Professional Documents

Culture Documents

11. N-7018-2.5mm-64210048(F18)

11. N-7018-2.5mm-64210048(F18)

Uploaded by

hanz bermejoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

11. N-7018-2.5mm-64210048(F18)

11. N-7018-2.5mm-64210048(F18)

Uploaded by

hanz bermejoCopyright:

Available Formats

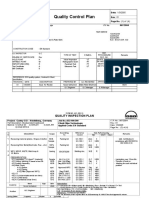

CUSTOMER:

P.O. NO.:

INSPECTION TEST CERTIFICATE

KORWELD WELDING AND INDUSTRIAL SUPPLY D

NIHeNWELD

Product Name Dimension (mm) Lot No. Applicable Specification and Certificate No. Date of Issue

Classification

NIHONWELD N-7018 2.5 X 350 64210048 AWS A5.1: E7018 24-03571 April 5, 2024

CHEMICAL COMPOSITION(%) ACCORDING TO EN10204 TYPE 3.1

Elements C Si Mn p s Cr Mo Ni V *1

Specifications

All Weld Metal 0.06 0.42 0.96 0.021 0.013 0.04 0.004 0.019 0.010 1.03

Elements

Specifications

ACCORDING TO EN10204 TYPE 2.2 remarks/notes: *1 = Mn+Cr+Mo+Ni+V

Tensile Test of Deposited Metal Impact Test of Deposited Metal

Yield Strength Tensile Strength Test Impact Value

at 0.2% offset (N/mm2 ) Elongation Temp. (J)

(%)

(N/mm 2 ) (DC)

Specifications

All Weld Metal 488 563 33 -30 101

We hereby certify that this report is correct and that all test results are in

Test results for mechanical properties, deposit or electrode composition and othercompliance with the specification described herein.

oroperties were -obtained from a weld produced and tested according to ,,,., INDUSTRIAL WELDING CORPORATION

orescribed standards, and should not be assumed to be the expected results in a

oarticular application or weldment. Actual results will vary depending on many

factors, including, but not limited to, weld procedure, plate chemistry anu

�-(;

temperature, weldment design and fabrication methods. Users are cautioned to

confirm by qualification testing, or other appropriate means, the suitability of any H.B.Pel<

welding consumable and procedure before use in the intended application.

Technical Depa�rnt

0250 I rev. 03.25.15 R2

You might also like

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 4 out of 5 stars4/5 (9)

- Generator BasicsDocument100 pagesGenerator BasicsTravis Chesna100% (6)

- Material TCDocument1 pageMaterial TCgmbakshiNo ratings yet

- AWS Maintenance-of-Welder-Certification-Form (01-2023)Document1 pageAWS Maintenance-of-Welder-Certification-Form (01-2023)hanz bermejoNo ratings yet

- 652-100-FINAL (ITP) Rev1Document4 pages652-100-FINAL (ITP) Rev1Anonymous AdofXEYAgENo ratings yet

- Reinhold Ebertin - Transits - What Days Favor You - American Federation of Astrologers (2015)Document128 pagesReinhold Ebertin - Transits - What Days Favor You - American Federation of Astrologers (2015)ukoszapavlinje100% (24)

- 22 LNT Ni1 (ER80S-Ni1) 2.4mm 3.1 MTCDocument1 page22 LNT Ni1 (ER80S-Ni1) 2.4mm 3.1 MTCnwoforNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Portfolio (COMPILATION)Document67 pagesPortfolio (COMPILATION)Jamiel Catapang0% (1)

- N-7018-2.5mm-64210045 (F21)Document1 pageN-7018-2.5mm-64210045 (F21)hanz bermejoNo ratings yet

- N-7018-3.2mm-24211038 (F17)Document1 pageN-7018-3.2mm-24211038 (F17)hanz bermejoNo ratings yet

- 18. N-6011-2.5mm-94110059 (F25)Document1 page18. N-6011-2.5mm-94110059 (F25)hanz bermejoNo ratings yet

- N-7018-2.5mm-94110180 (F19)Document1 pageN-7018-2.5mm-94110180 (F19)hanz bermejoNo ratings yet

- 19. N-7016-2.5mm-94110034 (F26)Document1 page19. N-7016-2.5mm-94110034 (F26)hanz bermejoNo ratings yet

- 17. N-6011-2.5mm-94110060 (F24)Document1 page17. N-6011-2.5mm-94110060 (F24)hanz bermejoNo ratings yet

- N-6010-3.2mm - 33910715 (F22)Document1 pageN-6010-3.2mm - 33910715 (F22)hanz bermejoNo ratings yet

- N-6010-2.5mm-94140177 (F23)Document1 pageN-6010-2.5mm-94140177 (F23)hanz bermejoNo ratings yet

- N-7018-2.5mm-64110119 (F20)Document1 pageN-7018-2.5mm-64110119 (F20)hanz bermejoNo ratings yet

- Product CertificateDocument1 pageProduct CertificateMURSHID MUHAMMEDNo ratings yet

- Product CertificateDocument1 pageProduct CertificateAhmed IrakyNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerSathish Kumar SelvarajNo ratings yet

- AaaDocument2 pagesAaaN ANo ratings yet

- Inspection Certificate Type 3.1 DIN EN10204Document1 pageInspection Certificate Type 3.1 DIN EN10204INAM OlsztynNo ratings yet

- Product CertificateDocument1 pageProduct CertificateGonzalo TelleríaNo ratings yet

- Huehoco Composite Materials Co., LTD. ANT D 4012 /A277-CN (W98)Document1 pageHuehoco Composite Materials Co., LTD. ANT D 4012 /A277-CN (W98)anbu2810wsNo ratings yet

- ut_amr (1)Document1 pageut_amr (1)balaNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- Nihonweld Industrial Welding Corp - High Quality Producer of Steel and Welding Consumables - Stainless Steel Electrodes - NIHONWELD NSS-308 - E308-16 PDFDocument2 pagesNihonweld Industrial Welding Corp - High Quality Producer of Steel and Welding Consumables - Stainless Steel Electrodes - NIHONWELD NSS-308 - E308-16 PDFJohnny Jr TumangdayNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerSathish Kumar SelvarajNo ratings yet

- SM-70 CMR RevisedDocument1 pageSM-70 CMR RevisedNitin GhotekarNo ratings yet

- Certificate of Conformance: Qa@nouveaux - in WWW - Nouveaux.inDocument1 pageCertificate of Conformance: Qa@nouveaux - in WWW - Nouveaux.inharikrishnanNo ratings yet

- DPT Report 02Document2 pagesDPT Report 02Amit Hasan100% (1)

- Eqt 4Document10 pagesEqt 4santosh pasayatNo ratings yet

- Eqt 3Document10 pagesEqt 3santosh pasayatNo ratings yet

- 175-022501 Flanges (WN, BL, Forged Steel & As)Document2 pages175-022501 Flanges (WN, BL, Forged Steel & As)ALINo ratings yet

- Painting SpecificationDocument27 pagesPainting SpecificationMohamed Thasim100% (1)

- Huehoco Composite Materials Co., LTD. ANT D 4012 /A277-CN (W111)Document1 pageHuehoco Composite Materials Co., LTD. ANT D 4012 /A277-CN (W111)anbu2810wsNo ratings yet

- ISO Standards On Mech Test of MetalsDocument1 pageISO Standards On Mech Test of MetalsKiran NikateNo ratings yet

- Expansion Project at Panipat Refinery: Item Number Description Qty CWA NumberDocument49 pagesExpansion Project at Panipat Refinery: Item Number Description Qty CWA NumberAK RNo ratings yet

- T-1, F- 4, 5 U.T ProtocalDocument2 pagesT-1, F- 4, 5 U.T ProtocaltrivikramraoNo ratings yet

- Portafaston DatasheetDocument2 pagesPortafaston DatasheetMattia BelliniNo ratings yet

- MSB-TPL-REW-BV-HYD-8705-FIR 003 Dated 16-02-2023Document4 pagesMSB-TPL-REW-BV-HYD-8705-FIR 003 Dated 16-02-2023pl_arunachalam79No ratings yet

- 3403 Rev 1 - Functional Specification For Pressure Transmitter ElectronicDocument9 pages3403 Rev 1 - Functional Specification For Pressure Transmitter ElectronicYashwanth KumarNo ratings yet

- AMBICA 36mm Rod SS316L MTCDocument2 pagesAMBICA 36mm Rod SS316L MTCmetalexinNo ratings yet

- 36 - Declaration of PerformanceDocument1 page36 - Declaration of PerformanceScott TrainorNo ratings yet

- Werkszeugnis Altena Blech Vom 17.06.PDF 1Document2 pagesWerkszeugnis Altena Blech Vom 17.06.PDF 1MuzammilNo ratings yet

- FS 4015 NGR, Rev - 0Document8 pagesFS 4015 NGR, Rev - 0Dinesh RajNo ratings yet

- FS 3301 - FS-Temperature SwitchDocument8 pagesFS 3301 - FS-Temperature SwitchBinu ManiNo ratings yet

- 175 022503Document2 pages175 022503Abu Anas M.SalaheldinNo ratings yet

- CAIRN-TSG-L-TN-0006-B1-Technical Notes For Flanges, Spectacle Blinds and Drip RingsDocument7 pagesCAIRN-TSG-L-TN-0006-B1-Technical Notes For Flanges, Spectacle Blinds and Drip RingsGOPINATH KRISHNAN NAIRNo ratings yet

- 30 MM Gi Threaded Rod GR 8.8 - Tbi PDFDocument1 page30 MM Gi Threaded Rod GR 8.8 - Tbi PDFm.aliNo ratings yet

- A2LA 1101 01 Valid To February 28 2017Document4 pagesA2LA 1101 01 Valid To February 28 2017QA LAB ISMNo ratings yet

- Specification For Motor Operated Valve (MOVs)Document9 pagesSpecification For Motor Operated Valve (MOVs)prabha haranNo ratings yet

- QC10-H-051 M11 Special Fittings-Rev01Document8 pagesQC10-H-051 M11 Special Fittings-Rev01kkrq13No ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument1 pageInspection & Testing Requirements Scope:: Test and Inspection Perazhar enggNo ratings yet

- J-ST-2028 Rev.BDocument28 pagesJ-ST-2028 Rev.BErol DAĞNo ratings yet

- 175 023400Document2 pages175 023400Abu Anas M.SalaheldinNo ratings yet

- PV 6702 EnglischDocument13 pagesPV 6702 Englischjopster84No ratings yet

- Yonks Tubing A Inox 3-8Document1 pageYonks Tubing A Inox 3-8Fercomil S.A.SNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- Welding-Joining-InstructionsDocument1 pageWelding-Joining-Instructionshanz bermejoNo ratings yet

- SR Al WPS 011 BWDocument2 pagesSR Al WPS 011 BWhanz bermejoNo ratings yet

- JRY 02CS PipeDocument2 pagesJRY 02CS Pipehanz bermejoNo ratings yet

- Son WPS 262 WQTDocument1 pageSon WPS 262 WQThanz bermejoNo ratings yet

- PWPS Image 1 1024x1024Document1 pagePWPS Image 1 1024x1024hanz bermejoNo ratings yet

- C. 6GR Test Schedule (Mar. 13, 2023)Document1 pageC. 6GR Test Schedule (Mar. 13, 2023)hanz bermejoNo ratings yet

- AWS Certified-Welder-Application (01-2023)Document2 pagesAWS Certified-Welder-Application (01-2023)hanz bermejoNo ratings yet

- Tutorial How To Change The Sleep Settings On Your Acer Laptop ScreenshotsDocument3 pagesTutorial How To Change The Sleep Settings On Your Acer Laptop Screenshotshanz bermejoNo ratings yet

- Modes of Project FinancingDocument81 pagesModes of Project FinancingjasiaahmedNo ratings yet

- Prose: 5 The Summit Within: I Never Dreamed I Would Encounter A Snake in My BackyardDocument28 pagesProse: 5 The Summit Within: I Never Dreamed I Would Encounter A Snake in My BackyardSmiley CrochetNo ratings yet

- Application of Capital Structure Theories. A Systematic ReviewDocument27 pagesApplication of Capital Structure Theories. A Systematic ReviewAhmed BakhtNo ratings yet

- Max Test Strip Insert-En 190603Document2 pagesMax Test Strip Insert-En 190603Andy LavandeNo ratings yet

- Microsoft Excel 2007 Chris MenardDocument20 pagesMicrosoft Excel 2007 Chris MenardNandeesh GowdaNo ratings yet

- Classical and Quantum Chaos (Physics, Math)Document751 pagesClassical and Quantum Chaos (Physics, Math)dsecondoNo ratings yet

- 02 ExplorationDocument50 pages02 ExplorationYernar TiyntayevNo ratings yet

- Starrett Decimal Equivalent Card (Bulletin 1317)Document2 pagesStarrett Decimal Equivalent Card (Bulletin 1317)Franz CorasNo ratings yet

- E2.4 Indices 2A Topic Booklet 1 1Document8 pagesE2.4 Indices 2A Topic Booklet 1 1Ahmed AbdulhakeemNo ratings yet

- Time Value of Money-PowerpointDocument83 pagesTime Value of Money-Powerpointhaljordan313No ratings yet

- 100 Interview Questions On Hadoop - Hadoop Online TutorialsDocument22 pages100 Interview Questions On Hadoop - Hadoop Online Tutorialsamarbhai100% (1)

- .Labitec.: Platelet Aggregation & Coagulation SystemsDocument4 pages.Labitec.: Platelet Aggregation & Coagulation SystemsBivaria GrupNo ratings yet

- DPWH Specifications For WaterstopsDocument6 pagesDPWH Specifications For WaterstopsFrancis DomingoNo ratings yet

- Embraer Spec E195 web-ENDocument2 pagesEmbraer Spec E195 web-ENIgor MedeirosNo ratings yet

- Design and Analysis of COTTER JOINT Using Autodesk Inventor 2013 and ANSYS WorkbenchDocument22 pagesDesign and Analysis of COTTER JOINT Using Autodesk Inventor 2013 and ANSYS WorkbenchamuNo ratings yet

- MongoDB Practice CommandsDocument10 pagesMongoDB Practice Commandskapilkashyap3105No ratings yet

- CH 8 AnswersDocument5 pagesCH 8 AnswersMark Anthony25% (4)

- Fundamentals of Computer GraphicsDocument58 pagesFundamentals of Computer GraphicsISHAAN TAKKARNo ratings yet

- CMD-105 - Migrating Your CONTROL-M Environment To The Latest VersionDocument37 pagesCMD-105 - Migrating Your CONTROL-M Environment To The Latest Versionsam33961No ratings yet

- Karnaugh Map: Engr. Pablo B. Asi Engr. Leni A. Bulan Engr. Liza R. MaderazoDocument18 pagesKarnaugh Map: Engr. Pablo B. Asi Engr. Leni A. Bulan Engr. Liza R. MaderazoDexter DoteNo ratings yet

- Report 2 Water Absorption of BlockDocument8 pagesReport 2 Water Absorption of BlockZhiwar oramariNo ratings yet

- Technical Data Sheet: Rasant DBDocument2 pagesTechnical Data Sheet: Rasant DBRakesh SwamiNo ratings yet

- A Technical Seminar On: Suspension SystemDocument24 pagesA Technical Seminar On: Suspension SystemRanjan suvarnaNo ratings yet

- Sensorless Field OrientedDocument8 pagesSensorless Field Orientedmv1970No ratings yet

- MCQ's of Maths-IDocument11 pagesMCQ's of Maths-IAnsari Sameer100% (1)

- School ManualDocument69 pagesSchool Manualsushanta121808No ratings yet

- TNT PH 2 PLDT ROSARIO - As-Built PlanDocument3 pagesTNT PH 2 PLDT ROSARIO - As-Built PlanDebussy PanganibanNo ratings yet