Professional Documents

Culture Documents

Roofing & Reroofing

Roofing & Reroofing

Uploaded by

Lai Kok UeiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Roofing & Reroofing

Roofing & Reroofing

Uploaded by

Lai Kok UeiCopyright:

Available Formats

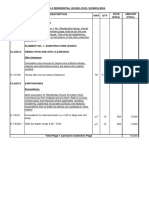

ROOFING & RE-ROOFING SOR 1

SCHEDULE OF RATES

ROOFING & RE-ROOFING

S/N DESCRIPTION UNIT RATE ($)

1 Supply and fix BRC 3315 welded fabric reinforcement to support m2 2.80

sisalation paper of roof.

Supply and fix wood wool slab to underside of roof.

2 25mm thick m2 23.40

3 50mm thick m2 32.40

Supply and lay the following ferrocement secondary roof slabs,

reinforced with galvanised fine mesh to reinforced concrete flat roof

including all necessary supporting concrete solid blocks, labour and

materials for sealing up pipes, etc.

4 900 x 600 x 20mm thick m2 33.90

5 600 x 600 x 30mm thick. m2 21.13

6 Supply and lay 3mm thick acrylic polymer modified cementitious m2 11.50

coating to roof surfaces and gutter.

7 Apply a complete Waterproofing Membrane System to reinforced m2 8.50

concrete flat roof consisting of 6 coats of waterproofing membranes, 1

layer of open woven glass membrane and 1 coat of bituminous

aluminium finishing paint; complying with SS133:19 and its latest

amendments and in accordance with the manufacturer's instructions

8 Apply a complete Panel Roofing System to roof surfaces consisting of m2 38.90

38mm thick waterproofing cement and sand panel (1:3), 50mm thick

Styrofoam insulation board or other approved equivalent and 6 coats of

waterproofing membranes, 1 layer of open woven glass membrane and

a minimum of 20mm thick waterproofing cement and sand screed (1:3)

laid to fall and including all necessary labour and materials for jointing

.

9 Supply and fix 22G galvanised steel flashing not exceeding 400mm m 5.30

girth.

CD11/SOR-Building, Sanitary & Plumbing/Roofing & Re-roofing/(1)/[2009 Edition]

ROOFING & RE-ROOFING SOR 2

SCHEDULE OF RATES

ROOFING & RE-ROOFING

S/N DESCRIPTION UNIT RATE ($)

10 Supply and install 0.6mm thick hot dipped galvanised steel Scantile m2 43.10

metal roofing coated with PVF2 Kynar 500 including all necessary

fixing accessories and in accordance with manufacturer's instructions.

11 Supply and install ridge/hip tile to Scantile metal roofing including all m 27.70

ridge/hip end capping piece and all necessary fixing accessories.

12 Supply and install 0.53mm thick Speed Deck Hi-Ten colorbond metal m2 32.90

roofing including all necessary fixing accessories.

13 Supply and install colorbond ridge capping (type A) to Speed Deck Hi- m 21.30

Ten roofing including all necessary fixing accessories.

14 Supply and install 0.47mm thick colorbond XRW Spandek Hi-Ten m2 32.40

metal roofing sheets including all necessary fixing accessories.

15 Supply and install 0.47mm thick colorbond XRW Trimdek Hi-Ten m2 28.50

metal roofing sheets including all necessary fixing accessories.

16 Supply and install 0.53mm thick colorbond XRW Kliplok Hi-Ten m2 37.90

metal roofing sheets including all necessary fixing accessories.

17 Supply and install 0.65mm thick colorbond XRW Kliplok Hi-Ten m2 43.25

metal roofing sheets including all necessary fixing accessories.

18 Supply and install 0.47mm thick colorbond XRW V-Crimp Hi-Ten m2 29.30

metal roofing sheets including all necessary fixing accessories.

19 Supply and install 0.60mm thick colorbond XRW standard ridge m 12.00

capping to Kliplok roofing including all necessary fixing accessories.

Supply and install 0.60mm thick custom made colorbond XRW

flashings/cappings/trims to Kliplok/ Spandek/V-Crimp roofing

including all necessary fixing accessories.

20 Not exceeding 100mm m 7.40

CD11/SOR-Building, Sanitary & Plumbing/Roofing & Re-roofing/(2)/[2009 Edition]

ROOFING & RE-ROOFING SOR 3

SCHEDULE OF RATES

ROOFING & RE-ROOFING

S/N DESCRIPTION UNIT RATE ($)

Supply and install 0.60mm thick custom made colorbond XRW

flashings/cappings/trims to Kliplok/ Spandek/V-Crimp roofing

including all necessary fixing accessories. Cont’d

21 Exceeding 100mm but not exceeding 200mm m 9.15

22 Exceeding 200mm but not exceeding 300mm m 12.35

23 Exceeding 300mm but not exceeding 400mm m 15.35

24 Exceeding 400mm but not exceeding 500mm girth m 18.00

25 Exceeding 500mm but not exceeding 600mm girth m 21.60

26 Exceeding 600mm but not exceeding 700mm girth m 26.75

27 Supply and lay one layer of 'Parsec Thermo-brite II' double sided m2 8.20

reflective roof heat insulation sheet including lapping with 'Parsec

Thermo-brite' tape and secured to roof structure by self-drilling

fasteners complete with metal washers and in accordance with

manufacturer's instructions.

28 Supply and lay one layer of 'Super Sisalation' double sided reflective m2 5.90

roof heat insulation sheet including lapping with PPC 493 reinforced

aluminium foil tape and secured to roof structure by self-drilling

fasteners complete with metal washers and in accordance with the

Manufacturer’s instructions.

29 Supply and lay one layer of 'Super Brite' double sided reflective roof m2 5.80

heat insulation sheet including lapping and secured to roof structure by

self-drilling fasteners complete with metal washers and in accordance

with manufacturer's instructions.

30 Supply and lay "Heisterholz K 21" semi-glazed shale clay roofing tiles m2 71.40

laid on and including 50 x 25mm timber batterns with 125mm head

laps and 52mm side laps including all necessary fixing accessories.

31 Extra Over "Heisterholz K 21" semi-glazed shale clay roofing tiles for m 38.60

Right/Left verge tiles.

32 Extra Over "Heisterholz K 21" semi-glazed shale clay roofing tiles for m 12.30

Boarding Plate tiles.

33 Supply and lay "Heisterholz K 21" semi-glazed shale clay roofing m 58.10

Ridge/Hip tiles including cement mortar (1:3) packing.

CD11/SOR-Building, Sanitary & Plumbing/Roofing & Re-roofing/(3)/[2009 Edition]

ROOFING & RE-ROOFING SOR 4

SCHEDULE OF RATES

ROOFING & RE-ROOFING

S/N DESCRIPTION UNIT RATE ($)

34 Extra Over "Heisterholz K 21" semi-glazed shale clay roofing no 47.90

Ridge/Hip tiles for Ridge Start/End tile including cement Mortar (1:3)

packing.

35 Supply and lay "Ergoldsbacher" plain unglazed coloured roof tiles m2 119.50

(straight cut with rounded corners) in double tiling pattern laid on and

including 50 x 25mm timber battens complete with all necessary fixing

accessories.

36 Supply and lay "Ergoldsbacher" plain unglazed coloured roof ridge m 63.10

tiles no. 16 including cement mortar (1:3) packing.

37 Extra Over "Ergoldsbacher" plain unglazed coloured roof ridge tiles no 9.60

no. 16 for Ridge Start/End tile including cement mortar (1:3) packing.

38 Extra Over "Ergoldsbacher" plain unglazed coloured roof mortar (1:3) no 225.00

packing.

RE-ROOFING

39 Removal of existing waterproofing bituminous membrane to m2 1.95

reinforced concrete flat roof including all necessary machinery for

hoisting, transportation and disposal off site.

40 Removal of existing precast concrete secondary roof slabs and m2 3.00

supports to reinforced concrete flat roof including all necessary

machinery for hoisting, transportation and disposal off site.

41 Hacking existing concrete surface to form keys, remove debris from m2 1.40

site, wash and clean surfaces to receive new finishing.

42 Apply 1 coat of approved bonding agent to existing reinforced m2 1.70

concrete roof slab.

43 20mm thick cement and sand (1:3) screed rendering to reinforced m2 8.90

concrete roof slab trowelled to a smooth finish.

44 Add to (or deduct from) Item 5 for each 5mm thickness over (or under) m2 1.50

20mm.

45 20mm thick cement and sand (1:3) screed rendering to skirtings, curbs m 3.90

and returns etc and trowelled to a smooth finish including coved and

rounded angles for 0 - 150mm girth.

CD11/SOR-Building, Sanitary & Plumbing/Roofing & Re-roofing/(4)/[2009 Edition]

ROOFING & RE-ROOFING SOR 5

SCHEDULE OF RATES

ROOFING & RE-ROOFING

S/N DESCRIPTION UNIT RATE ($)

46 20mm thick cement and sand (1:3) screed rendering to skirtings, curbs m 5.90

and returns etc and trowelled to a smooth finish including coved and

rounded angles for 151 - 300mm girth.

47 Add to (or deduct from) Item 7 for each 5mm thickness over (or under) m 1.00

20mm for 0 - 150mm girth.

48 Add to (or deduct from) Item 8 for each 5mm thickness over (or under) m 1.40

20mm for 151 - 300mm girth.

49 Extra over for approved waterproofing compound incorporated in the m2 2.60

cement and sand screed rendering for 20mm thickness.

50 Extra over for approved waterproofing compound incorporated in the m2 1.00

cement and sand screed rendering for each 5mm thickness.

51 Removal of existing cement and sand screed rendering, average 25mm m2 2.60

thick, to reinforced concrete flat roof including all necessary

machinery for hoisting, transportation and disposal off site.

52 Add to (or deduct from) Item 13 for each 5mm thickness over (or m2 0.35

under) 25mm.

53 Supply and fix 0.80mm thick x 150mm girth (twice-bent to edge) m 13.90

aluminium expansion joint cover with “V” shaped groove in the centre

including fixing with stainless steel screws and washers at 150mm c/c.

54 Supply and lay 600 x 600 x 30mm thick ferrocement secondary roof m2 28.45

slabs, reinforced with galvanised welded fabric to reinforced concrete

flat roof including all necessary supporting concrete solid blocks,

labour and materials for jointing.

55 Apply a complete Waterproofing Membrane System to reinforced m2 7.80

concrete flat roof consisting of 6 coats of waterproofing membranes,

complying with SS133:1987 and its latest amendments, 1 layer of open

woven glassfibre membrane and 1 coat of bituminous aluminium

finishing paint and in accordance with the manufacturer’s instructions.

56 Apply a complete Panel Roofing System to roof surfaces consisting of m2 42.00

38mm thick waterproofing cement and sand panel (1:3), 50mm thick

Styrofoam insulation board or other approved, and 6 coats of

waterproofing membranes, 1 layer of open woven glass membrane and

a minimum of 20mm thick waterproofing cement and sand screed (1:3)

laid to fall and including all necessary labour and materials for jointing

(measured flat on plan).

CD11/SOR-Building, Sanitary & Plumbing/Roofing & Re-roofing/(5)/[2009 Edition]

ROOFING & RE-ROOFING SOR 6

SCHEDULE OF RATES

ROOFING & RE-ROOFING

S/N DESCRIPTION UNIT RATE ($)

57 Removal and disposal of existing panel roofing including cement/sand m2 6.15

base screed to reinforced concrete flat roof, including all necessary

machinery for hoisting, transportation and disposal off site.

58 Provide and construct hot-dipped galvanised steel angle end thrust no 40.55

support for existing pipe and complete with cast-in-situ concrete

supports to reinforced concrete flat roof including all necessary fixing

and bolting.

59 Supply and lay 50mm thick rigid extruded polystyrene foam insulation m2 13.95

board of density min. 32 kg/m3 to roof surface.

Repair Seepage and Leaks

Supply labour and materials to rake out mortar joints to an even depth

of 25mm. Brush out all loose sand and mortar and fill the groove solid

to form a continuous sealant:-

60 With approved polyurethane sealant m 9.70

61 With approved polysulphide sealant m 10.50

62 Extra over item for filling groove / expansion joints solid with and m 1.50

approved backing rod

63 Supply labour and materials to rake out mortar joints at the interface to m 4.70

a depth of 25mm. Brush out loose sand and mortar and fill the groove

with polymer modified mortar.

64 Supply labour and materials to form spray/fillet with approved m 5.70

polymer modified cement mortar or non-shrink grout to the correct

gradient including hacking if necessary

65 Supply labour and materials to rack out mortar joints between bricks m2 13.60

and repointing with polymer modified cement mortar (based on area of

brick wall)

66 Apply 2 coats of clear elastomeric waterproof membrane including m2 6.40

patching hairline cracks on brick wall with brick colour cement if

necessary

67 Apply 2 coats of approved silane/siloxane based water penetrant m2 9.20

including patching hairline cracks on brick wall with brick colour

cement if necessary

CD11/SOR-Building, Sanitary & Plumbing/Roofing & Re-roofing/(6)/[2009 Edition]

ROOFING & RE-ROOFING SOR 7

SCHEDULE OF RATES

ROOFING & RE-ROOFING

S/N DESCRIPTION UNIT RATE ($)

68 Supply labour and materials to repair the plastered wall panels by m2 18.70

applying two coats of approved proprietary plaster such as Ventonite,

Esai-Plaster and Ready-Cote etc, including hacking, painting to the

repaired surface

69 Repair to cracks by hacking “U” groove on the cracks to 25mm width m 7.30

x 20mm depth. Brush out all loose sand and motor and fill the groove

with polymer modified mortar including painting to the repaired

surface.

Repair to cracks by hacking “V” groove on the cracks and patch

including painting to the repaired surface:-

70 With approved polyurethane sealant m 14.70

71 With approved polysulphide sealant m 18.10

72 Supply labour and material to repair the hollow and bulging plaster m2 27.20

with polymer modified mortar and skimming proprietary material

including hacking and painting to the repaired surface

73 Installation of special wall tie to existing brickwall including no 9.10

galvanized mesh sleeve, approved resin, stainless steel wall tie

74 Hack off all existing plastering to walls and prepare surface to receive m2 2.90

new finish including removal of debris

75 Hack existing plastered or concrete wall surface to form random keys, m2 2.10

clean and wash to receive new finish including removal of debris

76 Spatterdash of cement slurry on existing surface to form keys m2 1.00

CD11/SOR-Building, Sanitary & Plumbing/Roofing & Re-roofing/(7)/[2009 Edition]

You might also like

- BOQ Lotus Hotel Final 080709Document26 pagesBOQ Lotus Hotel Final 080709Jane NixonNo ratings yet

- Sor HDB 2021Document137 pagesSor HDB 2021Lai Kok UeiNo ratings yet

- 06C STD Specifications Building 2021Document967 pages06C STD Specifications Building 2021Lai Kok UeiNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Civil & Interior Works Boq - NXP SL - No Description Unit QTY A Civil Work 1.0 Block Work 100Mm THKDocument8 pagesCivil & Interior Works Boq - NXP SL - No Description Unit QTY A Civil Work 1.0 Block Work 100Mm THKShreya BhattacharyaNo ratings yet

- BOQ - Proposed House For Mr. W. M. Chanaka UdayangaDocument8 pagesBOQ - Proposed House For Mr. W. M. Chanaka UdayangaNadun AthukoralaNo ratings yet

- Empty BOQ SampleDocument9 pagesEmpty BOQ SampleCyprian Metobo100% (1)

- 06- ROOFINGDocument6 pages06- ROOFINGLai Kok UeiNo ratings yet

- Microsoft Word - Roofing & Re-RoofingDocument7 pagesMicrosoft Word - Roofing & Re-RoofingkokueiNo ratings yet

- Carpentry & JoineryDocument10 pagesCarpentry & JoineryLai Kok UeiNo ratings yet

- Gupsum Board PDFDocument2 pagesGupsum Board PDFMuhammadYehiaNo ratings yet

- Steel & Iron WorkDocument37 pagesSteel & Iron WorkLai Kok UeiNo ratings yet

- 14- Site Work & MiscellaneousDocument20 pages14- Site Work & MiscellaneousLai Kok UeiNo ratings yet

- Boq FormatDocument79 pagesBoq FormatacroxmassNo ratings yet

- 08- Carpentry & JoineryDocument13 pages08- Carpentry & JoineryLai Kok UeiNo ratings yet

- Boq For All ProjegtDocument18 pagesBoq For All ProjegtØwięs MØhãmmedNo ratings yet

- Attachment #6 1 - Schedule of Quantities FDC 22.09.21Document119 pagesAttachment #6 1 - Schedule of Quantities FDC 22.09.21El Charasquiada CharroNo ratings yet

- Rockwool Building Roll ENGDocument3 pagesRockwool Building Roll ENGAnwar SyedNo ratings yet

- Microsoft Word - CarpentryDocument2 pagesMicrosoft Word - CarpentrykokueiNo ratings yet

- Site Offices and HousingDocument38 pagesSite Offices and HousingMuhammad Al azaweyNo ratings yet

- 09- Steel & Iron WorkDocument49 pages09- Steel & Iron WorkLai Kok UeiNo ratings yet

- Appendix 2 Final BoqDocument50 pagesAppendix 2 Final BoqPatrick SipatelaNo ratings yet

- Bungalow at Putrajaya PDFDocument2 pagesBungalow at Putrajaya PDFShrimp HeadNo ratings yet

- Bill 1 BOQDocument9 pagesBill 1 BOQAaron AriifNo ratings yet

- BQ ModifiedDocument20 pagesBQ ModifiedzulNo ratings yet

- BOQ FOR INTERNAL BEAUTIFICATION WORKS AT ADMINISTRATIVE & HOSTEL BLOCK OF SBILD GUWAHATIDocument2 pagesBOQ FOR INTERNAL BEAUTIFICATION WORKS AT ADMINISTRATIVE & HOSTEL BLOCK OF SBILD GUWAHATIsivaganesh33No ratings yet

- Design No. R705: BXUVC.R705 Fire-Resistance RatingsDocument3 pagesDesign No. R705: BXUVC.R705 Fire-Resistance RatingsSimon BeaudoinNo ratings yet

- ClinicDocument11 pagesClinicPrince Adegoroye Adeniyi DicksonNo ratings yet

- Priced BOQ (DEDZA)Document38 pagesPriced BOQ (DEDZA)Chobwe Stephano KanyinjiNo ratings yet

- Castrol India Ltd. Bill of Quantities For Civil & Interior WorksDocument48 pagesCastrol India Ltd. Bill of Quantities For Civil & Interior WorksSarinNo ratings yet

- Boq For Construction of Waste Management Building &sorting Area S/N ADocument12 pagesBoq For Construction of Waste Management Building &sorting Area S/N Adonnec1No ratings yet

- Item Description Unit QTY Rate Amount Egp. Egp. Division 2: Site Construction EarthworkDocument15 pagesItem Description Unit QTY Rate Amount Egp. Egp. Division 2: Site Construction EarthworkAmr M. AbdallahNo ratings yet

- Pwcic: Carpenter and Joiner Description Unit Rate (RM) Percentage (%) No. Increase/DecreaseDocument3 pagesPwcic: Carpenter and Joiner Description Unit Rate (RM) Percentage (%) No. Increase/DecreasezikirabadiNo ratings yet

- Boq Kitale SMMSDocument18 pagesBoq Kitale SMMSsatejaNo ratings yet

- Standard Details For Metal Roofing & Siding: Post Frame and Residential StructuresDocument48 pagesStandard Details For Metal Roofing & Siding: Post Frame and Residential Structurespierre_oosthuizenNo ratings yet

- BOQ-01 Sabahiya VillaDocument22 pagesBOQ-01 Sabahiya VillaabobeedoNo ratings yet

- Element - 111 - 118-BOQ OKDocument7 pagesElement - 111 - 118-BOQ OKGuts GriffithNo ratings yet

- 2.2.3.1 Buildex® Screw Fasteners: 2.2.3.1.1 Fastener Assembly and DesignationDocument11 pages2.2.3.1 Buildex® Screw Fasteners: 2.2.3.1.1 Fastener Assembly and DesignationJoseph BookerNo ratings yet

- Bill of Quantities Riyadh - An Nakheel General Requirements Item No. Description Unit QTY Unit Price Amount SRDocument34 pagesBill of Quantities Riyadh - An Nakheel General Requirements Item No. Description Unit QTY Unit Price Amount SRmahmoud sayedNo ratings yet

- Bill of Quantities For Rehabilitation & Remodelling Works For City Boys HotelDocument9 pagesBill of Quantities For Rehabilitation & Remodelling Works For City Boys HotelEdward Z MachagatiNo ratings yet

- Interior Furnishing Work of New Circle Office in Bank'S Own Building at Plot No. 4, PSP, Saket Nagar, Near Aiims BhopalDocument37 pagesInterior Furnishing Work of New Circle Office in Bank'S Own Building at Plot No. 4, PSP, Saket Nagar, Near Aiims BhopalSAI ASSOCIATENo ratings yet

- RoofingDocument6 pagesRoofingPrince SinghNo ratings yet

- Scope of Job:-: Attachment To PR 10-2275 Page 1 of 9 Hot Insulation Jobs in Fre Job Scope & Notes To VendorsDocument9 pagesScope of Job:-: Attachment To PR 10-2275 Page 1 of 9 Hot Insulation Jobs in Fre Job Scope & Notes To VendorsraghbirNo ratings yet

- Catalogue of Roof SheetDocument8 pagesCatalogue of Roof Sheetcvsatheeh1No ratings yet

- Boq 01Document7 pagesBoq 01abobeedoNo ratings yet

- 8TH FLRDocument3 pages8TH FLRWaime DewNo ratings yet

- Building Description (PI-17-094)Document2 pagesBuilding Description (PI-17-094)Ali JafferyNo ratings yet

- Proposed Pediatric Hospital Bill of QuantityDocument12 pagesProposed Pediatric Hospital Bill of QuantityKhairoden SangcopanNo ratings yet

- Proposed School-renovation-Kicukiro-BoQs-COMPLETEDocument4 pagesProposed School-renovation-Kicukiro-BoQs-COMPLETEBrighton MUZAHURANo ratings yet

- BEQ2053 - Jordan Soo Mao Soon - Yong Hao Lin - Assignment 02Document61 pagesBEQ2053 - Jordan Soo Mao Soon - Yong Hao Lin - Assignment 02Jordan SooNo ratings yet

- Construction of Theatre in Chulaimbo HospitalDocument18 pagesConstruction of Theatre in Chulaimbo HospitalJoshuaNo ratings yet

- Boq - Fab - For ShedDocument3 pagesBoq - Fab - For ShedMariNo ratings yet

- Dharmagiri - 2 BOQDocument20 pagesDharmagiri - 2 BOQNani JupallyNo ratings yet

- Different Types of RoofingDocument163 pagesDifferent Types of RoofingPrethish KumarNo ratings yet

- SL No Description Unit Quantity Remarks Total Amount Excluding Taxes - Rate (INR) Amount (INR)Document18 pagesSL No Description Unit Quantity Remarks Total Amount Excluding Taxes - Rate (INR) Amount (INR)Chaitanya IdateNo ratings yet

- To Collection $Document2 pagesTo Collection $Koh YhNo ratings yet

- Tawa Ranger Post-Idanha Investiment (6pax)Document9 pagesTawa Ranger Post-Idanha Investiment (6pax)daudmahulu1No ratings yet

- School - Mbowa 2Document75 pagesSchool - Mbowa 2CSEC Uganda Ltd.0% (1)

- Proposed Concrete Water TankDocument9 pagesProposed Concrete Water TankAshiraf sserugoNo ratings yet

- Boq - Fab - For Small ShedDocument2 pagesBoq - Fab - For Small ShedMariNo ratings yet

- Sample BQ TNB Double ChamberDocument14 pagesSample BQ TNB Double ChamberrokiahhassanNo ratings yet

- BoQ 33 - 11 KV SUBSTATION - 01Document13 pagesBoQ 33 - 11 KV SUBSTATION - 01Ricky ChangNo ratings yet

- 19- ReroofingDocument3 pages19- ReroofingLai Kok UeiNo ratings yet

- IronmongeryDocument6 pagesIronmongeryLai Kok UeiNo ratings yet

- 02- EXCAVATIONDocument3 pages02- EXCAVATIONLai Kok UeiNo ratings yet

- 06- ROOFINGDocument6 pages06- ROOFINGLai Kok UeiNo ratings yet

- 20- WiringDocument75 pages20- WiringLai Kok UeiNo ratings yet

- 14- Site Work & MiscellaneousDocument20 pages14- Site Work & MiscellaneousLai Kok UeiNo ratings yet

- 06D MSCPTC Z1 GenSpecs-TC 2016Document39 pages06D MSCPTC Z1 GenSpecs-TC 2016Lai Kok UeiNo ratings yet

- 01- General PreamblesDocument18 pages01- General PreamblesLai Kok UeiNo ratings yet

- 5 - 2 Bca Sor 2020Q4Document27 pages5 - 2 Bca Sor 2020Q4Lai Kok UeiNo ratings yet

- Apr May 2021Document32 pagesApr May 2021Lai Kok UeiNo ratings yet

- Jan Feb 2021Document33 pagesJan Feb 2021Lai Kok UeiNo ratings yet

- 06B STD Specifications CE 2021Document183 pages06B STD Specifications CE 2021Lai Kok UeiNo ratings yet

- Mar 2021Document32 pagesMar 2021Lai Kok UeiNo ratings yet

- Dec 2020Document32 pagesDec 2020Lai Kok UeiNo ratings yet

- Chapter 1 The Singapore Legal System: Constitutional and Legal HistoryDocument20 pagesChapter 1 The Singapore Legal System: Constitutional and Legal HistoryLai Kok UeiNo ratings yet

- Dec 2021Document34 pagesDec 2021Lai Kok UeiNo ratings yet

- Jun Jul 2021Document32 pagesJun Jul 2021Lai Kok UeiNo ratings yet

- Counterfort Retaining WallDocument1 pageCounterfort Retaining WallAjay ThouraniNo ratings yet

- Rme 20971004Document35 pagesRme 20971004Asep ZaenalNo ratings yet

- Building Drawing Midterm ExamDocument6 pagesBuilding Drawing Midterm ExamRahul SinhaNo ratings yet

- Villa - BOQ - Medows With PriceDocument4 pagesVilla - BOQ - Medows With PriceAnthony AgnerNo ratings yet

- Architectural EstimatesDocument12 pagesArchitectural EstimatesNavi GabotNo ratings yet

- Nusantara MosqueDocument17 pagesNusantara MosqueVarsha DasNo ratings yet

- The Archaic Temple of Poseidon at Sounion PDFDocument55 pagesThe Archaic Temple of Poseidon at Sounion PDFLana PetroveckiNo ratings yet

- Stone MasonryDocument15 pagesStone MasonryLaxu KhanalNo ratings yet

- Chapter No. 15 Plastering & Pointing: NotesDocument7 pagesChapter No. 15 Plastering & Pointing: NotesMANJEET SINGHNo ratings yet

- Modern Housing Prototypes: - Roger SherwoodDocument58 pagesModern Housing Prototypes: - Roger SherwoodsamyakNo ratings yet

- Vocabulaire de La Maison en AnglaisDocument2 pagesVocabulaire de La Maison en AnglaisBill Prince NGONONo ratings yet

- CTH Tugasan 2 Working Drawing UKM KKSB3513Document1 pageCTH Tugasan 2 Working Drawing UKM KKSB3513A190680No ratings yet

- ITP-BWDF (Rev 0) - Brickwork & Door FramesDocument2 pagesITP-BWDF (Rev 0) - Brickwork & Door FramesJackNo ratings yet

- Internal Flooring: By: Shruti P.V., Vaishnavi S.S., Tarika B., Simran L., Sonika M., Tejal R.M., Yashika BDocument49 pagesInternal Flooring: By: Shruti P.V., Vaishnavi S.S., Tarika B., Simran L., Sonika M., Tejal R.M., Yashika BVarunNo ratings yet

- Unit 5 Goan HouseDocument42 pagesUnit 5 Goan HouseReghu Ramaswamy100% (3)

- Designer Brick Brochure WEBDocument28 pagesDesigner Brick Brochure WEBdirtapatroNo ratings yet

- S 5 Schedule of Column Beam Wall Footing Detail Wall Footing Details UpdatedDocument1 pageS 5 Schedule of Column Beam Wall Footing Detail Wall Footing Details UpdatedJBFP100% (1)

- Philips PLS 2-Pin Compact Fluorescent Lamps Bulletin 11-97Document2 pagesPhilips PLS 2-Pin Compact Fluorescent Lamps Bulletin 11-97Alan MastersNo ratings yet

- Bill of QuantitiesDocument14 pagesBill of QuantitiesYmon TuallaNo ratings yet

- Adaptation of Bengal ArchitectureDocument2 pagesAdaptation of Bengal ArchitectureShakil AhmedNo ratings yet

- 01 Alternative Methods of Structural ConstructionDocument30 pages01 Alternative Methods of Structural ConstructionJohn GaringNo ratings yet

- Computational Exercise 3 BANTAYANDocument78 pagesComputational Exercise 3 BANTAYANAriel LunaNo ratings yet

- Product Catalog: Lighting The Led Revolution™Document76 pagesProduct Catalog: Lighting The Led Revolution™Fernando MolinaNo ratings yet

- Induction and LED Lighting: An Overview of Interior ApplicationsDocument18 pagesInduction and LED Lighting: An Overview of Interior ApplicationsShantkumar S SambargimathNo ratings yet

- Philippine College of Science and TechnologyDocument4 pagesPhilippine College of Science and TechnologyIvan-Jeff AlcantaraNo ratings yet

- (Hot Elevator)Document13 pages(Hot Elevator)Jayaram VallabhaneniNo ratings yet

- HBL632RT2: Construction Electrical Optics Specification FeaturesDocument2 pagesHBL632RT2: Construction Electrical Optics Specification FeaturesVictor HernandezNo ratings yet

- Royal Quay BrochureDocument8 pagesRoyal Quay Brochureapi-26419872No ratings yet

- Traditional Kerala ArchitectureDocument10 pagesTraditional Kerala Architecturejincy vargheseNo ratings yet

- Illumination AssignmentDocument15 pagesIllumination AssignmentShadowdare VirkNo ratings yet