-Cone SealsDocument1 pageDisassembly and Assembly Procedures For Rollers With Inverted Duo-Cone Seals----No ratings yet

- Instalation Proposal Drawing Secador FD410 MetricDocument1 pageInstalation Proposal Drawing Secador FD410 MetricEddo CarrionNo ratings yet

- Schematics S-1221 CombinedDocument76 pagesSchematics S-1221 CombinedFernando CastilloNo ratings yet

- 6019A-501-001-00 Hydraulic Diagram - Thrust CylinderDocument6 pages6019A-501-001-00 Hydraulic Diagram - Thrust CylinderFernando CastilloNo ratings yet

- LB 40 - BM - 9820850004-01.idwDocument1 pageLB 40 - BM - 9820850004-01.idwyrliimgtluhqqhlxtzNo ratings yet

- 3.detail ThreeDocument1 page3.detail ThreemaxNo ratings yet

- Dissertation Topics in HindiDocument7 pagesDissertation Topics in HindiPaperWritingCompanyBillings100% (1)

- British Baker Top Bakery Trends 2023Document15 pagesBritish Baker Top Bakery Trends 2023kiagus artaNo ratings yet

- Data Sheets Ecc I On AdoraDocument23 pagesData Sheets Ecc I On AdoraAlanAvtoNo ratings yet

- Stones Unit 2bDocument11 pagesStones Unit 2bJamal Al-deenNo ratings yet

- ENISA Secure Software Engineering InitiativesDocument96 pagesENISA Secure Software Engineering InitiativesstrokenfilledNo ratings yet

- Steve Nison - Candlestick Patterns - RezumatDocument22 pagesSteve Nison - Candlestick Patterns - RezumatSIightlyNo ratings yet

- Metaverse Report - Thought Leadership 1Document17 pagesMetaverse Report - Thought Leadership 1Tejas KNo ratings yet

- Major Landforms of The Earth NotesDocument3 pagesMajor Landforms of The Earth NotesSIMMA SAI PRASANNANo ratings yet

- Operational Framework of Community Organizing ProcessDocument18 pagesOperational Framework of Community Organizing ProcessJan Paul Salud LugtuNo ratings yet

- Performance Evaluation of Selected Ceramic Companies of BangladeshDocument14 pagesPerformance Evaluation of Selected Ceramic Companies of BangladeshmotaazizNo ratings yet

- Commuter Crossword Puzzles UpdatedDocument3 pagesCommuter Crossword Puzzles UpdatedChidinma UwadiaeNo ratings yet

- Index: Monthly Bulletin-Dec 2022Document46 pagesIndex: Monthly Bulletin-Dec 2022Sanif KhanNo ratings yet

- Chapter - 04 - Lecture Mod PDFDocument72 pagesChapter - 04 - Lecture Mod PDFtahirNo ratings yet

- Unit - 2 Sensor Networks - Introduction & ArchitecturesDocument32 pagesUnit - 2 Sensor Networks - Introduction & Architecturesmurlak37No ratings yet

- Study Session8Document1 pageStudy Session8MOSESNo ratings yet

- Welspun Linen Customer Price List 2023Document4 pagesWelspun Linen Customer Price List 2023Vipin SharmaNo ratings yet

- Veronica Sanchez Vs CirDocument3 pagesVeronica Sanchez Vs CirArthur John Garraton0% (1)

- Dual-Band Wearable Rectenna For Low-Power RF Energy HarvestingDocument10 pagesDual-Band Wearable Rectenna For Low-Power RF Energy HarvestingbabuNo ratings yet

- Piglia - Hotel AlmagroDocument2 pagesPiglia - Hotel AlmagroJustin LokeNo ratings yet

- Shaping The Way We Teach English:: Successful Practices Around The WorldDocument5 pagesShaping The Way We Teach English:: Successful Practices Around The WorldCristina DiaconuNo ratings yet

- OX App Suite User Guide English v7.6.0Document180 pagesOX App Suite User Guide English v7.6.0Ranveer SinghNo ratings yet

- SOPDocument3 pagesSOPShreya BonteNo ratings yet

- SPOUSES SALVADOR ABELLA v. SPOUSES ROMEO ABELLADocument2 pagesSPOUSES SALVADOR ABELLA v. SPOUSES ROMEO ABELLAAlia Arnz-Dragon100% (1)

- Home Office and Branch Accounting Agency 1Document20 pagesHome Office and Branch Accounting Agency 1John Stephen PendonNo ratings yet

- State of The Handloom Industry of BangladeshDocument8 pagesState of The Handloom Industry of BangladeshNoshin NawarNo ratings yet

- Current Affairs October 2013kDocument76 pagesCurrent Affairs October 2013kKanthi Rekha VardhiNo ratings yet

1705135 03

1705135 03

Uploaded by

hassan awadallaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1705135 03

1705135 03

Uploaded by

hassan awadallaCopyright:

Available Formats

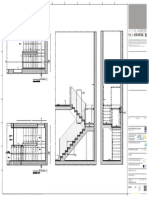

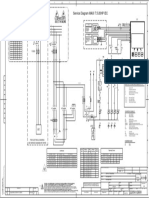

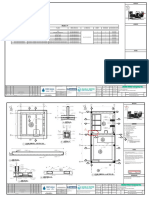

Example: Steel substructure for patient table 1:10 Dimensioning

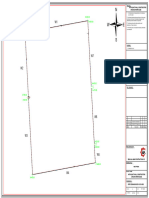

Unit arrangement

All installation measurements apply to finished wall/floor/ceiling and are to be checked prior to assembling the unit.

700 cm mm

324 376

781

Orientation point = reference point of the Siemens unit for planning and installation

Battery

UPS 1.29 General remarks

1.28 1.31 1.32 t = 20

Floor stand

200

The preinstallation parts are part of the preinstallation shipment.

Equipment Room

The preinstallation kit contains the mounting plate with installation hardware, as well as the ceiling outlet.

785

The installation gauge, Part No.65 72 627 G144E, is required for installation of the floor stand and patient

table mounting plates.

A 1 Patient table

The preinstallation parts are part of the preinstallation shipment.

The pre-installation parts include the installation plate and the mounting materials

Pre-installation in computer flooring

Recommendation: Floor stand installation plate on filled concrete or on the on-site substructure.

1.06 Patient table tension loads

A 1 3 Mounting plate on concrete fill-up.

Foot-end load per installation plate mounting point: max. tensile force 4.5 kN.

Floor stand/patient table

1.01

130

1.02 The two mounting plates for the stand and patient table must be installed on a solid base that has sufficient load

capacity. Cut away the floor covering. If necessary, any material in the location of the mounting plates that does

545

not have the required load capacity must be replaced with filled concrete.

4 For fixing purposes Hilti heavy-duty expansion anchors are supplied.

1.04 The minimum degree of firmness of the concrete is C 20/25 according to DIN 1045-1 for solid concrete If required,

1.05 the plates can be fixed with on-site threaded bolts through the solid concrete according to DIN 976-1-M12-8.8.

Examination Room If mounting using the Hilti floor anchors that are provided is not possible because of the floor conditions, other floor

509 anchors can also be used. These must have the same or better specifications (e.g. max. admissible pull forces) as

1 L-M the Hilti floor anchors that are provided.

459

229 Z

L M Center of gravity of the patient table

t=15 2

(not to scale)

1 Movement of center of gravity

434

1.18

Z 1:1

484

1.13 1.18d 2 Center of gravity, table rotated 120°

6 1

1.18c

1.17 1.10 3 Orientation point / center of rotation

5

218

1.18b 1.12 120°

1.15 1.09a 1.16 2 4 Center of gravity, table rotated -120°

1.11

Control Room 1 *1

Ø20.5 7 2 5 Center of gravity, table in 0° position

3

179

*1 A point load of max. 8 kN is exerted

1 Mounting plate patient table, fastening with 4 x M12 2 Substructure on the center of gravity

377

3 Substructure base plate 700 x 700 mm 4 Solid concrete min. C20/25

0

4

62

5 Seal continously with hygienic-grade silicone 6 Insulating parts 7 Floor covering

Site Preparation - Concrete Fill-UP 5

Substructure fastening with Hilti heavy-duty expansion anchors. 120°

Please note the instructions given by the manufacturer.

Concrete fill-up 1:20

500

420 6

Mounting plate patient table 1:10

Equipment 1 3 509

300 1 Z L-0

Room 459 2

min. 195

max. 70

5 229

3

12.2 Pb 2mm Lead lining for all walls,frames and doors

100 in accordance to the national regulation up to 220 cm. L M

200

t=15

4

min. 160

4

434

2

484

Examination ≥ 355 N O

Room Z 1:2 5 6

≤ 780

219

7

□900

50 40

Ø20.5 8

1 Cable duct 2 Cut-out for cable duct and cable lead-in

35

1 Screed 2 Insulation

20

90

Pb. Option: Injector floor outlet. Area in which the outlet is installed.

3

Pb. Please note the instructions given by the manufacturer. 3 Concrete-fill-up 4 Solid concrete min. C20/25

35

4 Outlet centered to the table longitudinal axis 5 Head side 5 Insulating parts 6 Mounting plate

90 152

Equipment 6 In this area a minimum cable duct height of 7cm to ensure that the table cable is not bent too much. 7 Seal continously with hygienic-grade silicone 8 Floor covering

Room

An injector cable may not be pulled through the table base. It is absolutely necessary to route the When assembling of the plate on concrete fill-up the provided Hilti heavy-duty expansion anchors

injector cable (control cable between table stand and injector control) via the floor outlet. HSL-3-G M12/100 are to be used. Please note the instructions given by the manufacturer.

Load on each mounting point at the table foot end max. tensile force equaling 4.5 kN

100 Mounting plate patient table 1:10

100

Pb. 509

Site preparations

L-0 1

459 Z Technical details - Floor

229 We reserve the right to make technical alterations.

200

All data serve for the on-site preparation for installation and cabling of the Siemens system in order to ensure

99

15.5 L M

2 correct operation.

Control t=15 This plan is not a construction drawing and is not to be used for carrying out construction work.

min. 160

Room

Control

88

434

Room Abdelrahman Gamal Kareem Zakaria Abdelrahman Gamal

484

4/8/2024 4/8/2024 4/8/2024

N O 4

3 Edited Checked Released

13

Z 1:2

5 Siemens Healthcare GmbH

Planning department

Hartmannstrasse 16

Ø20.5 6 D-91052 Erlangen

DELTA UNIVERSITY HOSPITAL

1 Bore hole Ø 100 2 Solid concrete min. C20/25 International Coastal Rd,

Al Hafir WA Al Amal

3 Insulating parts 4 Mounting plate

RADIOLOGY

5 Seal continously with hygienic-grade silicone 6 Floor covering

GROUND FLOOR

0m 1m 2m

When assembling of the plate on concrete fill-up the provided Hilti heavy-duty expansion anchors

HSL-3-G M12/25 are to be used. Please note the instructions given by the manufacturer.

Multi Modality

Load on each mounting point at the table foot end max. tensile force equaling 4.5 kN.

Floor mounting using studs (threaded bars) through the ceiling of the room below is possible (obtain studs locally). Project File Revision Page Size Scale

112332 1705135 01 03 of 04 A1 1:50

© Siemens Healthcare GmbH created by Sales CAD © Siemens Healthcare GmbH created by Sales CAD

You might also like

- MPM TroubleshootingDocument34 pagesMPM TroubleshootingMustafaNo ratings yet

- Renaissance Woman: Fat Loss, Muscle Growth & Performance Through Scientific EatingDocument20 pagesRenaissance Woman: Fat Loss, Muscle Growth & Performance Through Scientific EatingBenedict Ray Andhika33% (3)

- The Essentials of Psychodynamic PsychotherapyDocument6 pagesThe Essentials of Psychodynamic PsychotherapyMarthaRamirez100% (3)

- QM Hücre Kumanda Şemasi SM6-36Document15 pagesQM Hücre Kumanda Şemasi SM6-36Muhammed Demir100% (1)

- BIACS 2 - Seville Biennial: The Unhomely (Review)Document3 pagesBIACS 2 - Seville Biennial: The Unhomely (Review)foggy_notionNo ratings yet

- Acs 6t UsermanualDocument4 pagesAcs 6t UsermanualMuhammad rizkiNo ratings yet

- Sample Building Plans2 PDFDocument12 pagesSample Building Plans2 PDFAngel Lisette LaoNo ratings yet

- Ministry of Transportation: ImotkedtpDocument27 pagesMinistry of Transportation: Imotkedtpahmad kadafiNo ratings yet

- User Guide: NICE9000-V Series Integrated Villa Elevator Control CabinetDocument2 pagesUser Guide: NICE9000-V Series Integrated Villa Elevator Control Cabinetyanlay100% (1)

- AT&S Standard Scheme - Unigear ZS1 D1440Document8 pagesAT&S Standard Scheme - Unigear ZS1 D1440zhang1988No ratings yet

- Distance Sensor Dx35 Quickstart: Set KeyDocument2 pagesDistance Sensor Dx35 Quickstart: Set KeyNassNo ratings yet

- A 420 BBC WFC Stair SystemDetailsDocument1 pageA 420 BBC WFC Stair SystemDetailsEnfal AhmedogluNo ratings yet

- Operation Manual: Fieldbus DeviceDocument1 pageOperation Manual: Fieldbus DeviceRodrigo CostaNo ratings yet

- L950 Electrical SchematicsDocument64 pagesL950 Electrical Schematicsts5xxsw2m9No ratings yet

- 3048 (PIPE - 1-1/2'' - SCH. - 40 X 2515) : For ConstructionDocument1 page3048 (PIPE - 1-1/2'' - SCH. - 40 X 2515) : For ConstructionGHULAM NABINo ratings yet

- Rev-1Document8 pagesRev-1anwar sadatNo ratings yet

- Quickstart Dx35 de en FR Es PT ZH Ja It Ru Im0044955Document2 pagesQuickstart Dx35 de en FR Es PT ZH Ja It Ru Im0044955ROSSNo ratings yet

- Quickstart Dx35 de en FR Es PT ZH Ja It Ru Im0044955Document2 pagesQuickstart Dx35 de en FR Es PT ZH Ja It Ru Im0044955ROSSNo ratings yet

- Schéma Électrique 923043Document1 pageSchéma Électrique 923043ChriskvaNo ratings yet

- Ministry of Transportation: ImotkedtpDocument25 pagesMinistry of Transportation: Imotkedtpahmad kadafiNo ratings yet

- ST-1474 105 SteelDocument1 pageST-1474 105 Steelrazvan bossNo ratings yet

- NV3 - GFRC or UHPC (Concealed Fixing) : Thermally Broken Cladding Support SystemDocument16 pagesNV3 - GFRC or UHPC (Concealed Fixing) : Thermally Broken Cladding Support Systemart cafeNo ratings yet

- DD2050 LT704Document8 pagesDD2050 LT704vilmaNo ratings yet

- 1705135 02Document1 page1705135 02hassan awadallaNo ratings yet

- KT-302H Series: Instruction ManualDocument1 pageKT-302H Series: Instruction ManualputrastevanofyNo ratings yet

- Structural Design ResumeDocument15 pagesStructural Design Resumenkurunzizaapollinaire202No ratings yet

- DSGN DRWN CHKD Appd AG CB CCS CB: GMR Goa International Airport LimitedDocument10 pagesDSGN DRWN CHKD Appd AG CB CCS CB: GMR Goa International Airport LimitedAditya KNo ratings yet

- Layout Design of Base, Cable Entry & Terminals For Drive StandardDocument7 pagesLayout Design of Base, Cable Entry & Terminals For Drive Standardrizal arifinNo ratings yet

- Cmit 220046 000 SCW 15.01 0005 0Document5 pagesCmit 220046 000 SCW 15.01 0005 0Ali SalehNo ratings yet

- Rre Je Je1 A01 NSP Acm CH RDS A0 DWG 00563Document1 pageRre Je Je1 A01 NSP Acm CH RDS A0 DWG 00563BEN BENNo ratings yet

- Quick Start Atys QS 800 3200A-EnDocument1 pageQuick Start Atys QS 800 3200A-EnRofik NNo ratings yet

- Yamazumi Process Modeling Tool AdaptiveBMSDocument3 pagesYamazumi Process Modeling Tool AdaptiveBMSLaser MachineNo ratings yet

- Tidrqm7 PDFDocument11 pagesTidrqm7 PDFzizouhicheNo ratings yet

- G-102-01 (790DBBC) Al-Shahaniya: AR-SF-103-01Document1 pageG-102-01 (790DBBC) Al-Shahaniya: AR-SF-103-01AslamNo ratings yet

- Drawing DM1Document22 pagesDrawing DM1slamet haryadiNo ratings yet

- Piping Isometric - 9Document1 pagePiping Isometric - 9CosminMarianNo ratings yet

- Friend of KimDocument1 pageFriend of KimBernie QuepNo ratings yet

- JFN01 05 033 ADocument1 pageJFN01 05 033 Aluca.laniNo ratings yet

- Intake - Out Chamber Rev.01 SDR CombinedPDFDocument9 pagesIntake - Out Chamber Rev.01 SDR CombinedPDFJhonnel PunzalanNo ratings yet

- Epcc05 MDR 421 STR DWG 000 0072 05Document1 pageEpcc05 MDR 421 STR DWG 000 0072 05RANJEET PRATAP SINGHNo ratings yet

- 《NICE9000 V别墅梯一体化控制柜简易手册》 英文20181130 A01 19010649Document2 pages《NICE9000 V别墅梯一体化控制柜简易手册》 英文20181130 A01 19010649Zion LingNo ratings yet

- Sectiune 1-1: SCARA 1:50Document1 pageSectiune 1-1: SCARA 1:50George EnacheNo ratings yet

- BC-5600&5800 NewDocument2 pagesBC-5600&5800 Newsamuel debebeNo ratings yet

- Pvi Usb RS232 - 485Document2 pagesPvi Usb RS232 - 485Lucas CostaNo ratings yet

- Module 1 AssessmentDocument4 pagesModule 1 AssessmentSheela AliNo ratings yet

- DBU 10EDDocument2 pagesDBU 10EDDũng Nguyễn ViệtNo ratings yet

- Deepborewell - Ishwar House - Kichto PanchayatDocument13 pagesDeepborewell - Ishwar House - Kichto PanchayatShubham SinghNo ratings yet

- L L L L: Section Section SectionDocument1 pageL L L L: Section Section SectionajmainNo ratings yet

- Note Generale: Key NotesDocument1 pageNote Generale: Key NotesPablo BenedettoNo ratings yet

- FINETEK MAN PT76 TemperatureController enDocument2 pagesFINETEK MAN PT76 TemperatureController enMahmoud Abd-Elhamid Abu EyadNo ratings yet

- Rogers Wright-22.06.2020Document11 pagesRogers Wright-22.06.2020best essaysNo ratings yet

- D250E & D300E Series II Articulated Trucks Electrical SchematicDocument2 pagesD250E & D300E Series II Articulated Trucks Electrical SchematicOscar Tello Huaripata0% (1)

- INSPECTION AND TEST PLAN FOR INSTALLATION & TESTING FOR ACOUSTIC FALSE CEILING & GYPSUM BOARD FRAMING SYSTEMSDocument8 pagesINSPECTION AND TEST PLAN FOR INSTALLATION & TESTING FOR ACOUSTIC FALSE CEILING & GYPSUM BOARD FRAMING SYSTEMSMaqsood ChannaNo ratings yet

- ITP Ceiling worksDocument1 pageITP Ceiling worksMaqsood ChannaNo ratings yet

- Logan DelphiDocument5 pagesLogan Delphieugeh11No ratings yet

- H500i - H500 Manual Ver5 021119 - WebDocument2 pagesH500i - H500 Manual Ver5 021119 - WebBagaskara NurNo ratings yet

- Fire Door Details Black and WhiteDocument1 pageFire Door Details Black and WhiteFRANKLYN SPENCERNo ratings yet

- Disassembly and Assembly Procedures For Rollers With Inverted Duo-Cone SealsDocument1 pageDisassembly and Assembly Procedures For Rollers With Inverted Duo-Cone Seals----No ratings yet

- Instalation Proposal Drawing Secador FD410 MetricDocument1 pageInstalation Proposal Drawing Secador FD410 MetricEddo CarrionNo ratings yet

- Schematics S-1221 CombinedDocument76 pagesSchematics S-1221 CombinedFernando CastilloNo ratings yet

- 6019A-501-001-00 Hydraulic Diagram - Thrust CylinderDocument6 pages6019A-501-001-00 Hydraulic Diagram - Thrust CylinderFernando CastilloNo ratings yet

- LB 40 - BM - 9820850004-01.idwDocument1 pageLB 40 - BM - 9820850004-01.idwyrliimgtluhqqhlxtzNo ratings yet

- 3.detail ThreeDocument1 page3.detail ThreemaxNo ratings yet

- Dissertation Topics in HindiDocument7 pagesDissertation Topics in HindiPaperWritingCompanyBillings100% (1)

- British Baker Top Bakery Trends 2023Document15 pagesBritish Baker Top Bakery Trends 2023kiagus artaNo ratings yet

- Data Sheets Ecc I On AdoraDocument23 pagesData Sheets Ecc I On AdoraAlanAvtoNo ratings yet

- Stones Unit 2bDocument11 pagesStones Unit 2bJamal Al-deenNo ratings yet

- ENISA Secure Software Engineering InitiativesDocument96 pagesENISA Secure Software Engineering InitiativesstrokenfilledNo ratings yet

- Steve Nison - Candlestick Patterns - RezumatDocument22 pagesSteve Nison - Candlestick Patterns - RezumatSIightlyNo ratings yet

- Metaverse Report - Thought Leadership 1Document17 pagesMetaverse Report - Thought Leadership 1Tejas KNo ratings yet

- Major Landforms of The Earth NotesDocument3 pagesMajor Landforms of The Earth NotesSIMMA SAI PRASANNANo ratings yet

- Operational Framework of Community Organizing ProcessDocument18 pagesOperational Framework of Community Organizing ProcessJan Paul Salud LugtuNo ratings yet

- Performance Evaluation of Selected Ceramic Companies of BangladeshDocument14 pagesPerformance Evaluation of Selected Ceramic Companies of BangladeshmotaazizNo ratings yet

- Commuter Crossword Puzzles UpdatedDocument3 pagesCommuter Crossword Puzzles UpdatedChidinma UwadiaeNo ratings yet

- Index: Monthly Bulletin-Dec 2022Document46 pagesIndex: Monthly Bulletin-Dec 2022Sanif KhanNo ratings yet

- Chapter - 04 - Lecture Mod PDFDocument72 pagesChapter - 04 - Lecture Mod PDFtahirNo ratings yet

- Unit - 2 Sensor Networks - Introduction & ArchitecturesDocument32 pagesUnit - 2 Sensor Networks - Introduction & Architecturesmurlak37No ratings yet

- Study Session8Document1 pageStudy Session8MOSESNo ratings yet

- Welspun Linen Customer Price List 2023Document4 pagesWelspun Linen Customer Price List 2023Vipin SharmaNo ratings yet

- Veronica Sanchez Vs CirDocument3 pagesVeronica Sanchez Vs CirArthur John Garraton0% (1)

- Dual-Band Wearable Rectenna For Low-Power RF Energy HarvestingDocument10 pagesDual-Band Wearable Rectenna For Low-Power RF Energy HarvestingbabuNo ratings yet

- Piglia - Hotel AlmagroDocument2 pagesPiglia - Hotel AlmagroJustin LokeNo ratings yet

- Shaping The Way We Teach English:: Successful Practices Around The WorldDocument5 pagesShaping The Way We Teach English:: Successful Practices Around The WorldCristina DiaconuNo ratings yet

- OX App Suite User Guide English v7.6.0Document180 pagesOX App Suite User Guide English v7.6.0Ranveer SinghNo ratings yet

- SOPDocument3 pagesSOPShreya BonteNo ratings yet

- SPOUSES SALVADOR ABELLA v. SPOUSES ROMEO ABELLADocument2 pagesSPOUSES SALVADOR ABELLA v. SPOUSES ROMEO ABELLAAlia Arnz-Dragon100% (1)

- Home Office and Branch Accounting Agency 1Document20 pagesHome Office and Branch Accounting Agency 1John Stephen PendonNo ratings yet

- State of The Handloom Industry of BangladeshDocument8 pagesState of The Handloom Industry of BangladeshNoshin NawarNo ratings yet

- Current Affairs October 2013kDocument76 pagesCurrent Affairs October 2013kKanthi Rekha VardhiNo ratings yet