Professional Documents

Culture Documents

Technical Description EHS-B 12m3 Drawing-no 01117526

Technical Description EHS-B 12m3 Drawing-no 01117526

Uploaded by

tim kaminskyCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Stoichiometry Worksheet6-1Document6 pagesStoichiometry Worksheet6-1Von AmoresNo ratings yet

- Sintef A17034 Organisational Accidents and Resilience Organisations Six Perspectives. Revision 2 PDFDocument143 pagesSintef A17034 Organisational Accidents and Resilience Organisations Six Perspectives. Revision 2 PDFAparupa KarNo ratings yet

- 14cbm Remote Control Grab Users Manual-En (Rev. 20.07.13)Document62 pages14cbm Remote Control Grab Users Manual-En (Rev. 20.07.13)tim kaminskyNo ratings yet

- Traverse 70tDocument1 pageTraverse 70ttim kaminskyNo ratings yet

- Working PrincipleDocument6 pagesWorking Principletim kaminskyNo ratings yet

- Remote Control Dismantle of CylinderDocument4 pagesRemote Control Dismantle of Cylindertim kaminskyNo ratings yet

- Remote CylinderDocument1 pageRemote Cylindertim kaminskyNo ratings yet

- PCH1543 ST0-ST1ADocument78 pagesPCH1543 ST0-ST1Atim kaminskyNo ratings yet

- Traverse 50tDocument1 pageTraverse 50ttim kaminskyNo ratings yet

- Technical Drawing Greifergestell Drawing-no 41118581Document2 pagesTechnical Drawing Greifergestell Drawing-no 41118581tim kaminskyNo ratings yet

- Behrens JU 001Document450 pagesBehrens JU 001tim kaminskyNo ratings yet

- UPS Operation ManualDocument27 pagesUPS Operation Manualtim kaminskyNo ratings yet

- HFO Transfer Pump-KomprimiertDocument34 pagesHFO Transfer Pump-Komprimierttim kaminskyNo ratings yet

- St3en08 20150624Document60 pagesSt3en08 20150624tim kaminskyNo ratings yet

- 2622.0-Emri 2490Document1 page2622.0-Emri 2490tim kaminskyNo ratings yet

- Hatlapa L160 BA - EnglDocument18 pagesHatlapa L160 BA - Engltim kaminskyNo ratings yet

- Erma First Fit BWTSDocument4 pagesErma First Fit BWTStim kaminskyNo ratings yet

- Pumps Azcue - Final DrawingsDocument391 pagesPumps Azcue - Final Drawingstim kaminskyNo ratings yet

- BMZ 349 ManualDocument68 pagesBMZ 349 Manualtim kaminskyNo ratings yet

- Azcue Pump ListDocument2 pagesAzcue Pump Listtim kaminskyNo ratings yet

- Idcs-500 Programing Manual (Eng.)Document547 pagesIdcs-500 Programing Manual (Eng.)tim kaminskyNo ratings yet

- Green Passport WAS 3000Document2 pagesGreen Passport WAS 3000tim kaminskyNo ratings yet

- Gas Was LrosDocument2 pagesGas Was Lrostim kaminskyNo ratings yet

- Noun (Subject) + Verb + The + Superlative Adjective + Noun (Object)Document6 pagesNoun (Subject) + Verb + The + Superlative Adjective + Noun (Object)anaNo ratings yet

- Resume of Noah C.D. HillDocument3 pagesResume of Noah C.D. HillNoah (AmericanGuy)No ratings yet

- Ultra Dense NetworkDocument27 pagesUltra Dense NetworkYounesNo ratings yet

- Error Handling in ASPDocument116 pagesError Handling in ASPkagga1980No ratings yet

- Report RubricsDocument2 pagesReport Rubricsswaggerz95No ratings yet

- Textbook - Thermal Physics PopleDocument26 pagesTextbook - Thermal Physics PoplecowsarechillNo ratings yet

- 3d Internet PDFDocument3 pages3d Internet PDFSam CrazeNo ratings yet

- Shortest Route ProblemDocument7 pagesShortest Route ProblemkaushalmightyNo ratings yet

- IPS-230X-IR 1.1 Starlight enDocument1 pageIPS-230X-IR 1.1 Starlight enahmed hashemNo ratings yet

- Assignment Activity On Expenditure Cycles - To Be ContinuedDocument3 pagesAssignment Activity On Expenditure Cycles - To Be ContinuedRico, Jalaica B.No ratings yet

- International Strategic Alliances 1Document21 pagesInternational Strategic Alliances 1mukesh93567No ratings yet

- 13-GB 50018-2002-EnDocument109 pages13-GB 50018-2002-Enyyyy071220100% (1)

- E4nb71 PDFDocument99 pagesE4nb71 PDFtambache69100% (1)

- Office of The President: Bicol UniversityDocument1 pageOffice of The President: Bicol UniversityElmer BelgaNo ratings yet

- Physics Lab Heat and HumidityDocument3 pagesPhysics Lab Heat and HumidityLAUREN YAPNo ratings yet

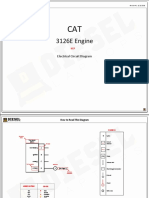

- 3126E Engine: Electrical Circuit DiagramDocument10 pages3126E Engine: Electrical Circuit DiagramPhil B.No ratings yet

- DMA Actuator Drives For - Motorised Butterfly Valve DMK - Motorised Throttle DMLDocument8 pagesDMA Actuator Drives For - Motorised Butterfly Valve DMK - Motorised Throttle DMLemil_88No ratings yet

- Item Wise Rate TenderDocument5 pagesItem Wise Rate TenderB-05 ISHA PATELNo ratings yet

- Zen and The ArtDocument3 pagesZen and The ArtMaria GonzálezNo ratings yet

- Total DataDocument984 pagesTotal DataajayNo ratings yet

- Aptis Writing C1Document33 pagesAptis Writing C1Sanjar JumayevNo ratings yet

- Power Quality Enhancement Using Custom Power DevicesDocument1 pagePower Quality Enhancement Using Custom Power DevicesankitNo ratings yet

- Aras Innovator Programmers GuideDocument105 pagesAras Innovator Programmers Guidem0de570No ratings yet

- 0 Theme 2 Stalin SOWDocument14 pages0 Theme 2 Stalin SOWEl DeNo ratings yet

- TL Files Struktol Content Maerkte-Produkte Kautschuk-Additive en Technische-Merkblaetter 01032 WB16FLAKES GB TECHDocument2 pagesTL Files Struktol Content Maerkte-Produkte Kautschuk-Additive en Technische-Merkblaetter 01032 WB16FLAKES GB TECHJoban AroraNo ratings yet

- The Relationship Between Dimensions of Love, Personality, and Relationship LengthDocument11 pagesThe Relationship Between Dimensions of Love, Personality, and Relationship LengthjuaromerNo ratings yet

- Lesson 3 DiscussionDocument3 pagesLesson 3 DiscussionElaineVidalRodriguezNo ratings yet

- SCIETECHNODocument19 pagesSCIETECHNOChini ChanNo ratings yet

Technical Description EHS-B 12m3 Drawing-no 01117526

Technical Description EHS-B 12m3 Drawing-no 01117526

Uploaded by

tim kaminskyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Description EHS-B 12m3 Drawing-no 01117526

Technical Description EHS-B 12m3 Drawing-no 01117526

Uploaded by

tim kaminskyCopyright:

Available Formats

ORTS GmbH Maschinenfabrik

Greifer , Transport- und Umschlagsgeräte , Sonderkonstruktionen

-----------------------------------------------------------------------

Grabs, Transport- and Handling Equipment, Engineering

Schwartauer Straße 99, D 23611 Sereetz

Phone: + 49 / 451 / 39885-0 Fax: + 49 / 451 / 392374

Technical Description

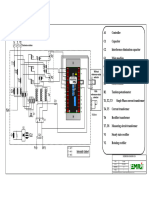

Electro - Hydraulic Clamshell Grab

Type EHS - B 12,0m³

Technical Description EHS-B 12m3 Drawing-no 01117526.doc

Page 1 of 7

Sus pension, Draw. no. : 31105769

Aufhängung, Zg.Nr.: 31105769

Shac kles C 32, DIN 82101

Schäk el C 32, DIN 82101

750

2979

3964 4405

Page 2 of 7

3000

4676

3444

Der Greifer schließt bzw.

Inhalt Aufböschung Schüttgewicht Eigengwicht : 7.200 kg

öffnet im Reversierbetrieb.

12,0 m³ 30° 1,8 t/m³ zum

Motorleistung : 54 kW : 45kW

13,2 m³ 40° 1, 1 t/m³ (Kohle ) Bespiel Spannung : 440 V / 60 Hz : 380 V / 60 Hz Reversing operating system.

9,0 m³ 30° 2, 2 t/m³ Bei geö ffn ete n Schließzeit : 14,5 s : 18,5 s DATE: C O N ST R ./ D R AW . : TRACED: SCALE:

6,0 m³ 30° 2, 6 t/m³ Redu zierklapp en Öffnungszeit : 9,0 s 12.06.06 Krebs 1:35 ORTS GmbH M aschinen fabrik

: 11,0 s C ON T R: ST A N D. C O N T R .: : AP PR OVE D: P R O J. M ET H .: D 2 3 6 1 1 Sereetz

Phone: 0451/39 8850 Fax: 3 92374

Volume Dome D ensity D e a d w e ig h t : 7.200 kg RR EPL. F OR: R EPL. BY:

12,0 m³ 30° 1,8 t/m³ M. - Output : 54 kW : 45 kW G

for G

13,2 m³ 40° 1,1 t/m ³ (Coal) example Voltage : 440 V / 60 Hz : 380 V / 50 Hz EHS-B 12m³

9,0 m³ 30° 2 , 2 t / m ³ whe n kick - C lo s in g t i m e : 14,5 s : 18,5 s T 01117526

RE F .: C AL C .:

6,0 m³ 30° 2,6 t/m ³ plates open O p e n i n g t im e : 9,0 s : 11,0 s

This drawing is property

of Ing. S. F. Orts.

It shall not be copied, duplicated

or submitted to outside parties

without our written consent.

Technical Description EHS-B 12m3 Drawing-no 01117526.doc

General

The electro - hydraulic clamshell grab is a modern and sturdy high performance

machine for the handling of bulk material.

The grab consists mainly of the following construction groups:

- Main power section

- Drive unit

- Hydraulic cylinders

- Clamshells

After connecting the grab to the proper power supply (380 V / 50 cycles or

440 V / 60 cycles) it is ready for working as a crane grab.

By changing the direction of rotation of the electro - motor the operating cylinders

are alternately fed via the hydraulic system with a pressure of up to 260 bar.

The closing and opening function of the grab is hydraulically remote controlled by

the crane driver, depending of crane type, by a change of the sense of rotation or

solenoid valves. The necessary cable between grab and crane house and the

switch are not in our scope of supply. The compact construction design in

combination with a suitable arrangement of all components and the optimised

grab kinematics are resulting in:

- A suitable course of the grab closing forces (especially at the end of the closing

process high closing forces are ensured),

- A wide grabbing distance between the shells.

Additionally there is a good filling of the grab due to the suitable shell shape and

grab curves.

A high utilisation of the cranes lifting capacity and therefore an optimised load

turn - over is guaranteed due to the low dead weight of the grab in combination

with the designed grab volume and load capacity.

The mechanical stability is guaranteed by a homogeneous construction, ample

dimensioned components and a good welding workmanship.

Main power section

Is made of a sturdy welded steel construction of steel quality St 52-3. It is

simultaneously hydraulic tank, support for the clamshells and bearing point for the

hydraulic cylinders. The electro - hydraulic drive unit is protected mounted in the

main power section. For the connection to the main electric power supply an

electric socket is installed.

The connection and the necessary parts and cables are not in our scope of supply.

The turntable grab suspension (top and lower traverse, shackles and chains) is

bolted to the top of the housing.

Technical Description EHS-B 12m3 Drawing-no 01117526.doc

Page 3 of 7

Drive unit

The drive unit consists mainly of an electric motor with flange - mounted axial -

piston pump. The complete unit is flanged vertically onto the tank top, with the

hydraulic pump submerged into the hydraulic tank. This ensures an oil flow free of

cavitations on the pump's suction side.

The special hydraulic valves and other necessary items are mounted on this tank

top too.

Hydraulic cylinders

Double - acting hydraulic cylinders with sea - water - resistant nickel - chrome -

plated piston rods (18Mn V5 / 0,04mm nickel / 0,025mm chrome). The cylinders

are protected against bulk a.s.o. by steel covers.

Clamshells

The grab clamshells are of a welded, stiff steel construction with solid designed

bearings to be connected to the main power section and to the hydraulic cylinders.

A pipe of a large diameter is installed across to the clamshell upper section and

both yoke plates, which are descending from the clamshell to the grab arm bearing

point.

This thick walled pipe is additionally stiffening the clamshell - side plates and

provides a high constructive twist resistance.

The bottom- and side plates are of steel quality St 52-3.

The clamshell bearings are arranged rearwards, in order to enable the grab

gripping into the areas underneath the top wing tanks of the vessel. The knives

(side - knifes and under - knifes) are a massive construction of highly wear

resistant steel type HARDOX 400 (or similar quality / hardness: 400 - 500 HB). For

an additional price standard type clamshell - teeth (choice of owner) are available.

Bolts

Bolt clamshell - cylinder and case : X20Cr13

Bolt clamshell - case : 42CrMo4

Bearings

Clamshell connection to main power section and cylinders:

- sealed joint bearings with additional sealing

Lubrication

Each bearing point is provided with an individual lubrication bore, witch ensures

that all bearing points can be checked with regard to proper grease passing.

Lubrication nipples:

Countersunk mounted high pressure nipples of DIN - type 71 412

Technical Description EHS-B 12m3 Drawing-no 01117526.doc

Page 4 of 7

General remark

All components are easily accessible and dismountable. Screws, axles, supports

a.s.o. are DIN - standard type as far as possible.

Connecting parts made from stainless steel (A4).

Coatings / Painting

Sandblasted SA 2,5.

First coat : 2x Primer

Topcoat : synthetic resign vanish

Colour : yellow RAL 1004

Our grabs / lifting equipment is tested and with certificate from “Germanischer

Lloyd”

Technical Description EHS-B 12m3 Drawing-no 01117526.doc

Page 5 of 7

190

310 ø50

750

Safe working Load (SWL) = 32 t

Prüflast (Test load) = 59 t

DATE: C ONSTR. /DRAW.: TRACED: SCALE:

09.04.98 Krebs / ORTS GmbH Maschinenfabrik

It shall not be copied, duplicated

CONTR: STAND. CONTR.:: APPROVED: PRO J. METH.: D 2 3 6 1 1 Sereetz

or submitted to outside parties

Phone: 0451/398850 Fax: 392374

without our written consent.

RREPL . FO R: REPL. BY:

This drawing is property

G

Aufhängung

of Ing. S. F. Orts.

G

T (Suspension) 31105769

REF.: CALC.:

Technical Description EHS-B 12m3 Drawing-no 01117526.doc

Page 6 of 7

Pos. 1 Kette f ür Einfachhaken

chain for single hook

Standard

Aufh ängu ng

Zg .Nr . 31 1057 69

Sus pe ns i on

Dr aw. - no. 31 1057 69

Pos. 2 Ketten für Doppelhaken

chains for double hook

Optional,

Price on request

Pos. 3 Ketten mit Traverse

chains with traverse

Optional,

Price on request

DATE: CONSTR./DRAW.: TR ACED: SCALE:

23.06.02 Krebs / ORTS GmbH Maschinenfabrik

It shall not be copied, duplicated

CONTR: APPRO VED: PROJ. METH .: D 2 3 6 1 1 Sereetz

or submitted to outside parties

STAND. CO NTR.::

Phone: 0451/398850 Fax: 392374

without our written consent.

RREPL. F OR: REPL. BY:

This drawing is property

G

Aufhängung

of Ing. S. F. Orts.

G

T Suspension

REF.: CALC.:

Technical Description EHS-B 12m3 Drawing-no 01117526.doc

Page 7 of 7

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Stoichiometry Worksheet6-1Document6 pagesStoichiometry Worksheet6-1Von AmoresNo ratings yet

- Sintef A17034 Organisational Accidents and Resilience Organisations Six Perspectives. Revision 2 PDFDocument143 pagesSintef A17034 Organisational Accidents and Resilience Organisations Six Perspectives. Revision 2 PDFAparupa KarNo ratings yet

- 14cbm Remote Control Grab Users Manual-En (Rev. 20.07.13)Document62 pages14cbm Remote Control Grab Users Manual-En (Rev. 20.07.13)tim kaminskyNo ratings yet

- Traverse 70tDocument1 pageTraverse 70ttim kaminskyNo ratings yet

- Working PrincipleDocument6 pagesWorking Principletim kaminskyNo ratings yet

- Remote Control Dismantle of CylinderDocument4 pagesRemote Control Dismantle of Cylindertim kaminskyNo ratings yet

- Remote CylinderDocument1 pageRemote Cylindertim kaminskyNo ratings yet

- PCH1543 ST0-ST1ADocument78 pagesPCH1543 ST0-ST1Atim kaminskyNo ratings yet

- Traverse 50tDocument1 pageTraverse 50ttim kaminskyNo ratings yet

- Technical Drawing Greifergestell Drawing-no 41118581Document2 pagesTechnical Drawing Greifergestell Drawing-no 41118581tim kaminskyNo ratings yet

- Behrens JU 001Document450 pagesBehrens JU 001tim kaminskyNo ratings yet

- UPS Operation ManualDocument27 pagesUPS Operation Manualtim kaminskyNo ratings yet

- HFO Transfer Pump-KomprimiertDocument34 pagesHFO Transfer Pump-Komprimierttim kaminskyNo ratings yet

- St3en08 20150624Document60 pagesSt3en08 20150624tim kaminskyNo ratings yet

- 2622.0-Emri 2490Document1 page2622.0-Emri 2490tim kaminskyNo ratings yet

- Hatlapa L160 BA - EnglDocument18 pagesHatlapa L160 BA - Engltim kaminskyNo ratings yet

- Erma First Fit BWTSDocument4 pagesErma First Fit BWTStim kaminskyNo ratings yet

- Pumps Azcue - Final DrawingsDocument391 pagesPumps Azcue - Final Drawingstim kaminskyNo ratings yet

- BMZ 349 ManualDocument68 pagesBMZ 349 Manualtim kaminskyNo ratings yet

- Azcue Pump ListDocument2 pagesAzcue Pump Listtim kaminskyNo ratings yet

- Idcs-500 Programing Manual (Eng.)Document547 pagesIdcs-500 Programing Manual (Eng.)tim kaminskyNo ratings yet

- Green Passport WAS 3000Document2 pagesGreen Passport WAS 3000tim kaminskyNo ratings yet

- Gas Was LrosDocument2 pagesGas Was Lrostim kaminskyNo ratings yet

- Noun (Subject) + Verb + The + Superlative Adjective + Noun (Object)Document6 pagesNoun (Subject) + Verb + The + Superlative Adjective + Noun (Object)anaNo ratings yet

- Resume of Noah C.D. HillDocument3 pagesResume of Noah C.D. HillNoah (AmericanGuy)No ratings yet

- Ultra Dense NetworkDocument27 pagesUltra Dense NetworkYounesNo ratings yet

- Error Handling in ASPDocument116 pagesError Handling in ASPkagga1980No ratings yet

- Report RubricsDocument2 pagesReport Rubricsswaggerz95No ratings yet

- Textbook - Thermal Physics PopleDocument26 pagesTextbook - Thermal Physics PoplecowsarechillNo ratings yet

- 3d Internet PDFDocument3 pages3d Internet PDFSam CrazeNo ratings yet

- Shortest Route ProblemDocument7 pagesShortest Route ProblemkaushalmightyNo ratings yet

- IPS-230X-IR 1.1 Starlight enDocument1 pageIPS-230X-IR 1.1 Starlight enahmed hashemNo ratings yet

- Assignment Activity On Expenditure Cycles - To Be ContinuedDocument3 pagesAssignment Activity On Expenditure Cycles - To Be ContinuedRico, Jalaica B.No ratings yet

- International Strategic Alliances 1Document21 pagesInternational Strategic Alliances 1mukesh93567No ratings yet

- 13-GB 50018-2002-EnDocument109 pages13-GB 50018-2002-Enyyyy071220100% (1)

- E4nb71 PDFDocument99 pagesE4nb71 PDFtambache69100% (1)

- Office of The President: Bicol UniversityDocument1 pageOffice of The President: Bicol UniversityElmer BelgaNo ratings yet

- Physics Lab Heat and HumidityDocument3 pagesPhysics Lab Heat and HumidityLAUREN YAPNo ratings yet

- 3126E Engine: Electrical Circuit DiagramDocument10 pages3126E Engine: Electrical Circuit DiagramPhil B.No ratings yet

- DMA Actuator Drives For - Motorised Butterfly Valve DMK - Motorised Throttle DMLDocument8 pagesDMA Actuator Drives For - Motorised Butterfly Valve DMK - Motorised Throttle DMLemil_88No ratings yet

- Item Wise Rate TenderDocument5 pagesItem Wise Rate TenderB-05 ISHA PATELNo ratings yet

- Zen and The ArtDocument3 pagesZen and The ArtMaria GonzálezNo ratings yet

- Total DataDocument984 pagesTotal DataajayNo ratings yet

- Aptis Writing C1Document33 pagesAptis Writing C1Sanjar JumayevNo ratings yet

- Power Quality Enhancement Using Custom Power DevicesDocument1 pagePower Quality Enhancement Using Custom Power DevicesankitNo ratings yet

- Aras Innovator Programmers GuideDocument105 pagesAras Innovator Programmers Guidem0de570No ratings yet

- 0 Theme 2 Stalin SOWDocument14 pages0 Theme 2 Stalin SOWEl DeNo ratings yet

- TL Files Struktol Content Maerkte-Produkte Kautschuk-Additive en Technische-Merkblaetter 01032 WB16FLAKES GB TECHDocument2 pagesTL Files Struktol Content Maerkte-Produkte Kautschuk-Additive en Technische-Merkblaetter 01032 WB16FLAKES GB TECHJoban AroraNo ratings yet

- The Relationship Between Dimensions of Love, Personality, and Relationship LengthDocument11 pagesThe Relationship Between Dimensions of Love, Personality, and Relationship LengthjuaromerNo ratings yet

- Lesson 3 DiscussionDocument3 pagesLesson 3 DiscussionElaineVidalRodriguezNo ratings yet

- SCIETECHNODocument19 pagesSCIETECHNOChini ChanNo ratings yet