Professional Documents

Culture Documents

Risk Assessment for Installation of Electrical Wiring Amp Cable Pulling

Risk Assessment for Installation of Electrical Wiring Amp Cable Pulling

Uploaded by

debruynbeerCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment for Installation of Electrical Wiring Amp Cable Pulling

Risk Assessment for Installation of Electrical Wiring Amp Cable Pulling

Uploaded by

debruynbeerCopyright:

Available Formats

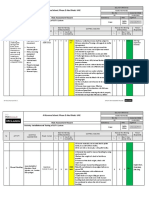

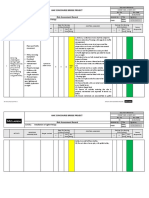

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-ME-A-MST-013

Rev. No. Rev. Date

00 07/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Electrical Wiring & Cable Pulling Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. Delivery/ collection drivers shall be subject to

McLaren induction/Training with regards to

traffic management.

Plant and Traffic 2. Ensure exclusion zone is set up around the

movement preparation work area and all plant

movement and checked by supervisor

3. Always use the pedestrian access provided

Run over by

4. Traffic light batons shall be provided for banks

vehicles/plants

man at night

Hit by reversing

5. All plant to have a fully trained banks man

Delivering, equipment

unloading and present all times.

Overhead

storing of 6. No plant to reverse without banks man.

obstructions

Cable/wire Drums Operatives 7. Ensure access route are sufficient and safe to Site Eng.

Vehicle break

1 materials using Staff/visitors use. Supervisor,

down 4 4 16 High 1 4 4 Low

pickup and 8. Do not take rest in or under vehicles Foreman,

unloading by Property damage

9. Proper barricade and safety

manual handling Collision with

signboard provided on open

and using Forklift other

excavation

for heavy load. vehicles

10.All vehicles must be fitted with reverse alarm /

Personal injury Flashing light.

Fatality 11.The work place and all access to be

Accident due to well illuminated.

poor lighting and 12.Ensure close supervision, Effective

visibility (operation Communication & Coordination with McLaren

at night 13.Enforce Speed limit

14.Ensure all vehicles entering the site is properly

maintained and reported if found any defect

15.Ensure materials are secured/tied in pallet

trolley to avoid fall from trolley.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-ME-A-MST-013

Rev. No. Rev. Date

00 07/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Electrical Wiring & Cable Pulling Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

16.STARRT card briefing must before start the

activity.

SAF-010 (UAE) 03/18 SPECIFIC RISK ASSESSMENT

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-ME-A-MST-013

Rev. No. Rev. Date

00 07/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Electrical Wiring & Cable Pulling Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

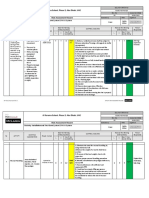

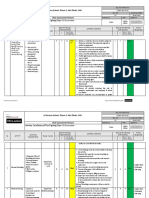

1. Eliminate the need for manual handling by

using mechanical aid.

2. Adequate manpower if load is more.

3. Ensure proper manual handling procedure

4. Ensure appropriate PPE.

musculoskeletal 5. Ensure individual load carrying only 20kg per Supervisor,

disorders, Med person

2

Manual Handling Operatives

Low Foreman,

Hand injuries, 6. Supervisor must make sure while manual

involved in work 3 4 12 ium 1 4 4 Site Eng.

cut & bruises handling load individual task and environment

to be considered to reduce the risk of manual

Sharp edges

handling.

7. During manual handling take precaution for

armoured cable both end sharp edge.

SAF-010 (UAE) 03/18 SPECIFIC RISK ASSESSMENT

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-ME-A-MST-013

Rev. No. Rev. Date

00 07/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Electrical Wiring & Cable Pulling Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. Site supervisor will monitor the activity and

should be aware of AMC site safe system of work

and premises rules.

2. Loading /unloading load should be controlled by

competent person and strictly follow SWL(Safe

Working Load)

Over Loading 3. Workers should away from the lifting area and

must be barricaded with caution signage and

Lifting Failure banksman must be active on work.

Unloading of cable Unstable support 4. Store yard/access to be inspected prior to activity.

drum using Forklift Operators,

Workers/ Supervisor,

Physical 5. Only 3rd party certified lifting gears/plant

3 Helpers 4 4 16 High 1 4 4 Low Foreman,

Injury/fatality equipment’s are to be used

Foreman Site Eng.

Poor illumination in 6. Ensure forklift must have reverse alarm and

night work beacon light.

Poor Weather 7. Load must be secured and ensure safe height of

Forklift mast to avoid visible obstruction of

operator.

8. No unloading activity will carry if high wind, rain

or poor visibility.

9. Enforce speed limit

10. Forklift operator, rigger and banksman’s must be

competent and certified by 3rd party.

SAF-010 (UAE) 03/18 SPECIFIC RISK ASSESSMENT

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-ME-A-MST-013

Rev. No. Rev. Date

00 07/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Electrical Wiring & Cable Pulling Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

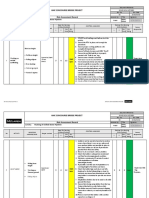

11. Overload cut off device will be inspected

12. Tool box talk will be providing before starting

the activity and risk assessment must briefed to

the work force.

13. Operatives must have PPE and high visible vest.

14. Pedestrian access to be followed

15. Fire extinguisher must be inside cabin.

SAF-010 (UAE) 03/18 SPECIFIC RISK ASSESSMENT

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-ME-A-MST-013

Rev. No. Rev. Date

00 07/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Electrical Wiring & Cable Pulling Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

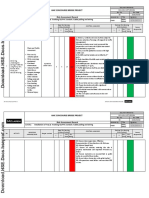

1. Ensure accesses are kept clear at all times.

2. Housekeeping to be carried out regularly

throughout the day when required

3. Supervisor to ensure operatives are stacking

material neatly and stacks are stable and in a

Slips safe condition

Operatives Supervisor,

Trips and fall 4. Provide adequate lighting especially during

Staff/storekeeper Med Foreman,

3 Material storing Poor house 3 4 12 night hours 1 4 4 Low

ium Site Eng.

keeping 5. Appropriate space is allowed around storage

areas for employees to move around safely

without the risk being trapped between

stacked materials.

6. Maintain good housekeeping.

SAF-010 (UAE) 03/18 SPECIFIC RISK ASSESSMENT

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-ME-A-MST-013

Rev. No. Rev. Date

00 07/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Electrical Wiring & Cable Pulling Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. Manual pulling of cable shall be performed in

a slow and study manner

2. Any return back movement due to slipping

of cable/wire or tension shall be immediately

Back pain, stopped and precautionary measure shall be

adopted.

Cable/wire Lump injury

pulling

3. Work areas should be clear from

(Manually) Bruises,

into GI/PVC unwanted materials that are scattered

conduits everywhere

Slipping Hazard .

4. Always wear suitable hand gloves

Property damage during cable/wire pulling.

Supervisors,

Medi Foreman, Site

4 Cable pulling group 3 4 12 1 4 4 Low

Personal injuries um 5. Take a rest every time it is needed.

Eng.

Eye, Hand and 6. Workers are to be aware of uneven ground

skin irritations and natural tripping hazards.

7. Competent supervision shall be ensured.

8. Barricade the area with caution/warning signage

9. Tool box talk will be conducted before

starting activity

10. Provision of welfare facility on site

11. Risk Assessment must be briefed to the operatives

SAF-010 (UAE) 03/18 SPECIFIC RISK ASSESSMENT

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-ME-A-MST-013

Rev. No. Rev. Date

00 07/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Electrical Wiring & Cable Pulling Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

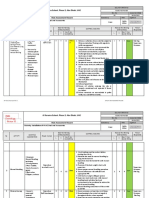

SAF-010 (UAE) 03/18 SPECIFIC RISK ASSESSMENT

Cable

Pulling/Laying on 1. Ensure Proper supervision and skilled workers

cable tray and Slip will be deployed for the activity.

trunking using trip 2. Hand gloves must use to protect from sharp

Mobile Tower cut edge object.

bruise 3. Work area must clean and free from obstruction

Fall from height 4. Ensure the PTW in place and task briefing

Falling objects by supervisor to work force.

Protruding objects 5. Ensure proper working platform with

Sharp edge complete fall protection

6. Secure the tools and objects kept on

the platform

7. Ensure safe access to the working platform.

8. Ensure Full body harness and 100% tie off Site Eng.

Medi 9. Ensure the scaffold platform is properly Supervisor

5 Cable pulling group 3 4 12 1 4 4 Low

um erected with "Safe to use" tag. Foreman

10. Ensure castor wheels are locked and out

Riggers are in place.

11. Cable pulling crew must have clear

instruction by supervisor and close

communication

12. Ensure armoured cable pulling activity, jacks

are placed suitable location and is properly

supported.

13. Hydraulic Jacks shall be tested and certified

by 3rd party is to be ensured.

14. Ensure jack and spindle will use properly to

smooth cable pulling

15. Ensure jack/rollers are properly maintained

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-ME-A-MST-013

Rev. No. Rev. Date

00 07/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Electrical Wiring & Cable Pulling Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

(Without Controls) (With Controls)

SAF-010 (UAE) 03/18 SPECIFIC RISK ASSESSMENT

IDENTIFIED Risk Risk Risk Risk Person

No ACTIVITY People Involved L S L S

HAZARDS/RISKS Score Rating Score Rating Responsible

and is good working condition.

16. Ensure Housekeeping done

17. Don’t move scaffoldings while personals are

on board.

SAF-010 (UAE) 03/18 SPECIFIC RISK ASSESSMENT

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-ME-A-MST-013

Rev. No. Rev. Date

00 07/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Electrical Wiring & Cable Pulling Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. Arrange adequate drinking water and rest shelter

2. Drink plenty of water with electrolyte

3. If feel something unusual immediately

Heat exhaustion.

inform supervisor and report to site clinic.

Working under Heat stroke

4. Make shift to operate the routine work

High temperature Dehydration Site Eng.

Workers 5. Do not allowed alone work

6 Direct sun light Personal injuries 4 4 16 High 1 4 4 Low Supervisors,

6. Frequent breaks

Dusty due to high Foreman

7. Proper supervision available

High wind temperature, Burn,

8. Correct PPE must use

Tiredness

9. Provide heat stress training

10. Conduct tool box talk

11. Proper signage for drinking water

SAF-010 (UAE) 03/18 SPECIFIC RISK ASSESSMENT

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-ME-A-MST-013

Rev. No. Rev. Date

00 07/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Electrical Wiring & Cable Pulling Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. Ensure proper night work permit is obtained

2. Proper lighting system should be in place

3. Ensure proper Communication / Coordination

and close supervision

4. Industrial safe torches to be available

Operatives/staff

Poor visibility due to for emergency situations Site Engr

Working at night darkness / poor Med 5. High visibility Traffic Vest for personnel’s in

7 time 3 4 12 1 4 4 Low Supervisor

illumination night shift

ium Foreman

Lone worker 6. Avoid lone working and always ensure buddy

system while working at night

7. Employees to be trained and

understand McLaren Crises plan.

SAF-010 (UAE) 03/18 SPECIFIC RISK ASSESSMENT

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-ME-A-MST-013

Rev. No. Rev. Date

00 07/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Electrical Wiring & Cable Pulling Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. Hand tools should be visually inspected for

defects, prior to use.

Improper selection

2. Never use damaged, blunt or broken tools to

of hand tools.

avoid injury.

Damaged and

3. Select right tools for right Job Site engg

Defective Hand

Operatives/Staf 4. Ensure no Homemade or makeshift tools to Supervisor

tools

Use of Hand tools f be used at site Foreman

Hand injuries Med

8 3 3 9 5. Remove from service any tool that shows 1 3 3 Low

Pinch point ium

signs of damage or defect

Ergonomics

6. Ensure Hand tools are Stored in

Repetitive strain

accordance with the manufacturer’s

injury

instructions.

7. Ensure hands are not in direct line of fire

while working with hand tools

8. Ensure appropriate PPE at all times.

Approved By: Name Position Signature

SAF-010 (UAE) 03/18 SPECIFIC RISK ASSESSMENT

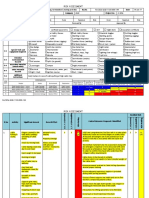

RISK ASSESSMENT & CONTROL GUIDELINES

1. Executing Steps:

1.1. Planning

a) Construction and HSE team must ensure that hazard identification is complete.

b) Construction and HSE team must prioritize the hazard issues, which are of significant in nature. (It means that risks have

well established legal requirements, potentially high risks).

c) Construction and HSE team to prepare the risk assessment plan for the priorities identified hazards for these potential

high risks.

1.2. Risk Assessment

Risk is the probability of an event occurring in a given set of circumstances. The ‘event’ is an exposure to hazard. The hazard is the

potential to cause harm. The risk assessment is the technique of evaluating not just the likelihood of an event occurring, but also the

outcome will be in terms of injury, loss, damage or harm.

1.3. Risk Assessment Process

The process of carrying out a risk assessment should be as follows.

1. Identify the hazards.

2. Identify who might be harmed and how.

3. Evaluate the risk and implement the control measures.

4. Record the significant findings.

5. Review the assessment and update if necessary.

1.4. Examination of the Hazards and Risk Associated

Competent staff must be used in examining the risk associated with the identified hazard.

Competent staff should examine following aspect to determine the risk involved:

o Examine the existing control measures in place.

o Identify employees at risk.

o Likelihood of risk.

o Severity

o Risk level and their tolerability.

1.5. Evaluating the risk:

Once the necessary information has been obtained on the hazards encountered by work activities, next stage is to access the risks.

1.5.1. Risk Rating Score

Risk rating score is a combination of two factors.

The severity of the risk that could injure persons or cause damage to plant.

The likelihood of the risk that it could happen (Probability).

RISK RATING = LIKELIHOOD X SEVERITY

NOTE: Each activity has to be assessed for the risk value for determining the level of Severity and likelihood are mentioned in the table

below.

No Injury Minor Moderate Major

Catastrophic (5)

(1) Injury (2) Injury (3) Injury (4)

1 2 3 4 5

Rarely (1)

Unlikely (2) 2 4 6 8 10

LIKELIHOOD Possible (3) 3 6 9 12 15

Likely (4) 4 8 12 16 20

Almost

RISK LEVEL: 5 10 15 20 25

Certain (5)

Low Medium High

SAF-010 (UAE) 03/18 Rev C SPECIFIC RISK ASSESSMENT RECORD

You might also like

- Risk Assessment For Installation of Fire Fighting SystemDocument20 pagesRisk Assessment For Installation of Fire Fighting SystemAnandu Ashokan91% (35)

- Risk Assessment For Kerb Stones, Wheel Stopper and Paving InterlocksDocument4 pagesRisk Assessment For Kerb Stones, Wheel Stopper and Paving Interlockspete chiz91% (23)

- Risk Assessment For Installation of Ducts and AccessoriesDocument17 pagesRisk Assessment For Installation of Ducts and AccessoriesAnandu Ashokan86% (14)

- Risk Assessment For Structured CablingDocument7 pagesRisk Assessment For Structured CablingAnandu Ashokan75% (8)

- Risk Assessment For Installation of Light FittingsDocument11 pagesRisk Assessment For Installation of Light FittingsAnandu Ashokan89% (9)

- Risk Assessment For Pressure TestingDocument13 pagesRisk Assessment For Pressure TestingAnandu Ashokan83% (6)

- Risk Assessment For Installation of Electrical Wiring & Cable PullingDocument13 pagesRisk Assessment For Installation of Electrical Wiring & Cable PullingAnandu Ashokan95% (19)

- Risk Assessment For Testing and Commissioning of Electrical SystemDocument7 pagesRisk Assessment For Testing and Commissioning of Electrical Systemvo100% (3)

- Risk Assessment For Testing and Commissioning of Electrical SystemDocument8 pagesRisk Assessment For Testing and Commissioning of Electrical SystemAnandu Ashokan100% (9)

- Risk Assessment For Installation and Testing of CCTVDocument11 pagesRisk Assessment For Installation and Testing of CCTVAnandu Ashokan100% (5)

- Risk Assessment For MEP Isolation WorksDocument8 pagesRisk Assessment For MEP Isolation WorksAnandu Ashokan100% (6)

- Risk Assessment For Installation & Testing Commissioning of PumpsDocument17 pagesRisk Assessment For Installation & Testing Commissioning of PumpsAnandu Ashokan82% (11)

- Risk Assessment For Installation of Fan Coil UnitsDocument18 pagesRisk Assessment For Installation of Fan Coil UnitsAnandu Ashokan67% (3)

- Risk Assessment For Installation of Fire Alarm System & PAVA SystemDocument11 pagesRisk Assessment For Installation of Fire Alarm System & PAVA SystemAnandu Ashokan88% (8)

- Risk Assessment For Installation & Testing of BMS UnitDocument15 pagesRisk Assessment For Installation & Testing of BMS UnitAnandu Ashokan100% (3)

- Risk Assessment For Installation of HVAC Systems (RA34)Document19 pagesRisk Assessment For Installation of HVAC Systems (RA34)Anandu Ashokan83% (6)

- Risk Assessment For Installation of Sanitary WaresDocument14 pagesRisk Assessment For Installation of Sanitary WaresAnandu Ashokan75% (8)

- Risk Assessment of Installation of Chilled Water PipesDocument19 pagesRisk Assessment of Installation of Chilled Water PipesAnandu Ashokan82% (11)

- Risk Assessment of Heavy LiftingDocument5 pagesRisk Assessment of Heavy Lifting채종언100% (3)

- Risk Assessment For Installation of Toilet Exhaust FanDocument11 pagesRisk Assessment For Installation of Toilet Exhaust FanAnandu Ashokan67% (3)

- Risk Assessment For Flushing of Chilled Water PipingDocument9 pagesRisk Assessment For Flushing of Chilled Water PipingAnandu AshokanNo ratings yet

- Risk Assessment For Installation of HVAC Duct and AccessoriesDocument15 pagesRisk Assessment For Installation of HVAC Duct and AccessoriesAnandu Ashokan67% (3)

- Risk Assessment For Installation and Testing of ACS (RA33)Document11 pagesRisk Assessment For Installation and Testing of ACS (RA33)Anandu Ashokan100% (3)

- DashanDocument105 pagesDashanKristina TingNo ratings yet

- Risk Assessment For Installation of Toilet Exhaust FanDocument10 pagesRisk Assessment For Installation of Toilet Exhaust FanMaria Carmela Rachel GazilNo ratings yet

- Risk Assessment For Installation of Fire Fighting SystemDocument14 pagesRisk Assessment For Installation of Fire Fighting SystemMohamed Elhadad100% (5)

- MS For Installation of Light FittingsDocument11 pagesMS For Installation of Light FittingsAnandu Ashokan100% (2)

- Risk Assessment For Installation of Sanitary Fixtures and Mixers (New)Document12 pagesRisk Assessment For Installation of Sanitary Fixtures and Mixers (New)Anandu Ashokan100% (1)

- Risk Assessment For Installation of Grill, Diffuser & Louvers RA 36Document12 pagesRisk Assessment For Installation of Grill, Diffuser & Louvers RA 36Anandu Ashokan100% (1)

- Amc Concourse Bridge Project: Activity: Flushing of Chilled Water PipelineDocument8 pagesAmc Concourse Bridge Project: Activity: Flushing of Chilled Water PipelineEm Niax100% (1)

- Risk Assessment For Installation of MDBSMDB DB (Modified)Document15 pagesRisk Assessment For Installation of MDBSMDB DB (Modified)Anandu Ashokan100% (1)

- Risk Assessment For Installation of Fire Fighting Pipe & AccessoriesDocument15 pagesRisk Assessment For Installation of Fire Fighting Pipe & AccessoriesAnandu Ashokan83% (6)

- Risk Assessment For Integration of FACP, PAVA & ELV SystemDocument11 pagesRisk Assessment For Integration of FACP, PAVA & ELV SystemAnandu Ashokan100% (1)

- Flushingchemical Cleaning of Chilled Water PipesDocument9 pagesFlushingchemical Cleaning of Chilled Water PipesAnandu AshokanNo ratings yet

- GTGC-RID-IMS-MAN-00 Integrated Management System Manual PDFDocument64 pagesGTGC-RID-IMS-MAN-00 Integrated Management System Manual PDFMaria Magdalena Palacios Hernandez100% (1)

- Unit 1 Health and Safety in The Engineering WorkplaceDocument14 pagesUnit 1 Health and Safety in The Engineering WorkplaceTom Woods0% (1)

- განათების რისკები ინგლისურიDocument10 pagesგანათების რისკები ინგლისურიNino TsjelidzeNo ratings yet

- NPCL Project Chennai Risk Assessment Record: Activity: Installation of Fire Fighting SystemDocument15 pagesNPCL Project Chennai Risk Assessment Record: Activity: Installation of Fire Fighting Systemabbas100% (1)

- Risk Assessment For PAS InstallationDocument18 pagesRisk Assessment For PAS Installationjide.atolagbe3737No ratings yet

- Risk Assessment For Installation of Light FittingsDocument11 pagesRisk Assessment For Installation of Light FittingsHerdhiska Pradhiarta AjiprayogaNo ratings yet

- Risk Assessment For Installation of Toilet Exhaust Fan (New)Document12 pagesRisk Assessment For Installation of Toilet Exhaust Fan (New)Anandu AshokanNo ratings yet

- Ra For Installation of Light Fittings-10042024Document12 pagesRa For Installation of Light Fittings-10042024kwame fosterNo ratings yet

- Risk Assessment For Modification of Phase 1 Existing Building GPR TankDocument15 pagesRisk Assessment For Modification of Phase 1 Existing Building GPR TankAnandu Ashokan100% (1)

- Risk Assessment Record Activity: Installation ofDocument17 pagesRisk Assessment Record Activity: Installation ofvasanth pugazhendhi0% (1)

- Risk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitDocument17 pagesRisk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitAnandu Ashokan100% (1)

- RA For Cable Pulling and WiringDocument11 pagesRA For Cable Pulling and Wiringnikhilsingh1087No ratings yet

- Risk Assessment (INTERCOM)Document9 pagesRisk Assessment (INTERCOM)rocknNo ratings yet

- Risk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaDocument12 pagesRisk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaAnandu Ashokan100% (3)

- 6 RA - Template - BROGAN r2Document9 pages6 RA - Template - BROGAN r2Daniel100% (1)

- CHW & LTHW Installation - Risk Assesment.docxDocument21 pagesCHW & LTHW Installation - Risk Assesment.docxMohammad OsmanNo ratings yet

- RA of Tanks Activity - FDocument5 pagesRA of Tanks Activity - Frashid khattakNo ratings yet

- JSA - 008 - Hydraulic Rig and Mobile Crane MarchingDocument2 pagesJSA - 008 - Hydraulic Rig and Mobile Crane MarchingAhmed AlderbiNo ratings yet

- Tra 002Document6 pagesTra 002Bilal0% (1)

- TRA For ScaffoldingDocument3 pagesTRA For Scaffoldingaparna_losariNo ratings yet

- Jesa-Construction of Chemical Storage Shelter For CPP RegenDocument28 pagesJesa-Construction of Chemical Storage Shelter For CPP RegenResearcherNo ratings yet

- Risk Assessment - Sheet Piling DraftDocument8 pagesRisk Assessment - Sheet Piling DraftSinaNo ratings yet

- Stringing, Welding and Coating Process.Document2 pagesStringing, Welding and Coating Process.Beyar. ShNo ratings yet

- Jesa FGDDocument26 pagesJesa FGDResearcherNo ratings yet

- JSA Hot Work and ModificationDocument19 pagesJSA Hot Work and ModificationBrings MotoVlogNo ratings yet

- Risk Assessment For Installation of Diesel Generator111111Document8 pagesRisk Assessment For Installation of Diesel Generator111111Baher Mohamed100% (1)

- RA Underground Fire Pipe Installation Work R02Document15 pagesRA Underground Fire Pipe Installation Work R02vinayNo ratings yet

- Risk Assessment For Dismantling of Temporary ServicesDocument17 pagesRisk Assessment For Dismantling of Temporary ServicesAnandu AshokanNo ratings yet

- Risk Assessment - 002 PDFDocument5 pagesRisk Assessment - 002 PDF채종언No ratings yet

- Risk Rating Matrix in SafetyDocument7 pagesRisk Rating Matrix in SafetydebruynbeerNo ratings yet

- Forming Openings in Internal WallsDocument4 pagesForming Openings in Internal WallsdebruynbeerNo ratings yet

- Risk Assessment of Electrical WorkDocument10 pagesRisk Assessment of Electrical WorkdebruynbeerNo ratings yet

- Waste Handling and RecyclingDocument5 pagesWaste Handling and RecyclingdebruynbeerNo ratings yet

- Unloading of VehiclesDocument5 pagesUnloading of VehiclesdebruynbeerNo ratings yet

- Lone Worker Unoccupied PremisesDocument3 pagesLone Worker Unoccupied PremisesdebruynbeerNo ratings yet

- 03. Construction Supervisor 8.7 - ToM MORELLODocument1 page03. Construction Supervisor 8.7 - ToM MORELLOdebruynbeerNo ratings yet

- Risk Assessment - Workplace Temporary Electrical SupplyDocument2 pagesRisk Assessment - Workplace Temporary Electrical SupplydebruynbeerNo ratings yet

- S8.2.i HCS Co-OrdinatorDocument2 pagesS8.2.i HCS Co-OrdinatordebruynbeerNo ratings yet

- GSR8 Stacking and Storage SupervisorDocument2 pagesGSR8 Stacking and Storage SupervisordebruynbeerNo ratings yet

- 1st & 2nd Fix Plumbing, Gas & Electrical Works - Method StatementDocument10 pages1st & 2nd Fix Plumbing, Gas & Electrical Works - Method StatementdebruynbeerNo ratings yet

- 08. Incident Investigator - FRED DURSTDocument2 pages08. Incident Investigator - FRED DURSTdebruynbeerNo ratings yet

- Health and Safety Consultant RegistrationDocument1 pageHealth and Safety Consultant RegistrationdebruynbeerNo ratings yet

- Forming External Openings Risk AssessmentDocument4 pagesForming External Openings Risk AssessmentdebruynbeerNo ratings yet

- First Aid Risk AssessmentDocument3 pagesFirst Aid Risk AssessmentdebruynbeerNo ratings yet

- Difr - Clinic InfoDocument5 pagesDifr - Clinic InfodebruynbeerNo ratings yet

- Natural HazardsDocument15 pagesNatural HazardsYour NameNo ratings yet

- Enablon Health and Safety Management - 2023Document4 pagesEnablon Health and Safety Management - 2023Ihtisham UlhaqNo ratings yet

- Hazardous Materials Management PlanDocument25 pagesHazardous Materials Management PlanVaradaraju Thirunavukkarasan50% (2)

- DRRR Student Guide LM1Disaster 2021Document13 pagesDRRR Student Guide LM1Disaster 2021spicypusa69No ratings yet

- Lactonova FSMDocument29 pagesLactonova FSMvictoria3go100% (1)

- 8 - 2019 - Global Mapping of Eco-Environmental Vulnerability From Human and Nature Disturbances PDFDocument10 pages8 - 2019 - Global Mapping of Eco-Environmental Vulnerability From Human and Nature Disturbances PDFAndres DelgadoNo ratings yet

- Method Statement For Coring and Breaking Works: Rev. No Date Description Prepared Reviewed ApprovedDocument14 pagesMethod Statement For Coring and Breaking Works: Rev. No Date Description Prepared Reviewed ApprovedHARISH ROHANNo ratings yet

- Rig 812-A-001-Jha Prepare and Lower The Rig Floor & DerrickDocument5 pagesRig 812-A-001-Jha Prepare and Lower The Rig Floor & DerrickMalik Muhammad Nauman ZiaNo ratings yet

- Daily Lesson Plan in Electrical Grade 9Document11 pagesDaily Lesson Plan in Electrical Grade 9Gab Olarte50% (2)

- Management of Hazardous Waste in Malaysia - 194351Document5 pagesManagement of Hazardous Waste in Malaysia - 194351Adib HilmanNo ratings yet

- CHN I Chapter 14Document30 pagesCHN I Chapter 14jonaTOTNo ratings yet

- Warwick MSC Statistics DissertationDocument6 pagesWarwick MSC Statistics DissertationWriteMyPapersDiscountCodeCleveland100% (1)

- Bailan Integrated SchoolDocument41 pagesBailan Integrated SchoolHanah Joy SucgangNo ratings yet

- Unit 2Document25 pagesUnit 2Ifiye RuntaNo ratings yet

- 3618 Marine 2MW00001-UP (SEBP3774 - 107) - Systems & ComponentsDocument140 pages3618 Marine 2MW00001-UP (SEBP3774 - 107) - Systems & Componentsmohamed100% (1)

- Presostato HEDEDocument48 pagesPresostato HEDEMoLNo ratings yet

- Computing and Quality: SQM XxviDocument178 pagesComputing and Quality: SQM XxviAbdul Shakoor sabirNo ratings yet

- Criteria For Acceptable Risk in The NetherlandsDocument15 pagesCriteria For Acceptable Risk in The NetherlandsSNo ratings yet

- IC-01 Principles of InsuranceDocument257 pagesIC-01 Principles of InsuranceNeeraj MandaiyaNo ratings yet

- RA-2026-LEAD-1130-0008-67 Cable Pulling Laying Dressing Glanding Termination & Testing ActivitiesDocument5 pagesRA-2026-LEAD-1130-0008-67 Cable Pulling Laying Dressing Glanding Termination & Testing ActivitiesazerNo ratings yet

- CBC CSSDocument102 pagesCBC CSSErnesto OgarioNo ratings yet

- Preview ANSI+B11.0 2020Document9 pagesPreview ANSI+B11.0 2020Gilberth Mamani MedinaNo ratings yet

- IM 12 EHS Risk Management ProcedureDocument166 pagesIM 12 EHS Risk Management Procedureharish14586100% (1)

- HaccpgmpssopDocument40 pagesHaccpgmpssopRyza MartizanoNo ratings yet

- Disaster Readiness and Risk ReductionDocument296 pagesDisaster Readiness and Risk ReductionElpi Ferrer100% (1)

- Hand Safety PresentationDocument20 pagesHand Safety PresentationIsagani Vino100% (1)

- Ethical Sourcing CodeDocument122 pagesEthical Sourcing Codetsayed2009No ratings yet