Professional Documents

Culture Documents

30-PU-152-51602_H

30-PU-152-51602_H

Uploaded by

hasan.mohamed2305Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

30-PU-152-51602_H

30-PU-152-51602_H

Uploaded by

hasan.mohamed2305Copyright:

Available Formats

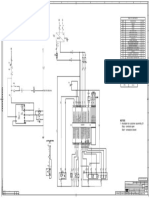

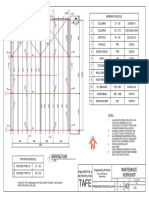

8 7 6 5 4 3 2 1

30-XC-501 C V

GENERAL NOTES

V C PELLETS

PART OF PP3/PP4 PELLET BLENDING PACKAGE 12"-30XC501-AP-81021-CON51-H8-DB-GK41 DB

PELLETS

12"-30XC501-AP-81041-CON51-H8-DB-GK41 DB 30-PU-152-51652 7382 NOTES:

35323 30-PU-152-51654 30-XC-501 FROM DIVERTER VALVE 1) ALL EQUIPMENT TO BE GROUNDED.

PART OF PP3/PP4 PELLET BLENDING PACKAGE 30-XC-501-MD-574B

FROM DIVERTER VALVE BLENDING HOPPER 2) PSV DIRECTLY INSTALLED ON K21 NOZZLE FLANGE.

A1

30-XC-501-MD-572D 30-XC-501-MH-570B 3) DELETED.

BLENDING HOPPER PELLETS

30-XC-501-MH-570D DB 8"-45XC801-AP-74031-CON72-H8-DB-GK41 4) THREE WASHING NOZZLES IN EACH SILO. SUBJECT TO VENDOR INFORMATION.

PELLETS 45-PU-152-81523 35336 5) BOTTOM SILO CONE PROVIDED WITH NO. 5 NOZZLES FOR FLUSHING OF PP PELLETS WITH AIR.

DB

F

8" -45XC801-AP-74031-CON72-H8-DB-GK41

35330 45-PU-152-81523 I-5231 FROM DIVERTER VALVE 6) HS FOR FFS BAGGING MACHINE. (NEAR FFS BAGGING MACHINE).

45-I-8201 45-XC-801-MD-814

FROM DIVERTER VALVE 7) HS FOR FFS BAGGING MACHINE. (NEAR FFS BAGGING MACHINE)

45-XC-801-MD-814 45-XC-801 I-5402 ELUTRIATOR

8) PROVIDE POWER CONNECTION AND DATA CONNECTION FOR BAGGING MACHINE. PLANT AIR CONNECTION IS

I-5401 45-XC-809-NE-807

ELUTRIATOR 45-XC-809-NE-807 PART OF PELLET CONVEYING SYSTEM 55 SHOWN ON UTILITY DISTRIBUTION. DWG. NO 30-PU-152-09090-02

I-5211

PELLETS I-5353 9) HS FOR BIG BAG MACHINE OR CONTAINER BACK FILLER (AT GROUND FLOOR,

8" -44XC801-AP-74023-CON72-H8-DB-GK41 DB I-5303 CLOSE TO BIG BAG MACHINE WORKING PLACE).

7114 44-PU-152-81522 45-I-7874 I-5333 45-XC-801 10) UTILITY AIR FLOW CONTROLLED BASED ON SILO BOTTOM VALVE POSITION.

44-I-7874 PART OF PELLET CONVEYING SYSTEM 55 V

FROM DIVERTER VALVE I-5310 11) WASH WATER PIPING CONNECTION BY VENDOR, NO POCKETS ALLOWED.

44-XC-801-MD-812 12) CONNECTIONS FOR PP3/PP4 FFS BAGGING MACHINE 30-XL-601A/B NO FLANGE / COUNTER FLANGE IS NEEDED

I I 45-I-7874

ELUTRIATOR

V

44-XC-801 44-I-7874 C 13) TOP MANHOLE TO BE EQUIPPED WITH MANCATCHER SIDE MANHOLE TO BE EQUIPPED WITH PLUG INSERT,

44-XC-809-NE-807 PART OF PELLET CONVEYING SYSTEM 45 NOTE 11 NOTE 21 I-5304

I-5354 BOLT COVER.

45-XC801-SP-5587 I I

30-SP-5029 6"x2"

14) RADAR PROBE (K6 NOZZLE) TO BE LOCATED TO ENSURE MINIMAL INTERFERENCE

6"x2"

NOTE 11 LSHH LAHH HS I-5311

C 2" 2" DURING BLENDER FILLING.

30-XC501-SP-5596 5226

45-XC801-SP-5590

5226 5226 2" 2" I-5334

2" 2" 12"-30-PP-50045-A0KP12-V 15) NOZZLE FOR BOTTOM OF THE BLENDER WASHING BELOW CHINESE HAT AND FOR WASHING INTERNAL

NOTE 21 LSHH LAHH HS

30-SP-5031

30-SP-5028

VIBR. AVAILABLE BLENDING PIPES. INTERNAL DISTRIBUTION RING DETAILS BY BLENDER VENDOR.

30-SP-5030

44-XC801-SP-5586

TO SAFE NOTE 17 8003

30-SP-5032

5020 5020 5227 2" LINE TO BE SELF DRAINING TO HEADER PIPE.

SEE DETAIL `B'

LOCATION VIBR.

PSET=0.005/0.125 barg NOTE 17 I-5401

NOTE 18

30-SP-5027

30-XC501-SP-5588 16) K7 NOZZLE SHALL BE PLACED MINIMUM AT 1 METER FROM NOZZLES N3, N4 AND N13.

ATM NOTE 2 PSV I-5402

12"-30-PP-50044-A0KP12-V NOTE 2 PSET=0.005/0.125 barg I-5211 17) N3, N4 WITHOUT FLANGE. PIPE/SILO CONNECTION WITH EXPANSION JOINT.

PSV 4" 4" 5821

4" 2" ATM 45-I-8201 18) BREAK FLANGES TO BE AVOIDED IN WASH WATER LINE ALONG SILO SHELL.

4" 5820 H 20" NC H

8003 4" LT LI 4"

SEE DETAIL `B'

N10C

LI

N10C

2"3" LT NOTE 14 19) MIN.SLOPE 60° FROM THE HORIZONTAL.

E

N3 N3 3"

N10B

N10B

N8

20" N4 28" 4" 5019 NOTE 14 5019 N8 28" 4" 5015 5015 20) SLIDE GATE VALVE SHALL BE ABLE TO CLOSE EVEN INCASE OF LINE FILLED WITH PRODUCT.

N10A

N10A

L 2" K14

NC N22 K7

16" N5

K6

RADAR 16" 20" N22 K7

12" N5

K6 L

NOTE 13 3" NOTE 13 2" M1B 2" RADAR 21) WITH CHINESE CAP.

N13 24" M1B N13 24"

NOTE 10

I-5303

GENERAL NOTES:

K25 K25 22) SAMPLING PIPE TO BE EXTENDED TO FLOOR LEVEL. CAP TO BE PROVIDED ON SAMPLING LINE

K14 T H N15 T H

N15 20" NOTE 17

K21 PT PI N4 NOTE 17 K21 PT PI 23) FIRST SAMPLE VALVE AS CLOSE AS POSSIBLE TO THE SAMPLING NOZZLE. SECOND SAMPLING VALVE AT

FDALL O FIC 12" 3" 12" 12" FLOOR LEVEL.

3/4" 5182 5182 3/4" 5183 5183 A) PROVIDE

ALL FLAREALINES TO BECONNECTION

SLOPED TOWARDS THE FLARE HEADER WITHSO

TOPTO

ENTRY.

5008 5008 24) FLANGED ON THE SAMPLING VALVE HAVE THE POSSIBILITY TO MOVE

NOTE 4 NOTE 4 THE WASHING SPOOL IN POSITION.

B) SCOPE BREAK BETWEEN VENDOR AND BOROUGE 3 EPC CONTRACTOR C V

FDAL 30-DJ-503C 30-DJ-504C GENERAL

IS INDICATEDNOTES:

BY:

3"

2"-30-UA-50019-A0KU01-V 5008 30-DJ-503B 30-DJ-504B A)C)ALL

424 ALLFLARE LINES TOTAG

INSTRUMENT BE SLOPED TOWARDS

AND INTERLOCK THE FLARE

NUMBERS ON HEADER WITH TOP

THIS DRAWING ENTRY.

HAVE THE PREFIX 30.

V V

FV 30-DJ-503A FDALL

30-DJ-504A CONTAINER XHS I

I-5334

B) SCOPE BREAK BETWEEN VENDOR AND BOROUGE 3 EPC CONTRACTOR C V H

LOADING IS INDICATED BY:

3/4" 3/4" 5008 5009 NOTE 10 5250A

PLANT AIR I-5304 PERMISSIVE

FT FDAL O FIC C) ALL INSTRUMENT TAG AND INTERLOCK NUMBERS ON THIS DRAWING HAVE THE PREFIX 30.

13007 30-PU-152-09090-02

5008 FO 5009 5009

2"x1"

VORTEX

2"x1" 3"x2"

BIG BAG XHS I

I-5334 REFERENCES:

1-1/2" LOADING FOR GENERAL NOTES AND REFERENCES SEE DRG. P3-PU-152-01000-01÷17;

6"

6"

V V 5250B

PERMISSIVE PIPING AND INSTRUMENTATION DIAGRAM-SYMBOLS, ABBREVIATIONS AND GENERAL NOTES.

NC 30-TS-503 FV 30-TS-504

3"

30-VZ-50006-A0KP12-N 3/4" 3/4" 5009 30-VZ-50005-A0KP12-N DETAIL "A" (WATER DISCHARGE CONNECTION)

PLANT AIR

2"-30-UA-50018-A0KU01-V FT NORMAL POSITION

13008 30-PU-152-09090-02 8003 8003 OPEN XHSH

424 2"x1"

5009

2"x1" FO 3"x2"

D

5250B 20"

VORTEX 30-XC521-SP-5783 / 30-XC521-SP-5784 ZEL ZLL I

1-1/2" I #1 #1

NOTE 9

NC I ZLH ZEH 30-ME-252-8001(MAGENETIC BARS) I-

CONTAINER I-5333 I-5334 CLOSE XHSL FLEXIBLE HOSE

XHS I #1 #1 8" 2"

T

OPEN XHSH LOADING CONNECTION NOTE 22,

5248A 5250B 30-ME-252-8001

I-5333 5248B PERMISSIVE I- FLEXIBLE

#18" 20" T 2" 23, 24 H

24" 24" FOR SILOS #1 I- HOSE CONNECTION

I DETAIL "B" (FLUSHING OFF-GAS OUTLET)

NOTE 9 M1A M1A NOTE 13

ZLH 5310 TO BLENDER SILOS OFF-GAS HEADER

I-5333 FOR SILOS

30-TS-503 #5417

1 I-

ZLL I-5333 WASHING POSITION

XHSL BIG BAG XHS I (SEE PID 30-PU-152-51646-01)

CLOSE NOTE 13 ZLH 5310

LOADING ZLH 5311

5248B 5248B 30-TS-503

30-TS-504 5417

5418 ZLL I-5333 20"

PERMISSIVE ZLL I-5334

NOTE 18

ZLH 5311

30-TS-504 5418

ZLL I-5334 8" DETAIL "B" (FLUSHING OFF-GAS OUTLET)

LAL 20" NOTE 24

V TO BLENDER SILOS OFF-GAS HEADER

60° 5513B 60°

H

(SEE PID 30-PU-152-51646-01)

I-5377 ÷ I-5380 C V

I-5390 2" LAL LAL I-5377 ÷ I-5380 C

V 2" 20"X12"

I-5311 ÷ I-5320 30-SP-5059 6" N12 HZLL 6" N9 N12 5514A 5514B I-5390

I-5308 ÷ I-5309 NOTE 15 NOTE 15 I-5334 HZEH

LSL LAL 5404 12"-30-PP- 50005/50007 HVL

I-5328 N9 C FOR DETAILS SEE P&ID I-5328 XXXX

LSL TO COLLECTING

30-SP-5060

I-5333 6" FOR DETAILS SEE P&ID I-5312 ÷ I-5320 XXXX

I-5310 VIBR 5513 5513A 30-PU-152-51646-01 SYSTEM

H HVL 30-PU-152-51646-01 8" N19 5514 I-5311 I-5308 ÷ I-5310 V

I O HZEL K24 2" VIBR H

C

I-5310 I 8" N19 O I N.B. : SPOOL PIECE SHALL BE OPERABLE HZEL

5403 I-5311 HZEL HVL K24 2" I-5311 C

5403 6" N18 I-5353 I-5303 I 6"-30-UW-50012-A0KU16-V BY ONLY ONE PERSON.

L HZLL I-5354

XXXX 30-SP-YYYY

I-5310 I 5404 5404 6" N18 2" L N22

XV EP2 5403 LSLL

K23 2" I-5353 EP2 K23 130 24"

3" N17 LSLL LALL I-5353 I-5333 5021

5233 3" N17 VIBR. LALL

I-5353 5018 5018 H XV

WASH WATER 20" VIBR. O O I HZLH HZEH 20"

I-5310 5021 5234 WASH WATER

19429 30-PU-152-51611 O N2 5404 5404 N2 NOTE 5

FC HZEH HZLH I L 2" 2" 30-PU-152-51611 7496

FROM WASH WATER FILTER 30-51602-V1 N16A N16B

I-5354 TYPE 2A

TYPE 2A 2" LO 5403 5403 2" 2" NOTE 5 N16A N16B FC LO FROM WASH WATER FILTER 30-XC-510

30-NF-508 WASH WATER 2" T

TANK 30-TK-508 T O 30-NF-508 WASH WATER

6"-30-UW-50011-A0KU16-V NOTE 20 30-XC521-SP-5516 30-51602-V2 REVAMP SCOPE FOR PP3/PP4 PART OF PP3/PP4 BLENDER

NOTE 20 30-XC521-SP-5515 TANK 30-TK-508

20"-30XC521-PE-81630-GRA51-H8-V-GK46.3 6"X4" FLUSHING SYSTEM PACKAGE

130 6" X4" 1"x3/4" MANUAL VALVE MANUAL VALVE PLANT AIR

20" 30-XC521-SP-5783 1"x3/4" 1"-30-UA-50017-A0KU01-V

30-XC521-SP-5783

34

30-XC521-SP-5783

M

I-5354

M

30-PU-152-09090-02 15065

WASHING WATER 0.2%

424

REVAMP PROJECT SCOPE OF WORK IS RED-MARKED.

30-XC-510

4"-30-PP-50006-A0KP12-V O 1"x3/4" 20" 1"x3/4" 0.2%

30-PU-152-09141 15964 SEE DETAIL "A" 30-ME-252-8001

WASHING WATER

4"-30-PP-50008-A0KP12-V

TO COLLECTING SYSTEM 8003 NOTE 22 15950 30-PU-152-09141

NOTE 22 8003 TO COLLECTING SYSTEM

PLANT AIR SEE DETAIL "A"

1"-30-UA-50020-A0KU01-V I-5334 H I-5304 H 24-Jul-20 ISSUED FOR FEED PACKAGE Baratelli Spinelli Brambilla

XV XV O I I-5334

15067 30-PU-152-09090-02 3/4" I-5311 ISSUED FOR COMPANY REVIEW

AF 3/4

30-XC521-SP-5784

G 20-Sep-19 Baratelli Spinelli

5321 FFS Brambilla

424 SEQ-5231 TY L /E " 5322 AFL /EFC XHS I

SEQ-5232 XV XV 3/4" L BAGGING Prepared Checked Approved

PE FC TYPE 4A 3/4" 5251A

Rev. Date Description

20" X 12" I-5333 4A 20" X 12" 5323 4A

5323 PERMISSIVE By By By

/4"

1" 5324 AFL /EFC C

x3

x3 SEQ-5211 AFL /EFC ABU DHABI POLYMERS COMPANY LIMITED

1"

O /4" TYPE 4A TYPE 4A

XHSH OPEN 1" 1" 20"-30XC521-PE-81636-GRA51-H8-V-GK46.3 30-XC-521 SEQ-5212 1" (BOROUGE)

/4"

x3 V

B

12" PP3/PP4 DIVERTER O I-5334 OPEN CLOSE

x3

I-5333 /4"

1"

5249B VALVES PACKAGE 1" 1" XV NOTE 8, 12

XHSH XHSL

MI "

PETROCHEMICALS PROJECT

16

I XHS TO PP3/PP4 FFS

N.

NOTE 8, 12 12" 5251

NOTE 7 AFL 12"-30XC521-PE-81637-GRA51-H8-V-GK46.3 BAGGING MACHINE 5251B 5251B COMPANY PROJECT NO PROJECT TITLE:

MI "

5249A H

16

H AFL TO PP3/PP4 FFS 7500000872

N.

I EFC GRAVITY FLOW I 30-XL-601A/B/C NOTE 6

XHSL

5249B CLOSE FFS

EFC

TYPE 4A

TYPE 4A

XV

NOTE 19 BAGGING MACHINE

30-XL-601A/B/C XV

AFL AFL

12"-30XC521-PE-81631-GRA51-H8-V-GK46.3

GRAVITY FLOW

(P&ID 30-PU-152-

CONTRACTOR PROJECT NO

4080 - P4

BOROUGE 4 MAIN FEED PROJECT

L L EFC EFC NOTE 19 61001/61002/61003 PELLETS

BAGGING 5249 (P&ID 30-PU-152- I-5304 TYPE 4A TYPE 4A 16"-30XC521-PE-81632-GRA51-H8-V-GK46.3 DRAWING TITLE:

I-5303 5250 PIPING AND INSTRUMENTATION DIAGRAM

PERMISSIVE XV 61001/61002/61003 I-5311

7119 30-PU-152-51622

UNIT -30, PRODUCT HANDLING PP3/PP4

I-5310 NOTE 19

5248 TO DIVERTER VALVE BLENDER SILOS TS-503/504

WASHING WATER 30-XC-521-MD-542D

12"-30-PP-50005-A0KP12-V VERTICAL BOROUGE DOCUMENT CLASS' N PROJECT DRAWING NO REV: H

30-PU-152-09141 14013

8003 WASHING WATER

TO COLLECTING SYSTEM 12"-30-PP-50007-A0KP12-V VERTICAL CONTRACTOR: 4080-XZ-DM-300051602 SHEET UNIT: 30

14012 30-PU-152-09141 1 BOROUGE: 30-PU-152-51602 OF AREA: 51

8003 TO COLLECTING SYSTEM

16"-30XC521-PE-81638-GRA51-H8-V-GK46.3 NOTE 19 CADD

REF.

30-PU-152-51602-ISH SCALE: - SHEET

SIZE A1

This document contains CONFIDENTIAL and PROPRIETARY information of Borouge. Tecnimont Identification code

PELLETS 3583-XZ-DM-3051602

This information is not to be used, disclosed or reproduced in whole or in part to anyone

30-DJ-503A 30-DJ-503B 30-DJ-503C 30-DJ-504A 30-DJ-504B 30-DJ-504C 30-TS-503 30-TS-504 30-XC-521 30-XC-501 44-XC-801 45-XC-801 7115 30-PU-152-51622

outside of Borouge and subsidiaries, except pursuant to a written agreement with Borouge

TO DIVERTER VALVE

PP3/PP4 PELLET PELLET CONVEYING PELLET CONVEYING 30-XC-521-MD-542C

SPRAY NOZZLE SPRAY NOZZLE SPRAY NOZZLE SPRAY NOZZLE SPRAY NOZZLE SPRAY NOZZLE PP3/PP4 DIVERTER BLENDING PACKAGE SYSTEM 45 SYSTEM 55

PP BLENDER SILO PP BLENDER SILO VALVES PACKAGE

A

PRESSURE DROP: 1 BAR PRESSURE DROP: 1 BAR PRESSURE DROP: 1 BAR PRESSURE DROP: 1 BAR PRESSURE DROP: 1 BAR PRESSURE DROP: 1 BAR TYPE: VERTICAL TYPE: VERTICAL CAPACITY: 72 t/h CAPACITY: 72 t/h CAPACITY: 72 t/h

TOT. VOL.: 2140 m³ TOT. VOL.: 2140 m³ CAPACITY: 170 t/h

FLOWRATE: 60 m³/h FLOWRATE: 60 m³/h FLOWRATE: 60 m³/h FLOWRATE: 60 m³/h FLOWRATE: 60 m³/h FLOWRATE: 60 m³/h (EACH LINE) POLYOLEFINS UNITS - BOROUGE 3 PROJECT - RUWAIS, U.A.E.

MAT'L: SS MAT'L: SS MAT'L: SS MAT'L: SS MAT'L: SS MAT'L: SS DIA.: 9.5 m DIA.: 9.5 m

CYL. HEIGHT: 27.5 m CYL. HEIGHT: 27.5 m PIPING AND INSTRUMENTATION DIAGRAM

CONE HEIGHT: 8050 mm CONE HEIGHT: 8050 mm DENSE PHASE DENSE PHASE

DP (barg): -0.015/0.15 DP (barg): -0.015/0.15

NOTE 1 UNIT-30,

NOTE 1

DT (°C): 5/100

LINING:

DT (°C): 5/100

LINING:

PRODUCT HANDLING, PP3/PP4

MOC: ALUMINIUM MOC: ALUMINIUM BLENDER SILOS, TS-503/504

INSUL.: N INSUL.: N

DESIGN FV: NO DESIGN FV: NO Company document classification Size Original scale Borouge Identification Code Rev

NOTE 1 NOTE 1 30-PU-152-51602 R1

1 A1 -

FILE :30-PU-152-51602 REV R

You might also like

- M365 BMS NE100R-R0E: BATT - Pack - SCHDocument2 pagesM365 BMS NE100R-R0E: BATT - Pack - SCHKoma Tozz88% (8)

- Rumble 200 V3 Schematics-DiagramsDocument4 pagesRumble 200 V3 Schematics-DiagramsOrlandd Sanchezz100% (1)

- Group 3 Disassembly and Assembly: 1. Hydraulic Gear PumpDocument19 pagesGroup 3 Disassembly and Assembly: 1. Hydraulic Gear PumpAndré TarginoNo ratings yet

- Fender Rumble 40 v3 SCHDocument7 pagesFender Rumble 40 v3 SCHCarlos ZaninNo ratings yet

- Fender Rumble 100 V3 TDA8950-88534Document7 pagesFender Rumble 100 V3 TDA8950-88534Claudio Ariel Vera trussy100% (1)

- Electrical Wiring: DN 32 DN 32Document1 pageElectrical Wiring: DN 32 DN 32juring bitolaNo ratings yet

- No Requiere Aprobación Del Cliente: IG N E DDocument1 pageNo Requiere Aprobación Del Cliente: IG N E Dnestor159357No ratings yet

- General Notes:: Dhi Qar Combined Cycle Power Plant ProjectDocument1 pageGeneral Notes:: Dhi Qar Combined Cycle Power Plant Projectmustafa1989ocNo ratings yet

- Fluidics 5800Document1 pageFluidics 5800Héctor GarcíaNo ratings yet

- TA22-24DEF-001 PNID D-400-24-50-0003 - REV - F4 - MarkupDocument1 pageTA22-24DEF-001 PNID D-400-24-50-0003 - REV - F4 - Markupjk.jackycheokNo ratings yet

- No Requiere Aprobación Del Cliente: Responsabilidad Exclusiva Del Autor U Originador, Según ContratoDocument1 pageNo Requiere Aprobación Del Cliente: Responsabilidad Exclusiva Del Autor U Originador, Según Contratonestor159357No ratings yet

- 3 Detalle 2 Detalle: IE IE IEDocument1 page3 Detalle 2 Detalle: IE IE IEHans ContrerasNo ratings yet

- 220 M6 0330 00005 - Rev5Document1 page220 M6 0330 00005 - Rev5Cristhian Alexander Aguilar ChavezNo ratings yet

- No Requiere Aprobación Del Cliente: in WorkDocument1 pageNo Requiere Aprobación Del Cliente: in Worknestor159357No ratings yet

- Ig N e D: Ags Ral WMV Cle WMV Ral VSM AcpDocument1 pageIg N e D: Ags Ral WMV Cle WMV Ral VSM Acpnestor159357No ratings yet

- Drawing For Lubrication MillDocument2 pagesDrawing For Lubrication MillDeepakNo ratings yet

- Epcc05 MDR 421 STR DWG 000 0072 05Document1 pageEpcc05 MDR 421 STR DWG 000 0072 05RANJEET PRATAP SINGHNo ratings yet

- Ø Holes: GirderDocument1 pageØ Holes: GirderErika Faye GutierrezNo ratings yet

- Section E-E: Slab On Grade CORBEL 20x16ht DemolitionDocument1 pageSection E-E: Slab On Grade CORBEL 20x16ht DemolitionjafarNo ratings yet

- I I I I: No Requiere Aprobación Del ClienteDocument1 pageI I I I: No Requiere Aprobación Del Clientenestor159357No ratings yet

- Second Floor Plan (Main Building) : Stair Lobby Connecting Walk/PathwayDocument1 pageSecond Floor Plan (Main Building) : Stair Lobby Connecting Walk/PathwayCarl Justin AzucenaNo ratings yet

- Paladin Pellet Mill 2000Document2 pagesPaladin Pellet Mill 2000Britton HarperNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Pe1024-Mb-Mfb030-011200 11 GT#1 MBH 2Document1 pagePe1024-Mb-Mfb030-011200 11 GT#1 MBH 2Aldo Quispe HuarachiNo ratings yet

- Construction PlansDocument57 pagesConstruction PlansDaniel TrivinoNo ratings yet

- Alternar Conectores (600mm) : Sección A-A (Viga Transversal Superior)Document1 pageAlternar Conectores (600mm) : Sección A-A (Viga Transversal Superior)Manolo Gonzalez PolarNo ratings yet

- Epcc05 MDR 421 STR DWG 000 0072 01Document1 pageEpcc05 MDR 421 STR DWG 000 0072 01RANJEET PRATAP SINGHNo ratings yet

- HCD-ECL77BT - ECL99BT DiagramaDocument14 pagesHCD-ECL77BT - ECL99BT DiagramaAmin Santana100% (1)

- CBT3 LCR SC - CBT3-DES1 Control CircuitDocument1 pageCBT3 LCR SC - CBT3-DES1 Control Circuitsreeagile.esNo ratings yet

- Item DesignationDocument1 pageItem DesignationTahseenNo ratings yet

- Chip - Pu: 100nF C32 100nFDocument1 pageChip - Pu: 100nF C32 100nFCheft Lit RamosNo ratings yet

- HH45, HH55, HH65, and HH75 Harvester Heads Electrical SystemDocument2 pagesHH45, HH55, HH65, and HH75 Harvester Heads Electrical SystemGilvan JuniorNo ratings yet

- Item DesignationDocument1 pageItem DesignationTahseenNo ratings yet

- N OR TH: Key PlanDocument1 pageN OR TH: Key PlanArnold Ochochoque ArcosNo ratings yet

- PSP01 Ag10 Mta01 00001 Ou100053862 R1Document1 pagePSP01 Ag10 Mta01 00001 Ou100053862 R1Louis BujandaNo ratings yet

- Epcc05 MDR 421 STR DWG 000 0072 16Document1 pageEpcc05 MDR 421 STR DWG 000 0072 16RANJEET PRATAP SINGHNo ratings yet

- Turbo-Ups Intn'L 640-0218Document1 pageTurbo-Ups Intn'L 640-0218shalkuNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Epcc05 MDR 421 STR DWG 000 0072 15Document1 pageEpcc05 MDR 421 STR DWG 000 0072 15RANJEET PRATAP SINGHNo ratings yet

- 2INCHES UPVC PIPE (73.47%) : (1,484 / 2,020 Meters)Document1 page2INCHES UPVC PIPE (73.47%) : (1,484 / 2,020 Meters)Jhn Cbllr BqngNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Ae304 - Wall Section 1&2Document1 pageAe304 - Wall Section 1&2Omar ZakiNo ratings yet

- Samb108 sch0.8 - de - EfrcomDocument8 pagesSamb108 sch0.8 - de - EfrcomHotel WijayaNo ratings yet

- NT1000 - Spindle 1Document1 pageNT1000 - Spindle 1Felipe SalesNo ratings yet

- 6M33 Series CAD English Version Drawing UNLCKD-ModelDocument1 page6M33 Series CAD English Version Drawing UNLCKD-ModelMukulNo ratings yet

- Ele Schematic With Links PDFDocument25 pagesEle Schematic With Links PDFPeter JohnNo ratings yet

- Connected To Sdvr-G-Co: SCC-TC-E-601Document1 pageConnected To Sdvr-G-Co: SCC-TC-E-601SaeidKHOKHANo ratings yet

- SEE DRAWING 1925-001A - PC For Pull Cord Cable Installation: Req'D QtyDocument1 pageSEE DRAWING 1925-001A - PC For Pull Cord Cable Installation: Req'D QtyYerko NavarroNo ratings yet

- RP2 - D Ep R420 1225 1102 - Z1 - 0030Document1 pageRP2 - D Ep R420 1225 1102 - Z1 - 0030Mubashir fareedNo ratings yet

- ACC AutoDocument1 pageACC AutoKMTEC Prudente Movel1No ratings yet

- Anchor Cage (Weight For Components) - 75921113 - R0Document1 pageAnchor Cage (Weight For Components) - 75921113 - R0Milena CabarcasNo ratings yet

- Schematic STM32F103Document1 pageSchematic STM32F103khoaNo ratings yet

- Cielorraso LivingDocument1 pageCielorraso LivingLucia SaranNo ratings yet

- 6029 716 777 V PDFDocument1 page6029 716 777 V PDFMarcelo Gomez100% (1)

- KA2 KA3 S1a: NotesDocument1 pageKA2 KA3 S1a: NotescristianNo ratings yet

- La Cartagenera by Francisco TarregaDocument9 pagesLa Cartagenera by Francisco TarregaDANIEL PARKNo ratings yet

- Lanzar Opts150.4 Car Amplifier SCHDocument1 pageLanzar Opts150.4 Car Amplifier SCHabung teaNo ratings yet

- Section A-A: Issued For ConstructionDocument1 pageSection A-A: Issued For ConstructionjafarNo ratings yet

- H047&H048-CMS-SD-04-12-2 - Cctv-General Position - As Built DrawingDocument1 pageH047&H048-CMS-SD-04-12-2 - Cctv-General Position - As Built DrawingDedeNazaludinNo ratings yet

- Ae305 - Wall Section 3Document1 pageAe305 - Wall Section 3Omar ZakiNo ratings yet

- 30-PU-152-51603_HDocument1 page30-PU-152-51603_Hhasan.mohamed2305No ratings yet

- 30-PU-152-51604_HDocument1 page30-PU-152-51604_Hhasan.mohamed2305No ratings yet

- 30-PU-152-51606_HDocument1 page30-PU-152-51606_Hhasan.mohamed2305No ratings yet

- 30-PU-152-11601_HDocument1 page30-PU-152-11601_Hhasan.mohamed2305No ratings yet

- 30-PU-152-11610_HDocument1 page30-PU-152-11610_Hhasan.mohamed2305No ratings yet

- 30-PU-152-51605_HDocument1 page30-PU-152-51605_Hhasan.mohamed2305No ratings yet

- PS02 - 11 of 12Document1 pagePS02 - 11 of 12hasan.mohamed2305No ratings yet

- Planner For JEE Advanced 2024Document1 pagePlanner For JEE Advanced 2024hasan.mohamed2305No ratings yet

- Ameer LoaDocument2 pagesAmeer Loahasan.mohamed2305No ratings yet

- PS13-58 of 58Document1 pagePS13-58 of 58hasan.mohamed2305No ratings yet

- PS14 - 01 of 04Document1 pagePS14 - 01 of 04hasan.mohamed2305No ratings yet

- PS02 - 10 of 12Document1 pagePS02 - 10 of 12hasan.mohamed2305No ratings yet

- Natural GasDocument1 pageNatural Gashasan.mohamed2305No ratings yet

- PS02 - 12 of 12Document1 pagePS02 - 12 of 12hasan.mohamed2305No ratings yet

- 6001 CorrectedDocument2 pages6001 Correctedhasan.mohamed2305No ratings yet

- PS13-58 of 58 1Document1 pagePS13-58 of 58 1hasan.mohamed2305No ratings yet

- Gain and Phase Margin Questions No AnnoDocument54 pagesGain and Phase Margin Questions No Annohasan.mohamed2305No ratings yet

- PS12 - 16 of 21Document1 pagePS12 - 16 of 21hasan.mohamed2305No ratings yet

- Si JobsDocument45 pagesSi Jobshasan.mohamed2305No ratings yet

- Notes: Status-CDocument1 pageNotes: Status-Chasan.mohamed2305No ratings yet

- Mechanical OperationDocument76 pagesMechanical Operationhasan.mohamed2305No ratings yet

- Marine ValvesDocument6 pagesMarine ValvesENG PTBBSNo ratings yet

- Belt Cleaning Systems REMA TIP TOP AustraliaDocument44 pagesBelt Cleaning Systems REMA TIP TOP AustraliadexNo ratings yet

- 21castellated Steel BeamDocument11 pages21castellated Steel BeamHozaifaNo ratings yet

- SPI Parameter & Standrad: Process DetailDocument2 pagesSPI Parameter & Standrad: Process DetailAkhilesh KushwahaNo ratings yet

- Structural DrawingsDocument5 pagesStructural DrawingsppprrrabhNo ratings yet

- VT2514 EuroricambiDocument8 pagesVT2514 Euroricambiwilfredo escobar gutierrezNo ratings yet

- Janome 4052LX Sewing Machine Service ManualDocument30 pagesJanome 4052LX Sewing Machine Service ManualiliiexpugnansNo ratings yet

- TecData ASO-BSOL Part1Document1 pageTecData ASO-BSOL Part1Air Repair, LLCNo ratings yet

- Impeller Clutch Torque ConverterDocument3 pagesImpeller Clutch Torque ConverterHack BaeNo ratings yet

- Blackbook On Steam Turbine Power PlantDocument51 pagesBlackbook On Steam Turbine Power PlantvedNo ratings yet

- Course Registration FormDocument1 pageCourse Registration Formabdulghaniyu obaroNo ratings yet

- Reckon-Price List FinalDocument13 pagesReckon-Price List FinalnagarapulaxmiprasadNo ratings yet

- RHB323-V: Document No.: A099-0182 Revision Date: 2008-11-11Document38 pagesRHB323-V: Document No.: A099-0182 Revision Date: 2008-11-11Charlie QiNo ratings yet

- Torque Procedure: 4 and 8 Bolt FlangesDocument8 pagesTorque Procedure: 4 and 8 Bolt FlangesBSL PanipatNo ratings yet

- List of API and ISO Standards For Artificial LiftDocument4 pagesList of API and ISO Standards For Artificial LiftPetroleum PetroleumNo ratings yet

- Questions - All Questions Just To Be Answered For 5 Marks. TOPIC-Engine Room TerminologyDocument5 pagesQuestions - All Questions Just To Be Answered For 5 Marks. TOPIC-Engine Room TerminologyAshutosh Kumar Singh100% (1)

- Sewage Pump DASDocument11 pagesSewage Pump DASindra putraNo ratings yet

- MP April 04Document154 pagesMP April 04Budoy SmithNo ratings yet

- Forged Steel PropertiesDocument2 pagesForged Steel Propertiesrumabiswas853No ratings yet

- Chain Pulley Block: Bhaskar DuttaDocument8 pagesChain Pulley Block: Bhaskar DuttaBhaskar DuttaNo ratings yet

- RFE For Unit 42HA - 41HA - 32HA - 31HA 22HA - 21HA - 12HA - 11HA 2015 - 21-SAG-PSP-T-000886 2016-09-20Document1 pageRFE For Unit 42HA - 41HA - 32HA - 31HA 22HA - 21HA - 12HA - 11HA 2015 - 21-SAG-PSP-T-000886 2016-09-20el_sharkawy2011No ratings yet

- DS AnimalFeedMilling CA 1214 ENGDocument2 pagesDS AnimalFeedMilling CA 1214 ENGmarianoNo ratings yet

- Centrifugal CastingDocument10 pagesCentrifugal CastingRavi Joshi50% (2)

- C19 Square DiffusersDocument21 pagesC19 Square DiffusershimajcpNo ratings yet

- Weld Types and PositionsDocument11 pagesWeld Types and Positionsjohn christian de leonNo ratings yet

- Gambar Kerja Puskesmas Setu RevDocument3 pagesGambar Kerja Puskesmas Setu RevResya AstinNo ratings yet

- ACTAIR 1,5 To 1600Document20 pagesACTAIR 1,5 To 1600Muhamad Ekbar SeninNo ratings yet

- Progressive Safety Gear AdjustmentsDocument31 pagesProgressive Safety Gear AdjustmentsFERNSNo ratings yet

- Seamless Tubes CatalogueDocument10 pagesSeamless Tubes CatalogueHoJienHauNo ratings yet