Professional Documents

Culture Documents

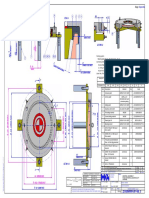

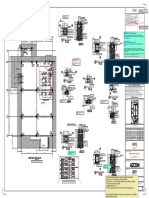

30-PU-152-51606_H

30-PU-152-51606_H

Uploaded by

hasan.mohamed2305Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

30-PU-152-51606_H

30-PU-152-51606_H

Uploaded by

hasan.mohamed2305Copyright:

Available Formats

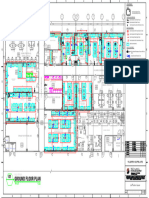

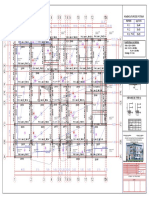

8 7 6 5 4 3 2 1

PELLETS PELLETS GENERAL NOTES

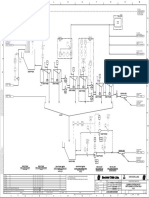

DB 12"-30XC501-AP-81020-CON51-H8-DB-GK41 12"-30XC501-AP-81030-CON51-H8-DB-GK41 DB

35351 30-PU-152-51653 30-PU-152-51653 33980

FROM DIVERTER FROM DIVERTER VALVE NOTES:

30-XC-501-MD-573C

VALVE

30-XC-501 BLENDING HOPPER 1) ALL EQUIPMENT TO BE GROUNDED.

30-XC-501-MD-573B

BLENDING HOPPER PART OF PP3/PP4 PELLET BLENDING PACKAGE 30-XC-501 30-XC-501-MH-570C 2) PSV DIRECTLY INSTALLED ON K21 NOZZLE FLANGE.

A1

30-XC-501-MH-570B PART OF PP3/PP4 PELLET BLENDING PACKAGE 3) DELETED.

4) THREE WASHING NOZZLES IN EACH SILO. SUBJECT TO VENDOR INFORMATION.

PELLETS

DB 5) BOTTOM SILO CONE PROVIDED WITH NO. 5 NOZZLES FOR FLUSHING OF PP PELLETS WITH AIR.

F

8"-45XC801-AP-74033-CON72-H8-DB-GK41 PELLETS

29917 45-PU-152-81522 8"-45XC801-AP-74032-CON72-H8-DB-GK41 DB 6) HS FOR FFS BAGGING MACHINE (NEAR TO FFS BAGGING MACHINE).

FROM DIVERTER VALVE 45-PU-152-81521 35352 7) HS FOR FFS BAGGING MACHINE (NEAR TO FFS BAGGING MACHINE).

45-XC-801-MD-825 FROM DIVERTER VALVE 8) PROVIDE POWER CONNECTION AND DATA CONNECTION FOR BAGGING MACHINE. PLANT AIR CONNECTION IS

ELUTRIATOR 45-XC-801 45-XC-801-MD-826 SHOWN ON UTILITY DISTRIBUTION. DWG. NO 30-PU-152-09090-02

45-XC-809-NE-807 PART OF PELLET CONVEYING SYSTEM 55 45-XC-801 ELUTRIATOR 9) HS FOR BIG BAG MACHINE OR CONTAINER BACK FILLER (AT GROUND FLOOR,

PART OF PELLET CONVEYING SYSTEM 55 45-XC-809-NE-807 CLOSE TO BIG BAG MACHINE WORKING PLACE).

V V 10) UTILITY AIR FLOW CONTROLLED BASED ON SILO BOTTOM VALVE POSITION.

11) WASH WATER PIPING CONNECTION BY VENDOR.NO POCKETS ALLOWED.

PSET=-0.005/0.125 barg

C PSET=-0.005/0.125 barg C 12) CONNECTIONS FOR PP3/PP4 FFS BAGGING MACHINE 30-XL-601A/B NO FLANGE / COUNTER FLANGE IS NEEDED

30-SP-5056 6"x2"

SEE DETAIL "B" 30-XC501-SP-5612

NOTE 2 PSV 44-I-7874 I-5211 NOTE 11 44-I-7874 I-5221

6"x2"

NOTE 2 13) TOP MANHOLE TO BE EQUIPPED WITH MANCATCHER SIDE MANHOLE TO BE EQUIPPED WITH PLUG INSERT,

45-XC801-SP-5614

NOTE 11 PSV

30-XC501-SP-5609

45-I-8201 45-I-8201

45-XC801-SP-5611

2" 2" 5828 45-I-7874 2" 2" 2" 45-I-7874

2" I-5361 I-5342 BOLTED COVER.

5829

30-SP-5052

30-SP-5055

I I I I

SP 30-SP-5053

I-5318 I-5362 14) RADAR PROBE (K6 NOZZLE) TO BE LOCATED TO ENSURE MINIMAL INTERFERENCE DURING

SP 30-SP-5054

SP 30-SP-5051

ATM I-5341 ATM I-5326 BLENDER FILLING.

NOTE 21 I-5325 I-5319 15) NOZZLE FOR BOTTOM OF THE BLENDER WASHING BELOW CHINESE HAT AND FOR WASHING INTERNAL BLENDING PIPES.

SEE DETAIL "B"

LSHH LAHH HS NOTE 21 LSHH LAHH HS I-5403 INTERNAL DISTRIBUTION RING DETAILS BY BLENDER VENDOR.2" LINE TO BE SELF DRAINING TO HEADER PIPE.

I-5403

SP

NOTE 16 5082 5082 5171 I-5404 NOTE 16 5087 5087 5172 I-5404 16) K7 NOZZLE SHALL BE PLACED MINIMUM AT 1 METER FROM NOZZLES N3, N4 AND N13.

4" 4" VIBR.

SP

VIBR.

SP

4" AVAILABLE AVAILABLE 17) N3, N4 WITHOUT FLANGE, PIPE/SILO CONNECTION WITH EXPANSION JOINT.

3" 4"

N10C

4" 2"

N10C

H 18) BREAK FLANGES TO BE AVOIDED IN WASH WATER LINE ALONG SILO SHELL.

3"

N10B

N10B

3" 4" N3 N4 N5 LT LI 16" N3 H

28" 20" N13N8 28" LT LI 19) MIN. SLOPE 60° FROM THE HORIZONTAL.

N10A

N10A

20" 16"N8

12"-30-PP-50053-A0KP12-V

NC 4" 5074 5074 NC 20" K7N5 4" 20) SLIDE GATE VALVE SHALL BE ABLE TO CLOSE EVEN INCASE OF LINE FILLED WITH PRODUCT.

E

K7

12"-30-PP-50052-A0KP12-V

FDALL N22 2" 2" K6 L N22

2" M1B K6 5075 5075

K14 N13 24" NOTE 13 M1B N4 24" NOTE 13 L

5000 NOTE 14 K14 NOTE 14 21) WITH CHINESE CAP.

12" N15 20" NOTE 17 2" NOTE 17 K21 2"

K21 RADAR 12" N15 RADAR 22) SAMPLING PIPE TO BE EXTENDED TO FLOOR LEVEL. CAP TO BE PROVIDED ON SAMPLING LINE

H 3" 12" K25

GENERAL NOTES:

8003

12" K25 T T H 23) FIRST SAMPLE VALVE AS CLOSE AS POSSIBLE TO THE SAMPLING NOZZLE. SECOND SAMPLING VALVE AT

FDAL PT PI PT PI

8003

NOTE 4 FLOOR LEVEL.

5000 NOTE 10 NOTE 4 3/4" 5190 5190 3/4" 5191 5191 A) ALL

24) FLARE ALINES

PROVIDE TO BE SLOPED

FLANGED TOWARDS

CONNECTION ONTHE

THEFLARE HEADER

SAMPLING WITH TOP

VALVE ENTRY.

SO TO HAVE THE POSSIBILITY TO MOVE

THE WASHING SPOOL IN POSITION.

O FIC B) SCOPE BREAK BETWEEN VENDOR AND BOROUGE 3 EPC CONTRACTOR

I-5325

5000 FDALL 30-DJ-516C GENERAL

IS INDICATEDNOTES:

BY:

C V

H

3"

30-DJ-515C 5002 30-DJ-516B A) ALL FLARE LINES TO BE SLOPED TOWARDS THE FLARE HEADER WITH TOP ENTRY.

C) ALL INSTRUMENT

B) SCOPE TAG AND

BREAK BETWEEN INTERLOCK

VENDOR NUMBERS

AND BOROUGE ONCONTRACTOR

3 EPC THIS DRAWING HAVE THE PREFIX 30.

V V FV 30-DJ-515B FDAL I-5342 I-5342 IS INDICATED BY:

C V

5000 5002

30-DJ-516A CONTAINER XHS I BIG BAG XHS I

3"

3/4" 3/4" NOTE 10

PLANT AIR 30-DJ-515A LOADING

5266A

LOADING

5266B

PERMISSIVE PERMISSIVE C) ALL INSTRUMENT TAG AND INTERLOCK NUMBERS ON THIS DRAWING HAVE THE PREFIX 30.

FT O FIC

13012 30-PU-152-09090-02

2"x1"

5000

2"x1" FO 3"x2"

I-5326 5002 REFERENCES:

2"-30-UA-50034-A0KU01-V VORTEX FOR GENERAL NOTES AND REFERENCES SEE DRG. P3-PU-152-01000-01÷17;

1-1/2" PIPING AND INSTRUMENTATION DIAGRAM-SYMBOLS, ABBREVIATIONS AND GENERAL NOTES.

424 V V

NC FV

3/4" 3/4" 5002

PLANT AIR

30-TS-515 30-TS-516

6"

2"-30-UA-50035-A0KU01-V FT ZLH I

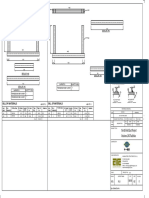

13011 30-PU-152-09090-02 DETAIL "A" (WATER DISCHARGE CONNECTION)

424

30-VZ-50014-A0KP12- 5002 FO 30-VZ-50013- - 1

2"x1" 2"x1" 3"x2" OPEN XHSH I-

NORMAL POSITION

D

8003 VORTEX 8003 I-5342 5266B

I-

6"

30-XC521-SP-5791

24" 1-1/2" 24" I 30-XC521-SP-5792

NOTE 13 NOTE 9 ZEH 20" ZEL ZLL I

M1A M1A

NC 1 1 1

CONTAINER I-5341 NOTE 13 CLOSE XHSL

XHS I 30-ME-252-8001(MAGENETIC BARS)

OPEN XHSH LOADING

5264A 5266B FLEXIBLE

2" HOSE H

T

I-5341 5264B PERMISSIVE 8" NOTE 22,

CONNECTION

LAL FLEXIBLE 23, 24 FOR SILOS #1 I-

I #1 20" T

2"

NOTE 9 HOSE CONNECTION ZLH I-5318

5522B WASHINGPOSITION

WASHING POSITION 30-TS-515 5425 ZLL

I-5341 I-5341

XHSL BIG BAG XHS I

CLOSE ZLH I-5319

LOADING 20"

NOTE 18

5264B 5264B 30-TS-516 5426

PERMISSIVE ZLL I-5342

I-5377 ÷ I-5380

NOTE 18

LAL

I-5377 ÷ I-5380 60° 60° I-5390 8" NOTE 24 H DETAIL ``B''

C V 5522A I-5308 ÷ I-5318 V

I-5390 HZLL 2" I-5342 20" DETAIL ``B'' OUTLET)

I-5319 ÷ I-5320 N12 V (FLUSHING OFF-GAS

5412 N9 NOTE 15

N12 I-5328

I-5308 ÷ I-5317 6" 2" I-5320 I-5319 C TO BLENDER SILOS

(FLUSHING OFF-GAS

OFF-GAS HEADER

OUTLET)

I-5341 NOTE 15 20"X12" (SEE P&IDSILOS

30-PU-152-51647-02)

N9 C H TO BLENDER OFF-GAS HEADER

I-5328 HZLL VIBR. LSL LAL LAL I O

30-SP-5068

I-5318 LSL (SEE P&ID 30-PU-152-51647-02)

30-SP-5067

H 5521 5521A 5521B VIBR. 12"-30-PP- 50023/50024

I O 5411

HZEL K24 2" 5522 L TO COLLECTING

HVL I-5361 5412 HVL SYSTEM HZEH HVL

L 8" N19 I-5319

6"-30-UW-50009-A0KU16-V 6" K24 2" I-5318 I I N.B: SPOOL PIECE SHALL BE OPERABLE XXXX XXXX

5411 N18

N19 5412 8" I-5362

6"-30-UW-50010-A0KU16-V BY ONLY ONE PERSON

C

130 XV HZEL 3" N17 N18 2" 6"

FOR DETAIL SEE P&ID K23 HZEH EP2 XV

2" LSLL LALL K23 LSLL LALL 130

5241 5411 HZEH 30-PU-152-151647-02 3" N17 5242 V HZEL

EP2 5412 FOR DETAIL SEE P&ID

WASH WATER 20" 5083 5083 30-PU-152-51647-02 20" 5090 5090 WASH WATER XXXX

5411 N2 VIBR. N2

VIBR. 6"-30-UW-50010-A0KU16-V C 30-SP-YYYY

19427 30-PU-152-51611 I-5319 30-PU-152-51611 19428

I-5318 2" N22

FROM WASH WATER FILTER FC 2" T 2" N16B 2" N16B 130 FC

N16A 2" NOTE 5 I HZLH 2" T TYPE 2A FROM WASH WATER FILTER 24"

30-NF-508 WASH WATER TYPE 2A 30-51606-V1 LO HZLH I N16A NOTE 5 30-NF-508 WASH WATER

TANK 30-TK-508 30-XC521-SP-5523 5412 LO 30-51606-V2

5411 NOTE 20 SEE DETAIL "A" NOTE 20 30-XC521-SP-5524

TANK 30-TK-508

20"-30XC521-PE-81678-GRA51-H8-V-GK46.3 I-5362

PLANT AIR O PLANT AIR

1"-30-UA-50033-A0KU01-V

6"X4" MANUAL C521-PE-81678-GRA51

MANUAL 20"-30XC521-PE-81672-GRA51-H8-V-GK46.3

20" VALVE 1"-30-UA-50036-A0KU01-V REVAMP SCOPE FOR PP4

20"

15078 30-PU-152-09090-02 30-XC521-SP-5791 30-PU-152-09090-02 15077

SEE DETAIL "A"

VALVE MANUAL 1"x3/4" 6"X4"

30-XC521-SP-5791

424 1"x3/4" 1"x3/4" 1"x3/4" N I-5362 424

O I-5361 1"x3/4"

30-XC521-SP-5792

1"x3/4" VALVE 30-ME-252-8001 O 30-XC-510

91

NO 30-ME-252-8001 O

WASHING WATER 0.2%

3/4"

3/4" M I-5342 0.2%

4"-30-PP-50022-A0KP12-V REVAMP PROJECT SCOPE PART OF PP3/PP4 BLENDER

4"-30-PP-50024-A0KP12-V O 15962 30-PU-152-09141

OF WORK IS RED-MARKED. FLUSHING SYSTEM PACKAGE

30-PU-152-09141 15961 I-5361 H I-5328 8003

SEQ-5211 I I-5319

TO COLLECTING SYSTEM 8003 3/4" 3/4" I-5342 AS BUILT

SEQ-5212 AFL /EFC I-5325 NOTE 22 C FFS

I-5341 H 1" L

I-5341 TYPE 4ANOTE 22 O I I-5318 I-5342 AFL/EFC x3 BAGGING XHS I

AFL /EFC /4" AFL /EFC

/4"

/4"

XV 1" O TYPE 4A PERMISSIVE 5267A

x3

x3

O x3 TYPE 4A SEQ-5221 TYPE 4A

1"

1"

/4" L V G 10-JUL-2019

20-SEP ISSUED for COMPANY REVIEW Baratelli Spinelli Brambilla

5348 SEQ-5222 XV XV H 24-Jul-20 ISSUED FOR FEED PACKAGE Baratelli Spinelli Brambilla

CLOSED

1" 1" XV 1" 1" ISSUED FOR COMPANY REVIEW

5350 5375 G 20-Sep-19 Baratelli Spinelli

OPEN

Brambilla

5349 16" 12"

16" 12" NOTE 8, 12 NOTE 6 R1 14-Mar-1 ISSUED

R 14-Mar-17 ISSUED FOR

FOR CONSTRUCTION

CONSTRUCTION PMP#PO-000691

PMP#PO-000691 VPU

VPU MVW

MV

Prepared

UMS

Checked UMS

Approved

SEE DETAIL "A" 1

N.

TO PP3/PP4 FFS

Rev.

1 7 Date Description

W

MI

By By By

N.

XHSH AS BUILT

SEE DETAIL "A" BAGGING XHSL R 25-May-15 RAC/SAF/

MI

ABU DHABI POLYMERS COMPANY LIMITED ASW BEO

12"-30XC521-PE-81673-GRA51-H8-V-GK46.3 PRE

OPEN XHSH 20" X 12" 30-XC-521 I

H AFL AFL MACHINE 5267B 5267B (BOROUGE)

B

H AFL AFL EFC EFC NOTE 19 GRAVITY FLOW

20" X 12"

I-5341 PART OF PP3/PP4 DIVERTER VALVES PACKAGE XV 30-XL-601 A/B/C

TYPE 4A XV

ISSUED FOR CONSTRUCTION-REVISED WHERE SHOWN

5265B I EFC EFC TYPE 4A Q1 20-Jul-12 ASW

RAC/SAF/

BEO

FFS L (P&ID 30-PU-152- PRE

XHS I XV TYPE 4A TYPE 4A 5266 5267 PELLETS PETROCHEMICALS PROJECT

BAGGING NOTE 7 L XV NOTE 8, 12 I-5328 16"-30XC521-PE-81674-GRA51-H8-V-GK46.3 61001/61002/61003)

PERMISSIVE 5265A

COMPANY PROJECT ISSUED FOR CONSTRUCTION

I-5325 5264 TO PP3/PP4 FFS I-5319 7167 30-PU-152-51626 Q 19-Jan-12 NO PROJECT TITLE: VAC/SAF/

5265 NOTE 19 7500000872 ASW

PRE

BEO

XHSL I-5318 BAGGING

CLOSED 5265B

12"-30XC521-PE-81679-GRA51-H8-V-GK46.3

MACHINE

TO DIVERTER VALVE

30-XC-521-MD-542M

P4

CONTRACTOR PROJECT NO

4080 - P4 HAZOP COMMENTS INCLUDED

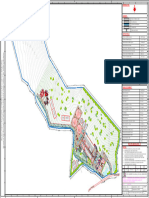

BOROUGE 4 MAIN FEED PROJECT

GRAVITY FLOW NOTE 19 30-XL-601 A/B/C P 31-Aug-11 PIPING AND INSTRUMENTATION DIAGRAM ASW

VAC/SAF/

BEO

DRAWING TITLE: UNIT -30, DIAGRAM PRE

(P&ID 30-PU-152- PIPING AND INSTRUMENTATION

UNIT -30, PRODUCT

PRODUCT HANDLING

HANDLING PP4

PP4 HOWN

61001/61002/61003) WASHING WATER 30-Nov-10 ISSUED AFTER COMPANY REVIEW-REVISED WHERE VAC/SAF/

VERTICAL L1 BLENDER SILOS BLENDER SILOS TS-515/516

TS-515/516 ASW PRP

12"-30-PP-50021-A0KP12-V PRE

WASHING WATER 14038 30-PU-152-09141 G

12"-30-PP-50023-A0KP12-V VERTICAL 8003 BOROUGE DOCUMENT CLASS' N

ISSUED FOR COMPANY REVIEW

PROJECT DRAWING NO REV: H

30-PU-152-09141 14037 V C TO COLLECTING SYSTEM 17-Jul-10 BOH/SAF/

11

L 4080-XZ-DM-2400 300051606 ASW PRP/BEO

30

TO COLLECTING SYSTEM 8003 2 CONTRACTOR: 4080-XZ-DM-300051606

BOROUGE:

30

24-PU-152- 51606

30-PU-152-51606

PRE

SHEET

1 OF 1

UNIT:

AREA:

24

30

51

CADD DATE

REV 30

24-PU-152- 51606 DESCRIPTION Drawn up Checked SHEETApproved

PELLETS 30-PU-152-51606-ISH SCALE: - A1

16"-30XC521-PE-81680-GRA51-H8-V-GK46.3 NOTE 19 REF. SIZE

7168 30-PU-152-51626 This document contains CONFIDENTIAL and PROPRIETARY information of Borouge. Tecnimont Identification code

TO DIVERTER VALVE This information is not to be used, disclosed or reproduced in whole or in part to anyone 3583-XZ-DM-3051606

30-XC-521-MD-542L

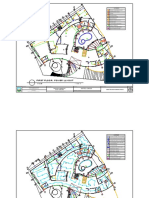

30-XC-521 30-XC-501 44-XC-801 30-DJ-515A 30-DJ-515B 30-DJ-515C 30-DJ-516A 30-DJ-516B 30-DJ-516C 30-TS-515 30-TS-516 45-XC-801 outside of Borouge and subsidiaries, except pursuant to a written agreement with Borouge

PP3/PP4 DIVERTER PP3/PP4 PELLET PELLET CONVEYING PELLET CONVEYING

VALVES PACKAGE BLENDING PACKAGE SYSTEM 45 SYSTEM 55

SPRAY NOZZLE SPRAY NOZZLE SPRAY NOZZLE SPRAY NOZZLE SPRAY NOZZLE SPRAY NOZZLE PP BLENDER SILO PP BLENDER SILO

A

TYPE: VERTICAL TYPE: VERTICAL CAPACITY: 72 t/h

CAPACITY: 170 t/h CAPACITY: 60 t/h CAPACITY: 72 t/h PRESSURE DROP: 1 bar PRESSURE DROP: 1 bar PRESSURE DROP: 1 bar PRESSURE DROP: 1 bar PRESSURE DROP: 1 bar PRESSURE DROP: 1 bar

TOT. VOL.: 2140 m³ TOT. VOL.: 2140 m³ POLYOLEFINS UNITS - BOROUGE 3 PROJECT - RUWAIS, U.A.E.

(EACH LINE)

DIA.: 9.5 m DIA.: 9.5 m

FLOWRATE: 60 m³/h FLOWRATE: 60 m³/h FLOWRATE: 60 m³/h FLOWRATE: 60 m³/h FLOWRATE: 60 m³/h FLOWRATE: 60 m³/h PIPING AND INSTRUMENTATION DIAGRAM

DENSE PHASE DENSE PHASE CYL. HEIGHT: 27.5 m CYL. HEIGHT: 27.5 m

MAT'L: SS MAT'L: SS MAT'L: SS MAT'L: SS MAT'L: SS MAT'L: SS CONE HEIGHT: 8050 mm CONE HEIGHT: 8050 mm UNIT-30,

NOTE 1 NOTE 1

DP (barg): -0.015/0.15 DP (barg): -0.015/0.15

DT (°C): 5/100 DT (°C): 5/100 PRODUCT HANDLING, PP4

LINING: LINING:

MOC: ALUMINIUM MOC: ALUMINIUM BLENDER SILOS, TS-515/516

INSUL.: INSUL.:

Company document classification Size Original scale Borouge Identification Code Rev

DESIGN FV: NO DESIGN FV: NO

NOTE 1 NOTE 1 1 A1 - 30-PU-152-51606 R1

FILE :30-PU-152-51606 REV R

You might also like

- Wd11y021s10Document28 pagesWd11y021s10cages48160No ratings yet

- 1998 Terex T340 Electric Schematic LowerDocument3 pages1998 Terex T340 Electric Schematic LowerRussMahn75% (4)

- Proposed Grandview Heights SheetzDocument9 pagesProposed Grandview Heights SheetzWSYX/WTTENo ratings yet

- Consumption of MaterialDocument14 pagesConsumption of MaterialRita Saigal72% (18)

- PID Turbcompr Desc1raEtapaDocument1 pagePID Turbcompr Desc1raEtapaJholman SanchezNo ratings yet

- Nelly Alarcon-2Document1 pageNelly Alarcon-2milagrosNo ratings yet

- Corrosion Loops Example 4 - Separator Template1Document1 pageCorrosion Loops Example 4 - Separator Template1Christian JoseNo ratings yet

- GCP 1001 01 CS 0138 0391 M Pid 00002Document1 pageGCP 1001 01 CS 0138 0391 M Pid 00002Leonel Gamero CardenasNo ratings yet

- S-03710 P42118-Rev. 3-P18-Steam DrumDocument1 pageS-03710 P42118-Rev. 3-P18-Steam Drumwylie01No ratings yet

- Coo 4Document1 pageCoo 4Jok PrasNo ratings yet

- Vibrafono 2huapangoDocument6 pagesVibrafono 2huapangoCarlos XavierNo ratings yet

- T-4.002.788 A 1 PublicationDocument1 pageT-4.002.788 A 1 PublicationNadeem AkramNo ratings yet

- 210-23-Pr-Pid-00002 - 01 - Piping and Instrumentation Diagram Riser Platform Rt2 32 Pipeline Pig LauncherDocument1 page210-23-Pr-Pid-00002 - 01 - Piping and Instrumentation Diagram Riser Platform Rt2 32 Pipeline Pig LauncherIndra GunawanNo ratings yet

- P&id Demineralized Water DistributionDocument1 pageP&id Demineralized Water DistributionAjeng OctaviaNo ratings yet

- Electrica Puerta de Riel: Dell Dell DellDocument1 pageElectrica Puerta de Riel: Dell Dell DellJ Antonio ZamudioNo ratings yet

- Schedule of Pipe Supports For Structural SteelDocument1 pageSchedule of Pipe Supports For Structural SteelrajendraNo ratings yet

- 25351-220-M6-0310-00412-Screens Pebbles CrushingDocument1 page25351-220-M6-0310-00412-Screens Pebbles CrushingRolando AcevedoNo ratings yet

- Eec Serie KDocument1 pageEec Serie KmiltonNo ratings yet

- CMN.18.477 Smart Plant Documentation Ruwais NGL Train 3: EL. 98250 TO EL. 106000 Piping Ga Area WC 743Document1 pageCMN.18.477 Smart Plant Documentation Ruwais NGL Train 3: EL. 98250 TO EL. 106000 Piping Ga Area WC 743steepa22No ratings yet

- IQ360-000-M6-SG-00003 Rev03Document1 pageIQ360-000-M6-SG-00003 Rev03mustafa1989ocNo ratings yet

- NK SNKZDocument43 pagesNK SNKZMehran AbbasiNo ratings yet

- To Control Unit OCS, See Circuit Diagram 2081507Document1 pageTo Control Unit OCS, See Circuit Diagram 2081507andrestkaNo ratings yet

- 1RNZ - Lab Furniture Layout - R6-Layout1Document1 page1RNZ - Lab Furniture Layout - R6-Layout1zafrikhan875No ratings yet

- 2 Ar Berea Final Layout1Document1 page2 Ar Berea Final Layout1Jaspergroup 15No ratings yet

- Site Plan: R 0 A D 60' (34C)Document1 pageSite Plan: R 0 A D 60' (34C)BatWing ZNo ratings yet

- 25635-220-M6-0210-00001-R2 Chancadora 1Document1 page25635-220-M6-0210-00001-R2 Chancadora 1Victor Guzman PretellNo ratings yet

- ZF Ecolife K280Document1 pageZF Ecolife K280miltonNo ratings yet

- SSCM First ModelDocument1 pageSSCM First ModelPrince ShaikNo ratings yet

- Xstrata Bechtel Alliance: A. Gonzalez A. GonzalezDocument1 pageXstrata Bechtel Alliance: A. Gonzalez A. GonzalezjhonNo ratings yet

- 02 - Site LayoutDocument1 page02 - Site LayoutVigneshwaran BNo ratings yet

- DWC7894 11 08 - 00Document1 pageDWC7894 11 08 - 00nthekkumpuramNo ratings yet

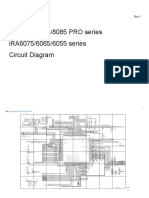

- Ira6000 8000 Series-CdDocument427 pagesIra6000 8000 Series-Cdluongnam100% (1)

- 02.plan de Amplasare PDFDocument1 page02.plan de Amplasare PDFPopa SergiuNo ratings yet

- Ig N e D: WMV Ral VSM Acp Ags Ral Cle WMV JCF FCM CleDocument1 pageIg N e D: WMV Ral VSM Acp Ags Ral Cle WMV JCF FCM Clenestor159357No ratings yet

- Hit The Road Jack Ray Charles Piano CoverDocument2 pagesHit The Road Jack Ray Charles Piano CoverLévy BenjaminNo ratings yet

- Defect Plot Plan U22-23Document1 pageDefect Plot Plan U22-23jk.jackycheokNo ratings yet

- Refer To Building 4 Package: For ConstructionDocument1 pageRefer To Building 4 Package: For ConstructionjanNo ratings yet

- L&T Construction: B D F K N Q S CDocument1 pageL&T Construction: B D F K N Q S CPowerhouse ShaftNo ratings yet

- SSEM 010Document1 pageSSEM 010Prince ShaikNo ratings yet

- Instructions KepeeDocument18 pagesInstructions Kepeedoog unbeuNo ratings yet

- 54-28974 QPDocument2 pages54-28974 QPpratikdeNo ratings yet

- Kenr5406 03 00 PubDocument2 pagesKenr5406 03 00 PubAhmed MoustafaNo ratings yet

- Analisi Triadi E Rivolti: Esercizio 2Document2 pagesAnalisi Triadi E Rivolti: Esercizio 2televisioneNo ratings yet

- Abk SD 219 WS 002 Rev 1Document1 pageAbk SD 219 WS 002 Rev 1Muhammed Irshad MahdiNo ratings yet

- NEBB Psych Chart Sea Level 11x17Document1 pageNEBB Psych Chart Sea Level 11x17JojolasNo ratings yet

- 01 LintelDocument1 page01 LintelHitesh DabhiNo ratings yet

- Nawcpf Msbi Ca01 950 HV DRW 59249 - 003 - Acoserv Nac Cob Hvac General Arrangement1Document2 pagesNawcpf Msbi Ca01 950 HV DRW 59249 - 003 - Acoserv Nac Cob Hvac General Arrangement1Mlayeh MohamedNo ratings yet

- XC2003 Controller Notes:: X2:1 X2:6 X2:7 X2:8 X2:9 X2:6 X2:14 X2:15 X2:11 X2:17 X2:20 X2:21 X2:22 X2:24 X2:26 X2:25 X2:18Document1 pageXC2003 Controller Notes:: X2:1 X2:6 X2:7 X2:8 X2:9 X2:6 X2:14 X2:15 X2:11 X2:17 X2:20 X2:21 X2:22 X2:24 X2:26 X2:25 X2:18percyctba FilhoNo ratings yet

- E-T2-02-Vigas Sotano 2Document1 pageE-T2-02-Vigas Sotano 2recepcionNo ratings yet

- 2210306WW SF1 00 - 3Document1 page2210306WW SF1 00 - 3Victor PodlozovikNo ratings yet

- Prelude No. 21 BWV 866 in B MajorDocument3 pagesPrelude No. 21 BWV 866 in B MajorĐại Lâm NguyễnNo ratings yet

- RT400Document6 pagesRT400RASMAJON100% (1)

- Rencana HMI Monitoring BusiDocument3 pagesRencana HMI Monitoring BusiEko BeryonoNo ratings yet

- Plano 01Document1 pagePlano 01Erick VeraNo ratings yet

- Pode Alguém - Trumpet 1Document1 pagePode Alguém - Trumpet 1Jairo FilhoNo ratings yet

- First Floor: Power Layout: Hotel GroupDocument1 pageFirst Floor: Power Layout: Hotel GroupMichael BelusoNo ratings yet

- 2. 26280-220-M6S-1910-10066-001- 1830-PW-001.Document2 pages2. 26280-220-M6S-1910-10066-001- 1830-PW-001.karinaNo ratings yet

- Plancher Haut RDCDocument1 pagePlancher Haut RDChaidaru adamsNo ratings yet

- 30-PU-152-51604_HDocument1 page30-PU-152-51604_Hhasan.mohamed2305No ratings yet

- 30-PU-152-51605_HDocument1 page30-PU-152-51605_Hhasan.mohamed2305No ratings yet

- 30-PU-152-51603_HDocument1 page30-PU-152-51603_Hhasan.mohamed2305No ratings yet

- 30-PU-152-11601_HDocument1 page30-PU-152-11601_Hhasan.mohamed2305No ratings yet

- 30-PU-152-11610_HDocument1 page30-PU-152-11610_Hhasan.mohamed2305No ratings yet

- 30-PU-152-51602_HDocument1 page30-PU-152-51602_Hhasan.mohamed2305No ratings yet

- PS02 - 11 of 12Document1 pagePS02 - 11 of 12hasan.mohamed2305No ratings yet

- Planner For JEE Advanced 2024Document1 pagePlanner For JEE Advanced 2024hasan.mohamed2305No ratings yet

- Ameer LoaDocument2 pagesAmeer Loahasan.mohamed2305No ratings yet

- PS13-58 of 58Document1 pagePS13-58 of 58hasan.mohamed2305No ratings yet

- PS14 - 01 of 04Document1 pagePS14 - 01 of 04hasan.mohamed2305No ratings yet

- PS02 - 10 of 12Document1 pagePS02 - 10 of 12hasan.mohamed2305No ratings yet

- Natural GasDocument1 pageNatural Gashasan.mohamed2305No ratings yet

- PS02 - 12 of 12Document1 pagePS02 - 12 of 12hasan.mohamed2305No ratings yet

- 6001 CorrectedDocument2 pages6001 Correctedhasan.mohamed2305No ratings yet

- PS13-58 of 58 1Document1 pagePS13-58 of 58 1hasan.mohamed2305No ratings yet

- Gain and Phase Margin Questions No AnnoDocument54 pagesGain and Phase Margin Questions No Annohasan.mohamed2305No ratings yet

- PS12 - 16 of 21Document1 pagePS12 - 16 of 21hasan.mohamed2305No ratings yet

- Si JobsDocument45 pagesSi Jobshasan.mohamed2305No ratings yet

- Notes: Status-CDocument1 pageNotes: Status-Chasan.mohamed2305No ratings yet

- Mechanical OperationDocument76 pagesMechanical Operationhasan.mohamed2305No ratings yet

- 2 Case StudiesDocument18 pages2 Case StudiesolaNo ratings yet

- Fuller: Eaton TransmissionsDocument23 pagesFuller: Eaton Transmissionsgestada023No ratings yet

- Western Red Cedar Shingles Shakes Application Handbook - 2015Document28 pagesWestern Red Cedar Shingles Shakes Application Handbook - 2015M100S2No ratings yet

- MANUAL COMPUTATION For 2nd FloorDocument4 pagesMANUAL COMPUTATION For 2nd FloorAlora DawnNo ratings yet

- Working Drawing ReferenceDocument1 pageWorking Drawing ReferenceDexter LarawanNo ratings yet

- Statement of Quantity of Concrete, P.C.C. & Soling Per 'M' of Rectangular R.C.C. Drain With Cover at StretchesDocument18 pagesStatement of Quantity of Concrete, P.C.C. & Soling Per 'M' of Rectangular R.C.C. Drain With Cover at StretchesBilal Ahmed BarbhuiyaNo ratings yet

- PWHTDocument118 pagesPWHTSumedh Singh100% (19)

- Assa Abloy DS6060P Curtain Dock Shelter ParallelDocument2 pagesAssa Abloy DS6060P Curtain Dock Shelter ParallelmujahaddadNo ratings yet

- Madhulika Liddle - Crimson City-Hachette Book Publishing India (2014)Document306 pagesMadhulika Liddle - Crimson City-Hachette Book Publishing India (2014)Medha KNo ratings yet

- Circular Amendments To Fire Code 2018 - 9th Batch of AmendmentsDocument43 pagesCircular Amendments To Fire Code 2018 - 9th Batch of AmendmentsAndreas IndrakusumaNo ratings yet

- 19 Sea Inlets and Overboard Discharges: 17.5 Group II Piping FlangesDocument2 pages19 Sea Inlets and Overboard Discharges: 17.5 Group II Piping FlangesDorin SavaNo ratings yet

- Midterm Exam CMTDocument13 pagesMidterm Exam CMTLester CabungcalNo ratings yet

- New Horizons and Opportunities of Modular Constructions and Their TechnologyDocument9 pagesNew Horizons and Opportunities of Modular Constructions and Their TechnologyPhD. Arch. Klodjan XhexhiNo ratings yet

- Ga 600 03Document142 pagesGa 600 03rweld1028No ratings yet

- Design of Ultra High Performance Concrete As An Overlay in Pavements and Bridge DecksDocument127 pagesDesign of Ultra High Performance Concrete As An Overlay in Pavements and Bridge DecksHendri Hadisi100% (1)

- MCQ CMDocument12 pagesMCQ CMAviNo ratings yet

- M. Rivera Rizal Ville Housing Project Ref No 1Document2 pagesM. Rivera Rizal Ville Housing Project Ref No 1Mervin RiveraNo ratings yet

- Tauntons Tool Guide 2006Document148 pagesTauntons Tool Guide 2006koaa85No ratings yet

- Boq (110912)Document144 pagesBoq (110912)Ali AlaliNo ratings yet

- Engineering Graphics and Design Grade 12 Tasks For The Year Grade 12 Task Description Engineering Graphics and DesignDocument5 pagesEngineering Graphics and Design Grade 12 Tasks For The Year Grade 12 Task Description Engineering Graphics and Designkrokedil2002No ratings yet

- Total Building Cost CalculationsDocument6 pagesTotal Building Cost CalculationshadeeqaNo ratings yet

- KXD4630YSS Dimension Guide enDocument3 pagesKXD4630YSS Dimension Guide enChris AdamsNo ratings yet

- Experimental Analysis On Ultra High Performance Concerte Using Binary Packing Density Modulus-Thesis-r9Document60 pagesExperimental Analysis On Ultra High Performance Concerte Using Binary Packing Density Modulus-Thesis-r9Gokulnath MahalingamNo ratings yet

- TiDocument108 pagesTidsureshcivilNo ratings yet

- National Plastic Emulsion TDSDocument3 pagesNational Plastic Emulsion TDSHTE (ONLINE)No ratings yet

- Composite Propeller ConstructionDocument8 pagesComposite Propeller Construction이재국No ratings yet

- AISC Intro Steel Bridge Design r1 Handout 2perDocument67 pagesAISC Intro Steel Bridge Design r1 Handout 2perDarline Cano CardonaNo ratings yet

- Opc PPC Fly Ash Study Jan 06 by MR Anil Banchhor and MR S Krishnan 241Document15 pagesOpc PPC Fly Ash Study Jan 06 by MR Anil Banchhor and MR S Krishnan 241Abdul RashidNo ratings yet