Professional Documents

Culture Documents

2131, Gemarc (10kN) 0523020111[2498] (2)

2131, Gemarc (10kN) 0523020111[2498] (2)

Uploaded by

Einjel TenaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2131, Gemarc (10kN) 0523020111[2498] (2)

2131, Gemarc (10kN) 0523020111[2498] (2)

Uploaded by

Einjel TenaCopyright:

Available Formats

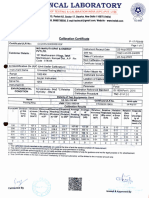

CERTIFICATE OF CALIBRATION

Issued to: MATEST LABORATORY

GEMARC ENTERPRISES SERVICES and TECHNICAL SOLUTION INC. PIC:

INCORPORATED Laboratory Supervisor

Address: 5 Chile

15 ChileStreet,

St., Greenheights Subdivision, Phone: n/a

Concepcion Subdivision

0 Greenheights Uno, 1800 Phase

Marikina City

1 Concepcion, Issued Date: 21/03/2023

0 Uno Marikina City, Philippines. *PIC - Person incharge.

*CTD - Customer to determine.

MACHINE DETAILS:

Description: Load Cell (Use In: Triaxial machine)

Manufacturer: NL SCIENTIFIC INSTRUMENTS (model: NL 5019 X / 003)

Serial No: 0523020111

Capacity (resolution): 10 kN (resolution: 1 N)

Calibration Range: 1000 N - 9000 N

Condition before calibration: Excellent (New)

Condition after calibration: Calibrated according to standard method

Location of calibration: In-house (NL Laboratory)

ENVIRONMENTAL CONDITIONS:

Temperature: (31.2 to 31.2) °C Relative Humidity: (60.2 to 60.6) %R.H

Date of Calibration: 21/03/2023 Sticker Number: N 2131

Due Date Specified Job Number: 23G 11414

By Customer: *CTD Certificate Number: CR/LC/2131

*The user should be aware that there are number of factors that may cause this instrument to drift out of calibration before the specified

calibration interval has expired.

REFERENCE STANDARDS:

Calibration device: Reference Instruments Certificate No. Traceable to

Thermohygrometer STT 22 03-0481-1 NMIM

Load Cell PSYP-22080931 NMIM

Calibration method: NL Scientific internal calibration procedure (NL-CP-05) with

reference to international standard test method.

REMARKS:

The machine was calibrated at the stated location using NL Scientific internal calibration procedure with

Page 1 of 2

reference to BS EN ISO 7500-1:2018 "Metallic materials - Calibration and verification of static uniaxial

testing machines". The user should determine the suitability of this machine for its intended use.

Not SAMM Accredited

This certificate is issued in accordance with the measurement capability of laboratory and its traceability to recognized national standards and to the units

of measurement realized to corresponding national standard laboratory. Any data/content on this certificate may not be reproduce except with

permission with issuing laboratory or head of laboratory.

Certificate Number: CR/LC/2131 Sticker Number: N 2131

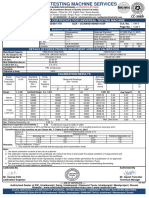

RESULT:

Nominal Device Reading Mean Error Relative Error

Force (N) (N) (N) of Indication

(N) 1 2 3 q (%)

1000 1010 1010 1000 1007 6.67 0.66

2000 2010 2010 2010 2010 10.00 0.50

3000 3020 3030 3020 3023 23.33 0.77

4000 4020 4040 4040 4033 33.33 0.83

5000 5030 5050 5050 5043 43.33 0.86

6000 6030 6070 6060 6053 53.33 0.88

7000 7030 7070 7070 7057 56.67 0.80

8000 8040 8080 8090 8070 70.00 0.87

9000 9030 9080 9100 9070 70.00 0.77

*Calibration in unit: Newton (N)

Relative Error of

Nominal Force Relative

Repeatability,b Zero, f0

(N) Resolution, a (%)

(%) Test run (%)

1000 1.00 0.001

2000 0.00 Run 1 0.00 0.000

3000 0.33 0.000

4000 0.50 0.000

5000 0.40 Run 2 0.00 0.000

6000 0.67 0.000

7000 0.57 0.000

8000 0.63 Run 3 0.00 0.000

9000 0.78 0.000

MEASUREMENT UNCERTAINTY:

Exp.Uncertainty, U = ± 26 N. The reported uncertainty is expanded using a coverage factor k = 2

for a level of confidence of approximately 95%.

The uncertainty was estimated according to the method in ‘JCGM Guide to the Expression of Uncertainty in Measurement

(GUM Ed. 2008)’. The measurement results only relate to the instrument calibrated.

Calibrated by: Approved signatory: Witnessed by:

Page 2 of 2

n/a

Calibration Personnel Q.M.

Hairul Anwar Ahmad Mohd Nuruddin Zulkepeli

End of Result

Not SAMM Accredited

This certificate is issued in accordance with the measurement capability of laboratory and its traceability to recognized national standards and to the units

of measurement realized to corresponding national standard laboratory. Any data/content on this certificate may not be reproduce except with

permission with issuing laboratory or head of laboratory.

Supplementary Page

Characteristic values of the force-measuring system

Class of Relative error of Indication, q Relative error of Relative error of Zero, Relative Resolution

Machine Range (%) Repeatability, b (%) f0 (%) a (%)

0.5 ±0.5 0.5 ±0.05 0.25

1 ±1.0 1.0 ±0.1 0.5

2 ±2.0 2.0 ±0.2 1.0

3 ±3.0 3.0 ±0.3 1.5

* the tabulated percentages are the maximum permitted values which characterize a testing machine range in accordance with the

appropriate class

This table are quote from BS EN ISO 7500 -1

Notes:

1 The classification of a testing machine calibrated and certified to meet a specific class does not ensure that the accuracy

including uncertainty will be less than a specific value.

2 This certificate contains results obtained during the measurement and calibration work. The measurement uncertainty does

not include the change in the capability of the equipment during post-calibration operation, the change in environmental

conditions and effect of vibrations experienced during transport or laboratory's capability to repeat the measurement and

calibration.

3 It is the responsibility of the customers to determine the calibration schedule of their equipment, taking into account the

equipment's frequency of usage and level of precision. Customers should determine the suitability of the machine for its

intended use.

You might also like

- CPCCBC4012 Student Assessment Task 1Document39 pagesCPCCBC4012 Student Assessment Task 1SIMRAN SINGHNo ratings yet

- Kato Hei - Puhekielen Alkeet (PDFDrive)Document186 pagesKato Hei - Puhekielen Alkeet (PDFDrive)Nathan FrancisNo ratings yet

- BS 7882Document23 pagesBS 7882Curtis Keller100% (2)

- Sound Level Meter and Thermometer CalibrationDocument2 pagesSound Level Meter and Thermometer CalibrationVIKASH RAI67% (3)

- Cal Cert FormatDocument6 pagesCal Cert FormatINSTRUCAL CALIBRATION SERVICESNo ratings yet

- Agitator SelectionDocument20 pagesAgitator SelectionRamakrishna Koushik100% (2)

- Cranes Rigging Your Organization Iti - Com r031512Document33 pagesCranes Rigging Your Organization Iti - Com r031512Mohsin Majeed0% (1)

- 3) Minda Industries (AW2W)Document2 pages3) Minda Industries (AW2W)VikasNo ratings yet

- Adobe Scan 06-Aug-2023Document2 pagesAdobe Scan 06-Aug-2023meerut nazibabad projectNo ratings yet

- CR1000X 46301Document2 pagesCR1000X 46301mitziNo ratings yet

- Calibration Certificate : ®imisensors ADocument1 pageCalibration Certificate : ®imisensors Aram ANo ratings yet

- TSC - 22-23 - 5490-1 TachometerDocument2 pagesTSC - 22-23 - 5490-1 TachometerDebabrata MajhiNo ratings yet

- 020-600kN-UTM-CELL COM TELESERVICES PVT. LTD. - 11.03.2023Document1 page020-600kN-UTM-CELL COM TELESERVICES PVT. LTD. - 11.03.2023SwaleheenNo ratings yet

- 249-317 Tec Aero Tue-C-100-293Document1 page249-317 Tec Aero Tue-C-100-293KiranNo ratings yet

- Tag No TL0010730Document4 pagesTag No TL0010730Arvin AmiriNo ratings yet

- (A Division of Testing & Calibration India (Opc) Pvt. LTD)Document1 page(A Division of Testing & Calibration India (Opc) Pvt. LTD)santanushee8No ratings yet

- Calibration CertificateDocument1 pageCalibration Certificatedaniel cabel rebazaNo ratings yet

- Draft Certificate (Impulse Analyzer)Document3 pagesDraft Certificate (Impulse Analyzer)mallikarjun_kNo ratings yet

- PD QC 02Document2 pagesPD QC 02surangkanapukwarnNo ratings yet

- QEL-C6-22-004 Programme Testing Unit WARTISILLA EADocument2 pagesQEL-C6-22-004 Programme Testing Unit WARTISILLA EAjoshuaNo ratings yet

- Ngg. YO UN G: Calibration Services PVT LTDDocument2 pagesNgg. YO UN G: Calibration Services PVT LTDchitranjan4kumar-8No ratings yet

- Calibration Certificate: Metrological CentreDocument2 pagesCalibration Certificate: Metrological CentrenduenasNo ratings yet

- Kankaria PropertiesDocument2 pagesKankaria PropertiesSK Emran AliNo ratings yet

- U 897 DWM 600Document1 pageU 897 DWM 600Amit KumarNo ratings yet

- Testi: OrationDocument1 pageTesti: OrationSusil Kumar SahooNo ratings yet

- MET. Microscope 249FDocument1 pageMET. Microscope 249Fumang100% (1)

- L19-456-2 Com FinalDocument7 pagesL19-456-2 Com FinalVERONICANo ratings yet

- Micrometer 1Document1 pageMicrometer 1Ikhuosho AbodeNo ratings yet

- KC EntDocument12 pagesKC Entsai associatesNo ratings yet

- Calibration Certificate PQW-1500Document4 pagesCalibration Certificate PQW-1500VikasNo ratings yet

- Lab Fl14a086cDocument5 pagesLab Fl14a086czyassNo ratings yet

- Bassy Certificate 2021Document12 pagesBassy Certificate 2021AMUDI EMEKANo ratings yet

- Dosimetria Tu CereralDocument19 pagesDosimetria Tu CereralNatalie RamosNo ratings yet

- CTM MC calibration-PHPLDocument2 pagesCTM MC calibration-PHPLRajeev KumarNo ratings yet

- 2-AC DC Clamp Meter Kyortsu 2003ADocument2 pages2-AC DC Clamp Meter Kyortsu 2003AAhmed IrakyNo ratings yet

- Cube Mould PDFDocument13 pagesCube Mould PDFkishor boruahNo ratings yet

- UNCERTAINTYDocument7 pagesUNCERTAINTYVenkateshNo ratings yet

- 1 NablDocument11 pages1 NablNeha SharmaNo ratings yet

- Spare Feeder P10Document80 pagesSpare Feeder P10Yogesh JethwaNo ratings yet

- 1111-1179 Tata Steel BSL Limited ETM-2000-1153Document1 page1111-1179 Tata Steel BSL Limited ETM-2000-1153VikasNo ratings yet

- Calibration Certificate PNW-2000Document4 pagesCalibration Certificate PNW-2000VikasNo ratings yet

- 43-Utm Load Cell Tensile Calibration CartificateDocument1 page43-Utm Load Cell Tensile Calibration CartificateCustomer SupportNo ratings yet

- S355J2 Plate MTCDocument2 pagesS355J2 Plate MTCHarminder Kumar100% (1)

- Sercal Mtms Ltd. Sercal Mtms Ltd. Sercal Mtms Ltd. Sercal Mtms LTDDocument3 pagesSercal Mtms Ltd. Sercal Mtms Ltd. Sercal Mtms Ltd. Sercal Mtms LTDLuân Nguyễn QuỳnhNo ratings yet

- 2018-12-01 Sound Calibrator NC-74Document3 pages2018-12-01 Sound Calibrator NC-74chunyao0602No ratings yet

- Certificado de Calibração - Validador 2023Document2 pagesCertificado de Calibração - Validador 2023Edson RamosNo ratings yet

- Calibration Certificate Compression Machine C0065-22 (2000 KN)Document1 pageCalibration Certificate Compression Machine C0065-22 (2000 KN)muhirwa raymondNo ratings yet

- Velomitor CT LowFreqCalDocument1 pageVelomitor CT LowFreqCalJuan Pablo Morales GutiérrezNo ratings yet

- ManometerDocument3 pagesManometerdimulescuremusNo ratings yet

- J5 DhuleDocument351 pagesJ5 DhuleShashank revdekarNo ratings yet

- Inst - Calibration Report For TXDocument2 pagesInst - Calibration Report For TXsujitNo ratings yet

- AMS-CAL-0153-15 Dial IndicatorDocument2 pagesAMS-CAL-0153-15 Dial IndicatorMuhammad RahimNo ratings yet

- Digital Inclinometer - 2022-15-FM1Document1 pageDigital Inclinometer - 2022-15-FM1Chethan Nagaraju KumbarNo ratings yet

- SamplecertDocument2 pagesSamplecertAsongwe HansNo ratings yet

- Calibration Certificate: MechanicalDocument2 pagesCalibration Certificate: MechanicalAmit KumarNo ratings yet

- TD1250 Verification Device For Earth Continuity TestersDocument13 pagesTD1250 Verification Device For Earth Continuity Testerskhanhnd.hwNo ratings yet

- Transformer Testing For New 10mva Power Transfomer: Batangas Ii Electric Cooperative (Batelec Ii)Document4 pagesTransformer Testing For New 10mva Power Transfomer: Batangas Ii Electric Cooperative (Batelec Ii)Edmar BataqueNo ratings yet

- Measuring TapeDocument1 pageMeasuring TapeOmkar PrindavankarNo ratings yet

- 7. 3Ph HT Motor Test Report_SignedDocument5 pages7. 3Ph HT Motor Test Report_SignedDeepen SharmaNo ratings yet

- Acred 019 CDMXDocument7 pagesAcred 019 CDMXVERONICANo ratings yet

- 1056 - TCDocument2 pages1056 - TCArun KumarNo ratings yet

- Ejex Sen041f P264421Document1 pageEjex Sen041f P264421Universo Enorme Aquel DíaNo ratings yet

- Design and Implementation of Portable Impedance AnalyzersFrom EverandDesign and Implementation of Portable Impedance AnalyzersNo ratings yet

- Handbook of Microwave Component Measurements: with Advanced VNA TechniquesFrom EverandHandbook of Microwave Component Measurements: with Advanced VNA TechniquesRating: 4 out of 5 stars4/5 (1)

- Different Tests For RebarDocument16 pagesDifferent Tests For RebarEinjel TenaNo ratings yet

- EURAMET cg-18 - State-Of-The-Art Calibration GuideDocument9 pagesEURAMET cg-18 - State-Of-The-Art Calibration GuideEinjel TenaNo ratings yet

- Calibrations of WeightsDocument5 pagesCalibrations of WeightsEinjel TenaNo ratings yet

- TBTUTM-1000A UTM With PC Display Operation ManualDocument9 pagesTBTUTM-1000A UTM With PC Display Operation ManualEinjel TenaNo ratings yet

- Operating Manual of TestMaster3Document47 pagesOperating Manual of TestMaster3Einjel TenaNo ratings yet

- Instructions For Use and Warnings: General IndexDocument40 pagesInstructions For Use and Warnings: General IndexEinjel TenaNo ratings yet

- Span Calibration Guide: Client Document NumberDocument28 pagesSpan Calibration Guide: Client Document NumberEinjel TenaNo ratings yet

- TS550 - HB - Utm2 PDFDocument240 pagesTS550 - HB - Utm2 PDFEinjel TenaNo ratings yet

- CCNA1 CaseStudy Structured CablingDocument39 pagesCCNA1 CaseStudy Structured CablingsantanuengineerNo ratings yet

- Augmented Power Pack (APP) : Reducing The Battery Burden, Enhancing Operational EffectivenessDocument2 pagesAugmented Power Pack (APP) : Reducing The Battery Burden, Enhancing Operational EffectivenessАндрей ГусевNo ratings yet

- Indian Standard: Code of Practice For Design and Construction OF Pile FoundationsDocument55 pagesIndian Standard: Code of Practice For Design and Construction OF Pile Foundationssumedh11septNo ratings yet

- Packet Tracer - Investigate STP Loop Prevention: ObjectivesDocument2 pagesPacket Tracer - Investigate STP Loop Prevention: ObjectivesJuan JuancarlosNo ratings yet

- Networking - Foundation: Duration: 60hrsDocument4 pagesNetworking - Foundation: Duration: 60hrsBalaNo ratings yet

- Model 15: Precision Open Face Flat Lapping MachineDocument2 pagesModel 15: Precision Open Face Flat Lapping MachineJoram Marín HernándezNo ratings yet

- PSVAlveDocument24 pagesPSVAlvevenkatesh801No ratings yet

- Bluetooth UART Module 1545 RobokitsDocument23 pagesBluetooth UART Module 1545 Robokitsf4a2dl5939No ratings yet

- Iso 7619 2 2010Document9 pagesIso 7619 2 2010amnajamNo ratings yet

- Quality Control Guidelines Quality Control Check ListsDocument3 pagesQuality Control Guidelines Quality Control Check ListsRizkyHaryogiNo ratings yet

- PP - IGC2 - Element 8 - Sample 2nd Edn v.1.0Document5 pagesPP - IGC2 - Element 8 - Sample 2nd Edn v.1.0Ahsan ChuhadryNo ratings yet

- Parenteral Process ValidationDocument30 pagesParenteral Process Validationravindra82% (11)

- New in CncKad v10Document63 pagesNew in CncKad v10Nguyễn Minh Hiếu100% (1)

- Installation and Wire Connection Manual: Warning Caution CautionDocument6 pagesInstallation and Wire Connection Manual: Warning Caution Cautiongamer1No ratings yet

- AJ-HPX2000: P2 Cam - Memory Card Camera RecorderDocument8 pagesAJ-HPX2000: P2 Cam - Memory Card Camera RecorderLudwingPFNo ratings yet

- Ludeca - A Practical Guide To Pulley Alignment PDFDocument13 pagesLudeca - A Practical Guide To Pulley Alignment PDFAlberto BalvinNo ratings yet

- Mig 250c ManualDocument18 pagesMig 250c ManualBondan PratamaNo ratings yet

- Final Compilation EnglishDocument126 pagesFinal Compilation EnglishSiva3444No ratings yet

- 7XG22 2RMLG Catalogue Sheet PDFDocument12 pages7XG22 2RMLG Catalogue Sheet PDFAldo Bona HasudunganNo ratings yet

- RTU5024 GSM Gate Opener User Manual V1.7Document12 pagesRTU5024 GSM Gate Opener User Manual V1.7Susana Rodas100% (1)

- Steyr MannlicherDocument18 pagesSteyr MannlicherAdrian Kozel100% (1)

- Workshop Technology-Course MaterialDocument59 pagesWorkshop Technology-Course Materialiamback09No ratings yet

- VW CNG Manual SSP 373 d1Document30 pagesVW CNG Manual SSP 373 d1Oskó József100% (1)

- Brake System Design For A Single Seater VehicleDocument27 pagesBrake System Design For A Single Seater VehicleAshraf Zulkafli100% (1)

- Xplore FAQ (English)Document9 pagesXplore FAQ (English)Xavier Joy GomesNo ratings yet

- Piping - Pipeline Design PressureDocument3 pagesPiping - Pipeline Design Pressureankur2061No ratings yet