Professional Documents

Culture Documents

1714560 CT - 01SP

1714560 CT - 01SP

Uploaded by

hassan awadallaCopyright:

Available Formats

You might also like

- 313B CR Excavator Electrical System: Area CDocument2 pages313B CR Excavator Electrical System: Area CWilfer Alexis Grain Diaz100% (1)

- Rent-A-Movie Database Project: YOUR ASSIGNMENT (Deliverables Are Underlined)Document2 pagesRent-A-Movie Database Project: YOUR ASSIGNMENT (Deliverables Are Underlined)Miguel Flores FloresNo ratings yet

- Speech & Language Therapy in Practice, Spring 2002Document32 pagesSpeech & Language Therapy in Practice, Spring 2002Speech & Language Therapy in PracticeNo ratings yet

- Overall Project - Detail Progress Tracking Sheet - JHP - Updated - 19-Aug-21 - PMDocument59 pagesOverall Project - Detail Progress Tracking Sheet - JHP - Updated - 19-Aug-21 - PMMRadwanNo ratings yet

- C.H. - 0+465.5 Section No5Document1 pageC.H. - 0+465.5 Section No5Fran LuqueNo ratings yet

- Civil Work & Finishes ServicesDocument1 pageCivil Work & Finishes ServicesdadaraoNo ratings yet

- QC02002 CNP DRW PLN Id 04 Ce1 00004 00 (PDF)Document1 pageQC02002 CNP DRW PLN Id 04 Ce1 00004 00 (PDF)Moosa RizwanNo ratings yet

- 2023-09-22 Link Bridge AIPDocument6 pages2023-09-22 Link Bridge AIPMorris KwokNo ratings yet

- Cab Radio Wiring RH Console Wiring (Rear, Right View) : 326F, 329F and 330F Excavator Electrical System 330F MHPUDocument8 pagesCab Radio Wiring RH Console Wiring (Rear, Right View) : 326F, 329F and 330F Excavator Electrical System 330F MHPUDozer KamilNo ratings yet

- Umw Ip - Genset Shop Drawing ApprovalDocument4 pagesUmw Ip - Genset Shop Drawing ApprovalLevel Kita Semua SamaNo ratings yet

- Kingspan - Kingzip - Roof - KS500 1000 ZIP IP Installation Guide - 032017 - UKDocument1 pageKingspan - Kingzip - Roof - KS500 1000 ZIP IP Installation Guide - 032017 - UKGeorgios PNo ratings yet

- Goldfields-Esperance Key In-Print & Online Advertising ApprovalDocument1 pageGoldfields-Esperance Key In-Print & Online Advertising ApprovalJO JONo ratings yet

- Cicpa - C&mcig1w922Document782 pagesCicpa - C&mcig1w922mahmoudNo ratings yet

- 345 CDocument4 pages345 Cedi0% (1)

- 916-CEG-Excel Astra Structure PackageDocument4 pages916-CEG-Excel Astra Structure PackageramNo ratings yet

- Construction Plan Cooling Tower Pad-1 R&D CenterDocument11 pagesConstruction Plan Cooling Tower Pad-1 R&D CenterAdlin ArifinNo ratings yet

- SDSSSSDDocument1 pageSDSSSSDmirfanjpcgmailcomNo ratings yet

- WHORKSHOP 1 -Document3 pagesWHORKSHOP 1 -ramNo ratings yet

- Tcs-P4-B8-Dra-05-G521-005-Tcs-Ufh-Installation-Layout-Type-3a - C00 - Epa & HLDocument2 pagesTcs-P4-B8-Dra-05-G521-005-Tcs-Ufh-Installation-Layout-Type-3a - C00 - Epa & HLuozceylanNo ratings yet

- GH22148 0100D TD Gen A 50001 Rev0Document1 pageGH22148 0100D TD Gen A 50001 Rev0felix sowah-laryeaNo ratings yet

- Akh Ymi DD Im10x D Ar DWG 0001 1Document1 pageAkh Ymi DD Im10x D Ar DWG 0001 1Tamrayehu KuremaNo ratings yet

- 1824 000 SS DST 0040 - 2 - IfcDocument1 page1824 000 SS DST 0040 - 2 - IfcAquiles MartinezNo ratings yet

- 1824 000 SS DST 0040 - 2 - IfcDocument1 page1824 000 SS DST 0040 - 2 - IfcAquiles MartinezNo ratings yet

- Complete: DistributionDocument1 pageComplete: DistributionTeam RooneyNo ratings yet

- SENR6238Document2 pagesSENR6238Gilvan JuniorNo ratings yet

- 1714802 2Document1 page1714802 2hassan awadallaNo ratings yet

- PreviewDocument4 pagesPreviewالعندليب الاسمرNo ratings yet

- July 2021 Daily MeetingDocument4 pagesJuly 2021 Daily MeetingPegelou Jhon LagutinNo ratings yet

- 966K and 972K Wheel Loader Electrical SystemDocument4 pages966K and 972K Wheel Loader Electrical SystemFlorencio MaximilianoNo ratings yet

- Electrical Plan PDFDocument1 pageElectrical Plan PDFDJNo ratings yet

- S781-CV-DWG-00004-01-213036-B - OQ Approved - 14.03.2023Document2 pagesS781-CV-DWG-00004-01-213036-B - OQ Approved - 14.03.2023MDhana SekarNo ratings yet

- Drawing 3.Document1 pageDrawing 3.tiyaniNo ratings yet

- Desenho de Vigas CypeDocument1 pageDesenho de Vigas CypeAntónio VascoNo ratings yet

- Ferris Campus MapDocument1 pageFerris Campus MapWXMINo ratings yet

- Ethiopian Electric Power (Eep) : Submission ofDocument6 pagesEthiopian Electric Power (Eep) : Submission ofjie zhangNo ratings yet

- AdelaidaDocument10 pagesAdelaidaNeil AdrianNo ratings yet

- BLOCK PRODUCTION LOCATION-ModelDocument1 pageBLOCK PRODUCTION LOCATION-Modellucio444No ratings yet

- Plano Eléctrico d7r TractorDocument4 pagesPlano Eléctrico d7r TractorCarlos Andres Ávila PuertaNo ratings yet

- MAQUINAplano 320 9kk PDFDocument2 pagesMAQUINAplano 320 9kk PDFRuben Dario CasiqueNo ratings yet

- Electronic SchematicDocument2 pagesElectronic SchematicXerxNo ratings yet

- ProjectHotDofTRCRev1 RedactedDocument5 pagesProjectHotDofTRCRev1 RedactedMichael PraatsNo ratings yet

- List Gambar Penerimaan Klas Rev2Document14 pagesList Gambar Penerimaan Klas Rev2Dolok Joko KenconoNo ratings yet

- 6th FP. G+6 Mixed Use Abera Lisanu Building-ModelDocument1 page6th FP. G+6 Mixed Use Abera Lisanu Building-Modelberra 2373No ratings yet

- System Layout Twitter 27-11-18 PDFDocument3 pagesSystem Layout Twitter 27-11-18 PDFKevin ApostolNo ratings yet

- Gambar Concrete Pole PDFDocument1 pageGambar Concrete Pole PDFrifkynetNo ratings yet

- 07A2 YSR LIST 036 Rev04 - FT Instrument ListDocument1 page07A2 YSR LIST 036 Rev04 - FT Instrument ListAli JameelNo ratings yet

- July 2021 Daily MeetingDocument4 pagesJuly 2021 Daily MeetingPegelou Jhon LagutinNo ratings yet

- CTA - Site Instruction #027Document5 pagesCTA - Site Instruction #027otuse557No ratings yet

- Kop-Flex - KS (Membranas HP)Document3 pagesKop-Flex - KS (Membranas HP)marcelo castilloNo ratings yet

- SCOR MySQLDocument1 pageSCOR MySQLEdgar EspinozaNo ratings yet

- Basement DDA Car ParkingDocument1 pageBasement DDA Car Parkingrajen raghwaniNo ratings yet

- Plano Electrico 785D Actual 2Document12 pagesPlano Electrico 785D Actual 2Escuela EntrenamientoNo ratings yet

- Ib Mon CD Master Plan Layout Ground FloorDocument1 pageIb Mon CD Master Plan Layout Ground FloorsedanaNo ratings yet

- 916-CEG-Excel Astra Structure Package WORKSHOP 1Document4 pages916-CEG-Excel Astra Structure Package WORKSHOP 1ramNo ratings yet

- Electro 323Document2 pagesElectro 323Pușcă MartinNo ratings yet

- 030 RFI ELLIPSE Beam Admin Auditorium ACT Response 20231113Document4 pages030 RFI ELLIPSE Beam Admin Auditorium ACT Response 20231113Muriyanto MuriNo ratings yet

- 28 Piano-1Document5 pages28 Piano-1Jaciene PessoaNo ratings yet

- Cab Radio Wiring RH Console Wiring (Rear, Right View) : 336F and 340F Excavator 336F MHPU Electrical SystemDocument8 pagesCab Radio Wiring RH Console Wiring (Rear, Right View) : 336F and 340F Excavator 336F MHPU Electrical SystemDozer Kamil100% (1)

- Operating Instructions - 7817454 - en WATCDOGDocument1 pageOperating Instructions - 7817454 - en WATCDOGjcarlosguerrasNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: MathFrom EverandInstant Assessments for Data Tracking, Grade 1: MathRating: 4 out of 5 stars4/5 (1)

- CHAP 2 - Diode Applications-Clippers ClampersDocument33 pagesCHAP 2 - Diode Applications-Clippers Clampersksreddy2002No ratings yet

- Briefcase On Company Law Briefcase Series Michael Ottley Z LibraryDocument181 pagesBriefcase On Company Law Briefcase Series Michael Ottley Z Libraryhillaryambrose030No ratings yet

- QD StudentsDocument14 pagesQD StudentsBimboy CuenoNo ratings yet

- ML-C and C Micro PDFDocument94 pagesML-C and C Micro PDFvulcanescuNo ratings yet

- Title: Investigation of Agriculture Related Problems of Rural Women in District LayyahDocument10 pagesTitle: Investigation of Agriculture Related Problems of Rural Women in District LayyahMuhammad Asim Hafeez ThindNo ratings yet

- Entr CH 1Document7 pagesEntr CH 184kaveri8650% (2)

- Resistance BodiesDocument20 pagesResistance BodiesraisecainNo ratings yet

- NYC DOE Fact Sheet On Closure of Monroe Academy of Business/Law in The BronxDocument4 pagesNYC DOE Fact Sheet On Closure of Monroe Academy of Business/Law in The BronxCity Limits (New York)No ratings yet

- Class 3 4 KeyDocument12 pagesClass 3 4 Keyshivamsingh.fscNo ratings yet

- M2 Imalis Schedule 2021-2022-: July 21StDocument1 pageM2 Imalis Schedule 2021-2022-: July 21StMohammed Abdul Rahman KhanNo ratings yet

- Citizen Instruction Manual C651Document38 pagesCitizen Instruction Manual C651vbadsNo ratings yet

- CDS4004 AnntDocument5 pagesCDS4004 AnntJiaxing ShenNo ratings yet

- Contadores 2GDocument5 pagesContadores 2GJosé Luis Gutiérrez NietoNo ratings yet

- The Yoga Sutras of Patanjali PDFDocument168 pagesThe Yoga Sutras of Patanjali PDFjhonprestonNo ratings yet

- Ti Bajssít Ajkáyo NaljjajjegénjDocument8 pagesTi Bajssít Ajkáyo NaljjajjegénjDennis ValdezNo ratings yet

- Rubric For Group WorkDocument1 pageRubric For Group WorkAlven ReyNo ratings yet

- Behavioral Finance AssignmentDocument8 pagesBehavioral Finance Assignmentthulli06No ratings yet

- Com - Pg.game6327838 LogcatDocument53 pagesCom - Pg.game6327838 Logcatfordcannabis07No ratings yet

- Ae 191 Lesson 1Document14 pagesAe 191 Lesson 1Erna DavidNo ratings yet

- Guillain-Barré Syndrome (GBS) : Prepared By: Aeshah Al-Azmi Pharm.D CandidateDocument56 pagesGuillain-Barré Syndrome (GBS) : Prepared By: Aeshah Al-Azmi Pharm.D CandidateAeshah Al-AzmiNo ratings yet

- Chapter OneDocument5 pagesChapter OneJosam Montero FordNo ratings yet

- Burocco S3000 ManualDocument4 pagesBurocco S3000 ManualJose David Leon BetancourtNo ratings yet

- Voltage Stresses in Electric Submergible Pumps Operated by Variable Speed DrivesDocument26 pagesVoltage Stresses in Electric Submergible Pumps Operated by Variable Speed Drivesandresv10No ratings yet

- Progressive Design Update 10.10.22Document9 pagesProgressive Design Update 10.10.22Vikas PaiNo ratings yet

- MCQ Transdermal Drug DeliveryDocument2 pagesMCQ Transdermal Drug DeliveryVVB100% (3)

- PerformanceDocument10 pagesPerformancecsl1600No ratings yet

- EPC Saur Energy InternationalDocument3 pagesEPC Saur Energy InternationalNarendra PatelNo ratings yet

- BAHRIA UNIVERSITY, (Karachi Campus) : Components of Presentation & ReportDocument2 pagesBAHRIA UNIVERSITY, (Karachi Campus) : Components of Presentation & ReportAsad IsmailNo ratings yet

1714560 CT - 01SP

1714560 CT - 01SP

Uploaded by

hassan awadallaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1714560 CT - 01SP

1714560 CT - 01SP

Uploaded by

hassan awadallaCopyright:

Available Formats

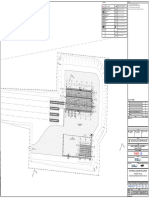

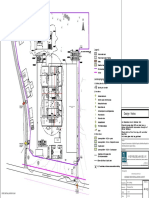

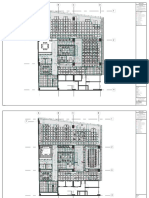

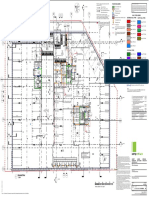

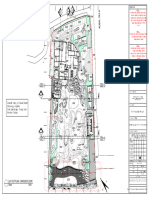

Unit arrangement Site Preparations - Floor Electrical Site Preparations - Concrete fill up

Fixpoints Notes on preparations for installation

IK 10*5 cm Fixpoint Components

To Pull Box Contracts for performing and supervising on-site installation preparations should be concluded with technically

350 167 400 competent companies by the customer. The customer is responsible for timely and proper completion and

123 25 CT P.D.B Pb 2mm Lead lining for all walls,frames and doors GR Gantry (incl. REPO contact)

AFFL140 cm. in accordance to the national regulation supervision of all preparations for installation at the construction site in observance of all applicable legal regulations

(e.g. X-ray regulations, radiation protection regulations) and all applicable general recognized rules of technology

Operating console (controlbox, monitor, keyboard)

(e.g. VDE regulations, DIN standards).

10

1.05 Execution and supervision of installation preparations at the construction site and later observance of the standard

1 UPS P.D.B Wireless Access Point

AFFL140 cm. operating conditions are not included in our duties. The customer is responsible for checking the static calculations

Battery

X1 Grounded socket for Wireless Access Point and, where applicable, the air conditioning in the building to be equipped.

Pull Box

128

20*20*10 cm. 42

IM Interventional monitor

1.02

250

UPS

250

MD MEDRAD Injector Room dimensioning

MEDRAD Injector Control panel The indicated room dimensions have to be checked on site. The planning department has to be informed about

UPS Room 10 possible deviations. Otherwise we cannot assume any guarantee for the accurate implementation of the dimensions

1.01 X2 Grounded socket for control unit MEDRAD injector indicated in the planning documents.

10

2 P.V.C Pipes AT Emergency off button with locking mechanism

544

D=4'' UFFL

50

1 67 90 On-off button with pilot lamp Room lighting

25

10 SW Radiation warning lamp Ambient lighting in rooms with diagnostics or with workstations must comply with the respective local and national

1.02 1.01 regulations.

P.V.C Pipes Radiation ready indicator

D=4'' UFFL General requirements like the needed intensity of illumination - adjustable, reproducible, flicker-free or a limitation of

Examination Room

25

P.V.C Pipe AT dazzlings and reflections etc. have to be observed (EN 12464-1, DIN 5035-7).

D=4'' UFFL

Electrical outlet Electrical outlet

aABGD PVC pipe D= 32 mm aABGD Electrical outlet Available cable sets

120

130

180 cm AFFL aABGD

1.04 To Floor duct in control room Display screen workstations

pipe connected to CT PDB

Cable set

For setting up display screen workstations, take account of the guidelines in the Display Screen Workstation

15 m directive as well as any national regulations (e.g. EN ISO 9241-5).

1.03

180 cm AFFL 80 60 100 100 140 30 m

pipe connected to CT PDB 53 30 70 10

1.06 25 25 25 10 * *For the shown installation the selected option has to be used. Safety distances

220

1.07

1.08 FK 20 x10 cm Legend Distances from moving parts of the medical device to walls, furniture and other equipment have to be kept to avoid

Control Room

Control Room X-ray warning lamp injuries by crushing in compliance with local regulations, e.g. a minimum distance of 50 cm according to EN 349.

above door frame

80

pipes routed to gantry cut-out, LxW (i. e. in FK or raised floor) It is the customer's responsibility to ensure the above requirements are followed.

through the CT PDB This is to avoid the risk of injury.

cut-out, Ø in mm (i.e. in suspended ceiling)

10

If safety distances are not maintained appropriate on-site safety measures have to be put in place.

350 188 KB core hole, Ø in mm (minimum inner clearance required) Clear visible markings according to national guidelines, e.g. crushing warning signs, hazard warning

tape, hazard area cordon, safety mats, may be required.

BD floor opening, top view LxW (break-throughs and openings, which delimit the

fireproof area, must be closed on site after the installation is finished).

DD ceiling opening in ceiling above LxW (break-throughs and openings, which

delimite the fireproof area, must be closed on site after the installation is finished).

Concrete Fill-up Dimensions WD wall break WxH (break-throughs and openings, which delimit the Dimensioning

fireproof area, must be closed on site after the installation is finished).

All installation measurements apply to finished wall/floor/ceiling and are to be checked prior to assembling the unit.

110 110 name of a fixpoint or a connection point

SOMATOM go.All - Equipment Legend cm mm

cable fixing point

Weight (kg), Heat dissipation to the air (W)

Access hatch in suspended ceiling not required if the ceiling tiles are easily removable Orientation point = reference point of the Siemens unit for planning and installation

Pos. Description kg W Remark

65

Size and position depending on structural conditions on site.

1.01 Gantry with tablet, remote control, computer and UPS 1306 6800 #1

100

1.02 Patient table Vario RT (1600 mm scannable range) 338 300

switch, installation according to national guidelines

35

35 20 45

1.03 Control unit with TFT monitor, control box, keyboard 9 75 Notes

1.04 Wireless Access Point 3 grounded socket, installation according to national guidelines

245

#1 2250 W in stand-by mode, isocentre at 985 mm 15

grounded socket, switchable, installation according to national guidelines

145

TP telephone socket warning lamp / indicator,

Examination Room Examination Room ceiling mounted, wall mounted

RJ45 network socket

PVC pipe D= 32 mm

70 80 70 UK bottom edge OK top edge

To Floor duct on control room

Radiation protection in doors 220

Electrical outlet bottom edge suspended ceiling OK FFL top edge finished floor

180 cm AFFL aABGD UK ABGD

Milled lead inlay in doors pipe connected to CT PDB

bottom edge bare ceiling OK RFB top edge unfinished floor

The radiation protection must be well overlapped, especially UPS Room UK RHD

on doors and windows. door leaf RHD bare ceiling RFB unfinished floor level

milled lead door frame suspended Ceiling suspended Ceiling ABGD suspended ceiling FFL finished floor level

suspended Ceiling

Suspended Ceiling

aABGD above suspended ceiling AFFL above finished floor level

Examination

Control Room room aD on ceiling / suspended ceiling aFFL on finished floor / raised floor

Examination Room

BRH parapet height UZ downstand beam

CT- P.D.B CT- P.D.B

AFFL140 cm. AFFL140 cm.

FK cable duct WxD (minimum inner clearance required), accessible flush floor trunking system,

moisture-proof, grounded

IK cable trunking WxD, surface mounted

180

Examination

room

BK parapet channel WxD, surface mounted (for power and network sockets, etc.)

On/Off Switchs

80

30

KW cable tray WxD (i. e. in ceiling void)

140

LR ductwork, Ø in mm (minimum inner clearance required)

NOTE : ALL DOORS SYMBOLS MEAN CLEAR DOOR OPENING

NOT WALL OPENING FK 20 x10 cm The installations for cable routing depicted in the drawing need to be reserved for the exclusive

P.V.C Pipes use by SIEMENS Healthineers.

D=4'' UFFL

FK 20/10

Control Room

Cable lead-in and floor mounting - Gantry with Patient table not to scale

180 cm AFFL

pipe connected to CT PDB

Floor requirements: Gantry and patient table

1037 - The floor construction has to be performed solid and free of vibration, e.g. concrete flooring C20/25 to C50/60 corresponding

suspended Ceiling to DIN EN 206-1, according to the maximum values as specified in the text block “Floor and building vibrations”.

912 930 ESD flooring is not required for CT systems and CT options.

4) - NOTE: A solid and vibration-free floor is needed to avoid a negative influence on the vibration characteristic of the gantry. An

Wooden frame

incorrect vibration characteristic of the gantry can cause problems with balancing and image quality.

105 x 85 cm.

1) 1) - Level in the area of the gantry and the table base. Permissible tolerance in levelness max. 10 mm referenced to the length of

the gantry base.

- On-site subconstructions have to fulfil the flooring conditions

510

510

115

180

3)

- It is recommended to test the weight capacity of the concrete or composite flooring by a stress analyst.

X1 X1

TP

RJ45

RJ45

Floor- and building vibrations - Flooring in the area around the contact surfaces of the gantry and the patient table must be removed in the area around

100

the patient table and gantry.

146

Floor- and building vibrations can reduce image quality! 1) 1)

30

Permissable continuous floor vibrations

- Floor mounting, as well as principally every kind of CT system component mounting, must be performed in accordance with

Sources that produce vibrations are, e.g.:

1054 country-specific guidelines in countries prone to earthquakes.

Railroad routes, subways, roads, road works and construction

806

sites, hospital power plants, mines, open-cast minings, quarries - The gantry and the patient table have to be on the same (isocentric) plane.

(explosions), ferry moorings, any other sources of striking FK

20*10 cm 230 - Cables should be routed to the gantry through the cable inlet in the right stand of the gantry.

vibrations. Any transient vibration has to be less than 0.5 m/s² 1) Adjustable feet and drill holes: List of Documents

peak-to-peak in the time domain. The vibrations have to be drilling Ø 17 mm for attaching to

26

measured with a sampling rate of 1000 Hz. floor via adjustable feet; Floor mounting Gantry No. Document No. Document

Transport not to scale

bearing area Ø 54 mm - Not required for system operation. Possible by anchoring/screw connections at the 4 adjustable feet. Only required according Site Preparations

The CT system is not sensitive to common vibrations. If the CT is 01 112332-1714560-01SP

The transport route (doors and hallways) needs sufficient dimensions for the following parts! 2) 2) to the currently valid country guidelines, e.g. in countries prone to earthquakes. Technical details

away from vibrational sources, or the CT is replacing a CT system 2) Two sets of drilling holes:

that to date has not shown image quality problems due to Ø 25 mm (standard), Installation material has to be provided on-site.

vibrations, it is usually not necessary to execute vibrational 1 10 100 Gantry with transport device Ø 25 mm (alternatively) - Subgrade: Basically only concrete flooring/composite flooring; on-site mounting frame

Frequency [Hz]

measurements.

808

756

for mounting the patient table

Transport rollers swiveled out Transport rollers swiveled in - Stands on 4 adjustable feet. Levelling with 4 adjustable feet.

It is the customer's responsibility to contract a qualified specialist. to floor via mounting plate

ca. 2748 x 1631 x 1864* mm ( L x W x H ) ca. 3449 x 1040 x 1864* mm ( L x W x H ) Basics of Planning

The specialist must implement site modifications to meet the specific 3) Standard cable inlet 90 x 160 mm

limits, and to design structural solutions in case of deviations.

Floor mounting patient table No. Document No. from Document

2748

4) Alternative cable inlet 85 x 45 mm - As a rule, floor mounting of the patient table is required by the manufacturer. Add compensating plates (included in delivery

If there are any doubts, the following thresholds have to be verified by measurement: 3449 01 C2-081.891.01.09.02 04.19 PG SOMATOM go.

in Gantry rear volume). Installation material for floor mounting on concrete and a drilling template are included in delivery volume.

In the three spatial directions, acceleration in vibrations at the mounting points of the computer tomograph (Gantry and

250 02 CT00-000.891.04.19.02 03.19 PG Common CT Basic

Patient Handling System PHS) must not exceed the thresholds as described in the above shown diagram. - Subgrade: Basically only concrete flooring / composite flooring ≥ 140 mm; composite flooring up to max. 125 mm strength;

Floating screed with sub-construction only; on-site mounting frame; Access floor with sub-construction only 03 CT00-000.891.03.42.02 10.18 PG Common CT Options

330

- Required concrete thickness: min. 140 mm (when using the delivered HILTI anchors)

Statics not to scale - Required extraction force min. 4.2 kN per fastening point. According to IEC 60601-1, a factor of 4 safety margin is mandatory.

- Positioning and levelling as given on table base.

4 The floor construction has to be performed solid and free of vibration,

3

e.g. concrete flooring C20/25 to C50/60 corresponding to DIN EN 206-1,

according to the maximum values as specified in the textblock Power supply SOMATOM go.All

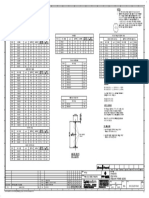

“Floor and building vibrations”. Mains TN-S 3/N/PE AC 50/60 Hz ± 2Hz Line impedance ≤ 110 mΩ Power consumption

It is recommended to test the weight capacity of the concrete or composite * The transport device with the gantry can be lowered to a ground clearance of 7 mm.

Voltage 400 V ± 10 % On site circuit breaker 100 A System

flooring by a stress analyst. ** The Gantry can be moved through the entrance < 1000 mm, when the transport adapter is partially removed.

Only copper cables are allowed Connection value 69,2 kVA Stand-by ≤ 3 kVA

Fastening the gantry on the floor is possible but only necessary in TIPPING HAZARD ! Transport with the rollers swivelled in is permissible only in narrow passages! Cable cross section is to be determined by national regulations. System off 0 kVA Room height finished floor to

1 2 countries prone to earthquakes or according to local regulations. As soon as the system has passed through narrow passages, the transport rollers Size of connector terminals in Gantry is 25 bis 95 mm². for time up to 4 s 115 kVA

Securing the patient table to the floor is mandatory. have to be swivelled out again. Suspended available Suspended required, min.

PE N L1 L2 L3 Electrical installation according to IEC 60364-7-710, national guidelines must be observed Location Concrete

Total weight of Gantry: 1295 kg Total static load (center of gravity ): Fstat total = 12.95 kN Gantry with transport device 1500 kg, transport device 220 kg. Additional electrical connectivity for the customer in Power supply EXAMINATION ROOM 345 cm. N.A 250 cm.

for CT System Minimum requirement for the on site

The maximum possible floor load (2-point load) per roller may be reached during gantry transport.

Partial load on gantry foot number 1 2 3 4 SIEMENS Customer Power distributor electrical installation

If necessary, cover the transport route with metal sheets to distribute the load. Healthineers

PE

Nominal static load after levelling Fstat nom [kN] 2.66 3.16 4.43 2.70 The door must have a final clearance of 1250 mm if bed entrance to the CT examination room is requested. +

2 3.3 min. 18

Maximum dynamic load (amplitude) during gantry rotation ± 0.3 ± 0.3 ± 0.3 ± 0.3 intern 1m

Fdyn max [kN] PHS Vario1 / RT Weight 570 kg 2574 x 824 x 1517 mm ( L x W x H ) max. 2,5 mm² flexible 16 □ 1.4 13 13 13 21 T1 T2 T3

T3

max. 3.4 Cu 15 80% 20% 5%

Outer diameter gantry foot [mm] 54 54 54 54 250 VAC / 2 A

K2 K3 K1 K1

PHS Vario2 Weight 592 kg 2574 x 824 x 1517 mm ( L x W x H ) 10s 1s 10s

24 VDC / 2 A PA 1.1 14 14 14 22 K K B

AUX 3 VA

1

Floor contact area gantry foot [cm²] 16 16 16 16 12 6 33

18 43

9 10 17

K4 Site Preparations

K1

L1

L2

L3

PE

During gantry installation and leveling, the maximum possible load on one gantry foot can be 7.76 kN (the gantry is 2 3.1 K5 2 T2 K1

Environment intern 1m 11 34

standing on two diagonal feet). Design access floors for a weight capacity of min. 400 kg per slab/plate. During max. 2,5 mm² flexible 5 15 44

18 Technical details

max. 3.2 ~

gantry transport, the load may be higher at certain individual points (3-point load, e.g. due to uneven flooring). All CT components Temperature 18 to 30 °C 250 VAC / 2 A T1

Relative humidity 20 to 75 % 24 VDC / 2 A 15

18

Absolute humidity max. 30 g/m³

6A A1 B1 A1 4 3 A1 A1 B1 F1 E1 Abdelrahman Gamal Karem Zakaria Abdelrahman Gamal

Barometric pressure 800 to 1060 hPa 5 Priority 1

2 1.1 Q1 T3 K5 MODE 1

M 3VA <U T1 T2 K2 K3 ZE + ZA K4 K1 5/1/2024 5/1/2024 5/1/2024

Temperature gradient 6 K/h intern 1m A2 E2

max. 2,5 mm² flexible 4 100A A2 A2 7

17 7 8 9 10 12 13 16 Edited Checked Released

not to scale max. 1.2 -

On-site cooling requirements Transport / storage Temperature -20 to 50 °C 3e

250 VAC / 2 A

Relative humidity 10 to 95 % 24 VDC / 2 A Siemens Healthcare GmbH

Workload CT-system [%] 100 (maximum power) 0 (stand-by) 2 3R Planning department

Absolute humidity max. 30 g/m³

Barometric pressure 700 to 1060 hPa Gantry outlet for Power Distribution System (PDS) Hartmannstrasse 16

Heat dissapation to ambient air 7.1 kW 2.25 kW 34 78 6 21 5 EXAMINA-

Temperature gradient 1 TION D-91052 Erlangen

10° K/h ROOM

Air temperature (air intake) 18 °C to 30 °C Maximum storage period 2 months Radiation ready indicator 2

1 Floating ground contact 250 VAC / 2 A or 24 VDC / 2 A. by customer L

DELTA UNIVERSITY HOSPITAL

max. ± 1 K/min; max. < 6 K/h; If it is not possible to maintain these ranges, an air conditioning system with or without humidifier / dehumidifier L

Temperature gradient (air intake) The need for the installation has to be clarified with the local authorities.

max. ± 4 K/h in 24 h 1 should be installed. By intake of outside air it is recommended to install air filters (Class EU3 to EU4)

International Coastal Rd,

CONTROL CONTROL

ROOM ROOM

for filtering dust particles of > 10 µm (DIN EN 779). Radiation warning indicator IEC 60601-2-44 and CFR 21 Al Hafir WA Al Amal

Humidity (air intake) 20 % to 75 % RE AR Floating ground contact 250 VAC / 2 A or 24 VDC / 2 A. [0.7m] RADIOLOGY

The need for the installation has to be clarified with the local authorities. X20.1-3

Air flow rate (through the Gantry) 1800 m³/h to 2200 m³/h 1) air intake 2) exhaust air PE L1/L2/L3/N

SIEMENS REPO

Door switchlock for blocking radiation 25 to GROUND FLOOR

X22.3

X22.4

X22.7

X22.8

X22.6

X22.2

X22.1

X22.5

Healthineers X20.1-4

Structural room conditions (e.g. windows, large glass areas, building and room thermal insulation, room size and 95 mm² 0m 1m 2m

Room height Floating ground contact 250 VAC / 2 A or 24 VDC / 2 A. CT System Multi Modality

volume...) influences the climatic room conditions for the air-cooled gantry and other air-cooled CT-system

The need for the installation has to be clarified with the local authorities.

components in general. These climatic influences must be taken into account by the Project Manager when Technically required minimum room height 2100 mm (with injector arm: 2300 mm).

dimensioning a new or checking an existing on-site room air condition. Measured from the highest point of the finished floor (with covering) to the lowest point of the ceiling. Project File Revision Page Size Scale

112332 1714560 01 01 of 01 A0 1:50

© Siemens Healthcare GmbH created by Sales CAD

You might also like

- 313B CR Excavator Electrical System: Area CDocument2 pages313B CR Excavator Electrical System: Area CWilfer Alexis Grain Diaz100% (1)

- Rent-A-Movie Database Project: YOUR ASSIGNMENT (Deliverables Are Underlined)Document2 pagesRent-A-Movie Database Project: YOUR ASSIGNMENT (Deliverables Are Underlined)Miguel Flores FloresNo ratings yet

- Speech & Language Therapy in Practice, Spring 2002Document32 pagesSpeech & Language Therapy in Practice, Spring 2002Speech & Language Therapy in PracticeNo ratings yet

- Overall Project - Detail Progress Tracking Sheet - JHP - Updated - 19-Aug-21 - PMDocument59 pagesOverall Project - Detail Progress Tracking Sheet - JHP - Updated - 19-Aug-21 - PMMRadwanNo ratings yet

- C.H. - 0+465.5 Section No5Document1 pageC.H. - 0+465.5 Section No5Fran LuqueNo ratings yet

- Civil Work & Finishes ServicesDocument1 pageCivil Work & Finishes ServicesdadaraoNo ratings yet

- QC02002 CNP DRW PLN Id 04 Ce1 00004 00 (PDF)Document1 pageQC02002 CNP DRW PLN Id 04 Ce1 00004 00 (PDF)Moosa RizwanNo ratings yet

- 2023-09-22 Link Bridge AIPDocument6 pages2023-09-22 Link Bridge AIPMorris KwokNo ratings yet

- Cab Radio Wiring RH Console Wiring (Rear, Right View) : 326F, 329F and 330F Excavator Electrical System 330F MHPUDocument8 pagesCab Radio Wiring RH Console Wiring (Rear, Right View) : 326F, 329F and 330F Excavator Electrical System 330F MHPUDozer KamilNo ratings yet

- Umw Ip - Genset Shop Drawing ApprovalDocument4 pagesUmw Ip - Genset Shop Drawing ApprovalLevel Kita Semua SamaNo ratings yet

- Kingspan - Kingzip - Roof - KS500 1000 ZIP IP Installation Guide - 032017 - UKDocument1 pageKingspan - Kingzip - Roof - KS500 1000 ZIP IP Installation Guide - 032017 - UKGeorgios PNo ratings yet

- Goldfields-Esperance Key In-Print & Online Advertising ApprovalDocument1 pageGoldfields-Esperance Key In-Print & Online Advertising ApprovalJO JONo ratings yet

- Cicpa - C&mcig1w922Document782 pagesCicpa - C&mcig1w922mahmoudNo ratings yet

- 345 CDocument4 pages345 Cedi0% (1)

- 916-CEG-Excel Astra Structure PackageDocument4 pages916-CEG-Excel Astra Structure PackageramNo ratings yet

- Construction Plan Cooling Tower Pad-1 R&D CenterDocument11 pagesConstruction Plan Cooling Tower Pad-1 R&D CenterAdlin ArifinNo ratings yet

- SDSSSSDDocument1 pageSDSSSSDmirfanjpcgmailcomNo ratings yet

- WHORKSHOP 1 -Document3 pagesWHORKSHOP 1 -ramNo ratings yet

- Tcs-P4-B8-Dra-05-G521-005-Tcs-Ufh-Installation-Layout-Type-3a - C00 - Epa & HLDocument2 pagesTcs-P4-B8-Dra-05-G521-005-Tcs-Ufh-Installation-Layout-Type-3a - C00 - Epa & HLuozceylanNo ratings yet

- GH22148 0100D TD Gen A 50001 Rev0Document1 pageGH22148 0100D TD Gen A 50001 Rev0felix sowah-laryeaNo ratings yet

- Akh Ymi DD Im10x D Ar DWG 0001 1Document1 pageAkh Ymi DD Im10x D Ar DWG 0001 1Tamrayehu KuremaNo ratings yet

- 1824 000 SS DST 0040 - 2 - IfcDocument1 page1824 000 SS DST 0040 - 2 - IfcAquiles MartinezNo ratings yet

- 1824 000 SS DST 0040 - 2 - IfcDocument1 page1824 000 SS DST 0040 - 2 - IfcAquiles MartinezNo ratings yet

- Complete: DistributionDocument1 pageComplete: DistributionTeam RooneyNo ratings yet

- SENR6238Document2 pagesSENR6238Gilvan JuniorNo ratings yet

- 1714802 2Document1 page1714802 2hassan awadallaNo ratings yet

- PreviewDocument4 pagesPreviewالعندليب الاسمرNo ratings yet

- July 2021 Daily MeetingDocument4 pagesJuly 2021 Daily MeetingPegelou Jhon LagutinNo ratings yet

- 966K and 972K Wheel Loader Electrical SystemDocument4 pages966K and 972K Wheel Loader Electrical SystemFlorencio MaximilianoNo ratings yet

- Electrical Plan PDFDocument1 pageElectrical Plan PDFDJNo ratings yet

- S781-CV-DWG-00004-01-213036-B - OQ Approved - 14.03.2023Document2 pagesS781-CV-DWG-00004-01-213036-B - OQ Approved - 14.03.2023MDhana SekarNo ratings yet

- Drawing 3.Document1 pageDrawing 3.tiyaniNo ratings yet

- Desenho de Vigas CypeDocument1 pageDesenho de Vigas CypeAntónio VascoNo ratings yet

- Ferris Campus MapDocument1 pageFerris Campus MapWXMINo ratings yet

- Ethiopian Electric Power (Eep) : Submission ofDocument6 pagesEthiopian Electric Power (Eep) : Submission ofjie zhangNo ratings yet

- AdelaidaDocument10 pagesAdelaidaNeil AdrianNo ratings yet

- BLOCK PRODUCTION LOCATION-ModelDocument1 pageBLOCK PRODUCTION LOCATION-Modellucio444No ratings yet

- Plano Eléctrico d7r TractorDocument4 pagesPlano Eléctrico d7r TractorCarlos Andres Ávila PuertaNo ratings yet

- MAQUINAplano 320 9kk PDFDocument2 pagesMAQUINAplano 320 9kk PDFRuben Dario CasiqueNo ratings yet

- Electronic SchematicDocument2 pagesElectronic SchematicXerxNo ratings yet

- ProjectHotDofTRCRev1 RedactedDocument5 pagesProjectHotDofTRCRev1 RedactedMichael PraatsNo ratings yet

- List Gambar Penerimaan Klas Rev2Document14 pagesList Gambar Penerimaan Klas Rev2Dolok Joko KenconoNo ratings yet

- 6th FP. G+6 Mixed Use Abera Lisanu Building-ModelDocument1 page6th FP. G+6 Mixed Use Abera Lisanu Building-Modelberra 2373No ratings yet

- System Layout Twitter 27-11-18 PDFDocument3 pagesSystem Layout Twitter 27-11-18 PDFKevin ApostolNo ratings yet

- Gambar Concrete Pole PDFDocument1 pageGambar Concrete Pole PDFrifkynetNo ratings yet

- 07A2 YSR LIST 036 Rev04 - FT Instrument ListDocument1 page07A2 YSR LIST 036 Rev04 - FT Instrument ListAli JameelNo ratings yet

- July 2021 Daily MeetingDocument4 pagesJuly 2021 Daily MeetingPegelou Jhon LagutinNo ratings yet

- CTA - Site Instruction #027Document5 pagesCTA - Site Instruction #027otuse557No ratings yet

- Kop-Flex - KS (Membranas HP)Document3 pagesKop-Flex - KS (Membranas HP)marcelo castilloNo ratings yet

- SCOR MySQLDocument1 pageSCOR MySQLEdgar EspinozaNo ratings yet

- Basement DDA Car ParkingDocument1 pageBasement DDA Car Parkingrajen raghwaniNo ratings yet

- Plano Electrico 785D Actual 2Document12 pagesPlano Electrico 785D Actual 2Escuela EntrenamientoNo ratings yet

- Ib Mon CD Master Plan Layout Ground FloorDocument1 pageIb Mon CD Master Plan Layout Ground FloorsedanaNo ratings yet

- 916-CEG-Excel Astra Structure Package WORKSHOP 1Document4 pages916-CEG-Excel Astra Structure Package WORKSHOP 1ramNo ratings yet

- Electro 323Document2 pagesElectro 323Pușcă MartinNo ratings yet

- 030 RFI ELLIPSE Beam Admin Auditorium ACT Response 20231113Document4 pages030 RFI ELLIPSE Beam Admin Auditorium ACT Response 20231113Muriyanto MuriNo ratings yet

- 28 Piano-1Document5 pages28 Piano-1Jaciene PessoaNo ratings yet

- Cab Radio Wiring RH Console Wiring (Rear, Right View) : 336F and 340F Excavator 336F MHPU Electrical SystemDocument8 pagesCab Radio Wiring RH Console Wiring (Rear, Right View) : 336F and 340F Excavator 336F MHPU Electrical SystemDozer Kamil100% (1)

- Operating Instructions - 7817454 - en WATCDOGDocument1 pageOperating Instructions - 7817454 - en WATCDOGjcarlosguerrasNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: MathFrom EverandInstant Assessments for Data Tracking, Grade 1: MathRating: 4 out of 5 stars4/5 (1)

- CHAP 2 - Diode Applications-Clippers ClampersDocument33 pagesCHAP 2 - Diode Applications-Clippers Clampersksreddy2002No ratings yet

- Briefcase On Company Law Briefcase Series Michael Ottley Z LibraryDocument181 pagesBriefcase On Company Law Briefcase Series Michael Ottley Z Libraryhillaryambrose030No ratings yet

- QD StudentsDocument14 pagesQD StudentsBimboy CuenoNo ratings yet

- ML-C and C Micro PDFDocument94 pagesML-C and C Micro PDFvulcanescuNo ratings yet

- Title: Investigation of Agriculture Related Problems of Rural Women in District LayyahDocument10 pagesTitle: Investigation of Agriculture Related Problems of Rural Women in District LayyahMuhammad Asim Hafeez ThindNo ratings yet

- Entr CH 1Document7 pagesEntr CH 184kaveri8650% (2)

- Resistance BodiesDocument20 pagesResistance BodiesraisecainNo ratings yet

- NYC DOE Fact Sheet On Closure of Monroe Academy of Business/Law in The BronxDocument4 pagesNYC DOE Fact Sheet On Closure of Monroe Academy of Business/Law in The BronxCity Limits (New York)No ratings yet

- Class 3 4 KeyDocument12 pagesClass 3 4 Keyshivamsingh.fscNo ratings yet

- M2 Imalis Schedule 2021-2022-: July 21StDocument1 pageM2 Imalis Schedule 2021-2022-: July 21StMohammed Abdul Rahman KhanNo ratings yet

- Citizen Instruction Manual C651Document38 pagesCitizen Instruction Manual C651vbadsNo ratings yet

- CDS4004 AnntDocument5 pagesCDS4004 AnntJiaxing ShenNo ratings yet

- Contadores 2GDocument5 pagesContadores 2GJosé Luis Gutiérrez NietoNo ratings yet

- The Yoga Sutras of Patanjali PDFDocument168 pagesThe Yoga Sutras of Patanjali PDFjhonprestonNo ratings yet

- Ti Bajssít Ajkáyo NaljjajjegénjDocument8 pagesTi Bajssít Ajkáyo NaljjajjegénjDennis ValdezNo ratings yet

- Rubric For Group WorkDocument1 pageRubric For Group WorkAlven ReyNo ratings yet

- Behavioral Finance AssignmentDocument8 pagesBehavioral Finance Assignmentthulli06No ratings yet

- Com - Pg.game6327838 LogcatDocument53 pagesCom - Pg.game6327838 Logcatfordcannabis07No ratings yet

- Ae 191 Lesson 1Document14 pagesAe 191 Lesson 1Erna DavidNo ratings yet

- Guillain-Barré Syndrome (GBS) : Prepared By: Aeshah Al-Azmi Pharm.D CandidateDocument56 pagesGuillain-Barré Syndrome (GBS) : Prepared By: Aeshah Al-Azmi Pharm.D CandidateAeshah Al-AzmiNo ratings yet

- Chapter OneDocument5 pagesChapter OneJosam Montero FordNo ratings yet

- Burocco S3000 ManualDocument4 pagesBurocco S3000 ManualJose David Leon BetancourtNo ratings yet

- Voltage Stresses in Electric Submergible Pumps Operated by Variable Speed DrivesDocument26 pagesVoltage Stresses in Electric Submergible Pumps Operated by Variable Speed Drivesandresv10No ratings yet

- Progressive Design Update 10.10.22Document9 pagesProgressive Design Update 10.10.22Vikas PaiNo ratings yet

- MCQ Transdermal Drug DeliveryDocument2 pagesMCQ Transdermal Drug DeliveryVVB100% (3)

- PerformanceDocument10 pagesPerformancecsl1600No ratings yet

- EPC Saur Energy InternationalDocument3 pagesEPC Saur Energy InternationalNarendra PatelNo ratings yet

- BAHRIA UNIVERSITY, (Karachi Campus) : Components of Presentation & ReportDocument2 pagesBAHRIA UNIVERSITY, (Karachi Campus) : Components of Presentation & ReportAsad IsmailNo ratings yet