Professional Documents

Culture Documents

PTR

PTR

Uploaded by

Omkar JoshiCopyright:

Available Formats

You might also like

- Manual Nissan CabstarDocument247 pagesManual Nissan CabstarCésar Augusto Villafañe Mármol90% (10)

- Manual Refrigerador Vesfrost MK-144 PDFDocument88 pagesManual Refrigerador Vesfrost MK-144 PDFangieNo ratings yet

- G574 - I3 - Digital Panel 541-1130Document5 pagesG574 - I3 - Digital Panel 541-1130Bam BANo ratings yet

- PTRDocument8 pagesPTROmkar JoshiNo ratings yet

- Transformer - GTP - IDT FormatDocument16 pagesTransformer - GTP - IDT FormatgohilnarendraNo ratings yet

- 2000kva 11000 - 433 EO16 AnnexureDocument7 pages2000kva 11000 - 433 EO16 Annexuredeepjyoti.newonlineNo ratings yet

- M/S Zhongding International Engineering Co., LTD and Hulas Steel Industries LTD., P.R.China and Nepal (Zhongding-Hulas JV)Document53 pagesM/S Zhongding International Engineering Co., LTD and Hulas Steel Industries LTD., P.R.China and Nepal (Zhongding-Hulas JV)JanardanPrasadGautam100% (1)

- 2000KVA Transformer Data SheetDocument2 pages2000KVA Transformer Data SheetCoral bhai50% (2)

- Supply of Cast Resin Transformers 11/0.433 KV, 1000 kVA - 2 NosDocument13 pagesSupply of Cast Resin Transformers 11/0.433 KV, 1000 kVA - 2 NosDarwish MammiNo ratings yet

- 19.auxiliary Trafo GTPDocument11 pages19.auxiliary Trafo GTPAnkit VishwakarmaNo ratings yet

- 10P149 E0028 102 - R0Document73 pages10P149 E0028 102 - R0PrasadNo ratings yet

- GTP - 250 kVADocument5 pagesGTP - 250 kVARamphani NunnaNo ratings yet

- Specification For Furnace TransformerDocument16 pagesSpecification For Furnace TransformerS Ray ChaudhuryNo ratings yet

- Technical Schedule 3Document16 pagesTechnical Schedule 3Prasenjit DeyNo ratings yet

- Transformer Design (Electrical) WO. No. Guaranteed Technical Particulars Bharat Bijlee Ltd. Transformer DivisionDocument3 pagesTransformer Design (Electrical) WO. No. Guaranteed Technical Particulars Bharat Bijlee Ltd. Transformer Divisionswarupkumarnayak100% (1)

- No Item Units Required Tendered: 2.12 Power TransformersDocument27 pagesNo Item Units Required Tendered: 2.12 Power TransformersdienlangchuNo ratings yet

- GTP 145 KV CBDocument3 pagesGTP 145 KV CBVipul HavaleNo ratings yet

- Transformer GTP 1MVA-11kV R1Document3 pagesTransformer GTP 1MVA-11kV R1Design TeamNo ratings yet

- Technical Specification of 3.15 MVA, 33-11 KV, POWER TRANSFORMER With OFF LOAD TAP CHANGER, ONAN................... 26.12.2014Document42 pagesTechnical Specification of 3.15 MVA, 33-11 KV, POWER TRANSFORMER With OFF LOAD TAP CHANGER, ONAN................... 26.12.2014Ritaban R. BanerjeeNo ratings yet

- Nesco Odisha Technical Specification of 8 MVA Power TransformerDocument52 pagesNesco Odisha Technical Specification of 8 MVA Power TransformerMPCZ ASSETMAPPINGNo ratings yet

- 56 Mva - GTPDocument5 pages56 Mva - GTPSuresh VadiveluNo ratings yet

- Technical Specification - IDTDocument14 pagesTechnical Specification - IDTgaurav mevadaNo ratings yet

- Technical Data Electrical (Rev-0)Document186 pagesTechnical Data Electrical (Rev-0)kattukoluNo ratings yet

- 630 Kva GTPDocument2 pages630 Kva GTPgovind yadavNo ratings yet

- Specification of 33-.63 KV 1.67MVA TransformerDocument8 pagesSpecification of 33-.63 KV 1.67MVA TransformerM Abu SayedNo ratings yet

- GTP For 110 KV 1250a Hdb-IsolatorDocument8 pagesGTP For 110 KV 1250a Hdb-IsolatorkapilNo ratings yet

- E1071400701-10MVA TR. GTP (66 - 33kV)Document4 pagesE1071400701-10MVA TR. GTP (66 - 33kV)Vishnu Shanker100% (1)

- Tech Spec - 6.3&10MVA With OLTC &SCADA-compatible-RTCCDocument34 pagesTech Spec - 6.3&10MVA With OLTC &SCADA-compatible-RTCCkushal BNo ratings yet

- GTP - 01 Power TransformersDocument8 pagesGTP - 01 Power Transformersraj_stuff006100% (1)

- Oman Electricity Transmission Co Tender PDFDocument7 pagesOman Electricity Transmission Co Tender PDFHossam AlzubairyNo ratings yet

- Technical Datasheet PDFDocument3 pagesTechnical Datasheet PDFAman SharmaNo ratings yet

- Technical Specification of 11Kv & 33Kv Oil Immersed CT:PT (Metering Equipment) UnitsDocument9 pagesTechnical Specification of 11Kv & 33Kv Oil Immersed CT:PT (Metering Equipment) Unitsrajeeb1985No ratings yet

- 400 KVA WAPDA Pad Mounted TF Technical SubmittalDocument10 pages400 KVA WAPDA Pad Mounted TF Technical SubmittalCh Saif UllahJuraaNo ratings yet

- Technical Specification: Specification No. CSC-V/R-I/DH/UH/P&D/2010-2011Document29 pagesTechnical Specification: Specification No. CSC-V/R-I/DH/UH/P&D/2010-2011PABLO MAURONo ratings yet

- S.No. Technical Parameters Specified 110Kv 1250A Electrically Motor (Cum) Manually Operated IsolatorDocument19 pagesS.No. Technical Parameters Specified 110Kv 1250A Electrically Motor (Cum) Manually Operated IsolatorneerajNo ratings yet

- Tech Spec 8mvaDocument40 pagesTech Spec 8mvachekurivishnu7No ratings yet

- ROQ-546 GTP 7670kVADocument3 pagesROQ-546 GTP 7670kVASumit TyagiNo ratings yet

- 1.a Power TransformerDocument28 pages1.a Power TransformerAnkur SinhaNo ratings yet

- 16 Kva 1Ø GTP & DRAWING PVVNLDocument10 pages16 Kva 1Ø GTP & DRAWING PVVNLmiteshsinghal21No ratings yet

- Technical Specification: EctionDocument22 pagesTechnical Specification: EctionmlutfimaNo ratings yet

- Call Off Contract No 47 2020Document23 pagesCall Off Contract No 47 2020talalNo ratings yet

- Transformer & Cable SpecsDocument297 pagesTransformer & Cable SpecsAulinoNo ratings yet

- 630 Kva GTP - L-1Document2 pages630 Kva GTP - L-1govind yadavNo ratings yet

- Section-7.4 TransformerDocument51 pagesSection-7.4 TransformerBRB CABLENo ratings yet

- Technical Specification - Transformer (31-8-2020)Document15 pagesTechnical Specification - Transformer (31-8-2020)Abhishek Kumar SinhaNo ratings yet

- Technical Specificationof IDT Solar ProjectDocument12 pagesTechnical Specificationof IDT Solar ProjectJitendra Pathak100% (1)

- Solar IDT SpecificationsDocument3 pagesSolar IDT SpecificationsVamsi PavuluriNo ratings yet

- Qa0874 2023Document7 pagesQa0874 2023Jaks JaksNo ratings yet

- ID MTRF 40215 P 01 - R0 - CommentsDocument13 pagesID MTRF 40215 P 01 - R0 - Commentsdivyasaw2003No ratings yet

- Sabah ScheduleDocument12 pagesSabah ScheduleLee RoNo ratings yet

- Tech Eq-50Document2 pagesTech Eq-50Mauricio Oropeza CabreraNo ratings yet

- Unit Auxiliary Transformer DatasheetDocument6 pagesUnit Auxiliary Transformer DatasheetYulianti Rahmi PurnamawatiNo ratings yet

- Btech Ee 8 Sem Power System Dynamics and Control 2011Document7 pagesBtech Ee 8 Sem Power System Dynamics and Control 2011Swagatam BanerjeeNo ratings yet

- 1600KVA GTP & DrawingsDocument8 pages1600KVA GTP & DrawingsDarshit VyasNo ratings yet

- Filled - 8.01. 33 KV OvcbDocument4 pagesFilled - 8.01. 33 KV OvcbAl ImranNo ratings yet

- 2-TSP- Technical Specification and GTP Section-7-盖章Document13 pages2-TSP- Technical Specification and GTP Section-7-盖章rubelNo ratings yet

- EE8353 - Electrical Drives and Controls MCQDocument41 pagesEE8353 - Electrical Drives and Controls MCQMadhesh RajuNo ratings yet

- P.Trafo TSDocument13 pagesP.Trafo TSmr.sumitenggNo ratings yet

- Voltech Manufacturing Company LTD.: Guaranteed Technical ParticularsDocument1 pageVoltech Manufacturing Company LTD.: Guaranteed Technical ParticularsRadhaNo ratings yet

- Master Spec Emax (EDC) 630kVA-OutdoorDocument4 pagesMaster Spec Emax (EDC) 630kVA-Outdoormaneth0001No ratings yet

- GTP 63 Mva - R0 FinalDocument10 pagesGTP 63 Mva - R0 FinalmidhunvarNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- STP-2 - Hi-Tech Park - BOQ - Final-071222Document5 pagesSTP-2 - Hi-Tech Park - BOQ - Final-071222Ashiq Elahi Design & Application EngineerNo ratings yet

- Motor2 PDFDocument2 pagesMotor2 PDFsherub wangdiNo ratings yet

- Ue VRVDocument2 pagesUe VRVRudy Nizama RosellNo ratings yet

- MV SkidDocument2 pagesMV SkidNikolaNo ratings yet

- CH 17 SCR IGBTDocument14 pagesCH 17 SCR IGBTPham LongNo ratings yet

- DSP MCQ1Document8 pagesDSP MCQ1Bala MuruganNo ratings yet

- A Solar Power-Assisted Battery Balancing System For Electric Vehicles PDFDocument12 pagesA Solar Power-Assisted Battery Balancing System For Electric Vehicles PDFCrispNo ratings yet

- RT430 RT434Document109 pagesRT430 RT434Nguyen NguyenNo ratings yet

- Huawei Enterprise Network CloudEngine S Series Campus Switch Portfolio - Print - A0Document4 pagesHuawei Enterprise Network CloudEngine S Series Campus Switch Portfolio - Print - A0adityabpNo ratings yet

- Feniex 4200 Controller Instruction Manual V2Document10 pagesFeniex 4200 Controller Instruction Manual V2donald_wilson4741No ratings yet

- Data SheetDocument76 pagesData SheetjonathanNo ratings yet

- Edc Project Report: Prof. Garima SolankiDocument32 pagesEdc Project Report: Prof. Garima SolankiAnime X100% (1)

- Lecture8 - PIPE CABLE ELECTROMAGNETIC LOCATORDocument39 pagesLecture8 - PIPE CABLE ELECTROMAGNETIC LOCATORMuhamadSadiq100% (1)

- !!all Product - Pricelist Wahana Data - SurabayaDocument23 pages!!all Product - Pricelist Wahana Data - SurabayaboncelhofNo ratings yet

- Continental Sid807evo Irom TC1797 VolvoDocument8 pagesContinental Sid807evo Irom TC1797 VolvoAlpine Lee100% (1)

- Voice Operated AutomationDocument31 pagesVoice Operated AutomationSahil PundNo ratings yet

- Fisher 3582 and 3582i Positioners and 582i Electro ...Document12 pagesFisher 3582 and 3582i Positioners and 582i Electro ...wderfNo ratings yet

- Metal Enclosed Switchgear in Plant Medium VoltageDocument4 pagesMetal Enclosed Switchgear in Plant Medium VoltagejuevesNo ratings yet

- Panasonic Sa-Ak220Document104 pagesPanasonic Sa-Ak220Cristian Chanampa67% (3)

- Catalogo General Unitronics 2010Document20 pagesCatalogo General Unitronics 2010INTRAVEcom Industrial AutomationNo ratings yet

- Barier Gate MIBDocument2 pagesBarier Gate MIBYhoyo Choyz'tNo ratings yet

- Socomec Delphys GP 2.0 500kva Control PanelDocument20 pagesSocomec Delphys GP 2.0 500kva Control PanelsharifmousaviNo ratings yet

- FabFilter Volcano 2Document43 pagesFabFilter Volcano 2David Esteves RuizNo ratings yet

- Few Basics: - Real Power (P) - Reactive Power (Q) - Frequency (F) - Voltage (V)Document21 pagesFew Basics: - Real Power (P) - Reactive Power (Q) - Frequency (F) - Voltage (V)gavinilaaNo ratings yet

- Clean Site Antennas MonopoleDocument45 pagesClean Site Antennas Monopoleculeros1100% (1)

- Ece2610 Chap9Document24 pagesEce2610 Chap9Bayar JargalNo ratings yet

- High Precision Dual Frequency RTK Board Instructions For UseDocument10 pagesHigh Precision Dual Frequency RTK Board Instructions For UseMishra dtuNo ratings yet

PTR

PTR

Uploaded by

Omkar JoshiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PTR

PTR

Uploaded by

Omkar JoshiCopyright:

Available Formats

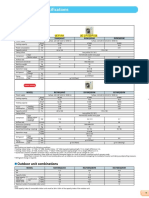

STEP UP POWER TRANSFORMERS GUARANTEED TECHNICAL PARTICULARS

S.N Vendor compliance on each

Description Unit Data

o point

1. Name & Place of Manufacturer

2. Service Outdoor

3. a) Application/Designation Step-up Transformer

b) Transformer type 2 winding transformer

4. Reference Standards IEC 60076 and CBIP

5. a) Rated MVA rating @ ONAF MVA 60

b) MVA rating at ONAN cooling MVA 45

6. Rated no load voltage ratio kV/kV 132/33

7. Rated frequency Hz 50

8. Number of phases 3

9. 3 Phase Connections -

a) HV winding Star

b) LV winding Star

10. Vector group for 3 phase YNyn0

11. Direction of Power flow Bi-directional Power Flow

12. On load tap Changer -

a) Make Eason MR / CTR

a) Type Vendro to Specify

b) Tap Range +10% to -10% @ 1.25%

c) Tap step % 1.25%

d) Provided on HV winding on neutral side

e) Model no Eason MR & MIII 600 Y 123/C 10.19.3W or

eq

f) Continuous rated current of OLTC Amps 600

g) OLTC range +10% to -10% @ 1.25%

h) No of Steps 17

i) OLTC shall be suitable for Number of

operations without any maintenance 80000

500000 & after contact replacement - 300000

(Total

j) OLTC shall be suitable for Total Number of

800000 Operation with contact replacement in

operations during its lifetime

OLTC

Complete Life).

k) Complete tap range for :

Constant flux variable voltage (CFVV)/ Variable

flux variable voltage (VFVV)/ Combined CFVV

regulation (CbVV)

l) Location of tapping (Line/Center/Neutral) end

of winding Neutral end of HV winding

m) Location of Tap winding wrt Core Core-LV-HV Main-HV tap winding

n) Design of Taps on winding (Linear/ Reversing

Reversing/ Coarse)

o) Mounting of OLTC (Inside main tank/ Inside main tank

outside main tank)

p) OLTC Motor rating Vendor to specify

q) Seperator conservator for OLTC Yes

(yes/no)

13. Reference ambient temperatures -

a) Maximum ambient air temperature °C 50

b) Maximum daily average ambient air °C 40

temperature

c) Maximum yearly weighted average °C 32

ambient temperature

Type of Transformer Neutral earthing for HV Solid earthing through bus bar fitted on tank

supported by insulators to bottom of the tank for

HVN and LVN and supplier shall provide the

14.

details of bus bar size, conductor material etc.

15. Type of Cooling ONAN/ONAF

16. Temperature rise over 50 deg C ambient

a) Top oil by Thermometer °C 50

method(Without Standby fan)

b) Windings by Resistance °C 55

method(Without Standby fan)

Hot spot temperature at weighted reference 98 DegC over yearly weighted average ambient

17. ambient temperature (For Winding) °C temp of 32 DegC ( 66 K winding hot spot rise over

yearly weighted average ambient temp of 32

18. Efficiencies at 75 Deg C( Approx) at 085 pf at 095 pf

at UPF

a) at full load % Vendro to Specify Vendro to

Specify Vendro to Specify

b) at 3/4 of full load % Vendro to Specify Vendro to

Specify Vendro to Specify

c) at 1/2 of full load % Vendro to Specify Vendro to

Specify Vendro to Specify

19. Load at Maximum Efficiency % Vendro to Specify Vendro to

Specify Vendro to Specify

20. a)Power factor at Maximum Efficiency Vendro to Specify Vendro to

Specify Vendro to Specify

b)maximum efficiency at 50% load at Vendro to Specify

unity power factor

21. Regulation at full load at 75 deg C -

a) at unity power factor % Vendro to Specify

b) at 085 pf lagging % Vendro to Specify

Total losses at rated voltage at Principal tapping

22. & at rated frequency including kW 143 kW (Max)

auxiliary loss

23. Component losses -

a) No load loss at rated voltage on principal kW 27.5 kW (Max)

tapping & at rated frequency

b) Load loss at rated current at principal tapping kW 110 kW (Max) at normal tap at 55 MVA base (

at 75 Deg C excluding auxiliary loss I2R+Stary loss= 85kW + 23kW Approx)

c) Auxiliary losses (Cooler loss) kW 5.5 kW (Max) (Without Stand by Fan)

d)-Ohmic losses at 75 degC (At 55 MVA Base) Below mentioned values are Calculated Actual

Value

will be measured during FAT

1)-Principal tap kW Vendro to Specify

2)-Minimum tap kW Vendro to Specify

3)-Maximum tap kW Vendro to Specify

e)-Reactive Power (40 MVA Based) consumed by Below mentioned values are based on Calculated

Transformer at impedance Actual Value may be different basd

on

1)-Principal tap % Vendro to Specify

2)-Minimum tap % Vendro to Specify

3)-Maximum tap % Vendro to Specify

24. Impedance voltage at rated current 60 MVA base

a) HV-LV ( Normal tap ) at 75˚C % 12.5% (Subjected to ± 75% IEC Tol)

b) HV-LV ( Maximum tap ) at 75˚C % Vendro to Specify

b) HV-LV ( Minimum tap ) at 75˚C % Vendro to Specify

25. Zero sequence impedance -

a) HV-LV ( Normal tap ) 85% to 90 % of '+'ve sequence impedance

b) HV-LV ( Maximum tap ) measured from HV side (Approx)

b) HV-LV ( Minimum tap )

26. No load current at rated voltage and rated % 0.5% (Approx) of full load current @ 100%

frequency of rated voltage

27. Rated HV current at rated voltage and Amps Vendro to Specify

rated frequency

28. Rated LV current at rated voltage and Amps Vendro to Specify

rated frequency

29. Resistance at rated current and rated % Vendro to Specify

frequency at principal tap

30. Reactance at rated current and rated % Vendro to Specify

frequency at principal tap

30 a) HV winding DC resistance at 75 degC

a- At Principal Tap (Ohms/phase) ohm/ph Vendro to Specify

b- At Maximum Tap (Ohms/phase ohm/ph Vendro to Specify

c- At Minimum Tap (Ohms/phase) ohm/ph Vendro to Specify

30 b) LV winding DC resistance at 75 degC ohm/ph Vendro to Specify

31. Capacitance Vendro to Specify

32. X/R ratio Vendro to Specify

Overload capacity as per IEC 60076-7 and IS-

32a) 6600 (No limits posed by Bushings and tap Yes

winding etcc) - Yes/ No

32b) Transformer short circuit thermal 2 Seconds (Thermal)

withstand time (sec)

33. Separate source power frequency -

withstand voltage Insulation level

(I) HV winding kVrms Vendro to Specify

(II) LV winding kVrms Vendro to Specify

34. Induced over Voltage withstand -

(I) HV winding kVrms 275

(II) LV winding kVrms 70

35. Full wave lightning Impulse withstand -

voltage

(I) HV winding kVpeak 650

(II) LV winding kVpeak 170

36. Switching Impulse withstand voltage -

(I) HV winding kVpeak 850

(II) LV winding kVpeak Not Applicable

37. Long duration AC withstand voltage -

(I) HV winding kVrms Vendro to Specify

(II) LV winding kVrms Vendro to Specify

38. Short duration AC withstand voltage -

(I) HV winding kVrms Vendro to Specify

(II) LV winding kVrms Vendro to Specify

(III) HV Neutral kVrms Vendro to Specify

(IV) LV Neutral kVrms Vendro to Specify

39. Short circuit withstand Duration seconds 2 Seconds (Thermal)

40. Short circuit withstand Current kA HV - 40 kA & LV - 31.5 KA for 1 sec

(system)

41. Radiator banks -

a No of banks 100% radiators mounted on tank

b Capacity of each radiator bank Not Applicable

c No of cooling units per transformer 1x 100% Bank provided

d Percentage cooling capacity of each 1 x 100% Tank mounted

cooling unit

e. No of radiators per cooling unit Vendro to Specify (provision for one additional

radiator shall be provided)

f. Number of standby radiators in a Nil

cooler bank

42. Type of Termination -

a) HV Bare Bushing

b) LV Cable box or Outdoor NSPBD shall be decided

durinig detailed engineering

43. HV Terminal arrangement -

(i) Make Reputed Make

(ii) Type OIP condenser Bushing

(iii) Minimum Creepage distance mm/kV 25 mm/kV (6125mm)

(iv) Rated Current Amp. 1000 Amps

(v) Lightening impulse voltage kVpeak 650 kVp

(vi)Power frequency withstand voltage kVrms 275 kVrms

vii) Phase to Phase Air clearance Vendor to specifiy

viii) Phase to Earth Air clearance Vendor to specifiy

(ix) Bushing Class kV 145 kV

(x) Maximum Tan delta value % 0.7 @ 20 Deg C

(xi)Minimum withstand value of N 1.6

Cantilever load on bushing

44. LV Terminal arrangement Cable box or NSPBD shall be decided durinig

detailed engineering

(i) Make Reputed Make

(ii) Type Oil communicating type Bushing

(iii) Minimum Creepage distance mm/kV 25 mm/kV (900mm approx)

(iv) Rated Current Amp. 1600 Amps

(v) Lightening impulse voltage kVpeak 170 kVp

(vi)Power frequency withstand voltage kVrms 70 kVrms

vii) Phase to Phase Air clearance mm 350mm approx

viii) Phase to Earth Air clearance mm 320mm approx

(ix) Bushing Class kV 36 kV

(x) Maximum Tan delta value Not applicable

(xi)Minimum withstand value of N 315.00

Cantilever load on bushing

(xii) Cable box suitable for cable size

45. HV Neutral Terminal arrangement -

(i) Make Reputed Make

(ii) Type Oil communicating type Bushing

(iii) Minimum Creepage distance mm/kV 25 mm/kV (900mm approx)

(iv) Rated Current Amp. 1000 Amps since to witnstand SC for 2 S

(v) Lightening impulse voltage kVpeak 170 kVp

(vi)Power frequency withstand voltage kVrms 70 kVrms

(vii) Phase to Phase Air clearance mm Not Applicable

(viii) Phase to Earth Air clearance mm 320mm approx

(ix) Bushing Class kV 36 kV

(x) Maximum Tan delta value Not applicable

(xi)Minimum withstand value of N 125.00

Cantilever load on bushing

46. LV Neutral Terminal arrangement -

(i) Make Reputed Make

(ii) Type Oil communicating type Bushing

(iii) Minimum Creepage distance mm/kV 25 mm/kV (900mm approx)

(iv) Rated Current Amp. 1600 Amps

(v) Lightening impulse voltage kVpeak 170 kVp

(vi)Power frequency withstand voltage kVrms 70 kVrms

(vii) Phase to Phase Air clearance mm Not Applicable

(viii) Phase to Earth Air clearance mm 320mm approx

(ix) Bushing Class kV 36 kV

(x) Maximum Tan delta value Not applicable

(xi)Minimum withstand value of N 3.15

Cantilever load on bushing

47. Weight -

a) Core stamping kg Vendro to Specify (Core and winding with

b) Copper winding kg & without clamping structure)

c) Oil kg Vendro to Specify

d) Cooler Units kg

e) Tank kg Vendro to Specify

f) fitting & accessories kg

g) Total Weight kg Vendro to Specify

48. Oil -

a) Oil quantity required for first filling (Ltrs) Vendro to Specify

b) Inhibited oil used (yes/no) No

c) Reference standard IS 335

d) Quantity of oil in Main Tank (Ltrs) Vendro to Specify

e)Quantity of oil in Main Conservator (Ltrs) Vendro to Specify

f)Quantity of oil in OLTC Conservator (Ltrs) Vendro to Specify

g)Quantity of oil in Cooling Units (Ltrs) Vendro to Specify

h)Total Quantity of oil in Transformer (Ltrs) Vendro to Specify

49. Overall dimensions -

a) Length mm Vendro to Specify

b) Breath mm Vendro to Specify

c) Height mm

50. Dispatch details -

a) mode of transport By Road

b) Weight of heaviest package kg Vendro to Specify

c) Dimensions of largest package -

(I) Length mm Vendro to Specify

(II) Breadth mm Vendro to Specify

(III) Height mm Vendro to Specify

51. Untanking height without sling mm Vendro to Specify

52. Max flux density in core at tap which -

corresponds to

a) Rated voltage & frequency 1.7 Tesla (Max)

b) 110% rated voltage & 100% rated 1.9 Tesla (Max) at 110% rated voltage

frequency

c) 125% rated voltage & 100% rated Vendro to Specify

frequency

d) 140% rated voltage & 100% rated Vendro to Specify

frequency

53. Overfluxing withstand capability of -

transformer at

a) 110% rated voltage & 100% rated Continuous

frequency

b) 125% rated voltage & 100% rated 60 Sec

frequency

c) 140% rated voltage & 100% rated 5 Sec

frequency

54. Type of windings -

a) HV windings Partial Inter shield disc winding

b) LV windings Helical

55 Winding Current density at all taps for all -

windings

a) HV 3 Amp/mm² (Approx)

b) LV 3 Amp/mm² (Approx)

56 Vacuum withstand capability of tank only 333 kN/m2 for 1hour approx

57 Thickness of transformer tank -

a) side plates 8 mm Approx

b) bottom plate 12 mm Min ( Approx)

c) Top plate 16 mm Min (Approx)

58 Core -

a) Material of core laminations CRGO Silicaon steel

b) Thickness of core laminations 0.27 mm or less

c) Type and thickness of insulation of core Carlite coating or Equivalent

laminations

d) material of core bolts Not Applicable (Boltless construction)

e) Insulation of core bolts Not Applicable (Boltless construction)

f) Grade of core material Vendro to Specify

g)No-load current at principal tap & rated 1- 0.5% APRROX OF FLA

frequency 2-0.4% APPROX OF FLA

on HV & LV side - 3-1.8% APPROX OF FLA

1-at 100% rated voltage 2-at 90% of voltage XXXcm2 Approx (Supplier shall provide guiding

hole at

h) Net core area (cm2) some location of core of xx or xx dia to make

manufature process easy, mentioned area is

without

i)Type of core joint Mitred

j) Whether core construction is without Yes

core bolts

k) Material of core clamping plate Mild steel

l)Thickness of core clamping plate Vendro to Specify

m)Insulation of core clamping plate PBD Material

n) Describe location and method of core Vendro to Specify

grounding

o) Details of oil ducts in core Vendro to Specify

p) Magnetising inrush comments amps Vendro to Specify

(LV)

q) Leakage Reactance 1-HV (Ohm) Vendro to Specify

2-LV (Ohm)

r)Air core reactance of HV winding Vendro to Specify

59 Means adopted to prevent displacement -

of core in tank during

a) Transport from works to site Active part locked with tank through Pin

and Cup arrangement

b) short circuits Active part locked with tank through Pin

and Cup arrangement

c) Seismic disturbances Active part locked with tank through Pin

and Cup arrangement

d) Conductor material Vendro to Specify

e) Conductor cross section (HV & LV) Vendro to Specify

(sqmm)

f) HV winding no load current at rated voltage Vendro to Specify

and at principal tap (Amp)

g) Insulating Material used & its thickness for 1-

HV Winding

Vendro to Specify

2-LV winding 3-Tap winding

4-Between HV and LV wdg

h) Type of axial coil support for 1-HV Winding

2-LV winding Vendro to Specify

3-Tap winding

i) Type of radial coil support for 1-HV Winding

2-LV winding Vendro to Specify

3-Tap winding

60 a) Type of Oil preservation system Air cell type oil preservation

b) Material of Aircell shall be Nitrile POLYAMIDE NITRILE COATED FABRIC

rubber

c) Max pressure of Rupture AS PER IS 7016 PT2

d) Aircell rupture relay to be provided Yes

61 a) Total volume of conservator 8% of total oil quantity of transformer

(Approx)

b) Type of conservator Air cell type

c) Aircell Rupture Relay Provided?

62 Volume of conservator between highest 90% of conservator volume (Approx)

and lowest levels

63 HV Line CT particulars

a) Type and Voltage class

b) Current ratio

c) Burden and accuracy class

d) Make of CT (Pl specify)

e) No of cores

f) Knee point voltage

g) Mag Current at Vk/2 (mA)

h) Resistance (Ohm) Not applicable for this transformer.

i) Function

j) Insulation class

k) Short time withstand current in amps

and duration in sec

1) Thermal current rating

2) Dynamic current rating

64 LV Neutral CT particulars LV Neutral CT

a)Type and Voltage class Ring Type Turret mounted

b) Current ratio Core 2 Core 1

700/1 700/1

c) Burden and accuracy class Core 2 Core 1

15/5P20 -/PS

d) Make of CT (Pl specify) Vendor to specify

e) No of cores 1 1

f) Knee point voltage NA >400 volts

g) Mag Current at Vk/2 (mA) NA < 30mA at Vk/2

h) Resistance (Ohm) < 5 ohms < 5 ohms

i) Function SEF REF

j) Insulation class Insulating paper

k) Short time withstand current in amps

and duration in sec

1) Thermal current rating and duration Vendor to specify

2) Dynamic current rating and duration Vendor to specify

65 HV Neutral CT particulars -

a) Type and Voltage class Ring Type Turret mounted

b) Current ratio Core 2 Core 1

250/1 250/1

c) Burden and accuracy class Core 2 Core 1

15/5P20 -/PS

d) Make of CT (Pl specify) Sinewave/Narayan Powertech

e) No of cores 1 1

f) Knee point voltage NA >400 volts

g) Mag Current at Vk/2 (mA) NA < 25mA at Vk/2

h) Resistance (Ohm) < 25 ohms <25 ohms

i) Function SEF REF

j) Insulation class Insulating paper

k) Short time withstand current in amps

and duration in sec

1) Thermal current rating and duration Vendor to specify

2) Dynamic current rating and duration Vendor to specify

66 Cooler Control Cabinet

a) Make Vendor to specify

b) Type Outdoor type

c) Panel material and thickness 2 mm (Approx)

e) Degree of Protection IP 55

e) Paint shade RAL 7032

f) Canopy provided Yes

67 Cooling Fans -

a) Type Industrial fans

b) Noof working fans nos. Vendor to specify

c) Noof standby fans nos. 2 for (100% Bank)

d) Motor data Vendor to specify

e) Make / Type Vendor to specify

f) Rating (kW) Vendor to specify

g) Voltage (V) 415 V,3-Ph,AC

h) No of cooling units per transformer 1 X 100%

i) Auto operation of cooler fan to be Yes

provided (Yes/No)

Voltage

j) Specification of Fan Motor (Voltage, kW, RPM,

No of phases Power

Insulation class, duty, temp rise)

RPM

68 Winding temperature indicator -Air Flow m3/hr Insulation class Temp range

a) Make Precimeasure/Perfect control

b) Type Dial Type

c) Range 0 - 150 mm

d) Size 270 Deg Angular Sweep

e) Setting for alarm Vendor to specify

f) Setting for trip Vendor to specify

g) Noof NO/NC contacts 4 Nos NO contacts

69 Oil Temperature Indicator -

a) Make Precimeasure/Perfect control

b) Type Dial Type

c) Range 0 - 150 mm

d) Size 270 Deg Angular Sweep

e) Setting for alarm Vendor to specify

f) Setting for trip Vendor to specify

g) Noof NO/NC contacts 2 Nos NO contacts

70 Magnetic oil level gauge -

a) Make Sukrut/Viat

b) Type Magnetic type

c) Size 250 mm dial for main conservator

d) Setting for alarm Low oil level

e) Noof NO/NC contacts 1 Nos Low Oil Level Alarm

71 Buchholz relay -

a) Make Sukrut/Viat

b) Type Double float type REED type

c) Setting for alarm As per supplier's Recommendation

d) Setting for trip As per supplier's Recommendation

e) Noof NO/NC contacts 2 Nos

72 Sudden pressure relay -

a) Make

b) Type

Not applicable for this transformer.

Not applicable for this transformer.

c) Setting for trip

d) Noof NO/NC contacts

73 Oil flow Indicator -

a) Make Not Applicable as cooling ONAN/ONAF

b) Type Not Applicable as cooling ONAN/ONAF

c) Range Not Applicable as cooling ONAN/ONAF

d) Size Not Applicable as cooling ONAN/ONAF

74 Tap Changer -

a) Make Eason MR / CTR

a) Type Vendro to Specify

b) Tap Range +10% to -10% @ 1.25%

c) Tap step % 1.25%

d) Provided on HV winding on neutral side

e) Model no Eason MR & MIII 600 Y 123/C 10.19.3W or

eq

f) Continuous rated current of OLTC Amps 600

g) OLTC range +10% to -10% @ 1.25%

h) No of Steps 17

i) OLTC shall be suitable for Number of 80000

operations without any maintenance

500000 & after contact replacement - 300000

j) OLTC shall be suitable for Total Number of

(Total

operations during its lifetime

800000 Operation with contact replacement in

k) Complete tap range for : OLTC

Constant flux variable voltage (CFVV)/ Variable CFVV

flux variable voltage (VFVV)/ Combined

l)regulation

Location (CbVV)

of tapping (Line/Center/Neutral) end Neutral end of HV winding

of winding

m) Location of Tap winding wrt Core Core-LV-HV Main-HV tap winding

n) Design of Taps on winding (Linear/ Reversing

Reversing/ Coarse)

o) Mounting of OLTC (Inside main tank/ Inside main tank

outside main tank)

p) OLTC Motor rating Vendor to specify

q) Seperator conservator for OLTC Yes

(yes/no)

75 Numerical Tap Changer control unit

a Make & Model no A-Eberle Relay

Model- REG-D

b Type Digital RTCC relay

16 Binary input/ 12 Binary output , 4 Analog

c Features provided Input, Communication Port as per IEC 61850

protocol- FO Communication

76 Nitrogen fire protection system -

a Make Supplier shall provide adequate provisions on the

b Type transformer suitable for CTR and

Eason MR make NIFPES.

c Features provided enclosed?

77 Partial Discharge Level Vendor to specify

78 Noise level when energised at normal voltage and As per NEMA TR-1

frequency without load (db)

79 Transformer Paint

a Shade RAL 7032

b thickness Vendor to submit the complete paint process

c Pl mention the paint process to be details and paint part of the offer.

followed

You might also like

- Manual Nissan CabstarDocument247 pagesManual Nissan CabstarCésar Augusto Villafañe Mármol90% (10)

- Manual Refrigerador Vesfrost MK-144 PDFDocument88 pagesManual Refrigerador Vesfrost MK-144 PDFangieNo ratings yet

- G574 - I3 - Digital Panel 541-1130Document5 pagesG574 - I3 - Digital Panel 541-1130Bam BANo ratings yet

- PTRDocument8 pagesPTROmkar JoshiNo ratings yet

- Transformer - GTP - IDT FormatDocument16 pagesTransformer - GTP - IDT FormatgohilnarendraNo ratings yet

- 2000kva 11000 - 433 EO16 AnnexureDocument7 pages2000kva 11000 - 433 EO16 Annexuredeepjyoti.newonlineNo ratings yet

- M/S Zhongding International Engineering Co., LTD and Hulas Steel Industries LTD., P.R.China and Nepal (Zhongding-Hulas JV)Document53 pagesM/S Zhongding International Engineering Co., LTD and Hulas Steel Industries LTD., P.R.China and Nepal (Zhongding-Hulas JV)JanardanPrasadGautam100% (1)

- 2000KVA Transformer Data SheetDocument2 pages2000KVA Transformer Data SheetCoral bhai50% (2)

- Supply of Cast Resin Transformers 11/0.433 KV, 1000 kVA - 2 NosDocument13 pagesSupply of Cast Resin Transformers 11/0.433 KV, 1000 kVA - 2 NosDarwish MammiNo ratings yet

- 19.auxiliary Trafo GTPDocument11 pages19.auxiliary Trafo GTPAnkit VishwakarmaNo ratings yet

- 10P149 E0028 102 - R0Document73 pages10P149 E0028 102 - R0PrasadNo ratings yet

- GTP - 250 kVADocument5 pagesGTP - 250 kVARamphani NunnaNo ratings yet

- Specification For Furnace TransformerDocument16 pagesSpecification For Furnace TransformerS Ray ChaudhuryNo ratings yet

- Technical Schedule 3Document16 pagesTechnical Schedule 3Prasenjit DeyNo ratings yet

- Transformer Design (Electrical) WO. No. Guaranteed Technical Particulars Bharat Bijlee Ltd. Transformer DivisionDocument3 pagesTransformer Design (Electrical) WO. No. Guaranteed Technical Particulars Bharat Bijlee Ltd. Transformer Divisionswarupkumarnayak100% (1)

- No Item Units Required Tendered: 2.12 Power TransformersDocument27 pagesNo Item Units Required Tendered: 2.12 Power TransformersdienlangchuNo ratings yet

- GTP 145 KV CBDocument3 pagesGTP 145 KV CBVipul HavaleNo ratings yet

- Transformer GTP 1MVA-11kV R1Document3 pagesTransformer GTP 1MVA-11kV R1Design TeamNo ratings yet

- Technical Specification of 3.15 MVA, 33-11 KV, POWER TRANSFORMER With OFF LOAD TAP CHANGER, ONAN................... 26.12.2014Document42 pagesTechnical Specification of 3.15 MVA, 33-11 KV, POWER TRANSFORMER With OFF LOAD TAP CHANGER, ONAN................... 26.12.2014Ritaban R. BanerjeeNo ratings yet

- Nesco Odisha Technical Specification of 8 MVA Power TransformerDocument52 pagesNesco Odisha Technical Specification of 8 MVA Power TransformerMPCZ ASSETMAPPINGNo ratings yet

- 56 Mva - GTPDocument5 pages56 Mva - GTPSuresh VadiveluNo ratings yet

- Technical Specification - IDTDocument14 pagesTechnical Specification - IDTgaurav mevadaNo ratings yet

- Technical Data Electrical (Rev-0)Document186 pagesTechnical Data Electrical (Rev-0)kattukoluNo ratings yet

- 630 Kva GTPDocument2 pages630 Kva GTPgovind yadavNo ratings yet

- Specification of 33-.63 KV 1.67MVA TransformerDocument8 pagesSpecification of 33-.63 KV 1.67MVA TransformerM Abu SayedNo ratings yet

- GTP For 110 KV 1250a Hdb-IsolatorDocument8 pagesGTP For 110 KV 1250a Hdb-IsolatorkapilNo ratings yet

- E1071400701-10MVA TR. GTP (66 - 33kV)Document4 pagesE1071400701-10MVA TR. GTP (66 - 33kV)Vishnu Shanker100% (1)

- Tech Spec - 6.3&10MVA With OLTC &SCADA-compatible-RTCCDocument34 pagesTech Spec - 6.3&10MVA With OLTC &SCADA-compatible-RTCCkushal BNo ratings yet

- GTP - 01 Power TransformersDocument8 pagesGTP - 01 Power Transformersraj_stuff006100% (1)

- Oman Electricity Transmission Co Tender PDFDocument7 pagesOman Electricity Transmission Co Tender PDFHossam AlzubairyNo ratings yet

- Technical Datasheet PDFDocument3 pagesTechnical Datasheet PDFAman SharmaNo ratings yet

- Technical Specification of 11Kv & 33Kv Oil Immersed CT:PT (Metering Equipment) UnitsDocument9 pagesTechnical Specification of 11Kv & 33Kv Oil Immersed CT:PT (Metering Equipment) Unitsrajeeb1985No ratings yet

- 400 KVA WAPDA Pad Mounted TF Technical SubmittalDocument10 pages400 KVA WAPDA Pad Mounted TF Technical SubmittalCh Saif UllahJuraaNo ratings yet

- Technical Specification: Specification No. CSC-V/R-I/DH/UH/P&D/2010-2011Document29 pagesTechnical Specification: Specification No. CSC-V/R-I/DH/UH/P&D/2010-2011PABLO MAURONo ratings yet

- S.No. Technical Parameters Specified 110Kv 1250A Electrically Motor (Cum) Manually Operated IsolatorDocument19 pagesS.No. Technical Parameters Specified 110Kv 1250A Electrically Motor (Cum) Manually Operated IsolatorneerajNo ratings yet

- Tech Spec 8mvaDocument40 pagesTech Spec 8mvachekurivishnu7No ratings yet

- ROQ-546 GTP 7670kVADocument3 pagesROQ-546 GTP 7670kVASumit TyagiNo ratings yet

- 1.a Power TransformerDocument28 pages1.a Power TransformerAnkur SinhaNo ratings yet

- 16 Kva 1Ø GTP & DRAWING PVVNLDocument10 pages16 Kva 1Ø GTP & DRAWING PVVNLmiteshsinghal21No ratings yet

- Technical Specification: EctionDocument22 pagesTechnical Specification: EctionmlutfimaNo ratings yet

- Call Off Contract No 47 2020Document23 pagesCall Off Contract No 47 2020talalNo ratings yet

- Transformer & Cable SpecsDocument297 pagesTransformer & Cable SpecsAulinoNo ratings yet

- 630 Kva GTP - L-1Document2 pages630 Kva GTP - L-1govind yadavNo ratings yet

- Section-7.4 TransformerDocument51 pagesSection-7.4 TransformerBRB CABLENo ratings yet

- Technical Specification - Transformer (31-8-2020)Document15 pagesTechnical Specification - Transformer (31-8-2020)Abhishek Kumar SinhaNo ratings yet

- Technical Specificationof IDT Solar ProjectDocument12 pagesTechnical Specificationof IDT Solar ProjectJitendra Pathak100% (1)

- Solar IDT SpecificationsDocument3 pagesSolar IDT SpecificationsVamsi PavuluriNo ratings yet

- Qa0874 2023Document7 pagesQa0874 2023Jaks JaksNo ratings yet

- ID MTRF 40215 P 01 - R0 - CommentsDocument13 pagesID MTRF 40215 P 01 - R0 - Commentsdivyasaw2003No ratings yet

- Sabah ScheduleDocument12 pagesSabah ScheduleLee RoNo ratings yet

- Tech Eq-50Document2 pagesTech Eq-50Mauricio Oropeza CabreraNo ratings yet

- Unit Auxiliary Transformer DatasheetDocument6 pagesUnit Auxiliary Transformer DatasheetYulianti Rahmi PurnamawatiNo ratings yet

- Btech Ee 8 Sem Power System Dynamics and Control 2011Document7 pagesBtech Ee 8 Sem Power System Dynamics and Control 2011Swagatam BanerjeeNo ratings yet

- 1600KVA GTP & DrawingsDocument8 pages1600KVA GTP & DrawingsDarshit VyasNo ratings yet

- Filled - 8.01. 33 KV OvcbDocument4 pagesFilled - 8.01. 33 KV OvcbAl ImranNo ratings yet

- 2-TSP- Technical Specification and GTP Section-7-盖章Document13 pages2-TSP- Technical Specification and GTP Section-7-盖章rubelNo ratings yet

- EE8353 - Electrical Drives and Controls MCQDocument41 pagesEE8353 - Electrical Drives and Controls MCQMadhesh RajuNo ratings yet

- P.Trafo TSDocument13 pagesP.Trafo TSmr.sumitenggNo ratings yet

- Voltech Manufacturing Company LTD.: Guaranteed Technical ParticularsDocument1 pageVoltech Manufacturing Company LTD.: Guaranteed Technical ParticularsRadhaNo ratings yet

- Master Spec Emax (EDC) 630kVA-OutdoorDocument4 pagesMaster Spec Emax (EDC) 630kVA-Outdoormaneth0001No ratings yet

- GTP 63 Mva - R0 FinalDocument10 pagesGTP 63 Mva - R0 FinalmidhunvarNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- STP-2 - Hi-Tech Park - BOQ - Final-071222Document5 pagesSTP-2 - Hi-Tech Park - BOQ - Final-071222Ashiq Elahi Design & Application EngineerNo ratings yet

- Motor2 PDFDocument2 pagesMotor2 PDFsherub wangdiNo ratings yet

- Ue VRVDocument2 pagesUe VRVRudy Nizama RosellNo ratings yet

- MV SkidDocument2 pagesMV SkidNikolaNo ratings yet

- CH 17 SCR IGBTDocument14 pagesCH 17 SCR IGBTPham LongNo ratings yet

- DSP MCQ1Document8 pagesDSP MCQ1Bala MuruganNo ratings yet

- A Solar Power-Assisted Battery Balancing System For Electric Vehicles PDFDocument12 pagesA Solar Power-Assisted Battery Balancing System For Electric Vehicles PDFCrispNo ratings yet

- RT430 RT434Document109 pagesRT430 RT434Nguyen NguyenNo ratings yet

- Huawei Enterprise Network CloudEngine S Series Campus Switch Portfolio - Print - A0Document4 pagesHuawei Enterprise Network CloudEngine S Series Campus Switch Portfolio - Print - A0adityabpNo ratings yet

- Feniex 4200 Controller Instruction Manual V2Document10 pagesFeniex 4200 Controller Instruction Manual V2donald_wilson4741No ratings yet

- Data SheetDocument76 pagesData SheetjonathanNo ratings yet

- Edc Project Report: Prof. Garima SolankiDocument32 pagesEdc Project Report: Prof. Garima SolankiAnime X100% (1)

- Lecture8 - PIPE CABLE ELECTROMAGNETIC LOCATORDocument39 pagesLecture8 - PIPE CABLE ELECTROMAGNETIC LOCATORMuhamadSadiq100% (1)

- !!all Product - Pricelist Wahana Data - SurabayaDocument23 pages!!all Product - Pricelist Wahana Data - SurabayaboncelhofNo ratings yet

- Continental Sid807evo Irom TC1797 VolvoDocument8 pagesContinental Sid807evo Irom TC1797 VolvoAlpine Lee100% (1)

- Voice Operated AutomationDocument31 pagesVoice Operated AutomationSahil PundNo ratings yet

- Fisher 3582 and 3582i Positioners and 582i Electro ...Document12 pagesFisher 3582 and 3582i Positioners and 582i Electro ...wderfNo ratings yet

- Metal Enclosed Switchgear in Plant Medium VoltageDocument4 pagesMetal Enclosed Switchgear in Plant Medium VoltagejuevesNo ratings yet

- Panasonic Sa-Ak220Document104 pagesPanasonic Sa-Ak220Cristian Chanampa67% (3)

- Catalogo General Unitronics 2010Document20 pagesCatalogo General Unitronics 2010INTRAVEcom Industrial AutomationNo ratings yet

- Barier Gate MIBDocument2 pagesBarier Gate MIBYhoyo Choyz'tNo ratings yet

- Socomec Delphys GP 2.0 500kva Control PanelDocument20 pagesSocomec Delphys GP 2.0 500kva Control PanelsharifmousaviNo ratings yet

- FabFilter Volcano 2Document43 pagesFabFilter Volcano 2David Esteves RuizNo ratings yet

- Few Basics: - Real Power (P) - Reactive Power (Q) - Frequency (F) - Voltage (V)Document21 pagesFew Basics: - Real Power (P) - Reactive Power (Q) - Frequency (F) - Voltage (V)gavinilaaNo ratings yet

- Clean Site Antennas MonopoleDocument45 pagesClean Site Antennas Monopoleculeros1100% (1)

- Ece2610 Chap9Document24 pagesEce2610 Chap9Bayar JargalNo ratings yet

- High Precision Dual Frequency RTK Board Instructions For UseDocument10 pagesHigh Precision Dual Frequency RTK Board Instructions For UseMishra dtuNo ratings yet