Professional Documents

Culture Documents

Mechanical Interview Jgc-Kjo Download Free PDF… 4

Mechanical Interview Jgc-Kjo Download Free PDF… 4

Uploaded by

abdul.smd90Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mechanical Interview Jgc-Kjo Download Free PDF… 4

Mechanical Interview Jgc-Kjo Download Free PDF… 4

Uploaded by

abdul.smd90Copyright:

Available Formats

Search

Mechanical Interview

Jgc-Kjo

Uploaded by naveed7861

100% (1) · 536 views · 6 pages

AI-enhanced title and description

Document Information

The document discusses various topics related…

Original Description:

Download now

Mechanical Interview

Download as doc, pdf, or txt

Original Title

Mechanical Interview Jgc-kjo

Copyright MECHANICAL POINTERS

1. What are the API’s used for MECHANICAL EQUIPMENTS?

© © All Rights Reserved

API 610 Centrifugal Pump

API 611 Steam Turbines

API 616 Gas Turbine

Available Formats

API 61! Centrifugal Compressor

API 61" Reciprocang Compressor

DOC, PDF, TXT or read online from Scribd

API 6#0 !el"e" Steel Tan#s

API 660 S$ell an" Tube Heat E%c$anger

API 661 Air Coole" $eat E%c$anger

Share this document

API 66$ Plate an" &rame T'pe Heat E%c$anger

API 6!% Posi(e )isplacement Pump

API 6!# Posi(e )isplacement Pump* Control +olume

API #60 &ire" Heaters

API #10 Pressure +essel

$. What &s SAMSS?

Sau"i Aramco Material S'stem Speci,caon

'. !$at are t$e SAMSS use" for Mec$anical-

Facebook

'1 SAMSS Twitter

(or )ota*+, E-u&/e+ts

./ 0.*SAMSS*11. A2IAL AN) CENTRI&3GAL COMPRESSORS AN) E2PAN)ER

COMPRESSORS

4/ 0.*SAMSS*114 PAC5AGE SCRE! PLANT AN) INSTR3MENT AIR COMPRESSORS

0/ 0.*SAMSS*110 RECIPROCATING COMPRESSORS &OR PROCESS AIR OR GAS SER+ICES

6/ 0.*SAMSS*116 CENTRI&3GAL P3MPS

7/ 0.*SAMSS*118 PAC5AGE)9INTEGRALL:9 GEARE) CENTI&3GAL AIR COMPRESSORS

8/ 0.*SAMSS*11; POSITI+E )ISPLACEMENT P3MPS CONTROL +OL3ME

Email

</ 0.*SAMSS*1.1 S3=MERSI=LE P3MPS AN) MOTORS &OR !ATER !ELL AN)

O&SHORE SER+ICE

>/ 0.*SAMSS*1.4 SHA&T SEALING S:STEMS &OR CENTRIG3GAL AN) ROTAR: P3MPS

'$ SAMSS (or Sta* E-u&/e+ts

./ 04*SAMSS*11. STEAM T3R=INES &OR PO!ER GENERATION

Did you find this document useful?

4/ 04*SAMSS*116 MAN3&ACT3RE O& PRESS3RE +ESSEL

0/ 04*SAMSS*117 MAN3&ACT3RE O& ATMOSPHERIC TAN5

6/ 04*SAMSS*118 MAN3&ACT3RE O& LO! PRESS3RE TAN5

7/ 04*SAMSS*11< MAN3&ACT3RE O& SHELL AN) T3=E HEAT E2CHANGERS

8/ 04*SAMSS*11; GENERAL P3POSE STEAM T3R=INES

</ 04*SAMSS*1.1 SPECIAL P3RPOSE STEAM T3R=INES

>/ 04*SAMSS*1.. MAN3&ACT3RE O& AIR*COOLE) HEAT E2CHANGER

;/ 04*SAMSS*1.; MAN3&ACT3RE O& PLATE AN) &RAME HEAT E2CHANGER

.1/ 04*SAMSS*141 MAN3&ACT3RE O& TRA:S AN) PAC5ING

../ 04*SAMSS*14. MAN3&ACT3RE O& INS)3STRIAL =OILERS

Is this content inappropriate? Report this Document

.4/ 04*SAMSS*144 MAN3&ACT3RE O& COMPONENTS AN) &LARE S:STEMS

.0/ 04*SAMSS*14< MAN3&ACT3RE O& ELECTRIC HEAT E2CHANGER

AD Download to read ad-free

.6/ 04*SAMSS*14; MAN3&ACT3RE O& &IRE) HEATER

.7/ 04*SAMSS*.11 COM=3STION GAS T3R=INES

%. SAEP ..7.

LE+EL 1 ? )OC3MENTS RE+IE! AN) NO INSPECTION RE@3IRE)

LE+EL . ? ONL: &INAL INSPECTION PRIOR &OR SHIPPING

LE+EL 4 ? PRE*INSPECTION MEETING/3NANNO3NCE) IN PROGRESS S3R+EILANCE/

LE+EL 0 ? SAME !ITH LE+EL 49 ANNO3NCE) S3R+EILLANCE ON REG3LAR =ASIS/

)AIL:9 !EE5L: OR =I !EE5L:B/

LE+EL 6 ? RESI)ENT INSPECTOR CONTIN3E MONITORING THE !OR5/

#. What resera*es used for the resera*o+ of Sta* E-u&/e+ts?

+pCI ? +apor P$ase Corrosion In$ibitor Po"er an" liDui" t'peB

Nitrogen =lan#eng ? 7 psi is t$e minimum pressure

6. Presera*o+ for )ota*+, E-u&/e+t?

Lubricaon of S$a an" Rotaon Per ee# 4/47 turnsB

Sig$t Glass Lubricaon

EnergiFaon of space $eater

Soli" Support an" Proper S$elter

)amage &ree

!. What to he2 r&or to a3&,+/e+t of E-u&/e+t?

&oun"aon $a(e reac$e" compressi(e strengt$ to 4</8 MPA 4> )a's

Pac#er Plates are installe" as per "raing ele(aon

C$ipping for groung is 47mm*71 mm

Anc$or Proecon9 +ercalit'

Anc$or bolt "iameter s$all be minimum of 41 mm 06JB unless speci,e" b' (en"or

Anc$or siFe s$oul" be c$ec#e" to ensure t$at it can be inserte" or matc$e" to eDuipment

bolt $ole importantB

Clean an" free of laitance

Locaon of (essel an" foun"aon ere (eri,e" to conform it$ t$e coor"inate in

construcon "raings/

". What are the a4ah/e+ts of )(I for &+sta33a*o+ of e-u&/e+t?

* SATR*)*411. ? HoriFontal eDuipment alignment recor"

* SATR*)*4114* +ercal EDuipment alignment recor"

* Appro(e" "raing

*S)R

*Calibraon Cer,cates

5. What &s the to3era+e to he2 for 3u/+ess of e-u&/e+t? What &s the too3 used?

* . mm per meter an" ma%imum of 47 mm/ Total staon is use to c$ec# for plumbness/

10. 7rou*+, used for Sta*?

* As per P@P

* 3suall' use" are Cementaous grout an" Non*s$rin#/

AD Download to read ad-free

11. What to he2 for /ater&a3 ree&&+,?

* IRC ? Inspecon Release Cer,cate

* +erif' Purc$ase Or"er is complie"

* &)R ? &inal )isposion report @ualit' Recor"s from manufacturer or (en"orB

*Pac#ing list/

* +en"or recommen"aon for preser(aon an" installaon

* )ata S$eets/

*SIS ? Safet' Instrucon S$eet

* ContractorKs Inspecon Reports

* )amage &ree

* ASME STAMP 3 STAMPB ? Pressure (essel it$ .7 psi or more reDuires ASME stamp/

Less t$an .7 PSI can $a(e or "onKt $a(e/

1$. SATIP?

*Sau"i Aramco T'pical Inspecon Plan/

1'. SATIP8E800%801 S$ell an" Tube Heat E%c$anger

SATIP8E800!801 Air coole" $eat e%c$anger

SATIP898001801 Pressure +essel

SATIP898100801 8 &IEL) ERECTE) STORAGE TAN5

SATIP8(8001801 &IRE) HEATERS

SATIP8(800180% ? =OILER PAC5AGE T:PE

SATIP8(800!80% ELE+ATE) &LARE

SATIP87800#801 CENTRI&3GAL P3MPS

SATIP878006801 POSITI+E )ISPLACEMENT P3MPS

SATIP8:8%0$801 8 CENTRI&3GAL COMPRESSOR

SATIP8:8%0'801 * RECIPROCATING COMPRESSOR

1%. SAIC for material recei(ing inspecon-

SAIC898$00$ ? PRESS3RE +ESSEL

SAIC8E8$00$ ? HEAT E2CHANGER SHELL AN) T3=EB

SAIC8:8$00$ ? CENTRI&3GAL COMPRESSOR

SAIC878$00$ ? CENTRI&3GAL P3MP

SAIC8(8$00% ? &IRE) HEATER

SAIC8E8$00# ? AIR*COOLE) HEAT E2CHANGER

AD Download to read ad-free

Learn more

Replay

INTER+IE! @3ESTIONS &OR ROTATING E@3IPMENT

1. !$at are t$e maor t'pes of Pumps-

a. O(er$ung pumps

b. In*beteen bearings

c. +ercall' suspen"e"

Pumps*centrifugal Pumpsa%ial9mi%e" &lo9Perip$eralB9Posi(e )isplacement Pumps

Reciprocang*piston Punger9"iap$ragmBRotar'*Single rotor9Mulple rotorB

$. !$at are t$e "ierence beteen (ercal pump an" $oriFontal pump-

T$e primar' "ierence beteen (ercal pump an" $oriFontal pump is t$e posion of t$e s$a/

HoriFontal is in $oriFontal posion an" (ercal pump is in (ercal posion/ &or (ercal sucon

an" "isc$arge posion in on opposite posion $ile $oriFontal is on si"e an" "isc$arge is on top/

'. !$at are t$e tolerance for ange parallelismalignment-

a. As per SAEP 07. parallelism is 1/> mm ma%imum "ierence SAEP 07.B

b. Certerline tolerance is ./7 mm SAEP 07.B

c. HoriFontal oset 4/6 mm

d. Rotaonal oset 4/6 mm

e. Combinaon oset 0/4 mm

f. &lange face lt across "iameter 1/147 mm per 47 mm of ange outsi"e "iameter up to a

ma%imum of 1/8<4 mm/ an" 1/476 mm 1/1.1 inc$B for all anges it$ an outsi"e

"iameter less t$an .1 inc$es/

g. &lange face lt across "iameter 1/147 mm per 47 mm of ange outsi"e "iameter up to

ma%imum of 1/8<4 mm/ an" 1/476 mm 1/1.1 inc$B for all anges it$ an outsi"e

"iameter less t$an .1 inc$es/

h. &lange face separaon gas#et t$ic#ness ./8 mm/

%. Ho to c$ec# pipe strain an" $at is t$e tolerance-

As per API 8>8 C$apter 8 in"icators s$all be mounte" on t$e coupling $ub to measure (ercal

an" $oriFontal mo(ement on t$e opposite mac$ine as t$e pipe ange bolts are being g$tene"

using a torDue renc$/ Ma%imum s$a mo(ement is 1/17 mm or less/

#. Hi an" lo rea"ings tolerance

a. .1 NPS abo(e ? 1/<7 mm ma%imum

b. .1 NPS belo ? 1/47 mm ma%imum

c. 1/11. inc$ per inc$ of outsi"e "iameter of ange/

6. Tolerance for le(elness of rotang-

&or general*purpose eDuipment an" ASME Pump is 611 micrometer per meter/ &or API pump

base plate is it$in 471 micrometer per meter/ 1/17 mm is use"/

!. !$at to c$ec# in "raing to c$ec# for t$e ele(aon-

T$e ele(aon s$oul" be c$ec# for sucon an" "isc$arge anges/

". T'pes of &langes-

a. !el" nec# &lange

b. Slip*on ange

c. Lap*oint ange

d. Si(el ring anges

e. =all si(el anges

f. Compact ange" connecons

AD Download to read ad-free

g. Clamp*t'pe anges

h. =lin" ange

i. Ori,ce ange ? $a(e $ole for instrumentaon o transmierB

j. T$rea"e" ange/

5. !$at are t$e groung material usuall' use"-

a. Cementaous grout s$all be use" for "ri(er $orsepoer less t$an 711 HP0<0 5!B90811

RPM or less an" combine eig$t of mac$ine9 "ri(er an" base plate up to 44<1 #g 7111

lbsB

SATIP*@*1.1*1.

b. Epo%' grout s$all be use" for eDuipment it$ "ri(er 711 HP 0<0 5!B or greater9 greater

t$an 0811 RPM9 greater t$an 44<1 5g 7111 lbsB

c. As per (en"or recommen"aon an" P@P/

10. ReDuire" for A%ial spacing tolerance or )=SE-

a. &or e%ible element couplings s$all be set b' (en"or or it$in 1/71 mm/ 1/47 mm

s$oul" be t$e anser/

b. &or Gear or elastomeric couplings s$all be set b' (en"or an" s$all be it$in . mm API

8>89C$apter < ? 7/6/./.

11. Material Recei(ing inspecon for Pumps/

a. &)R &inal )isposionRelease report Manufacturing Test Reports/B

b. Pumps conforms to t$e applicable co"especs

c. +en"or General Arrangement Inclu"e all "ata reDuire" to install t$e pump on its

foun"aonB

d. Nameplate stampings t$e same it$ "ata s$eets/

e. Pump Serial number is plainl' an" permanentl' mar#e" on pump casing/ API 8.1 para/

7/.0/0

f. Pump s#i" arrangement con,rms P an" I)/

1$. !$at is t$e eect of so foot- Ho to "etermine so foot- Ho to eliminate so foot-

a. It ma' aect t$e alignment "ue to mo(ement an" (ibraon of motor/

b. All hold-down bolts shall rst be tightened. If available, use the torque

specied by the equipment vendor at the support foot hold-down bolts. If

there are no torque requirements specied by the vendor, then use Table .!

and Table .". #easurement shall be ta$en as the bolt is loosened. The hold-

down bolt shall be tightened before going to the ne%t foot. &nless approved by

the user, soft-foot chec$s shall be made on each foot of the equipment and

not at the coupling.

c. To eliminate soft foot we have to apply shimming.

13. 'hat are the types of valve(

a. )all valve

b. )utter*y valve

c. +hec$ valve

d. ate valve

e. lobe valve

@C MECHANICAL INSPECTOR

AD Download to read ad-free

Share this document

You might also like

Document 3 pages

Aramco Interview

Questions

Md Sharique

100% (2)

Document 13 pages

Aramco Equipment

Interview Questions:…

Date: 28-11-

Amadco Ϯϭϭϲ 1. Mdmt

Established

86% (7)

Document 11 pages

Aramco Interview

Questions PR

hemant1284

100% (3)

Magazines Podcasts

Sheet music

Document 66 pages

Zoology Project On

Butterfly ?

kanha creations With kanha

100% (1)

Document 6 pages

Aramco Piping Questions

chandu666creator

89% (9)

Document 21 pages

Aramco Interview

Questions-4

chandu666creator

100% (4)

Document 14 pages

The Case of The Missing

Time

Sharingan Mangekyou

No ratings yet

Document 20 pages

300+ TOP PIPING

Engineering Interview…

Questions

steepa22 and Answers

100%PIPING

(1) Engineering

Interview Questions

Document 5 pages

Rotating Questions

Sud

100% (1)

Document 2 pages

Piping Latest Aramco

Questions

chandu666creator

0% (1)

Document 6 pages

Piping Inspector

Questions - 1

Sreejith Sreeraman

100% (2)

Document 10 pages

Piping Inspector

Questions

Richard Periyanayagam

100% (2)

Show more

About Support

About Scribd Help / FAQ

Everand: Ebooks & Accessibility

Audiobooks

Purchase help

SlideShare

AdChoices

Press

Join our team! Social

Contact us Instagram

Invite friends Twitter

Facebook

Legal

Pinterest

Terms

Privacy

Copyright

Cookie Preferences

Do not sell or share my

personal information

Get our free apps

Documents

Language: English

Copyright © 2024 Scribd Inc.

Download

You might also like

- PDF Solution Manual For Gas Turbine Theory 6th Edition Saravanamuttoo Rogers CompressDocument7 pagesPDF Solution Manual For Gas Turbine Theory 6th Edition Saravanamuttoo Rogers CompressErickson Brayner MarBer100% (1)

- Automotive Sensor Testing and Waveform AnalysisFrom EverandAutomotive Sensor Testing and Waveform AnalysisRating: 4.5 out of 5 stars4.5/5 (13)

- O&M Manual For FCUDocument30 pagesO&M Manual For FCUBeatrice Li50% (2)

- Centrifugal Pump - Working Principle, Main PartsDocument13 pagesCentrifugal Pump - Working Principle, Main Partsrishabh tomarNo ratings yet

- 8.1 - 5 MvaDocument4 pages8.1 - 5 MvafaharaNo ratings yet

- Sketch A320Document33 pagesSketch A320oscar horacio flores100% (1)

- Material List: Produced On 3/20/2014 With Xpress Selection V6.6.1 - Database DIL 9.4.1Document9 pagesMaterial List: Produced On 3/20/2014 With Xpress Selection V6.6.1 - Database DIL 9.4.1febimeNo ratings yet

- Optimal Ratio For Steel Tanks For StorageDocument7 pagesOptimal Ratio For Steel Tanks For Storagenelly del pilarNo ratings yet

- Energy Conversion Lab Manual NewDocument50 pagesEnergy Conversion Lab Manual NewRavi TejNo ratings yet

- Thermal Engineering Lab ManualDocument52 pagesThermal Engineering Lab ManualBharath ReddyNo ratings yet

- Pompa Air Sungai TyDocument4 pagesPompa Air Sungai TynovadwisafitriNo ratings yet

- 3 X Frame 9E 95mw OverviewDocument8 pages3 X Frame 9E 95mw OverviewbananosnetNo ratings yet

- A Report On Vocational TrainingDocument53 pagesA Report On Vocational TrainingJITENDRA MEENA100% (1)

- 8.01 Manufacturer'S Guaranteed Technical Data Schedule For 33/11 KV, 5/6.67 Mva Power TransformerDocument5 pages8.01 Manufacturer'S Guaranteed Technical Data Schedule For 33/11 KV, 5/6.67 Mva Power TransformerfaharaNo ratings yet

- Technical Specifications: Annex-2 Turbine AND Generator With Accessori ESDocument7 pagesTechnical Specifications: Annex-2 Turbine AND Generator With Accessori ESMKPashaPashaNo ratings yet

- Grid & Sub StationDocument39 pagesGrid & Sub StationPhani KumarNo ratings yet

- Piping Stress SpecificationDocument23 pagesPiping Stress Specificationpourang1361100% (1)

- Civil WorksDocument47 pagesCivil WorksAbdulyekini AhmaduNo ratings yet

- ASME CODE Section VIII Div 1 Vs Div 2 Design FactorDocument7 pagesASME CODE Section VIII Div 1 Vs Div 2 Design FactorsarvannnNo ratings yet

- API579 EXAMPLE CalculationsDocument4 pagesAPI579 EXAMPLE CalculationsJaclyn Henderson80% (5)

- Study of Piston Manufacturing and Completion of A Project On"Understandinng Piston Manufacturinng Process " in Piston PlantDocument26 pagesStudy of Piston Manufacturing and Completion of A Project On"Understandinng Piston Manufacturinng Process " in Piston PlantSambhav Jain100% (1)

- (131056537) Manual Centrala VestoWIN - enDocument21 pages(131056537) Manual Centrala VestoWIN - enviltermNo ratings yet

- Energy SupplyDocument172 pagesEnergy SupplygivamathanNo ratings yet

- API 510 Data Sheet - AnswersDocument11 pagesAPI 510 Data Sheet - Answersnikafiq100% (1)

- Areva P443 DistanceDocument10 pagesAreva P443 DistancesrinivasaphanikiranNo ratings yet

- Section - 7 Water Treatment PlantDocument24 pagesSection - 7 Water Treatment PlantRavi ShankarNo ratings yet

- Motor Volkswagen GolfDocument22 pagesMotor Volkswagen GolfcarbutzNo ratings yet

- Motor Re WindingDocument11 pagesMotor Re WindingAbhishek Singh Chauhan100% (4)

- ASME/ANSI and API Flanges: Pressure Class RatingDocument20 pagesASME/ANSI and API Flanges: Pressure Class RatingVimin PrakashNo ratings yet

- Car and Deep Cycle Battery Frequently Asked QuestionsDocument124 pagesCar and Deep Cycle Battery Frequently Asked QuestionsAbhishek Singh ChauhanNo ratings yet

- IC TDA-11115, TDA-11145 Service Manual enDocument24 pagesIC TDA-11115, TDA-11145 Service Manual enJeank Rivadeneyra50% (2)

- 3 Comments On Line Pipe Specifications 2013 08 27 RespuestasDocument3 pages3 Comments On Line Pipe Specifications 2013 08 27 Respuestasluisbazan7055No ratings yet

- Site Test Report Date: National Contracting Co. Ltd. NEW QAISUMAH 380/115/13.8 KV BSP Surge ArrestorDocument4 pagesSite Test Report Date: National Contracting Co. Ltd. NEW QAISUMAH 380/115/13.8 KV BSP Surge ArrestorElsayed Abdelmagid MohamedNo ratings yet

- Dynamech Quotation 100 KG - HR Potato Chips Plant Full AutoDocument12 pagesDynamech Quotation 100 KG - HR Potato Chips Plant Full AutoDhivyanthNo ratings yet

- Mill ExtractionDocument10 pagesMill ExtractionBahtiar Yudhistira100% (1)

- Successq 88Document6 pagesSuccessq 88Anonymous UCveMQ100% (1)

- Training Report On PTFEDocument24 pagesTraining Report On PTFEMaaz UkayeNo ratings yet

- Smp-12 Testing of Induction Motor-21Document2 pagesSmp-12 Testing of Induction Motor-21Sanjay RoutNo ratings yet

- The University of Asia Pacific: AC Ammeter 2Document4 pagesThe University of Asia Pacific: AC Ammeter 2sabitavabiNo ratings yet

- Welding (General) : Plant Location Page 1 of 17 RevDocument17 pagesWelding (General) : Plant Location Page 1 of 17 RevRavindra S. JivaniNo ratings yet

- Shripad Dattatray Vaishampayan Engineer - ProcessDocument3 pagesShripad Dattatray Vaishampayan Engineer - ProcessavaisharmaNo ratings yet

- SECTION 22 15 00 General Service Compressed-Air SystemsDocument8 pagesSECTION 22 15 00 General Service Compressed-Air Systemsm2110No ratings yet

- Vasanth.R: Contact Number: +91 9488365543 Email: Renvasanth@yahoo - Co.in AddressDocument4 pagesVasanth.R: Contact Number: +91 9488365543 Email: Renvasanth@yahoo - Co.in AddresskarueeeNo ratings yet

- Atita EngineDocument36 pagesAtita EngineSara AzamNo ratings yet

- Identifying Potential - in Offsites and Utilities Including Steam & PowerDocument45 pagesIdentifying Potential - in Offsites and Utilities Including Steam & Powerandrei12320003181No ratings yet

- Noi Hap Tiet Trung Sa 500aDocument19 pagesNoi Hap Tiet Trung Sa 500aBIOMED HCCNo ratings yet

- Fishing: Revision 1.0Document15 pagesFishing: Revision 1.0Dianna Ariza RNo ratings yet

- Excel Example BomsDocument19 pagesExcel Example BomsPacoNo ratings yet

- Performance Analysis of The Catalytic Converter: Experimental WorkDocument15 pagesPerformance Analysis of The Catalytic Converter: Experimental WorkRamya MandavaNo ratings yet

- Turbine Tip - Functional TestingDocument4 pagesTurbine Tip - Functional TestingRakesh GSNo ratings yet

- Checklist - SWM Jpif DBKLDocument4 pagesChecklist - SWM Jpif DBKLPhang S. SunNo ratings yet

- Power Plant EquipmentDocument2 pagesPower Plant Equipmentamrit403No ratings yet

- Nit 1987 2Document31 pagesNit 1987 2kunaldeoraNo ratings yet

- Damper Guide BookDocument21 pagesDamper Guide Booksbmmla100% (1)

- Asim CV UaeDocument3 pagesAsim CV UaeAsim Raza ZaidiNo ratings yet

- 8100 Series Brochure PDFDocument12 pages8100 Series Brochure PDFHeny MarthaNo ratings yet

- Questionairre of The Precooler Package: TG903833 Item 1 No Questions Answer/Explanantion RemarksDocument7 pagesQuestionairre of The Precooler Package: TG903833 Item 1 No Questions Answer/Explanantion RemarksabdhelraNo ratings yet

- Khaperkheda Project Execution An ExperienceDocument52 pagesKhaperkheda Project Execution An ExperiencePathella SudhakarNo ratings yet

- Checklist For Inspecting Vessels Loading Propylene Oxide PODocument7 pagesChecklist For Inspecting Vessels Loading Propylene Oxide POmorgoths100% (1)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Centrifugal CompressorDocument52 pagesCentrifugal CompressorKhaled AlmohammadiNo ratings yet

- General Pumping System and The Net Head Developed by A PumpDocument14 pagesGeneral Pumping System and The Net Head Developed by A PumpMohit SharmaNo ratings yet

- Typical Pump Station Bypass Connection To Force MainDocument1 pageTypical Pump Station Bypass Connection To Force Mainmirza057No ratings yet

- Multistage Air Compressor FinalDocument21 pagesMultistage Air Compressor FinalJames Thee100% (1)

- KS-SE3 SEK 50R (1050rpm, 254mm) Data SheetDocument1 pageKS-SE3 SEK 50R (1050rpm, 254mm) Data SheetRebi OkzamaNo ratings yet

- USACE - Water Hammer and Mass Oscillation (WHAMO) Ver. 3.0 - UserDocument256 pagesUSACE - Water Hammer and Mass Oscillation (WHAMO) Ver. 3.0 - UserAdrian FrantescuNo ratings yet

- Swash-Plate Pump (Portfolio)Document2 pagesSwash-Plate Pump (Portfolio)Jannen V. ColisNo ratings yet

- TE-18 Motor Overhaul and Megger Test Record MARCH-2023Document5 pagesTE-18 Motor Overhaul and Megger Test Record MARCH-2023Pramod Kumar SahuNo ratings yet

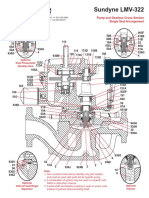

- Sundyne Pump API610 OH6 Gear Driven Vertical LMV-322 Cross SectionDocument1 pageSundyne Pump API610 OH6 Gear Driven Vertical LMV-322 Cross SectionRodrigo DonosoNo ratings yet

- Optimum Layout For A Turbofan EngineDocument37 pagesOptimum Layout For A Turbofan Enginevinod kapateNo ratings yet

- Ebara PumpsDocument69 pagesEbara PumpsMahtheerNo ratings yet

- Ce 370 - Centrifugal Pump CharacteristicsDocument29 pagesCe 370 - Centrifugal Pump CharacteristicsMohamed Abd El RahmanNo ratings yet

- Water Lifting Devices PDFDocument41 pagesWater Lifting Devices PDFSrinathRaghavan0% (1)

- Course Manual 2012Document144 pagesCourse Manual 2012IzzadAfif1990No ratings yet

- Marzocchi Gear Pump ALP2 - Series PDFDocument10 pagesMarzocchi Gear Pump ALP2 - Series PDFTeddy TjNo ratings yet

- TD13 enDocument12 pagesTD13 enkiyong namNo ratings yet

- Grundfosliterature 3982171Document7 pagesGrundfosliterature 3982171Parveez HusnooNo ratings yet

- STEAM TURBINE-Basic Comparitive StudyDocument7 pagesSTEAM TURBINE-Basic Comparitive StudySaravanan Ragupathy100% (1)

- Centrifugal Pump Operating Range As Per API 610 - LinkedInDocument2 pagesCentrifugal Pump Operating Range As Per API 610 - LinkedInragulNo ratings yet

- Typical Performance Curve Sru5Wld (Sru5/168) With Hyclean SealDocument1 pageTypical Performance Curve Sru5Wld (Sru5/168) With Hyclean Sealdanielagomezga_45545No ratings yet

- Design of Piping LoadsDocument13 pagesDesign of Piping LoadserodrguezNo ratings yet

- Ahe Lab Question Set 2Document8 pagesAhe Lab Question Set 2Vijay A HwreNo ratings yet

- Centrifugal Pumps Product OverviewDocument32 pagesCentrifugal Pumps Product Overviewbfuentes.segulaNo ratings yet

- Curva BombasDocument1 pageCurva BombasRodrigo Reyes GaNo ratings yet

- 23 EBRY 0251 Ebsray V Series Vane Pump - Brochure - WEBDocument8 pages23 EBRY 0251 Ebsray V Series Vane Pump - Brochure - WEBadymax211No ratings yet

- Influence of Impeller Diameter On The Performance of Centrifugal PumpsDocument11 pagesInfluence of Impeller Diameter On The Performance of Centrifugal PumpsKamendra KumarNo ratings yet

- MOTOR DATA FOR SDP 3&4 With PhotosDocument161 pagesMOTOR DATA FOR SDP 3&4 With PhotosAbhi7288No ratings yet

- 2103-Abj - Note - Fluid Mechancis - Conventions For The Angles Beta and Alpha For Turbomachine Blades and Euler and Mechanical Power PDFDocument6 pages2103-Abj - Note - Fluid Mechancis - Conventions For The Angles Beta and Alpha For Turbomachine Blades and Euler and Mechanical Power PDFMǾhămed TăwfiķNo ratings yet