Professional Documents

Culture Documents

P1484 Mazda protege 5 2003

P1484 Mazda protege 5 2003

Uploaded by

nsocoylCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P1484 Mazda protege 5 2003

P1484 Mazda protege 5 2003

Uploaded by

nsocoylCopyright:

Available Formats

2003 Mazda Protege5

2003 ENGINE PERFORMANCE Self-Diagnostics - Protege & Protege5

If PCM does not receive input signal from KS for 5 seconds, PCM determines that KS circuit is

malfunctioning. This is a Continuous Monitor (CM). MIL illuminates if PCM detects malfunction condition

during first drive cycle. Pending code is not available. Freeze Frame Data is available and DTC is stored in

PCM memory.

DTC P1487: EGR BOOST SENSOR SOLENOID VALVE CIRCUIT MALFUNCTION

Detection Condition

DTC is set when PCM detects input voltage from EGR boost sensor solenoid valve is too low or too high

just after turning ignition on. This is a diagnostic support DTC, monitored once per ignition key cycle. MIL

is not illuminated when PCM detects malfunction. Freeze frame data is not available. DTC is not stored in

PCM memory.

Possible Causes

EGR boost sensor solenoid valve malfunction.

Open or short circuit between EGR boost sensor solenoid valve and PCM.

Open circuit between EGR boost sensor solenoid valve and main relay.

PCM malfunction.

Diagnostic Procedure

1. Verify Related Repair Information Availability - Turn ignition off. Connect scan tool to DLC-2.

Turn ignition on, engine off. Check service bulletins for repair information related to this DTC. If

repair information is not available, go to next step. If repair information is available, perform

diagnosis and repair as necessary. After repair, go to step 10.

2. Classify Intermittent Concern Or Continuous Concern - Turn ignition off, then on (engine off).

Using scan tool, check for DTCs. See RETRIEVING DIAGNOSTIC TROUBLE CODES under

SELF-DIAGNOSTIC SYSTEM. If DTC P1487 is present, go to next step. If DTC P1487 is not

present, problem is intermittent. See INTERMITTENTS in TROUBLE SHOOTING - NO CODES

article.

3. Classify Open Circuit Or Short To Ground Malfunction - Ensure ignition is on. Disconnect EGR

valve vacuum hose at EGR boost sensor solenoid valve. Connect vacuum pump to EGR boost sensor

solenoid valve and apply vacuum. Wait 5 seconds. If vacuum does not hold, go to next step. If

vacuum holds, go to step 5.

4. Inspect Passage Control Of EGR Boost Sensor Solenoid Valve - Turn ignition off. Disconnect

EGR boost sensor solenoid valve 2-pin harness connector. For component location, see SYSTEM &

COMPONENT TESTING - MAZDA6, MIATA, MPV, PROTEGE & PROTEGE5 article. Apply

vacuum to EGR boost sensor solenoid valve. Wait 5 seconds. If vacuum does not hold, replace EGR

boost sensor solenoid valve. After repair, go to step 10. If vacuum holds, repair short circuit to ground

in Gray/Red wire between EGR boost sensor solenoid valve harness connector terminal "B" and PCM

104-pin harness connector terminal No. 98. See appropriate WIRING DIAGRAM under ENGINE

PERFORMANCE in SYSTEM WIRING DIAGRAMS. After repair, go to step 10.

5. Inspect EGR Boost Sensor Solenoid Valve Connector For Poor Connection - Disconnect EGR

boost sensor solenoid valve harness connector. Check for poor connection due to damaged, pulled-out

terminals, corrosion, etc. If no problem is found, go to next step. If any problem is found, repair as

necessary. After repair, go to step 10.

6. Inspect EGR Boost Sensor Solenoid Valve - Measure resistance between EGR boost sensor

solenoid valve terminals. If resistance reading is 22-26 ohms, go to next step. If resistance reading is

jueves, 02 de julio de 2020 20:27:09

20:27:05 Page 1 © 2011 Mitchell Repair Information Company, LLC.

2003 Mazda Protege5

2003 ENGINE PERFORMANCE Self-Diagnostics - Protege & Protege5

not 22-26 ohms, replace EGR boost sensor solenoid valve. After repair, go to step 10.

7. Inspect EGR Boost Sensor Solenoid Valve Power Supply Circuit For Open Circuit - Turn

ignition on, engine off. Measure voltage between ground and EGR boost sensor solenoid valve

harness connector terminal "A" (White/Red wire). If battery voltage is present, go to next step. If

battery voltage is not present, repair open circuit in White/Red wire between EGR boost sensor

solenoid valve harness connector terminal "A" and main relay 4-pin harness connector terminal "D".

See appropriate WIRING DIAGRAM under ENGINE PERFORMANCE in SYSTEM WIRING

DIAGRAMS. After repair, go to step 10.

8. Inspect PCM Connector For Poor Connection - Turn ignition off. Disconnect PCM 104-pin

harness connector. Check for poor connection due to damaged, pulled-out terminals, corrosion, etc. If

any problem is found, repair as necessary. After repair, go to step 10. If no problem is found, go to

next step.

9. Inspect EGR Boost Sensor Solenoid Valve Control Circuit - Connect 104-pin Breakout Box (49-

UN01-130) to PCM harness connector only. See Fig. 7. Turn ignition on, engine off. Measure voltage

between ground and EGR boost sensor solenoid valve harness connector terminal "B" (Gray/Red

wire). If battery voltage is present, repair short circuit to power in Gray/Red wire between EGR boost

sensor solenoid valve harness connector terminal "B" and PCM 104-pin harness connector terminal

No. 98. See Fig. 9. After repair, go to next step. If no voltage is present, check continuity of circuit

between EGR boost sensor solenoid valve harness connector terminal "B" (Gray/Red wire) and

breakout box terminal No. 98.

If continuity is present, go to next step.

If continuity is not present, repair open circuit in Gray/Red wire between EGR boost sensor

solenoid valve harness connector terminal "B" and PCM 104-pin harness connector terminal

No. 98. After repair, go to next step.

10. Verify Trouble Shooting Of DTC P1487 Completed - Reconnect all connectors. Turn ignition off

and then on. Check for DTCs. See RETRIEVING DIAGNOSTIC TROUBLE CODES under

SELF-DIAGNOSTIC SYSTEM. If DTC P1487 is present, replace PCM. For PCM removal and

installation, see POWERTRAIN CONTROL MODULE under COMPUTERIZED ENGINE

CONTROLS in REMOVAL, OVERHAUL & INSTALLATION article. After repair, go to next step.

If same DTC P1487 is not present, go to next step.

11. Verify After Repair Procedure - Using scan tool, perform After Repair Procedure. See AFTER

REPAIR PROCEDURE. If no other DTCs are present, testing is complete. If any other DTC is

present, follow appropriate DTC diagnostic procedure. See DIAGNOSTIC TROUBLE CODE

DEFINITIONS.

jueves, 02 de julio de 2020 20:27:05 Page 2 © 2011 Mitchell Repair Information Company, LLC.

You might also like

- 3406-40 Pin - ECM Diagramas PDFDocument2 pages3406-40 Pin - ECM Diagramas PDFDavid Fuentes79% (29)

- Volvo - S60 - Workshop Manual - 2000 - 2003Document3,231 pagesVolvo - S60 - Workshop Manual - 2000 - 2003James StaffNo ratings yet

- HD465-7 Shop Manual PDFDocument1,183 pagesHD465-7 Shop Manual PDFQuy Le Thanh100% (1)

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P0406Document5 pagesA L L Diagnostic Trouble Codes (DTC) : P Code Charts P0406801400No ratings yet

- Caterpillar ADEM II 3176C 3406E C10 C12 Completo PDFDocument2 pagesCaterpillar ADEM II 3176C 3406E C10 C12 Completo PDFOmar Garcia Cazares100% (3)

- Bentley Audi A6 C5 IgnitionDocument82 pagesBentley Audi A6 C5 Ignitiontjonkka100% (3)

- P1128-Closed Loop Fueling Not Achieved - Bank 1 - WH, XH, Ka, KK - 2007-2010Document9 pagesP1128-Closed Loop Fueling Not Achieved - Bank 1 - WH, XH, Ka, KK - 2007-2010Karl Heinz KerzenschuhNo ratings yet

- PEEC Electronic System Functional TestsDocument66 pagesPEEC Electronic System Functional TestsRichard Chua0% (1)

- 1991 Ford Festiva ManualDocument548 pages1991 Ford Festiva ManualMarivic Diaz0% (1)

- P0106 Mazda protege 5 2003Document3 pagesP0106 Mazda protege 5 2003nsocoylNo ratings yet

- DTC P0123 Caravan-97Document2 pagesDTC P0123 Caravan-97ORLANDONo ratings yet

- Description & Operation: WarningDocument6 pagesDescription & Operation: WarningTheJomVz PrNo ratings yet

- Service Manual ExtractDocument6 pagesService Manual ExtractNovica ŽivanovićNo ratings yet

- G - Tests W/Codes - 1.6L & 2.0L Article TextDocument25 pagesG - Tests W/Codes - 1.6L & 2.0L Article TextKoeswara SofyanNo ratings yet

- 2000 Buick Regal Prueba de Sistema y ComponentesDocument158 pages2000 Buick Regal Prueba de Sistema y ComponentesRubenNo ratings yet

- 12 VW Tiguan 09 Multiples DTCDocument63 pages12 VW Tiguan 09 Multiples DTCJose Huesca100% (1)

- P1259 VTEC MalfunctionDocument2 pagesP1259 VTEC Malfunctionmr_excelencia100% (1)

- Troubel Shoting Piston PumpDocument7 pagesTroubel Shoting Piston PumpAmir Bambang YudhoyonoNo ratings yet

- Diagnostic AidsDocument4 pagesDiagnostic AidsTony HerediaNo ratings yet

- Engine Pressure Sensor Open or Short Circuit - TestDocument10 pagesEngine Pressure Sensor Open or Short Circuit - TestGustavo GarzaNo ratings yet

- Altenator PDFDocument26 pagesAltenator PDFluisNo ratings yet

- Circuit DescriptionDocument2 pagesCircuit DescriptionJorge RaulNo ratings yet

- 5 Volt Engine Pressure Sensor Supply Circuit - TestDocument8 pages5 Volt Engine Pressure Sensor Supply Circuit - TestGustavo GarzaNo ratings yet

- Data-Tech 1995 Nissan Pickup - Motor Sistema Controles - 3.0L Pruebas BasicasDocument5 pagesData-Tech 1995 Nissan Pickup - Motor Sistema Controles - 3.0L Pruebas BasicasRubenNo ratings yet

- No Crank Reference Signal at PCMDocument7 pagesNo Crank Reference Signal at PCMAO5616No ratings yet

- On-Board Diagnostic (Immobilizer System)Document5 pagesOn-Board Diagnostic (Immobilizer System)pavel35No ratings yet

- P000b-Bank 1 Camshaft 2 Position Slow ResponseDocument7 pagesP000b-Bank 1 Camshaft 2 Position Slow Responseflash_24014910No ratings yet

- ТЕСТ ТОПЛИВОDocument14 pagesТЕСТ ТОПЛИВОАндрей ДубовецNo ratings yet

- Pajero Full 2008 13Document1,059 pagesPajero Full 2008 13Antonio GasparNo ratings yet

- C13, C15, and C18 Engines ARD Fuel Pressure Is LowDocument11 pagesC13, C15, and C18 Engines ARD Fuel Pressure Is LowRaphael Thorner80% (5)

- Prueba Sensores PM1360Document7 pagesPrueba Sensores PM1360miguel oswaldo gonzalez benitezNo ratings yet

- Rap System TestsDocument16 pagesRap System TestsBrad FrancNo ratings yet

- Mazda 626esDocument32 pagesMazda 626esRicardo AlbertoNo ratings yet

- Fuel Shutoff - TestDocument7 pagesFuel Shutoff - TestAdolfo Dario SaavedraNo ratings yet

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P0230Document2 pagesA L L Diagnostic Trouble Codes (DTC) : P Code Charts P0230Jose GarciaNo ratings yet

- Cid 2930 (Mid082)Document5 pagesCid 2930 (Mid082)Moch SuyonoNo ratings yet

- RAPTORDocument16 pagesRAPTORp.motortechNo ratings yet

- P020E-Fuel Injector 5 Performance: Theory of OperationDocument2 pagesP020E-Fuel Injector 5 Performance: Theory of OperationWillie AustineNo ratings yet

- Cart A Delco Dig Op 0740Document2 pagesCart A Delco Dig Op 0740josepadilla1987No ratings yet

- Fuel Metering Valve - Test - TecJet Valve PDFDocument6 pagesFuel Metering Valve - Test - TecJet Valve PDFwagner_guimarães_1No ratings yet

- Diagnosis ABS Windstar 1995Document3 pagesDiagnosis ABS Windstar 1995huicholeNo ratings yet

- AUTOMATIC TRANSMISSION 6T70 (M7W) - DIAGNOSTIC INFORMATION AND PROCEDURES-unlockedDocument187 pagesAUTOMATIC TRANSMISSION 6T70 (M7W) - DIAGNOSTIC INFORMATION AND PROCEDURES-unlockedMarco MeloncelliNo ratings yet

- Fuel Supply SystemDocument56 pagesFuel Supply Systemmkisa70No ratings yet

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P0031Document10 pagesA L L Diagnostic Trouble Codes (DTC) : P Code Charts P0031Elmer PerezNo ratings yet

- DTC P055B-P055D: Applies ToDocument5 pagesDTC P055B-P055D: Applies ToWillie AustineNo ratings yet

- Illustration 1 g02025271 Radiator Fan Speed Sensor Circuit SchematicDocument3 pagesIllustration 1 g02025271 Radiator Fan Speed Sensor Circuit SchematicLewis OlivoNo ratings yet

- 6.0 Late 2004 Hardstart - Nostart - DiagnosticsDocument1 page6.0 Late 2004 Hardstart - Nostart - DiagnosticsvixentdNo ratings yet

- 296-9 Cat CodeDocument5 pages296-9 Cat CodesuelifashNo ratings yet

- P020C-Fuel Injector 3 Performance: Theory of OperationDocument2 pagesP020C-Fuel Injector 3 Performance: Theory of OperationWillie AustineNo ratings yet

- Electronic Automotive Transmission Troubleshooter Nissan-Infinity VehiclesFrom EverandElectronic Automotive Transmission Troubleshooter Nissan-Infinity VehiclesNo ratings yet

- Electronic Automotive Transmission Troubleshooter Toyota & Lexus VehiclesFrom EverandElectronic Automotive Transmission Troubleshooter Toyota & Lexus VehiclesNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Automotive Electronic Diagnostics (Course 2)From EverandAutomotive Electronic Diagnostics (Course 2)Rating: 4 out of 5 stars4/5 (2)

- Automotive Actuators and EVAP System TestingFrom EverandAutomotive Actuators and EVAP System TestingRating: 4.5 out of 5 stars4.5/5 (4)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- HPM M66uaDocument78 pagesHPM M66uallopez100% (3)

- Automatic Hand Sanitizer Using IRDocument6 pagesAutomatic Hand Sanitizer Using IRsmartxdigital marketNo ratings yet

- MEMO - Equipment SCCRDocument4 pagesMEMO - Equipment SCCRBen SyNo ratings yet

- (V8106) DataSheet EN 160316 V1.1 PDFDocument27 pages(V8106) DataSheet EN 160316 V1.1 PDFnmc79No ratings yet

- Batt Cables NYYDocument1 pageBatt Cables NYYeplan drawingsNo ratings yet

- MEP EngineeringDocument4 pagesMEP EngineeringsalmanNo ratings yet

- Instruction Manual: HatsanDocument8 pagesInstruction Manual: HatsanAlejandro Patricio Cornejo NaranjoNo ratings yet

- NE40E-X3&X3A Quick Installation GuideDocument1 pageNE40E-X3&X3A Quick Installation GuideJeffreySulitNo ratings yet

- Ds-Wss 30 Leaflet eDocument4 pagesDs-Wss 30 Leaflet eHessam RejaliNo ratings yet

- Product Sheet - RGB LED ControllerDocument2 pagesProduct Sheet - RGB LED ControllerBynzNo ratings yet

- 380V Electrical Drawing PDFDocument34 pages380V Electrical Drawing PDFMujianaNo ratings yet

- Electrical: RC 5500 Calibration Menus Training ModuleDocument15 pagesElectrical: RC 5500 Calibration Menus Training ModuleGustavo Gamez100% (1)

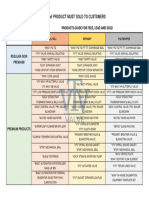

- List of Product Must Sold To Customers: Products Guide For Feed, Lead and SoldDocument1 pageList of Product Must Sold To Customers: Products Guide For Feed, Lead and SoldFendy ShirahNo ratings yet

- (PaperzoneVN - Com) - Paper Plane - by - AssembliDocument9 pages(PaperzoneVN - Com) - Paper Plane - by - AssembliBenedict CleonNo ratings yet

- Optic Fiber Cable-UnArmouredDocument2 pagesOptic Fiber Cable-UnArmouredAnonymous yugocxnNo ratings yet

- PH WR WattsRadiant Catalog FullLine 03 RadiantPEXAL-En-20100519Document6 pagesPH WR WattsRadiant Catalog FullLine 03 RadiantPEXAL-En-20100519sas999333No ratings yet

- MODEM AssDocument8 pagesMODEM AssMagesh KumarNo ratings yet

- BTA-131 Stereo Headset Adapte: User ManualDocument1 pageBTA-131 Stereo Headset Adapte: User ManualHervé RousselNo ratings yet

- Diagrama Relee SeguridadDocument8 pagesDiagrama Relee SeguridadrayplerNo ratings yet

- Quick Start Guide: LR1100U and LR1100EDocument2 pagesQuick Start Guide: LR1100U and LR1100EdauvinNo ratings yet

- ENG Donovan Brochure DIBv4201510Document4 pagesENG Donovan Brochure DIBv4201510Rajiv GandhiNo ratings yet

- 1.1 Hardware and SoftwareDocument22 pages1.1 Hardware and Softwareyasin mujjuziNo ratings yet

- Demand Ventilation For KitchensDocument5 pagesDemand Ventilation For KitchensOscar Barón GaonaNo ratings yet

- Solenoid Coils For Proportional Valves (Solenoid Operated) Types 40-1836 50-1836Document2 pagesSolenoid Coils For Proportional Valves (Solenoid Operated) Types 40-1836 50-1836Dew บุรุษสุดตีนNo ratings yet

- LC1D25M7: Product Data SheetDocument4 pagesLC1D25M7: Product Data SheetMathías Huillca CameronNo ratings yet

- Functions: Digital Camera Finepix S3000Document3 pagesFunctions: Digital Camera Finepix S3000Andi GeraNo ratings yet

- Annex 3 AphDocument2 pagesAnnex 3 AphJoydev GangulyNo ratings yet

- Guide Specifications: ZTS SeriesDocument6 pagesGuide Specifications: ZTS SeriesmikeNo ratings yet

- Eqpt List-3VLDocument2 pagesEqpt List-3VLsparkCENo ratings yet