Professional Documents

Culture Documents

Fuel or Oil leakage Limits for CFM-5C engine

Fuel or Oil leakage Limits for CFM-5C engine

Uploaded by

Ratsimba AndryCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fuel or Oil leakage Limits for CFM-5C engine

Fuel or Oil leakage Limits for CFM-5C engine

Uploaded by

Ratsimba AndryCopyright:

Available Formats

Customer : ATLAS Manual : AMM

Type : A340 Selected applicability : 163-163

Rev. Date : Apr 01, 2016

71-00-00-790-802-A - Fuel or Oil Leakage Limits for CFM56-5C (NON/P) engine

** ON A/C ALL

TASK 71-00-00-790-802-A

Fuel or Oil Leakage Limits for CFM56-5C (NON/P) engine

1. Reason for the Job

This TASK is only applicable for CFM56-5C (NON/P) engine models.

To measure the leakage rates if you see abnormal leaks (fuel or oil) coming out of the powerplant drain mast

and give limits.

2 Job Set-up Information

A. Fixtures, Tools, Test and Support Equipment

REFERENCE QTY DESIGNATION

No specific AR GUN - HOT AIR

B. Referenced Information

REFERENCE DESIGNATION

(Ref. 12-13-79-610-801-A). Check of the Oil Level and Gravity Filling

(Ref. 29-00-00-790-801-A). Check of the External Leakage of Hydraulic Components

(Ref. 71-00-00-000-801-A). Removal of the Engine

(Ref. 71-00-00-000-801-A-02). Removal of the Engine with the Engine Positioner TWW 75E (MIAG)

(Ref. 71-00-00-000-801-A-03). Removal of the Engine with Cobra Tool

(Ref. 71-00-00-400-801-A). Installation of the Engine

(Ref. 71-00-00-400-801-A-02). Installation of the Engine with the Engine Positioner TWW 75E (MIAG)

** ON A/C 051-099, 101-150, 153-159, 161-163, 165-199

(Ref. 71-00-00-400-801-A-03). Installation of the Engine with Cobra Tool

** ON A/C ALL

(Ref. 71-00-00-790-802-A). Fuel or Oil Leakage Limits for CFM56-5C (NON/P) engine

(Ref. 71-00-00-790-802-A-01). Fuel or Oil Leakage Limits for CFM56-5C/P engine

(Ref. 71-00-00-790-805-A). Drain Mast Leakage Identification Procedure

(Ref. 71-00-00-860-801-A). Engine Automatic Start

(Ref. 72-63-00-300-802-A). Replacement of a Sealol Seal (Typical) (Fuel Pump and Hydraulic

Pump Drive Pads)

(Ref. 72-63-00-300-805-A). Replacement of a Sealol Seal (Typical) (IDG and Starter Drive Pads)

(Ref. 73-11-10-000-801-A). Removal of the Fuel Pump and Filter Assembly

(Ref. 73-11-10-400-801-A). Installation of the Fuel Pump and Filter Assembly

(Ref. 73-11-31-960-801-A). Replacement of the Fuel Manifold Distributor Gasket Seals

(Ref. 73-11-40-790-801-A). Leak Check of the Fuel Nozzles

(Ref. 73-11-50-000-801-A). Removal of the Fuel Return Valve

(Ref. 73-11-50-400-801-A). Installation of the Fuel Return Valve

(Ref. 73-11-70-000-801-A). Removal of the Burner Staging Valve

(Ref. 73-11-70-400-801-A). Installation of the Burner Staging Valve

(Ref. 73-21-10-000-801-A). Removal of the Hydromechanical Unit (HMU)

(Ref. 73-21-10-400-801-A). Installation of the Hydromechanical Unit (HMU)

(Ref. 75-21-10-000-801-A). Removal of the HPT Active Clearance Control Valve

(Ref. 75-21-10-400-801-A). Installation of the HPT Active Clearance Control Valve

Print Date: August 17, 2016 Page 1 of 7

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : ATLAS Manual : AMM

Type : A340 Selected applicability : 163-163

Rev. Date : Apr 01, 2016

71-00-00-790-802-A - Fuel or Oil Leakage Limits for CFM56-5C (NON/P) engine

REFERENCE DESIGNATION

(Ref. 75-22-10-000-801-A). Removal of the LPT Active Clearance Control Valve

(Ref. 75-22-10-400-801-A). Installation of the LPT Active Clearance Control Valve

(Ref. 75-23-10-000-801-A). Removal of the Rotor Active Clearance Start Bleed Valve

(Ref. 75-23-10-400-801-A). Installation of the Rotor Active Clearance Start Bleed Valve

(Ref. 75-31-20-000-801-A). Removal of the Variable Bleed-Valve (VBV) Stop Mechanism

(5001ED)

(Ref. 75-31-20-400-801-A). Installation of the Variable Bleed-Valve (VBV) Stop Mechanism

(5001ED)

(Ref. 75-32-10-000-801-A). Removal of the Variable Stator Vane Actuator and Sensor

(Ref. 75-32-10-400-801-A). Installation of the Variable Stator Vane Actuator and Sensor

(Ref. 79-00-00-210-802-A). Visual Inspection of the Oil System.

(Ref. 79-21-20-000-801-A). Removal of the Main Oil/Fuel Heat Exchanger

(Ref. 79-21-20-400-801-A). Installation of the Main Oil/Fuel Heat Exchanger

3. Job Set-up

Subtask 71-00-00-869-077-A

A. Not applicable.

4. Procedure

Subtask 71-00-00-790-050-A

A. Leakage at the drain mast.

NOTE: Aircraft Maintenance Manual (AMM) overserviceable limits aim at providing operators with flexib-

ility in Line Replaceable Unit (LRU) replacement when fuel leakages are discovered at the drain

location, considering that a small leakage indicates the beginning of a component sealing deteri-

oration. This apply for static or dynamic fuel leaks observed on Outside Air Temperature (OAT)

above -20 deg.C (-4.00 deg.F).

POST SB CFM 73-036

WARNING: DO NOT LET THE HMU TEMPERATURE EXCEED 100 DEG.C (212 DEG.F).

(1) Safety precaution:

NOTE: Hydromechanical Units (HMUs) that have fluorocarbon (Viton) external seals can leak

fuel for a short time when they are below 0 deg.C (32.00 deg.F) (modification 1 and 2)

(Ref. AMM TASK 71-00-00-790-802) . If the ambient temperature is below -40 deg.C (-40.00

deg.F) it is recommended to heat the HMU (modification 1 and 2) to minimize leakage during

starts per the following procedure:

(a) Heat the HMU housing with a suitable GUN - HOT AIR (Keco GH100, Aerotech BT400-45 or

equivalent) operating at 140 deg.C (284.00 deg.F) until the HMU housing temperature is greater

than 25 deg.C (77.00 deg.F).

NOTE: The HMU should be warm to the touch but not hot.

· If the fuel leakage stops in less than 5 minutes at idle, continue operation of the engine.

· If the fuel leakage continues after 5 minutes at idle, shut down the engine and repair the

source of the leakage.

END POST SB CFM 73-036

Print Date: August 17, 2016 Page 2 of 7

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : ATLAS Manual : AMM

Type : A340 Selected applicability : 163-163

Rev. Date : Apr 01, 2016

71-00-00-790-802-A - Fuel or Oil Leakage Limits for CFM56-5C (NON/P) engine

(2) Fuel leakage at the drain mast assembly:

CAUTION: NO LEAKAGE IS PERMITTED FROM THE FUEL MANIFOLD SHROUD, AFT PYLON,

AND FORWARD PYLON DRAIN LINES.

(a) Non-running engine (static fuel leak) at the aircraft drain mast assembly:

NOTE: A different drain line identifies leakage for each of the drains, (drain No.1, 11, and 12)

(Ref. AMM TASK 71-00-00-790-805) .

NOTE: In the case of very cold weather conditions (Outside Air Temperature (OAT) < -20 deg.C

(-4.00 deg.F)), fuel leaks from the drains can occur on a non-running engine and dur-

ing engine start. This leakage should not be considered as unusual. This leakage should

stop after a 5 minute warm-up at minimum idle.

1 No maintenance action is necessary if leakage is less than:

· Drain No.4: 30 drops/min (90 ml/hr or 1.5 cc/min)

· Drain No.6: 14 drops/min (40 ml/hr or 2 cc/3 min)

· Drain No.8 and 9: 60 drops/min (180 ml/hr or 3 cc/3 min).

2 If fuel leakage rate is more than the above limits:

· Start the engine (Ref. AMM TASK 71-00-00-860-801)

· Let the engine become stable at minimum idle for 5 minutes

· Refer to leakage limits in step (b).

CAUTION: NO LEAKAGE IS PERMITTED FROM THE FUEL MANIFOLD SHROUD, AFT PYLON,

AND FORWARD PYLON DRAIN LINES.

(b) Running engine (dynamic fuel leak) at the aircraft drain mast assembly after a 5 minute warm-up

at minimum idle:

NOTE: A different drain line identifies leakage for each of the drains, (drain No.1 ,11 and 12)

(Ref. AMM TASK 71-00-00-790-805) .

1 No maintenance action is necessary if leakage is less than:

· Drain No.4: 30 drops/min (90 ml/hr or 1.5 cc/min)

· Drain No.6: 14 drops/min (40 ml/hr or 2 cc/3 min)

· Drain No.8 and 9: 60 drops/min (180 ml/hr or 3 cc/3 min).

2 If the fuel leakage rate is more than the above limits but less than:

· Drain No.4: 45 drops/min (135 ml/hr or 7 cc/min)

· Drain No.6: 20 drops/min (60 ml/hr or 3 cc/min)

· Drain No.8 and 9: 90 drops/min (270 ml/hr or 4.5 cc/min), then leakage test is necessary

in less than 5 cycles (Ref. AMM TASK 71-00-00-790-805) .

3 If the fuel leakage rate is greater than the above limit do a leakage test

(Ref. AMM TASK 71-00-00-790-805) .

(3) Oil leakage at the drain mast assembly (static or dynamic):

(a) If the oil leakage rate at this drain mast assembly is less than 7 drops per minute (20 ml/hr or 1

cc/3 min), no maintenance action is necessary.

(b) If the oil leakage rate at the drain mast assembly is greater than 7 drops per minute (20 ml/hr or 1

cc/3 min), do a leakage test (Ref. AMM TASK 71-00-00-790-805) .

(4) Hydraulic leakage at the drain mast assembly (Ref. AMM TASK 29-00-00-790-801) .

Print Date: August 17, 2016 Page 3 of 7

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : ATLAS Manual : AMM

Type : A340 Selected applicability : 163-163

Rev. Date : Apr 01, 2016

71-00-00-790-802-A - Fuel or Oil Leakage Limits for CFM56-5C (NON/P) engine

Subtask 71-00-00-790-066-A

B. Other leakage.

(1) Connectors:

(a) Fuel leakage is not serviceable (drops are continuous).

(b) Fuel wetting is serviceable.

NOTE: Fuel wetting is moisture that does not grow with time.

Subtask 71-00-00-790-052-A

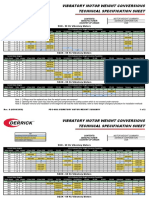

C. Read the leakage volumes that have collected in the different cavities of the tool set. Refer to the table

which follows for the oil and fuel leakage rate limits.

INSPECT/CHECK MAXIMUM SER- REMARK

VICEABLE LIMITS

1.The oil leaks from:

· The hydraulic pump pad (drain 20 ml/hr (1 cc/3 min) (7 drops/min) Replace the sealol seal (Ref. AMM

No.2) (engine only) (See NOTE below) TASK 72-63-00-300-802) and (Ref.

TASK 71-73-49-000-807,Fig.402) if

more than the limit.

NOTE: The hydraulic pump drive pad drain line also collects the hydraulic fluid which can leak from the

drive end of the hydraulic pump. If you are not sure about the kind of oil leak (engine oil or hy-

draulic fluid) it may be necessary to isolate the drain circuits of the pad and of the hydraulic pump

to troubleshoot the source of the leak (Ref. AMM TASK 71-00-00-790-805) .

· The IDG pad (drain No.3) 20 ml/hr (1 cc/3 min) Replace the sealol seal (Ref. AMM

(7 drops/min) TASK 72-63-00-300-805) and (Ref.

TASK 71-73-49-000-808, Fig.403) if

more than the limit.

· The fuel pump pad (drain 20 ml/hr (1 cc/3 min) Replace the sealol seal (Ref. AMM

No.4) (7 drops/min) (engine oil only) TASK 72-63-00-300-802) and (Ref.

(See NOTE below) TASK 71-73-49-000-806, Fig.402) if

more than the limit

NOTE: The fuel pump drive pad drain line also collects the fuel which can leak from the drive end of

the fuel pump. As a result, you can find a mixture of fuel and oil in cavity No.4 of the tool set.

If you are not sure about the volume of fuel or oil leakage, it may be necessary to isolate the

drain circuits of the pad and of the fuel pump to troubleshoot the source of the out - of - limit leak

(Ref. AMM TASK 71-00-00-790-805) . Refer to paragraph 2 of this procedure for the fuel leakage

limit.

· The starter pad (drain No.5) 20 ml/hr (1 cc/3 min) Replace the sealol seal (Ref. AMM

(7 drops/min) TASK 72-63-00-300-805) and (Ref.

TASK 71-73-49-000-809, Fig.403) if

more than the limit.

The main oil/fuel heat exchanger 20 ml/hr (1 cc/3 min) Replace the main oil/fuel heat ex-

(drain No.6) (7 drops/min) changer (Ref. AMM TASK 79-21-

20-000-801) (Ref. AMM TASK 7

9-21-20-400-801) and (Ref. TASK

71-73-49-000-805, Fig. 402) if more

than the limit.

Print Date: August 17, 2016 Page 4 of 7

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : ATLAS Manual : AMM

Type : A340 Selected applicability : 163-163

Rev. Date : Apr 01, 2016

71-00-00-790-802-A - Fuel or Oil Leakage Limits for CFM56-5C (NON/P) engine

INSPECT/CHECK MAXIMUM SER- REMARK

VICEABLE LIMITS

NOTE: The main oil/fuel exchanger drain line also collects the fuel which can leak.As a result, you can

find a mixture of fuel and oil in cavity No.6 of the tool set. Refer to paragraph 2 of this procedure

for the fuel leakage limit.

· The engine forward sump 60 ml/hr (1 cc/min) Replace the engine

(drain No.7) (20 drops/min) (Ref. AMM TASK 71-00-00-000-801) (Ref. AM

Ref. AMM TASK 71-

00-00-000-801) and

(Ref. AMM TASK 71-00-00-400-801) (

Ref. AMM TASK 71-00-00-400-801)

** ON A/C 051-099, 101-150,

153-159, 161-163, 165-199

(Ref. AMM TASK 71-00-0

0-400-801) and (Ref. TASK

71-00-00-000-810, Fig.404 Sheet 1)

if more than the limit.

· The oil tank scrubber (drain If leaks found, check that the oil tank

No.10) cap is installed correctly (Ref. AMM

TASK 12-13-79-610-801) and (Ref.

TASK 79-11-10-300-803, Fig.802).

· The engine aft sump A lightly oil wetted inner surface If a large amount of oil wet-

of centerbody is permitted (See ting is found in the centerbody

NOTE below) associated with high oil con-

sumption, replace the engine

(Ref. AMM TASK 71-00-00-000-801) (Ref. AM

Ref. AMM TASK 71-

00-00-000-801) and

(Ref. AMM TASK 71-00-00-400-801) (

Ref. AMM TASK 71-00-00-400-801)

** ON A/C 051-099, 101-150,

153-159, 161-163, 165-199

(Ref. AMM TASK 71-00-00-400-80

1)

NOTE: The aft sump oil drain system is not connected to the drain mast. The air/oil vapors in the aft

sump, together with those in the forward sump travel through the center vent tube and vent holes

aft of the turbine frame struts and then go in the exhaust stream through the centerbody.

NOTE: Oil puddling in the exhaust/aft sump area/centerbody must be considered as normal as long as

the oil consumption rate is within serviceable limits. Comparison must be done with the other en-

gines to quantify oil accumulation.

· Forward core compartment No oil leaks permitted from the No oil wetting permitted on the

ventilation exit hole at the bot- ventilation exit (See NOTE below) cascade vanes on the ventilation

tom rear of the reverser cowl exit. If they are oil wetted, do an in-

spection of the aft sump oil sup-

ply and scavenge lines at their

connection with the turbine frame

(Ref. AMM TASK 79-00-00-210-802) .

Print Date: August 17, 2016 Page 5 of 7

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : ATLAS Manual : AMM

Type : A340 Selected applicability : 163-163

Rev. Date : Apr 01, 2016

71-00-00-790-802-A - Fuel or Oil Leakage Limits for CFM56-5C (NON/P) engine

INSPECT/CHECK MAXIMUM SER- REMARK

VICEABLE LIMITS

NOTE: The oil supply and scavenge lines of the aft sump bearings each have a drain line at their connec-

tion with the related tubes of the turbine frame. These drain lines are not connected to the drain

mast but to the axial ventilation bulkhead. The drain lines go through the bulkhead and go in the

forward nacelle core compartment, upstream of the bulkhead.

2.The fuel leaks from:

· The fuel manifold shroud No leaks permitted Do a leak check of the fuel man-

(drain No.1) ifold assy (Ref. AMM TASK 73-

11-40-790-801) and (Ref. TASK

71-73-49-000-812, Fig.404, Sheet 1)

if leaks are found.

· Fuel pump pad (drain No.4) 90 ml/hr (1.5 cc/min) Replace the fuel pump (Ref.

(30 drops/min). Up to 40 drops/ AMM TASK 73-11-10-000-80

min allowed for 5 cycles 1) and (Ref. AMM TASK 73-1

1-10-400-801) and (Ref. TASK

71-73-49-000-806,Fig.402) if more

than the limit.

NOTE: The fuel pump drive pad drain line also collects oil which can leak from the drive end of the

fuel pump. As a result, you can find a mixture of fuel and oil in cavity No.4 or the tool set.

If not sure about the volume of fuel or oil leakage, it may be necessary to isolate the drain

circuits of the pad and of the fuel pump to troubleshoot the source of the out-of-limit leak

(Ref. AMM TASK 71-00-00-790-805) . Refer to paragraph 1 of this procedure for the oil leakage

limit.

The main oil/fuel heat exchanger 40 ml/hr (3 cc/3 min) Replace the main oil/

(drain No.6) (14 drops/min). Up to 20 drops/ fuel heat exchanger

min permitted for 5 cycles (Ref. AMM TASK 79-21-20-000-801) ,

(Ref. AMM TASK 79-21-2

0-400-801) and (Ref. TASK

71-73-49-000-805, Fig.402) if more

than the limit.

NOTE: The main oil/fuel heat exchanger drain line also collects the oil which can leak. As a result, you

can find a mixture of fuel and oil in cavity No.6 of the tool set. Refer to paragraph 2 of this proced-

ure for the fuel leakage limit.

HMU (drain No.8) 180 ml/hr (3 cc/min) Replace the HMU (Ref. AMM TASK

(60 drops/min) (See NOTE be- 73-21-10-000-801) and (Ref. AMM

low). Up to 90 drops/min permitted TASK 73-21-10-400-801) and (Ref.

for 5 cycles TASK 71-73-49-000-804, Fig.402) if

more than the limit.

· FRV (drain No.8) 180 ml/hr (3 cc/min) Replace the Fuel Return Valve

(60 drops/min) (See NOTE be- (FRV) (Ref. AMM TASK 73-11-5

low). Up to 90 drops/min permitted 0-000-801) (Ref. AMM TASK 73-

for 5 cycles 11-50-400-801) and (Ref. TASK

71-73-49-000-801, Fig.401 Sheet 1)

if more than the limit

NOTE: The HMU and FRV drain lines have the same drain tube at the drain mast manifold. If you

are not sure about the fuel leakage volumes from each of these two equipments, it may

Print Date: August 17, 2016 Page 6 of 7

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : ATLAS Manual : AMM

Type : A340 Selected applicability : 163-163

Rev. Date : Apr 01, 2016

71-00-00-790-802-A - Fuel or Oil Leakage Limits for CFM56-5C (NON/P) engine

INSPECT/CHECK MAXIMUM SER- REMARK

VICEABLE LIMITS

be necessary to isolate their drain line to troubleshoot the source of the out-of-limit leak.

(Ref. AMM TASK 71-00-00-790-805) .

The core servos (drain No.9). See NOTE below (Ref. TASK 71-73-49-000-811,

Fig.404, Sheet 1).

· The Variable Bleed Valve 180 ml/hr (3 cc/min) Replace the fuel motor (Ref. AMM

(VBV) fuel gear motor (60 drops/min). Up to 90 drops/ TASK 75-31-20-000-801) and (Re

min permitted for 5 cycles f. AMM TASK 75-31-20-400-801) if

more than the limit

· High Pressure Turbine Active 180 ml/hr (3 cc/min) Replace the HPTACC valve (Ref. A

Clearance Control (HPTACC) (60 drops/min). Up to 90 drops/ MM TASK 75-21-10-000-801) and (

valve min permitted for 5 cycles Ref. AMM TASK 75-21-10-400-801)

if more than the limit

· Low Pressure Turbine Active 180 ml/hr (3 cc/min) Replace the LPTACC valve (Ref. A

Clearance Control (LPTACC) (60 drops/min). Up to90 drops/min MM TASK 75-22-10-000-801) and (

valve permitted for 5 cycles Ref. AMM TASK 75-22-10-400-801)

if more than the limit

· Rotor Active Clearance Start 180 ml/hr (3 cc/min) Replace the RACSB valve (Ref. AM

Bleed (RACSB) valve (60 drops/min). Up to 90 drops/ M TASK 75-23-10-000-801) and (R

min permitted for 5 cycles ef. AMM TASK 75-23-10-400-801) if

more than the limit

· BSV 180 ml/hr (3 cc/min) Replace the BSV (Ref. AMM TAS

(60 drops/min). Up to 90 drops/ K 73-11-70-000-801) and (Ref. AM

min permitted for 5 cycles M TASK 73-11-70-400-801) if more

than the limit

· Variable Stator Vane (VSV) 180 ml/hr (3 cc/min) Replace the VSV actuator (Ref. AM

actuator (60 drops/min). Up to 90 drops/ M TASK 75-32-10-000-801) and (R

min permitted for 5 cycles ef. AMM TASK 75-32-10-400-801) if

more than the limit

Fuel distribution block 180 ml/hr (3 cc/min) Replace fuel distribution seals

(60 drops/min). Up to 90 drops/ (Ref. AMM TASK 73-11-31-960-801) .

min permitted for 5 cycles

NOTE: The VBV fuel gear motor, fuel distribution block, VSV actuators and the HPTACC, LPTACC, RAC-

SB, BSV valves have the same fuel drain tube at the drain mast manifold (drain No.9). If you

are not sure about the fuel leakage volumes from each of these equipment, it may be necessary

to isolate their related drain line to troubleshoot the source of the out-of-limit leak at drain No.9

(Ref. AMM TASK 71-00-00-790-805) .

· Aft pylon drain (drain tube No fuel leaks permitted Water only permitted from condensa-

No.11) tion

· Forward pylon (drain tube No fuel leaks permitted Water only permitted from condensa-

No.12) tion

End of document

Print Date: August 17, 2016 Page 7 of 7

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

You might also like

- Honeywell King Bendix RDR 2000 Radar Installation ManualDocument7 pagesHoneywell King Bendix RDR 2000 Radar Installation ManualRatsimba Andry0% (4)

- Sullair 1600RH Parts ManualDocument178 pagesSullair 1600RH Parts ManualTaj Pink100% (1)

- Cummins Isx QSX Disassembly and Assembly Abby PDFDocument514 pagesCummins Isx QSX Disassembly and Assembly Abby PDFLyn Evans100% (4)

- February 9, 2009 S-B-18.00/40a S-B-18.00/40 Dated October 28, 2008 18Document9 pagesFebruary 9, 2009 S-B-18.00/40a S-B-18.00/40 Dated October 28, 2008 18kevin gradinNo ratings yet

- 71-00-00-710-002-B - Wet Motoring CheckDocument8 pages71-00-00-710-002-B - Wet Motoring CheckEder Luciano100% (2)

- ON A/C 051-100: Zone/Access Zone DescriptionDocument7 pagesON A/C 051-100: Zone/Access Zone DescriptionEder LucianoNo ratings yet

- Airbus A320 Eng Starter SRVDocument8 pagesAirbus A320 Eng Starter SRVPanagiotis Diakidis100% (1)

- Airbus A320 Eng OilDocument13 pagesAirbus A320 Eng OilPanagiotis Diakidis100% (2)

- FRAMO Rbp250 Anti Heeling Pump ManualDocument13 pagesFRAMO Rbp250 Anti Heeling Pump ManualFatma KosovaliNo ratings yet

- M250-C47B O+mmDocument12 pagesM250-C47B O+mmturboshaftNo ratings yet

- Motor GE CJ610-1Document4 pagesMotor GE CJ610-1César Pérez Perrusquía75% (4)

- Air Compressor Intallation PDFDocument6 pagesAir Compressor Intallation PDFvictoverNo ratings yet

- Aircraft Batteries: Battery Replacement InformationDocument1 pageAircraft Batteries: Battery Replacement InformationMuhammad ZuhairizNo ratings yet

- JTP425 HFC Refrigerant Retrofit R134a PDFDocument74 pagesJTP425 HFC Refrigerant Retrofit R134a PDFNick LesterNo ratings yet

- - A318 _ A319 _ A320 _ A321 - AMM - FSN_ 002 - 01-Feb-2024 - 71-00-00-790-002-B - Fuel or Hydraulic or Oil Leakage LimitsDocument8 pages- A318 _ A319 _ A320 _ A321 - AMM - FSN_ 002 - 01-Feb-2024 - 71-00-00-790-002-B - Fuel or Hydraulic or Oil Leakage LimitsABDELBAST SADODHNo ratings yet

- A330 TSM Low Oil PressureDocument4 pagesA330 TSM Low Oil Pressureapplechamps565No ratings yet

- Dry MotorDocument6 pagesDry MotorIvan KryskoNo ratings yet

- A320 NE0 Fuel or Hydraulic or Oil Leakage LimitsDocument19 pagesA320 NE0 Fuel or Hydraulic or Oil Leakage LimitsArjuna SamaranayakeNo ratings yet

- 71-00-00-710-009-B - Vibration Check PDFDocument3 pages71-00-00-710-009-B - Vibration Check PDFEder Luciano100% (1)

- 71-00-00-710-006-B - Minimum Idle CheckDocument6 pages71-00-00-710-006-B - Minimum Idle CheckEder LucianoNo ratings yet

- Minimum Idle CheckDocument6 pagesMinimum Idle Checkomarzaboub1997No ratings yet

- Cranking of CFM 56-5BDocument6 pagesCranking of CFM 56-5BAnish Sinha100% (1)

- Customer: HVN Type: A330 Rev. Date: Oct 01/11 Manual: AMM Selected Effectivity: ALL 71-00-00-860-817-A - Engine Operation Limits and GuidelinesDocument7 pagesCustomer: HVN Type: A330 Rev. Date: Oct 01/11 Manual: AMM Selected Effectivity: ALL 71-00-00-860-817-A - Engine Operation Limits and GuidelinesLê Viết DũngNo ratings yet

- Oil SystemDocument2 pagesOil SystemRaj DaNo ratings yet

- Engine LimitationDocument19 pagesEngine LimitationRatsimba AndryNo ratings yet

- 4Document17 pages4Jai DeepNo ratings yet

- D155E 10.02 (DOWMAX English)Document50 pagesD155E 10.02 (DOWMAX English)Nastase Dan NicusorNo ratings yet

- C47B OmmDocument12 pagesC47B OmmturboshaftNo ratings yet

- A340 Check of the External Leakage of Hydraulic componentsDocument5 pagesA340 Check of the External Leakage of Hydraulic componentsRatsimba AndryNo ratings yet

- 71-00-00-869-001-B - Abnormal Operation and Emergency Procedures PDFDocument10 pages71-00-00-869-001-B - Abnormal Operation and Emergency Procedures PDFEder LucianoNo ratings yet

- RR250 - C40B OmmDocument13 pagesRR250 - C40B OmmturboshaftNo ratings yet

- CFMIAutomatic StartDocument5 pagesCFMIAutomatic StartJaskaran Singh BhatiaNo ratings yet

- Propeller Strike, Motor Do CARAVAN PT6A-114ADocument3 pagesPropeller Strike, Motor Do CARAVAN PT6A-114AVagner OliveiraNo ratings yet

- CcccqqwwwDocument7 pagesCcccqqwwwSyed ZeeshanNo ratings yet

- Comp Carly Scre Refrig 2004Document52 pagesComp Carly Scre Refrig 2004Deco DluxeNo ratings yet

- C47E OMM Inspection ChecksheetsDocument13 pagesC47E OMM Inspection ChecksheetsturboshaftNo ratings yet

- Engine WashingDocument12 pagesEngine Washingomarzaboub1997No ratings yet

- Removal v2500Document32 pagesRemoval v2500Magureanu ValeriuNo ratings yet

- 250 - C28 Series Operation and Maintenance: Rolls - RoyceDocument6 pages250 - C28 Series Operation and Maintenance: Rolls - RoyceturboshaftNo ratings yet

- 71-00-00-710-004-B - Engine Manual StartDocument9 pages71-00-00-710-004-B - Engine Manual StartEder LucianoNo ratings yet

- 71-00-00-710-003-B - Engine Automatic StartsDocument9 pages71-00-00-710-003-B - Engine Automatic StartsRodrigo SouzaNo ratings yet

- CmckcmcmcDocument134 pagesCmckcmcmcSyed ZeeshanNo ratings yet

- On A/C All: Reference DesignationDocument10 pagesOn A/C All: Reference DesignationOsama MagedNo ratings yet

- M250 - C20R Series Operation and MaintenanceDocument8 pagesM250 - C20R Series Operation and MaintenanceturboshaftNo ratings yet

- ON A/C FSN 551-600: Customization Aircraft Types Doctypes Revision Date Title Tail Number - MSN - FSNDocument7 pagesON A/C FSN 551-600: Customization Aircraft Types Doctypes Revision Date Title Tail Number - MSN - FSNEdson CarvalhoNo ratings yet

- 73 20 02 PDFDocument12 pages73 20 02 PDFAnonymous 298xlo3uUNo ratings yet

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 5Document32 pagesRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 5anony8103100% (1)

- Trim TankDocument4 pagesTrim TankEnrique Rodriguez NavaNo ratings yet

- LeaksDocument9 pagesLeaksIvan KryskoNo ratings yet

- 06T Semihermetic Screw CompressorDocument8 pages06T Semihermetic Screw CompressorAbu Malak CiprianoNo ratings yet

- Acceleation CheckDocument5 pagesAcceleation Checkomarzaboub1997No ratings yet

- On A/C All: Reference DesignationDocument10 pagesOn A/C All: Reference DesignationOsama MagedNo ratings yet

- RR250 - C30 OmmDocument16 pagesRR250 - C30 OmmturboshaftNo ratings yet

- Check of The External Leakage of Hydraulic ComponentsDocument6 pagesCheck of The External Leakage of Hydraulic ComponentsmariaNo ratings yet

- TSF 6000 Preflight Night Halt Transit Inspn. - Iss. 5 Rev 4 DT 21 - Sep - 2021Document8 pagesTSF 6000 Preflight Night Halt Transit Inspn. - Iss. 5 Rev 4 DT 21 - Sep - 2021Sonu kumarNo ratings yet

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 7Document12 pagesRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 7anony8103No ratings yet

- Leaks Permitted ValueDocument1 pageLeaks Permitted ValueRatsimba AndryNo ratings yet

- 1986 Landcruiser Maintenance ProceduresDocument40 pages1986 Landcruiser Maintenance ProceduresnapobNo ratings yet

- B17 OMM Inspection ChecksheetsDocument8 pagesB17 OMM Inspection ChecksheetsturboshaftNo ratings yet

- SM Si50-402A CompressorDocument61 pagesSM Si50-402A Compressorttt44967% (3)

- T7 BSI3 V 30Document24 pagesT7 BSI3 V 30ArabyAbdel Hamed SadekNo ratings yet

- Gear Pump IPHDocument13 pagesGear Pump IPHDian PramadiNo ratings yet

- A320 Lake FuelDocument9 pagesA320 Lake FuelCamilo MorenoNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Leaks Permitted ValueDocument1 pageLeaks Permitted ValueRatsimba AndryNo ratings yet

- Engine LimitationDocument19 pagesEngine LimitationRatsimba AndryNo ratings yet

- Circuit Breaker A340Document36 pagesCircuit Breaker A340Ratsimba Andry100% (2)

- Am29F010B: Continuity of SpecificationsDocument34 pagesAm29F010B: Continuity of SpecificationsRatsimba AndryNo ratings yet

- 62te GDDocument4 pages62te GDluiz fernando leal verneNo ratings yet

- v2 - Cars Models Pricelist KHP NA 11 2022Document36 pagesv2 - Cars Models Pricelist KHP NA 11 2022NigelNo ratings yet

- Norriseal Level ControllerDocument4 pagesNorriseal Level ControllerRio WitcandraNo ratings yet

- How It Works. Amazing Technology 18ed 2022Document164 pagesHow It Works. Amazing Technology 18ed 2022litoNo ratings yet

- MTM Tuning A4b5110Document3 pagesMTM Tuning A4b5110Adam GlazikNo ratings yet

- Engines 2G40 EngDocument6 pagesEngines 2G40 EngKenan TiroNo ratings yet

- How To Service Your Colibri C3, C4 Necta Coffee Vending MachineDocument3 pagesHow To Service Your Colibri C3, C4 Necta Coffee Vending MachineDintcherIssoufNo ratings yet

- KIA Obd Ii: Scanner - Diagnostico - CodigosDocument20 pagesKIA Obd Ii: Scanner - Diagnostico - Codigosmarquin84No ratings yet

- Sweeney Active NSN ListDocument2 pagesSweeney Active NSN ListIKMAL HAKIM NABIL IKMALNo ratings yet

- User Manual: SMC-450 Extrusion Kerb Slipforming MachineDocument14 pagesUser Manual: SMC-450 Extrusion Kerb Slipforming Machineshan ooiNo ratings yet

- Aerospatiale A350Document8 pagesAerospatiale A350Bruno Alonso PachecoNo ratings yet

- Yamaha Yz250 03Document59 pagesYamaha Yz250 03DenissonPagliaNo ratings yet

- DAF Truck en b4511Document119 pagesDAF Truck en b4511Ashraf MostafaNo ratings yet

- Recall Rover R2Document4 pagesRecall Rover R2Ingeniero SanchezNo ratings yet

- th350 04Document8 pagesth350 04AndreyNo ratings yet

- 466.01 821837931001 821837939999 Protection RoofDocument10 pages466.01 821837931001 821837939999 Protection Roofeshopmanual EnamNo ratings yet

- Kia Sorento TSB About Malfuction SwitchDocument5 pagesKia Sorento TSB About Malfuction Switchjohndere2090No ratings yet

- McmcatalogDocument30 pagesMcmcatalogmalekNo ratings yet

- PE-S-088 - Vibratory Motor Weight SummaryDocument2 pagesPE-S-088 - Vibratory Motor Weight SummaryVictor Barrios RiosNo ratings yet

- PT Tech HPTO12 2010 - EuropeNumberRemovedDocument2 pagesPT Tech HPTO12 2010 - EuropeNumberRemovedudiNo ratings yet

- TRATORDocument59 pagesTRATORNathan Crestani100% (1)

- John Deere EngineDocument368 pagesJohn Deere EngineAlexander López VillavicencioNo ratings yet

- Motores Tier III ENG-1030-08Document2 pagesMotores Tier III ENG-1030-08Julio Guerrero ValenciaNo ratings yet

- Harley-Davidson P&a 2020 en WebOptimisedDocument103 pagesHarley-Davidson P&a 2020 en WebOptimisedAmanNo ratings yet

- FR 9040Document61 pagesFR 9040Rulax Mtz0% (1)

- 14H Motor Grader ASE00001-) - Document StructureDocument3 pages14H Motor Grader ASE00001-) - Document StructureAHMED2ALINo ratings yet

- L90HDocument44 pagesL90HMaryamNo ratings yet