Professional Documents

Culture Documents

1705135 01

1705135 01

Uploaded by

hassan awadallaCopyright:

Available Formats

You might also like

- C32 Industrial Wiring DiagramDocument4 pagesC32 Industrial Wiring DiagramHữu Linh100% (2)

- High Speed Railway Track Technical Options Suitability Assessment GuideDocument90 pagesHigh Speed Railway Track Technical Options Suitability Assessment GuidelachguerNo ratings yet

- Waterbox 900Document28 pagesWaterbox 900cem jakartaNo ratings yet

- Demon Slayer Kimetsu No Yaiba Free Download Anime Calendar 2022Document12 pagesDemon Slayer Kimetsu No Yaiba Free Download Anime Calendar 2022Gokul M PNo ratings yet

- 1 Novacron S OverviewDocument3 pages1 Novacron S OverviewsaskoNo ratings yet

- Solar Water Heater Distributor Business PlanDocument32 pagesSolar Water Heater Distributor Business Planlutos267% (3)

- Gloria V CA DigestDocument3 pagesGloria V CA Digestbeaenriquez100% (3)

- 743 Etm 9003 - 3Document1 page743 Etm 9003 - 3Fernando SanchezNo ratings yet

- CJ LocationDocument1 pageCJ LocationTerry CheukNo ratings yet

- 12 Coedmore Bridge - F Shape Barrier & End Block Sheet 1 of 2Document1 page12 Coedmore Bridge - F Shape Barrier & End Block Sheet 1 of 2Malibongwe MbamboNo ratings yet

- Sobha Hartland Greens - Phase 02: InvestmentsDocument1 pageSobha Hartland Greens - Phase 02: InvestmentsrajatNo ratings yet

- Fpso OverviewDocument1 pageFpso OverviewSean ChoiNo ratings yet

- Mtip MapDocument1 pageMtip MapAlan PittmanNo ratings yet

- Conselho de Professores - Recuperação Final: Instituto Superior de Educação Do Rio de JaneiroDocument2 pagesConselho de Professores - Recuperação Final: Instituto Superior de Educação Do Rio de JaneiroAYLA APARECIDA LORENA SEIXASNo ratings yet

- Notes: Roof: Concrete Roof Tiles On TrussesDocument1 pageNotes: Roof: Concrete Roof Tiles On TrussesanzaniNo ratings yet

- 02 - Road & Drainage-ModelDocument1 page02 - Road & Drainage-ModelSyafiq NazriNo ratings yet

- STORMWATER SYSTEM REMEDIATION LAYOUT P202110-IOCL-BR-E-CS-DET-6015 Rev-0Document1 pageSTORMWATER SYSTEM REMEDIATION LAYOUT P202110-IOCL-BR-E-CS-DET-6015 Rev-0Nitin SakpalNo ratings yet

- Wh-1088pe DrawingDocument1 pageWh-1088pe Drawingom sai quality developmentNo ratings yet

- DRG 4Document1 pageDRG 4Neil AgshikarNo ratings yet

- POCVN-MF-SD-CON-M-SEW-04 - Rev03 - 1st FloorDocument5 pagesPOCVN-MF-SD-CON-M-SEW-04 - Rev03 - 1st FloorTôn Huỳnh ĐoànNo ratings yet

- GTC CivilDocument1 pageGTC CivilRadulescu AndreiNo ratings yet

- 2019 Zip Zone Map SmallDocument1 page2019 Zip Zone Map SmallKHOUNo ratings yet

- PNG2023 Plumb 012 ADocument1 pagePNG2023 Plumb 012 ANoel MoronaNo ratings yet

- Crt-Npc-Dmm-Hva-Dwg-Sd-Gn-33501 - Equipment Capacity Schedule 1-6Document1 pageCrt-Npc-Dmm-Hva-Dwg-Sd-Gn-33501 - Equipment Capacity Schedule 1-6Shah MuzzamilNo ratings yet

- Perfil y Secciones_parque 27 (1)Document1 pagePerfil y Secciones_parque 27 (1)Eduardo Tintaya MachacaNo ratings yet

- Perfil y Secciones_parque 27 (2)Document1 pagePerfil y Secciones_parque 27 (2)Eduardo Tintaya MachacaNo ratings yet

- Id-Gf09 Faisal ElevationsDocument61 pagesId-Gf09 Faisal ElevationsMuhannad AlaniNo ratings yet

- 5Document1 page5ahmadtaiyabiNo ratings yet

- DX225LC-3 Elec 2012.10.15 PDFDocument1 pageDX225LC-3 Elec 2012.10.15 PDFDmytro ManzykNo ratings yet

- G6 G5 G3 G2 G1 G5' G7 G4: 1 Elephant Holding Ground Floor Level Load MapDocument1 pageG6 G5 G3 G2 G1 G5' G7 G4: 1 Elephant Holding Ground Floor Level Load MaphemanthsridharaNo ratings yet

- Hvac Layout For Ground Floor - (r0) 09-08-15-ModelDocument1 pageHvac Layout For Ground Floor - (r0) 09-08-15-ModelRavi PanchalNo ratings yet

- NonTendered ElevationDocument1 pageNonTendered ElevationprabhuNo ratings yet

- Australian Operating Mines 2021Document1 pageAustralian Operating Mines 2021Patricio Andres Santos CornejoNo ratings yet

- Corlu VFR ChartDocument1 pageCorlu VFR Chartcod modernwarfareNo ratings yet

- Quality Control: Elevation FrontDocument5 pagesQuality Control: Elevation FrontAria NickbakhtNo ratings yet

- Column LayoutDocument1 pageColumn LayoutAugustine yigaNo ratings yet

- GF200 Quick Installation GuideDocument2 pagesGF200 Quick Installation GuidejazuoneNo ratings yet

- Brosur Koolpanel EPSDocument3 pagesBrosur Koolpanel EPSDenata Machmud SugandhiNo ratings yet

- ALIGNMENT PLAN STRIP-WP-02-TemplateDocument1 pageALIGNMENT PLAN STRIP-WP-02-TemplateMd Mukul MiahNo ratings yet

- 402FloorPlans PDFDocument2 pages402FloorPlans PDFSubas NaguNo ratings yet

- Revised Utandi Estate 2Document1 pageRevised Utandi Estate 2Bessie SiyadoNo ratings yet

- 9204-BP12A-MMJV-DWG-FA-P1-L05-02304-REV.D03 (Commented)Document1 page9204-BP12A-MMJV-DWG-FA-P1-L05-02304-REV.D03 (Commented)Michael Camit EsoNo ratings yet

- 7E 7E 6E 6E: Foh Truss 1 Foh Truss 1Document1 page7E 7E 6E 6E: Foh Truss 1 Foh Truss 1TimothyNo ratings yet

- Ground Floor Hvac LayoutDocument1 pageGround Floor Hvac LayoutMohammed AzharNo ratings yet

- Zamboanga Pet Line 110419Document1 pageZamboanga Pet Line 110419PAul JoHn MeNdozaNo ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument1 pageYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterRonal Castillo PedrazaNo ratings yet

- Instructivo Pista Luis BGJ55-EngDocument1 pageInstructivo Pista Luis BGJ55-Englspr_001No ratings yet

- Rjj000-E0-Lay-480-00201-Rev 1-New2Document1 pageRjj000-E0-Lay-480-00201-Rev 1-New2Alif Anshar RazaqnaNo ratings yet

- FJS 1923000149Document1 pageFJS 1923000149SHAHZAD LATIFNo ratings yet

- AV - B AL TA: Mercado CentralDocument1 pageAV - B AL TA: Mercado Centraldoctor psiquiatraNo ratings yet

- Drawing 3.Document1 pageDrawing 3.tiyaniNo ratings yet

- b777 - Memory Items Painel Do 777-1Document1 pageb777 - Memory Items Painel Do 777-1RejaneNo ratings yet

- S781-CV-DWG-00006-04-213036-A - OQ Comments - 19.03.2023Document1 pageS781-CV-DWG-00006-04-213036-A - OQ Comments - 19.03.2023MDhana SekarNo ratings yet

- Flow Control Valve-RightDocument1 pageFlow Control Valve-RightElton PintoNo ratings yet

- Detalles Constructivos para La Red de Agua PotableDocument4 pagesDetalles Constructivos para La Red de Agua PotableRoberto Cabrera MillerNo ratings yet

- A11-00h - Ground Level - Part HDocument1 pageA11-00h - Ground Level - Part Hconsultnadeem70No ratings yet

- Foundation Plan and Anchor Locations: Section CDocument1 pageFoundation Plan and Anchor Locations: Section CJavier Guerra TriviñoNo ratings yet

- BaltimoreDocument1 pageBaltimoreLadNo ratings yet

- SLD - CBSE Patna - PDF 2Document1 pageSLD - CBSE Patna - PDF 2nbcccbsepatnaNo ratings yet

- Vista en Planta Detalles de Instalacion: Plant View Installation DetailsDocument1 pageVista en Planta Detalles de Instalacion: Plant View Installation DetailsDulce victoria MorenoNo ratings yet

- LD 1Document1 pageLD 1E111 ChipiNo ratings yet

- Geri 2Document1 pageGeri 2Vincent NavaNo ratings yet

- SC Study Line To Ground FaultDocument1 pageSC Study Line To Ground FaultMurali100% (1)

- Economic and Political WeeklyDocument8 pagesEconomic and Political WeeklynaveensarimallaNo ratings yet

- Resource AllocationDocument10 pagesResource AllocationZoe NyadziNo ratings yet

- Recognition, Signaling, and Repair of DNA Double-Strand Breaks Produced by Ionizing Radiation in Mammalian Cells - The Molecular ChoreographyDocument89 pagesRecognition, Signaling, and Repair of DNA Double-Strand Breaks Produced by Ionizing Radiation in Mammalian Cells - The Molecular ChoreographyMaria ClaraNo ratings yet

- Nanda 1Document4 pagesNanda 1Ethel GeorgeNo ratings yet

- BE1 Final Without Recheckreassessment - 453112Document1 pageBE1 Final Without Recheckreassessment - 453112MoloNo ratings yet

- Manual Therapy in The Treatment of Facial WrinklesDocument4 pagesManual Therapy in The Treatment of Facial WrinklesKarolina MirosNo ratings yet

- Modulo Ii: Dra. Andrea Mogni SDocument23 pagesModulo Ii: Dra. Andrea Mogni SMarco Antonio CaceresNo ratings yet

- Iqra University - Karachi Faculty of Business AdministrationDocument31 pagesIqra University - Karachi Faculty of Business Administrationsyed aliNo ratings yet

- 7 - Miaa V AlaDocument10 pages7 - Miaa V AlaBelle MaturanNo ratings yet

- LSM MockDocument5 pagesLSM MockKazi Rafsan NoorNo ratings yet

- Industry ProfileDocument9 pagesIndustry ProfilesarathNo ratings yet

- Testable Concepts in MCQDocument188 pagesTestable Concepts in MCQrami100% (1)

- CAN LIN ProtocolDocument60 pagesCAN LIN ProtocolBrady BriffaNo ratings yet

- People Vs Vicente MenilDocument2 pagesPeople Vs Vicente MenilMarco Arpon100% (1)

- Digital Image Processing - S. Jayaraman, S. Esakkirajan and T. VeerakumarDocument4 pagesDigital Image Processing - S. Jayaraman, S. Esakkirajan and T. VeerakumarBenedict IsaacNo ratings yet

- Ax88796B With Ali M3602 Mcu Reference Schematic IndexDocument4 pagesAx88796B With Ali M3602 Mcu Reference Schematic IndexdistefanoNo ratings yet

- MLR LLRDocument41 pagesMLR LLRKUNNAMPALLIL GEJO JOHNNo ratings yet

- LEGAL REASONING SKILLS ProjectDocument19 pagesLEGAL REASONING SKILLS ProjectShreya Ghosh DastidarNo ratings yet

- Manual For Personnel: ProposedDocument11 pagesManual For Personnel: Proposedjsopena27No ratings yet

- Introduction To Industrial Relations and Performance ManagementDocument5 pagesIntroduction To Industrial Relations and Performance ManagementAchalKumarGargNo ratings yet

- Argument Forms: Proving InvalidityDocument13 pagesArgument Forms: Proving InvalidityDaniel Emmanuel De LeonNo ratings yet

- Synopsis Car Showroom ManagementDocument18 pagesSynopsis Car Showroom ManagementRaj Bangalore50% (4)

- Infosys Verification FormDocument6 pagesInfosys Verification Formamanueljoseph1310No ratings yet

- Lê Thị Thu Thuỷ - Luận vănDocument97 pagesLê Thị Thu Thuỷ - Luận vănĐào Nguyễn Duy TùngNo ratings yet

- Hanson Uk Cracked ConcreteDocument1 pageHanson Uk Cracked ConcreteAhmed Daahir AdenNo ratings yet

1705135 01

1705135 01

Uploaded by

hassan awadallaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1705135 01

1705135 01

Uploaded by

hassan awadallaCopyright:

Available Formats

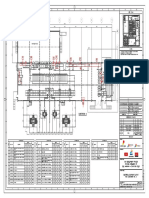

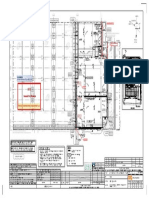

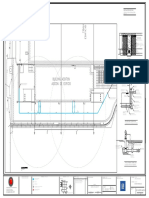

Unit arrangement Site Preparation - Floor Electrical Site Preparation - Concrete Fill-UP Site preparation - Ceiling Steel Details

IK 10*10 cm IK 10*10 cm

781 UPS P.D.B P.D.B Environmental conditions for transport / storage

AFFL140 cm. FK 20*10cm

AFFL140 cm.

Temperature range -20° to 70 °C

Relative humidity 10 to 95 % without condensation

Barometric pressure 50 to 106 kPa

Battery Acceleration There must be absolute compliance with the following transport conditions to

UPS 1.29 Equipment

1.28 1.31 1.32 prevent damage to the system:

Equipment Room Room Maximum acceleration spectral density according to DIN EN 60721-3-2 class 2M2

1 m²/s³ (0.01 g²/Hz) for oscillation frequencies from 10 to 200 Hz

200

25

Equipment Room 260 Maximum acceleration according to DIN EN 60721-3-2 class 2M2

12.2 Pb 2mm Lead lining for all walls,frames and doors 169 Permissible peak acceleration â (full shock response spectrum type I):

100 in accordance to the national regulation up to 220 cm. Horizontal shock (longitudinal / transverse): 40 m/s²

(corresponds to the shunting of a train car)

Vertical shock: 100 m/s²

Ceiling 62.9 93.3

Outlet

79.2

260

100

Examination

Examination

213

Room Environment

180

10

25 Room

20

219

10 10 Examination Temperature range 15 to 30 °C (recommended 22 °C)

67.5

1.06 67.5 67.5 67.5 67.5 67.5 67.5 and control room Relative humidity 20 to 75 % non-condensing

PVC 4"

Pipe 50 40 Image system Temperature range 10 to 35 °C

10.2

20

Relative humidity 20 to 75 % non-condensing

67.5

Max. temperature gradient 10 °C / h

Air flow volume 630 m³ / h

35

1.01 1.02 Max. noise generation 53 dB(A)

20

90

2 x C 16 beam

67.5

Examination Room Pb.

101.9

545

Pb. Length = 425 cm Ø16 holes Generator Temperature range 10 to 35 °C

35

Height = 272 cm. Relative humidity 20 to 75 % non-condensing

Max. temperature gradient 5 °C / h

67.5

1.04 90 152

Air flow volume 160 m³ / h

1.05

20

Examination Room PVC 4" Equipment Max. noise generation 55 dB(A)

Pipe 180 cm Room

AFFL

67.5

System- Temperature range 15 to 30 °C

AT control cabinet 1 Relative humidity 20 to 75 % non-condensing

Max. temperature gradient 5 °C / h

20 Air flow volume 500 m³ / h

175

67.5

39

Max. noise generation 48 dB(A)

130

100 100 Ø16 holes

Cooling set Cooling air 15 to 30 °C, frost-free room

10

Pb.

Flow rate 4,2 l / min.

Max. noise generation 55 dB(A), 57 dB(A) at altitude > 3000m

200 Stand with Max. temperature gradient 5 °C / h

1.18 AFFL 2 x C 16 beam

180 cm flat panel detector Air pressure 70 to 104 kPa

1.18d Length = 425 cm

99

1.13 15.5 Schocks max. 10 g / 16 ms

1.18c 30 52 25 25 25 25 25 25 X-Ray warning lamp Height = 272 cm. Vibrations max. 0.1 g / 10 to 200 Hz

1.17 1.10 FK 20*10cm Cables routed to system cabinet Control

218

1.18b 1.12 Passing through P.D.B

1.16 Room

1.15 1.09a Control Room

1.11 Control

88

Control Room Room

Transport

13

The transport route (doors and hallway) needs sufficient dimensions for the following parts:

377

Largest single part with transp. carriage (min. door opening) 247 x 100 x 190 cm ( W x D x H ) Weight 910 kg

Largest crate with packaging 263 x 118 x 207 cm ( W x D x H ) Weight 1175 kg

The door must have a final clearance of 125 cm if bed entrance is requested.

Site preparation - Ceiling Cable Trays View A View B Shocks: max. 10 g / 16 ms Vibration: max. 2 g / 58 to 150 Hz

Artis zee ceiling – Equipment Legend

P.D.B of UPS KW 20*10 cm. 180 cm AFFL

Sensis / Sensis Lite / Sensis Vibe / Sensis Vibe Combo - Equipment Legend AFFL 140 cm connected to Cath PDB

Weight (kg), Heat dissipation to the air (W) KW 20*10 cm.

Pos. Description kg W Remark Notes on preparations for installation

1.01 Ceiling stand 904 200 Contracts for performing and supervising on-site installation preparations should be concluded with technically

Cath LabP.D.P IK 20/10

1.02 Basic table narrow 452 200 AFFL140 Cm. competent companies by the customer. The customer is responsible for timely and proper completion and

suspended Ceiling suspended Ceiling

1.04 Control console and ECC I on patient table 4 supervision of all preparations for installation at the construction site in observance of all applicable legal regulations

1.06 Ceiling stand DCS 3 251 225 #6 (e.g. X-ray regulations, radiation protection regulations) and all applicable general recognized rules of technology

Equipment Room

1.07 Upper body radiation shield, moveable 85 optional Control Room (e.g. VDE regulations, DIN standards).

EQUIPMENT Execution and supervision of installation preparations at the construction site and later observance of the standard

1.09a Control module optional ROOM

IK 20*10 cm. operating conditions are not included in our duties. The customer is responsible for checking the static calculations

1.10 Control room distributor 29 100 and, where applicable, the air conditioning in the building to be equipped.

1.11 Workplace Display with keyboard 10 75

UPS

1.12 Referenz Display 10 75 optional

39 232 130

1.13 AXIS image system 150 1270

90

180

1.15 Archive Console Extension (ACE) 6 Room lighting

X1

1.17 TFT-Display 9 70 optional

TP

TP

RJ45

RJ45

Ambient lighting in rooms with diagnostics or with workstations must comply with the respective local and national

1.18b Sensis - Control Room Cabinet CR2 20 1000 OK FFB regulations.

30

1.18c Sensis - Computer DMC 10 275 General requirements like the needed intensity of illumination - adjustable, reproducible, flicker-free or a limitation of

1.18d Sensis - Tripplite SmartPro - UPS 16 500 dazzlings and reflections etc. have to be observed (EN 12464-1, DIN 5035-7).

1.28 Generator POLYDOROS A100 300 1000 1200W for Artis Q

1.29 Cooling unit - SMC one4all 28 2400 IK 20*10 FK 20*10cm

FK 20*10cm

1.31 System control cabinet 270 1600 80cm wide for Artis Q

1.32 Cable cabinet 120 optional

Display screen workstations

#6 Including 4.25 m longitudinal rails and system cable For setting up display screen workstations, take account of the guidelines in the Display Screen Workstation

(with 3 m longitudinal rails weight is reduced by ca. 16kg) directive as well as any national regulations (e.g. EN ISO 9241-5).

424

#20 heat dissipation: printing 800W, standby 17W

Examination Room Safety distances

Distances from moving parts of the medical device to walls, furniture and other equipment have to be kept to avoid

injuries by crushing in compliance with local regulations, e.g. a minimum distance of 50 cm according to EN 349.

583

It is the customer's responsibility to ensure the above requirements are followed.

This is to avoid the risk of injury.

11

NOTE : ALL DOORS SYMBOLS MEAN CLEAR DOOR OPENING

Dimensioning

NOT WALL OPENING All installation measurements apply to finished wall/floor/ceiling and are to be checked prior to assembling the unit.

Control cm mm

Room

Orientation point = reference point of the Siemens unit for planning and installation

Radiation protection in doors

Milled lead inlay in doors

Enabling Works Specification

The radiation protection must be well overlapped, especially

UPS - Notes

on doors and windows. door leaf

It is the responsibility of the Enabling Works Contractor to:

milled lead door frame In case of a power failure no moving of the system and motorized table is possible. For all Artis systems with

Fixpoint legend

1. Supply and install any necessary items to comply with the radiation protection advisers documentation. Artis Tilting table, Artis OR table or Artis zee Multipurpose an UPS is mandatory.

2. Supply and fix all floor trunking, cable tray, surface trunking, cable ducts as indicated on the drawings.

Fixpoint Components Location Minimum 15 kVA UPS for system and table movement e.g. Eaton Powerware 9355-15 kVA. If customer already

3. Ascertain that the structure (floor walls and ceiling) are capable of withstanding the loads indicated on

the drawings. has an on-site Full Power UPS, this can be used, if it fulfills this requirement.

Control Room Distributor - X-Ray Wall

4. Supply and install a ceiling grid as indicated on the drawings (e.g. 'Unistrut'). If required.

Sensis Control Room Distributor - E-Medicine Floor 5. Supply only M10 Unistrut Spring channel nuts (PNL10ZP) stamped with 'Unistrut' on the body of the fixing

and M10 Unistrut only steel square plates (P1063)

Cockpit Controller Wall Please check with the Siemens project manager how many items for each

single ceiling rail / pair of ceiling rails on this project have to be supplied.

Cooling unit tube plane 1 Floor 6. Supply a suitable ceiling support structure for all items suspended from the ceiling (see drawings for details) List of Documents

7. Supply and install all indicated data and power outlets, including all necessary cabling to these outlets

Cooling unit tube plane 2 8. Ensure all eletrical work is carried out in accordance with the specification and the installtion schematic No. Document No. Document

Floor

9. Ensure ALL building works indicated on these drawings is complete prior to the installation of the Siemens 01 112332-1705135-01 Unit arrangement

FD cooling unit Floor equipment. Failure to do so could result in the equipment not being delivered on time!!!

Site preparations

02 112332-1705135-02

Technical details - Ceiling

Display Ceiling Stand DCS Ceiling

Legend Site preparations

03 112332-1705135-03

Second Display Ceiling Stand DCS Ceiling Technical details - Floor

Site preparations

cut-out, LxW (i. e. in FK or raised floor) 04 112332-1705135-04

Display (Display carriage) Ceiling/Wall Electrical scheme

cut-out, Ø in mm (i.e. in suspended ceiling)

Display Boom Power Distributor Ceiling

KB core hole, Ø in mm (minimum inner clearance required)

Environment LD(s) on Display Boom(s) Ceiling

Room height BD floor opening, top view LxW (break-throughs and openings, which delimit the

Examination Temperature range 15 to 30 °C (recommended 22 °C) Display(s) on Display Booms Ceiling fireproof area, must be closed on site after the installation is finished).

and control room Relative humidity 20 to 75 % non-condensing

(not to scale)

DD ceiling opening in ceiling above LxW (break-throughs and openings, which

Injector Wall Outlet Wall delimite the fireproof area, must be closed on site after the installation is finished).

Image system Temperature range 10 to 35 °C Basics of Planning

MH

Relative humidity 20 to 75 % non-condensing Room lighting WD wall break WxH (break-throughs and openings, which delimit the

Injector Ceiling Outlet Ceiling No. Document No. from Document

Max. temperature gradient 10 °C / h fireproof area, must be closed on site after the installation is finished).

Air flow volume 630 m³ / h Ambient light in rooms where diagnosis take place on image display devices (monitors) must meet the following 01 AXA4-060.891.01.04.02 08.12 Artis zee ceiling

Large Display Container Wall name of a fixpoint or a connection point

Max. noise generation 53 dB(A) requirements:

- Free of dazzle, controllable, reproducible setting of the lighting intensity (e.g.dimmer with scale) cable fixing point 02 Site Inspection 02.11.2023

Generator Temperature range 10 to 35 °C Connection box for REPO cable + 3 m flexible cable on-site required

- No reflections from windows, lamps and viewing boxes in the usual operating position of the image display Wall

Relative humidity 20 to 75 % non-condensing for REPO

devices. This is a specification of DIN V 6868-57 in Germany, which should also be complied within all other Access hatch in suspended ceiling not required if the ceiling tiles are easily removable

Max. temperature gradient 5 °C / h

countries. In regard to the lighting of rooms for diagnostic imaging and treatment procedures, the intensity of the Image system Wall Size and position depending on structural conditions on site. Room height finished floor to

Air flow volume 160 m³ / h

RH

Max. noise generation 55 dB(A) lighting in general depends on the type of procedure. If only X-ray exposures are produced, the requirements for

Location Concrete Suspended available Concrete required, min.

lighting for diagnostic imaging with image intensifiers apply (50 lx). Ceiling stand plane 1 Ceiling switch, installation according to national guidelines

System- Temperature range 15 to 30 °C When images are displayed on monitors, the possibility of reducing the general lighting intensity must be provided Examination Room 300 cm N.A 300 cm

control cabinet 1 Relative humidity 20 to 75 % non-condensing (30 lx; if necessary, down to 1 lx). Reflections and glare on the screen must be avoided (DIN 5035-3; EN 12464). As Floor stand plane 1 Ceiling grounded socket, installation according to national guidelines

Max. temperature gradient 5 °C / h a rule, therapy rooms require a general lighting with a nominal lighting intensity of 300 lx.

Air flow volume 500 m³ / h This also applies to rooms where patients are treated with physical, radiological or electromedical procedures. Ceiling stand plane 2 Ceiling grounded socket, switchable, installation according to national guidelines

Max. noise generation 48 dB(A)

Generator - plane 1 Floor

Cooling set Cooling air 15 to 30 °C, frost-free room TP telephone socket warning lamp / indicator,

Flow rate 4,2 l / min. Room height (RH) 2700 to 2720 mm Generator - plane 2 Floor

ceiling mounted, wall mounted Unit arrangement

Max. noise generation 55 dB(A), 57 dB(A) at altitude > 3000m Display screen workstations Measured from the highest point of the finished floor (incl. floor covering) to the lowest point of the ceiling RJ45 network socket

This was made in conformity with the constructional planning references and the project equipment.

substructure. Here, the area of the ceiling substructure in which the longitudinal rails for the ceiling stand Robot Floor stand - Floor outlet Floor We reserve the right to make technical alterations. Before the construction work is completed it has to be

Stand with Max. temperature gradient 5 °C / h For setting up display screen workstations, take account of the guidelines in the Display Screen Workstation UK bottom edge OK top edge

are installed is the determining factor. ascertained that there are no changes in the original project.

flat panel detector Air pressure 70 to 104 kPa directive as well as any national regulations (e.g. EN ISO 9241-5).

Recommended room height 2710 mm. Robot Floor stand control cabinet Floor

Schocks max. 10 g / 16 ms bottom edge suspended ceiling OK FFL top edge finished floor The scope of delivery and services is described and determined in the order confirmation.

Required minimum height (MH) 150 mm in suspended ceiling for corrugated hose holder and cable routing. UK ABGD

Vibrations max. 0.1 g / 10 to 200 Hz All data serve for the on-site preparation for installation and cabling of the Siemens system in order to ensure

Transport The cross-hatched area is determined by the movement range of the ceiling stand. System control cabinet 1 Floor

Maximum admissible floor unevenness in the shaded area: 8 mm bottom edge bare ceiling OK RFB top edge unfinished floor correct operation.

The transport route (doors and hallway) needs sufficient dimensions for the following parts: System control cabinet 2 - only for OR table UK RHD

Floor

Planning recommendations RHD bare ceiling RFB unfinished floor level

Largest crate with packaging with FD 20 x 20 276 x 102 x 209 cm (W x D x H), Weight 1200 kg

System control cabinet 3 Floor Abdelrahman Gamal Kareem Zakaria Abdelrahman Gamal

ABGD suspended ceiling FFL finished floor level 4/8/2024 4/8/2024 4/8/2024

According to the German standard (DIN 6812) an inter-visibility and a voice communication is required between the Largest crate with packaging with FD 30 x 40 280 x 95 x 202 cm (W x D x H), Weight 1200 kg

patient and the operator. Surgery lamp Ceiling Edited Checked Released

Largest single part with transp. carriage with FD 20 x 20 250 x 82 x 190 cm (W x D x H), Weight 760 kg aABGD above suspended ceiling AFFL above finished floor level

Consider the ceiling mounted devices and light barriers by arranging the lamps.

Siemens Healthcare GmbH

Darkening of windows in X-ray and control rooms is recommended. Patient table 1 Floor

Largest single part with transp. carriage with FD 30 x 40 262 x 82 x 188 cm (W x D x H), Weight 760 kg aD on ceiling / suspended ceiling aFFL on finished floor / raised floor Planning department

Ceiling

Finished floor Room height Fixed transformator (for Maquet table) Wall Hartmannstrasse 16

The door must have a final clearance of 125 cm if bed entrance is requested. substructure BRH parapet height UZ downstand beam

(with covering) 2700-2720mm D-91052 Erlangen

(e g. Unistrut)

Shocks max. 10 g / 16 ms max. 25 g / 6 ms (in original packaging) Control Console Trolley Ceiling FK cable duct WxD (minimum inner clearance required), accessible flush floor trunking system,

UPS - Notes DELTA UNIVERSITY HOSPITAL

moisture-proof, grounded

In case of a power failure no moving of the System and motorized table is possible. Vibration max. 2 g / 58 to 150 Hz max. 10 g / 58 to 150 Hz (in original packaging) Uninterruptible Power Supply Wall/Floor International Coastal Rd,

IK cable trunking WxD, surface mounted

300 Al Hafir WA Al Amal

For all Artis systems with Artis Tilting table or Artis OR table and Artis zee Multipurpose an UPS is mandatory. Automatic Transfer Switch Wall/Floor BK parapet channel WxD, surface mounted (for power and network sockets, etc.)

Minimum 15kVA UPS for system and table movement e.g. Eaton Powerware 9355-15 kVA RADIOLOGY

Signal light for UPS 40 kVA Wall KW cable tray WxD (i. e. in ceiling void)

Safety distances

If customer already has an on-site Full Power UPS, this can be used, if it fulfills this requirement. GROUND FLOOR

Distances from moving parts of the medical device to walls, furniture and other equipment have to be kept to avoid Status Display for UPS 15 kVA Wall/Ceiling 0m 1m 2m

Orientation point LR ductwork, Ø in mm (minimum inner clearance required)

injuries by crushing in compliance with local regulations, e.g. a minimum distance of 50 cm according to EN 349. 300

Multi Modality

3300 patient table X-ray warning lamp Wall The installations for cable routing depicted in the drawing need to be reserved for the exclusive

It is the customer's responsibility to ensure the above requirements are followed. use by SIEMENS Healthineers. Project File Revision Page Size Scale

This is to avoid the risk of injury. St.Jude MediGuide MPSC Cabinet Floor

112332 1705135 01 01 of 04 A0 1:50

© Siemens Healthcare GmbH created by Sales CAD

You might also like

- C32 Industrial Wiring DiagramDocument4 pagesC32 Industrial Wiring DiagramHữu Linh100% (2)

- High Speed Railway Track Technical Options Suitability Assessment GuideDocument90 pagesHigh Speed Railway Track Technical Options Suitability Assessment GuidelachguerNo ratings yet

- Waterbox 900Document28 pagesWaterbox 900cem jakartaNo ratings yet

- Demon Slayer Kimetsu No Yaiba Free Download Anime Calendar 2022Document12 pagesDemon Slayer Kimetsu No Yaiba Free Download Anime Calendar 2022Gokul M PNo ratings yet

- 1 Novacron S OverviewDocument3 pages1 Novacron S OverviewsaskoNo ratings yet

- Solar Water Heater Distributor Business PlanDocument32 pagesSolar Water Heater Distributor Business Planlutos267% (3)

- Gloria V CA DigestDocument3 pagesGloria V CA Digestbeaenriquez100% (3)

- 743 Etm 9003 - 3Document1 page743 Etm 9003 - 3Fernando SanchezNo ratings yet

- CJ LocationDocument1 pageCJ LocationTerry CheukNo ratings yet

- 12 Coedmore Bridge - F Shape Barrier & End Block Sheet 1 of 2Document1 page12 Coedmore Bridge - F Shape Barrier & End Block Sheet 1 of 2Malibongwe MbamboNo ratings yet

- Sobha Hartland Greens - Phase 02: InvestmentsDocument1 pageSobha Hartland Greens - Phase 02: InvestmentsrajatNo ratings yet

- Fpso OverviewDocument1 pageFpso OverviewSean ChoiNo ratings yet

- Mtip MapDocument1 pageMtip MapAlan PittmanNo ratings yet

- Conselho de Professores - Recuperação Final: Instituto Superior de Educação Do Rio de JaneiroDocument2 pagesConselho de Professores - Recuperação Final: Instituto Superior de Educação Do Rio de JaneiroAYLA APARECIDA LORENA SEIXASNo ratings yet

- Notes: Roof: Concrete Roof Tiles On TrussesDocument1 pageNotes: Roof: Concrete Roof Tiles On TrussesanzaniNo ratings yet

- 02 - Road & Drainage-ModelDocument1 page02 - Road & Drainage-ModelSyafiq NazriNo ratings yet

- STORMWATER SYSTEM REMEDIATION LAYOUT P202110-IOCL-BR-E-CS-DET-6015 Rev-0Document1 pageSTORMWATER SYSTEM REMEDIATION LAYOUT P202110-IOCL-BR-E-CS-DET-6015 Rev-0Nitin SakpalNo ratings yet

- Wh-1088pe DrawingDocument1 pageWh-1088pe Drawingom sai quality developmentNo ratings yet

- DRG 4Document1 pageDRG 4Neil AgshikarNo ratings yet

- POCVN-MF-SD-CON-M-SEW-04 - Rev03 - 1st FloorDocument5 pagesPOCVN-MF-SD-CON-M-SEW-04 - Rev03 - 1st FloorTôn Huỳnh ĐoànNo ratings yet

- GTC CivilDocument1 pageGTC CivilRadulescu AndreiNo ratings yet

- 2019 Zip Zone Map SmallDocument1 page2019 Zip Zone Map SmallKHOUNo ratings yet

- PNG2023 Plumb 012 ADocument1 pagePNG2023 Plumb 012 ANoel MoronaNo ratings yet

- Crt-Npc-Dmm-Hva-Dwg-Sd-Gn-33501 - Equipment Capacity Schedule 1-6Document1 pageCrt-Npc-Dmm-Hva-Dwg-Sd-Gn-33501 - Equipment Capacity Schedule 1-6Shah MuzzamilNo ratings yet

- Perfil y Secciones_parque 27 (1)Document1 pagePerfil y Secciones_parque 27 (1)Eduardo Tintaya MachacaNo ratings yet

- Perfil y Secciones_parque 27 (2)Document1 pagePerfil y Secciones_parque 27 (2)Eduardo Tintaya MachacaNo ratings yet

- Id-Gf09 Faisal ElevationsDocument61 pagesId-Gf09 Faisal ElevationsMuhannad AlaniNo ratings yet

- 5Document1 page5ahmadtaiyabiNo ratings yet

- DX225LC-3 Elec 2012.10.15 PDFDocument1 pageDX225LC-3 Elec 2012.10.15 PDFDmytro ManzykNo ratings yet

- G6 G5 G3 G2 G1 G5' G7 G4: 1 Elephant Holding Ground Floor Level Load MapDocument1 pageG6 G5 G3 G2 G1 G5' G7 G4: 1 Elephant Holding Ground Floor Level Load MaphemanthsridharaNo ratings yet

- Hvac Layout For Ground Floor - (r0) 09-08-15-ModelDocument1 pageHvac Layout For Ground Floor - (r0) 09-08-15-ModelRavi PanchalNo ratings yet

- NonTendered ElevationDocument1 pageNonTendered ElevationprabhuNo ratings yet

- Australian Operating Mines 2021Document1 pageAustralian Operating Mines 2021Patricio Andres Santos CornejoNo ratings yet

- Corlu VFR ChartDocument1 pageCorlu VFR Chartcod modernwarfareNo ratings yet

- Quality Control: Elevation FrontDocument5 pagesQuality Control: Elevation FrontAria NickbakhtNo ratings yet

- Column LayoutDocument1 pageColumn LayoutAugustine yigaNo ratings yet

- GF200 Quick Installation GuideDocument2 pagesGF200 Quick Installation GuidejazuoneNo ratings yet

- Brosur Koolpanel EPSDocument3 pagesBrosur Koolpanel EPSDenata Machmud SugandhiNo ratings yet

- ALIGNMENT PLAN STRIP-WP-02-TemplateDocument1 pageALIGNMENT PLAN STRIP-WP-02-TemplateMd Mukul MiahNo ratings yet

- 402FloorPlans PDFDocument2 pages402FloorPlans PDFSubas NaguNo ratings yet

- Revised Utandi Estate 2Document1 pageRevised Utandi Estate 2Bessie SiyadoNo ratings yet

- 9204-BP12A-MMJV-DWG-FA-P1-L05-02304-REV.D03 (Commented)Document1 page9204-BP12A-MMJV-DWG-FA-P1-L05-02304-REV.D03 (Commented)Michael Camit EsoNo ratings yet

- 7E 7E 6E 6E: Foh Truss 1 Foh Truss 1Document1 page7E 7E 6E 6E: Foh Truss 1 Foh Truss 1TimothyNo ratings yet

- Ground Floor Hvac LayoutDocument1 pageGround Floor Hvac LayoutMohammed AzharNo ratings yet

- Zamboanga Pet Line 110419Document1 pageZamboanga Pet Line 110419PAul JoHn MeNdozaNo ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument1 pageYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterRonal Castillo PedrazaNo ratings yet

- Instructivo Pista Luis BGJ55-EngDocument1 pageInstructivo Pista Luis BGJ55-Englspr_001No ratings yet

- Rjj000-E0-Lay-480-00201-Rev 1-New2Document1 pageRjj000-E0-Lay-480-00201-Rev 1-New2Alif Anshar RazaqnaNo ratings yet

- FJS 1923000149Document1 pageFJS 1923000149SHAHZAD LATIFNo ratings yet

- AV - B AL TA: Mercado CentralDocument1 pageAV - B AL TA: Mercado Centraldoctor psiquiatraNo ratings yet

- Drawing 3.Document1 pageDrawing 3.tiyaniNo ratings yet

- b777 - Memory Items Painel Do 777-1Document1 pageb777 - Memory Items Painel Do 777-1RejaneNo ratings yet

- S781-CV-DWG-00006-04-213036-A - OQ Comments - 19.03.2023Document1 pageS781-CV-DWG-00006-04-213036-A - OQ Comments - 19.03.2023MDhana SekarNo ratings yet

- Flow Control Valve-RightDocument1 pageFlow Control Valve-RightElton PintoNo ratings yet

- Detalles Constructivos para La Red de Agua PotableDocument4 pagesDetalles Constructivos para La Red de Agua PotableRoberto Cabrera MillerNo ratings yet

- A11-00h - Ground Level - Part HDocument1 pageA11-00h - Ground Level - Part Hconsultnadeem70No ratings yet

- Foundation Plan and Anchor Locations: Section CDocument1 pageFoundation Plan and Anchor Locations: Section CJavier Guerra TriviñoNo ratings yet

- BaltimoreDocument1 pageBaltimoreLadNo ratings yet

- SLD - CBSE Patna - PDF 2Document1 pageSLD - CBSE Patna - PDF 2nbcccbsepatnaNo ratings yet

- Vista en Planta Detalles de Instalacion: Plant View Installation DetailsDocument1 pageVista en Planta Detalles de Instalacion: Plant View Installation DetailsDulce victoria MorenoNo ratings yet

- LD 1Document1 pageLD 1E111 ChipiNo ratings yet

- Geri 2Document1 pageGeri 2Vincent NavaNo ratings yet

- SC Study Line To Ground FaultDocument1 pageSC Study Line To Ground FaultMurali100% (1)

- Economic and Political WeeklyDocument8 pagesEconomic and Political WeeklynaveensarimallaNo ratings yet

- Resource AllocationDocument10 pagesResource AllocationZoe NyadziNo ratings yet

- Recognition, Signaling, and Repair of DNA Double-Strand Breaks Produced by Ionizing Radiation in Mammalian Cells - The Molecular ChoreographyDocument89 pagesRecognition, Signaling, and Repair of DNA Double-Strand Breaks Produced by Ionizing Radiation in Mammalian Cells - The Molecular ChoreographyMaria ClaraNo ratings yet

- Nanda 1Document4 pagesNanda 1Ethel GeorgeNo ratings yet

- BE1 Final Without Recheckreassessment - 453112Document1 pageBE1 Final Without Recheckreassessment - 453112MoloNo ratings yet

- Manual Therapy in The Treatment of Facial WrinklesDocument4 pagesManual Therapy in The Treatment of Facial WrinklesKarolina MirosNo ratings yet

- Modulo Ii: Dra. Andrea Mogni SDocument23 pagesModulo Ii: Dra. Andrea Mogni SMarco Antonio CaceresNo ratings yet

- Iqra University - Karachi Faculty of Business AdministrationDocument31 pagesIqra University - Karachi Faculty of Business Administrationsyed aliNo ratings yet

- 7 - Miaa V AlaDocument10 pages7 - Miaa V AlaBelle MaturanNo ratings yet

- LSM MockDocument5 pagesLSM MockKazi Rafsan NoorNo ratings yet

- Industry ProfileDocument9 pagesIndustry ProfilesarathNo ratings yet

- Testable Concepts in MCQDocument188 pagesTestable Concepts in MCQrami100% (1)

- CAN LIN ProtocolDocument60 pagesCAN LIN ProtocolBrady BriffaNo ratings yet

- People Vs Vicente MenilDocument2 pagesPeople Vs Vicente MenilMarco Arpon100% (1)

- Digital Image Processing - S. Jayaraman, S. Esakkirajan and T. VeerakumarDocument4 pagesDigital Image Processing - S. Jayaraman, S. Esakkirajan and T. VeerakumarBenedict IsaacNo ratings yet

- Ax88796B With Ali M3602 Mcu Reference Schematic IndexDocument4 pagesAx88796B With Ali M3602 Mcu Reference Schematic IndexdistefanoNo ratings yet

- MLR LLRDocument41 pagesMLR LLRKUNNAMPALLIL GEJO JOHNNo ratings yet

- LEGAL REASONING SKILLS ProjectDocument19 pagesLEGAL REASONING SKILLS ProjectShreya Ghosh DastidarNo ratings yet

- Manual For Personnel: ProposedDocument11 pagesManual For Personnel: Proposedjsopena27No ratings yet

- Introduction To Industrial Relations and Performance ManagementDocument5 pagesIntroduction To Industrial Relations and Performance ManagementAchalKumarGargNo ratings yet

- Argument Forms: Proving InvalidityDocument13 pagesArgument Forms: Proving InvalidityDaniel Emmanuel De LeonNo ratings yet

- Synopsis Car Showroom ManagementDocument18 pagesSynopsis Car Showroom ManagementRaj Bangalore50% (4)

- Infosys Verification FormDocument6 pagesInfosys Verification Formamanueljoseph1310No ratings yet

- Lê Thị Thu Thuỷ - Luận vănDocument97 pagesLê Thị Thu Thuỷ - Luận vănĐào Nguyễn Duy TùngNo ratings yet

- Hanson Uk Cracked ConcreteDocument1 pageHanson Uk Cracked ConcreteAhmed Daahir AdenNo ratings yet