Professional Documents

Culture Documents

Harshil Parikh Bluray Disc 359

Harshil Parikh Bluray Disc 359

Uploaded by

Harshil ParikhOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Harshil Parikh Bluray Disc 359

Harshil Parikh Bluray Disc 359

Uploaded by

Harshil ParikhCopyright:

Available Formats

1

SEMINAR REPORT

Entitled

BLU-RAY DISC TECHNOLOGY"

5ubmitted in portio/ fu/fi//ment of the requirement

for the ueqree of

resented Subm|tted 8y

Mr HARSHIL PARIKH

(RoII No. U08EC359)

B. TECH. IV (EIectronics & Communication) 7

th

Semester

6uided 8y

Prof. N. B. KANIRKAR

Associate Professor, ECED

(DECEMBER - 2011)

ELECTRONICS ENGINEERING DEPARTMENT

Sardar VaIIabhbhai NationaI Institute of TechnoIogy

Surat-395 007, Gujarat, INDIA.

ACKNOWLEDGEMENT

I take this opportunity with much pleasure to thank all the people who have helped me to

complete this seminar report titled 'BLU-RAY DISC TECHNOLOGY. I express my

sincere gratitude towards ProI. N. B. KANIRKAR , who gave me a chance to work under

his guidance and support. He was always there clear my doubts and queries. I would also

like to thank our Head oI the Department Dr. (Mrs.) Suprava Patnaik Ior the Iacilities

which were made available to me as and when required. Also a special thanks to all the

Iaculty members oI the Electronics Engineering Department who were always around to

help me and explore my area oI interest

I would also like to thank the administration oI the ECED department Ior being helpIul

and cooperative.

Signature

(Harshil Parikh)

LU-RAY DISC TECHNOLOGY

Abstract

Optical discs share a major part among the secondary storage devices. Blu-ray disc is a

next generation optical disc Iormat. The technology utilizes a blue laser diode operating at

a wavelength oI 405nm to read and write data. Because oI the blue laser it can store

enormous amount oI data than was ever possible. Data is stored on a BD in the Iorm oI

tiny ridges on the surIace oI an opaque1.1mm thick substrate. This lies beneath a

transparent .1mm protective layer. With the help oI Blu-ray recording devices it is

possible to record up to .5 hrs oI very high quality audio and video on a single BD.

Blu-ray also promises some added security, making ways Ior copyright protections. Bd

can have a unique ID written on them to have copyright protection inside the recorded

streams. Blu-ray Disc takes the DVD technology one step Iurther just by using a laser

with a nice colour. Because the Blu-ray Disc utilizes global standard "MPEG- Transport

Stream" compression technology highly compatible with digital broadcasting Ior video

recording, a wide range oI content can be recorded. It is possible Ior the Blu-ray Disc to

record digital high deIinition broadcasting while maintaining high quality and other data

simultaneously with video data iI they are received together. In addition, the adoption oI a

unique ID written on a Blu-ray Disc realizes high quality copyright protection Iunction.

-Prepared by - Guided by

HARSHIL PARIKH PROF. N.B.KANIRKAR

Roll No. U08EC59 Associate ProIessor

4

Sardar Vallabhbhai National Institute of Technology

Surat-395 007, Gujarat, INDIA.

ELECTRONICS ENGINEERING DEPARTMENT

This is to certiIy that the Tech IV (7

th

Semester) SEMINAR REPORT

entitled ~LU-RAY DISC TECHNOLOGY is presented & submitted by Candidate

Mr HARSHIL PARIKH, bearing Roll No.U08EC359, in the partial IulIillment oI the

requirement Ior the award oI Tech degree in Electronics & Communication

Engineering

He has successIully and satisIactorily completed his Seminar Exam in all respect.

We, certiIy that the work is comprehensive, complete and Iit Ior evaluation.

Prof. N. B. KANIRKAR Prof. N. B. KANIRKAR Dr. S. PATNAIK

Seminar Guide UG In-charge, ECED Head oI the Deptt., ECED

Associate ProIessor Associate ProIessor Associate ProIessor

SEMINAR EXAMINERS :

Name Signature with date

1.ProI.

.ProI.

.ProI.

DEPARTMENT SEAL

December-2011

5

INDEX

List of Figures 5

List of Tables 6

1 The objective of lu-ray Disc format 8

2 Optimization of the Cover Layer thickness 12

3 lu-ray Disc format 20

31 lu-ray Disc format overview 20

32 Physical format 20

33 Outline of the file system application format 29

331 Application format 29

332 File System format 31

4 Multi Layer disc 32

41 Dual Layer disc 32

42 Triple Layer disc and Quadruple Layer disc

(DXL) 35

43 Requirements for signal quality 38

5 Contents Protection System and Interface 46

6 Hard-Coating for are Discs 48

List of Figures

Fig No Description Page no

1(a) Evolution oI consumer optical discs

1(b) Relation oI Data transIer rate, Recording time and Required

capacity

1(c)

Evolution of the package media for movie application

1(d) The driving Iorce to promote HD

2(a) Numerical Aperture

2(b) ReIraction angle error

2(c) A wave Iront oI light diverging Irom an imaginary light source

2(d) Cover Layer has a Iunctio n oI optically diluting

2(e) Cover Layer is selected Ior BD-RE

3(a) Wavelength dependency on transparency

3(b) Comparison in the beam size

3(c) The structure oI Dual Layer disc

3(d) Groove recording

3(e) In-Groove or On-Groove

3(f) The density comparison in two modulation codes

3(g) An example oI the laser waveIorm Ior recording on RE media

3(h) Clip InIormation File

4(a) Dual Layer disc

4(b) The necessary condition on optical property oI L1 Layer

4(c) Eye diagrams oI read out sign al Irom BD -D u al L ay er d isc

with ca pa city oI 5 0 GB

4(d) BrieI parameters oI pickup and disc structure

4(e) Compatibility between legacy and BDXL

List of Tables

Table No Description Page no

3(a) Key parameters oI BD

4(a) BrieI physical speciIications oI SL disc and DL disc

4(b) BrieI physical speciIications oI all BD discs

8

The Objective of lu-ray Disc format Chapter-1

The standards Ior 1 cm optical discs, CDs, DVDs, and Blu-ray Rewritable discs (BD-RE

Standard V1.0) were established in 198, 199, and 00, respectively. The recording

capacity required by applications was the important issue when these standards were

decided (See Fig.1.(a)) The requirement Ior CDs was 4 minutes oI recording -channel

audio signals and a capacity oI about 800 MB. For DVDs, the requirement as a video disc

was the recording oI a movie with a length oI two hours and IiIteen minutes using the SD

(Standard DeIinition) with MPEG- compression. The capacity was determined to be 4.

GB considering the balance with image quality. In the case oI the Blu-ray Dis,

abbreviated as BD hereaIter, a recording oI an HDTV digital broadcast greater than two

hours is needed since the BS digital broadcast started in 000 and terrestrial digital

broadcast has begun in 00. It was a big motivation Ior us to realize this in an optical

disc the recorder. In a DVD recorder, received and decoded video signals are compressed

by an MPEG encoder and then recorded on the disc. To record in the same Iashion an

HDTV broadcast, an HDTV MPEG- encoder is required.

However, such a device Ior home use has not yet been produced. In the case oI BS digital

broadcasts, signals are sent as a program stream at a Iixed rate, which is 4 Mbps Ior one

HDTV program. In the program stream oI BS digital broadcast there is a case that the

additional data stream is multiplexed, and it is desirable to record and read the data as is.

Fig.1.(b) shows the recording capacity with the data transIer rate and recording time

parameters. Two hours oI recording requires a recording capacity oI GB or more. This

capacity is about 5 times that oI DVDs, which cannot achieve this capacity by merely

increasing the recording density.

9

Fig.1 (a)

Fig.1 (b)

To obtain this capacity we have developed a number oI techniques such as: employing a

blue-violet laser, increasing the numerical aperture oI objective lens, making the optical

10

beam passing Substrate thin, 0.1 mm, and evenly thick, using an aberration compensation

method oI pickup adapted to the Substrate thickness and Dual Layer discs, improving the

modulation method, enhancing the ability oI the Error Correction circuit without

sacriIicing the eIIiciency, employing the Viterbi decoding method Ior reading signals and

improving the S/N ratio and the Inter Symbol InterIerence, using the On-Groove

recording and highly reliable Wobbling address system, developing high speed recording

Phase Change media, etc. In addition, the convenient Iunctions oI a recording device have

also been realized in the application Iormats.

These techniques are described in this paper. Furthermore, the key concepts oI the Blu-

ray Disc standard such as the reason Ior employing 0.1 mm thick Transparent Layer and a

Dual Layer recording disc will be described in each dedicated chapter. Following the

Rewritable system, a Read Only system and Write-once system has been launched.

In addition to high picture quality, the introduction oI core and new Iunctions is

indispensable Ior the spread oI the next generation package media. For example, during

the switch Irom VHS to DVD, digital recording and interactive Iunctions were newly

introduced. Consequently, it is anticipated that the speciIications oI BD-ROM will

provide a high perIormance inter-activeness and a connection to broadband services,

reIlecting the demands oI the movie industry.

ig.1(c)

11

Recently, the digital HD broadcast started, and PDP and liquid crystal displays with large

and high picture quality screens are spreading Ior home use. The recording oI HD digital

broadcasts and HD packages with BD-ROM are considered to accelerate this tendency

and expected to be the trigger Iactors Ior the rapid spread oI HD

Fig.1(d)

* 1) The spelling oI "Blu-ray" is not a mistake. The character "e" is intentionally omitted

because a daily-used term cannot be registered as a trademark.

1

Optimization of the Cover Layer Thickness Chapter-2

Roots of a 12 mm Substrate existed in the video disc

One oI advantages oI laser discs has been that they are hardly aIIected by dirt or dust on

the disc surIace since inIormation is recorded and read through a Cover Layer. The Iirst

commercial optical disc, which was the videodisc called VLP or Laser Disc, used a 1.

mm thick transparent Substrate, through which inIormation was read. This thickness was

determined Irom conditions such as:

Deterioration oI the S/N ratio due to surIace contamination was suppressed to a minimum

since it used analog recording,

A disc oI 0 cm in diameter can be molded,

The disc has suIIicient mechanical strength,

The disc is as thin as possible while satisIying the Ilatness and optical uniIormity.

The last condition is because the thinner the Cover Layer, the more easily the

perIormance oI the objective lens to converge the laser beam can be improved. This

convergence perIormance oI the objective lens is expressed by what we call NA

(Numerical Aperture), and the diameter oI a converging light is inversely proportional to

NA (Fig.(a)). Thus NA is required to be as large as possible. However, when the optical

axis oI the objective lens shiIt Irom perpendicular to the disc surIace, a deterioration oI

the convergence perIormance (aberration) occurs and its amount grows proportionally to

the cube oI NA. Since we cannot avoid discs Irom tilting to some extent Irom the optical

axis oI the objective lens due to the bending oI discs or inclination oI the mounting, it has

prevented the value oI NA Irom increasing.

1

Fig.(a)

NA Numerical Aperture) is deIined as sin(0). Where 0 is halI angle oI converging light

converged by an objective lens. Around 80 oI light energy is converged in an area with

diameter oI / NA

On the other hand, an aberration caused by a disc inclination is proportional to the

thickness oI the Cover Layer. This aberration originates by the reIraction angle error at

the Cover Layer interIace resulting Irom the disc inclination. Further, the amount oI blur

in the beam spot due to the reIraction angle error is proportional to the distance between

the disc surIace and the Iocal point

Fig.(b)

When the disc tilts reIraction angle error, which is deviation Irom ideal angle to Iorm an

ideal light spot, occurs at the disc surIace. This reIraction angle error causes aberration at

the Iocal point. Then the aberration is in proportion to the distance between disc surIace

and the Iocal point, i.e., the aberration is in proportion to thickness oI Cover Layer.

14

The Objective Lens is designed in accordance with the Cover Layer Thickness

Although the Iirst two conditions, which stated that the Cover Layer was to be a 1. mm

thick Substrate, are not applicable to CD discs, the same thickness was eventually applied

to CD discs. This was because oI the great importance placed on the interchangeability oI

objective lens. Without raising the NA value oI the objective lens, discs with a diameter

as small as 1 cm could have suIIicient capacity Ior digital audio use.

The interchangeability oI the objective lens is generally lost when the thickness oI the

Cover Layer changes. This requires more explanation. An objective lens must converge a

laser beam in nearly ideal conditions. Such a laser beam has a spherical wave Iront in the

Cover Layer and a wave Iront distorted Irom a spherical surIace in the atmosphere beIore

entering the layer. It is acceptable that the distortion oI the spherical wave surIace in the

atmosphere is made equal to that oI light that is spread Irom a point source placed at the

spot where light converges. When a point light source is directed at the inIormation

surIace oI a laser disc, a spherical wave is Iormed and spread in the Cover Layer. The

wave will be distorted when it enters the atmosphere. This is because the length oI optical

path Irom the virtual light source to the interIace oI the Cover Layer diIIers between a

beam perpendicular to the interIace and ambient beams. Since the diIIerence in optical

paths is proportional to the thickness oI the Cover Layer, the thicker the layer is, the

greater the amount oI distortion Irom the spherical surIace wave in the atmosphere

Fig.(c)

An objective lens is designed to emit light with this distorted wave Iront. Because the

ideal distortion amount diIIers with the thickness oI Cover Layer, the design oI objective

15

lens also depends on the layer thickness. This is why the conventional thickness oI the

Cover Layer tends to be Iollowed even iI the Iormat is changed.

Thickness Reduction of the Cover Layer

Although a 1. mm thickness oI the Cover Layer was adopted when the CD standard was

deIined, another approach was adopted Ior DVDs and BDs. This is because the necessary

capacity could not be achieved iI that particular thickness oI the Cover Layer was used.

ThereIore, the optimization oI the Cover Layer thickness was examined again in order to

gain more capacity.

During digital recording, there`s no need Ior anxiety about the deterioration oI the S/N

ratio oI readout signals, compared with analog recording, as long as the signals can be

read without error. In addition, the manuIacturing process oI 1 cm diameter discs is quite

diIIerent Irom that oI 0 cm discs. Consequently, there were attempts to reduce the

thickness oI Cover Layer as much as possible and increase the NA value oI the objective

lens as much as possible.

It has been regarded that one oI principal advantages oI optical discs is that the inIluence

oI dust on the disc surIace is limited because the beams are deIocused Ior dust on the

surIace oI the Cover Layer when inIormation is recorded and read. When the Cover Layer

thickness is reduced, the NA value oI objective lens can easily be increased, while this

deIocus eIIect is sacriIiced. Since the Cover Layer thickness required Ior the deIocus

eIIect is diIIerent Ior digital and analog recordings, a reexamination is needed.

The deIocusing eIIect when light passes through the Transmission Layer means that by

increasing the cross section oI incoming laser beam on the SurIace Layer, the inIluence oI

small dust is diluted within the large section area oI the beam. In other words, although

the area inIluenced by dust is enlarged to entire section oI light beam, the signal

deterioration is reduced and reading errors are prevented. On the other hand, what we call

Error Correction is generally used as a means to remove reading errors. During this

operation, some redundancy data calculated Irom a large block oI data is attached to the

1

block as error check data. AIter the block is read, the check data is inversely calculated to

correct partial errors. This can be compared to an image modiIication process where a

partial deIect oI a photograph is corrected through estimations using adjacent image data.

Through this method, errors are prevented by diluting the inIluence oI partial signal

deIects in a large-scale data block. It can be said that this Error Correction method is the

electronic version oI deIocusing by the Cover Layer. This Iurther suggests that

deIocusing by the Cover Layer partially can be replaced by Error Correction (Fig.(d)).

However, there is a problem iI the thickness oI the cover layer is made nearly zero by

raising the Error Correction capability. This is because the smallest unit oI the Error

Correction calculation is one byte, and a very small error such as one bit is practically

magniIied to a one-byte error. ThereIore, deIocusing is still desired to prevent small dust

Irom causing bit errors. The thickness oI the Cover Layer Ior that purpose is about several

tens oI micrometers.

Fig. (d)

In the DVD standard, it was decided that the thickness oI Cover Layer could be as small

as 0. mm. This thickness could be made by the disc production Iacilities oI those days,

because the same mechanical strength as a CD could be obtained by sticking two pieces

together.

For the purpose oI BDs, this thickness was reconsidered with the essential condition to

realize a GB capacity, which is necessary to record a bit stream oI Japanese BS digital

HD broadcast Ior two hours.

1

At Iirst, it was natural to consider using the same production Iacilities as DVDs, that is, to

employ a thickness oI 0. mm. However, the capacity could only reach around 1 GB by

changing the wavelength Irom red (50 nm) to the blue (405 nm). As a Iurther

disadvantage, when there`s an incline in the disc, the magnitude oI aberrations increases

in inverse proportion to the wavelength. To suppress this aberration, the NA value oI the

objective lens must be reduced. In the mass-produced record type DVD, NA is 0.5 the

maximum, even iI a tilt servo controlling the tilt angle oI the optical pickup to the disc is

used. As described beIore, the aberration when a disc is inclined is proportional to the

cube oI NA. To cancel the increase in aberrations due to shortening oI the wavelength,

NA should be reduced to around 0.55. In this case, the recording capacity is lowered to

around 10 GB, Iar smaller than the GB allowed by one oI the newest reading

technologies such as PRML. Although the narrowing oI the Track Pitch was considered

while suppressing crosstalk by recording in and between the guide Grooves, the inIluence

oI heat conduction became relatively large when the Pitch was reduced. Further, the

problem where heat conduction erased the next Track`s inIormation could not be

overcome.

Thus, we tried to solve this problem by using Dual Layer recording. However, since the

area oI the beam spot Ior an NA value oI 0. is almost double that Ior a value oI 0.85, the

power density oI the spot decreases by halI, and it has been revealed that the output

power oI blue laser requires more than 100 mW Ior Dual Layer recording. To achieve

Dual Layer recording with a readily available blue laser, it is necessary to increase the

NA value by Iurther reducing the thickness oI the Cover Layer.

To determine the thickness oI the Cover Layer Ior BD, we had to either solve all oI

abovementioned problems Ior a 0. mm thickness, or reduce the thickness. AIter all, there

was no other choice than the latter because we could not Iind solutions Ior the above-

mentioned problems.

18

As describe beIore, the required thickness oI the Cover Layer is several 10 m or more.

Considering the balance oI the ease oI production and the possibility oI reducing costs in

the Iuture, a thickness oI 100 m was adopted as a base value Ior the Cover Layer. By

making the thickness oI Cover Layer 100 m, the NA value oI the objective lens could be

raised to 0.85. For a capacity oI 5 GB, the tilt margin (0.5 degrees) was conIirmed as

nearly equal to that oI DVD.

Compatibility was Obtained Using the Difference of Wavelengths

As described above, the thickness oI the Cover Layer has been inevitably changed each

time to achieve the required capacity. ThereIore, the problem has always been how to

maintain compatibility with past standards. The most accepted method is to switch the

objective lens. This was actually carried out in the DVD equipments Ior compatibility

with CDs. At the time, many proposals to maintain the compatibility with one objective

lens were presented. It is required to have an inIrared laser with a 80 nm wavelength Ior

reading CD-Rs, and a diIIerent wavelength red laser Ior DVD (50 nm wavelength) is

utilized Ior the compatibility. Since the NA value oI the objective lens Ior CDs is 0.45,

which is smaller than that Ior DVDs (0.), an optical device was introduced which lets a

80 nm wavelength beam pass through only the part oI the objective lens corresponding

to an NA value oI 0.45 and which has a high dependency on the wavelength. This

allowed the objective lens to perIorm in optimum conditions Ior a 1. mm thick Cover

Layer. Through this method, a diIIerence oI 0.mm in the Cover Layer thickness was

absorbed within the 0.45 NA range oI the objective lens.

A red laser is also required to be installed Ior BDs in order to guarantee compatibility

with DVDs. Gold or silicone is used Ior the semitransparent Film Layer as the First Layer

oI a Dual Layer disc. These materials have a high selectivity oI wavelength; the Iormer

prevents the reading oI a Iurther layer because it absorbs blue light and the latter prevents

reading oI a Nearer Layer because it does not reIlect blue light.

Installation oI red laser with blue laser can be utilized to realize compatibility with DVD

with one objective lens like as compatibility between DVD and CD.

19

To realize compatibility between BD and DVD, a diIIerence oI 0.mm in the Cover Layer

thickness has to be absorbed the 0. NA range oI the objective lens. Although the

conditions Ior BD/DVD are more severe than Ior CD/DVD, it is a matter oI degree. In

Iact, at the 00 CE show, a prototype that achieved compatibility oI BD/DVD with one

objective lens was demonstrated. II two objective lenses are used and switched, BD/DVD

compatibility can be easily achieved.

Although the diIIerence in wavelength has been used to respond to diIIerent thicknesses

oI the Cover Layer with one objective lens, this is diIIicult to achieve with the same

wavelength. For BD, the standard oI Rewritable discs (BD-RE Standard) will be

established Iirst, and it is very natural that in the upcoming standards Ior Read-Only type

and Recordable (Write-once) type discs, a Cover Layer thickness oI 0.1 mm will be

adopted

Fig. (e)

0

lu-ray Disc format overview Chapter-3

31 lu-ray Disc format overview

Table (a) shows key parameters oI Blu-ray Disc Iormats Ior R (Recordable), RE

(REwritable) and ROM (Read Only Media). The key parameters oI R, RE and ROM such

as wave length oI the laser diode, Numerical Aperture oI the objective lens, diameter oI

the disc, thickness oI the disc and diameter oI the center hole are common, and Blu-ray

Disc Iormat uses the same signal modulation as 1PP ((1, ) RLL Parity-Preserve,

Prohibit Repeated Minimum Transition Runlength code) and ECC (Error Correction

Code) as LDC (Long Distance Code) with BIS (Burst Indicating Subcode). Because oI

speciIying the same physical parameters and the same signal processing methods, we can

employ common technologies to the optical pickup and LSI, and then it becomes easier to

keep interoperability among R, RE and ROM.

Table (a) Key parameters oI BD

BD key parameters are deIined with a good balance oI conventional and new

technologies in the best possible manner considering requests Irom the current market

demands, interchangeability, and expandability in the Iuture. Detail explanations are

described at the later chapters.

32 Physical format

The physical Iormat oI the Blu-ray disc system, which Iollows the 80 nm CD and the

50 nm DVD, will be the last optical disc system using visible light. Based on this

1

inIormation, we decided to use the Iollowing basic optical disc parameters, knowing that

the development wasn`t complete, in order to maintain the expectation oI Iuture progress:

the shortest wavelength is 400 nm,

the highest value oI NA is 0.85,

the reasonable Substrate thickness oI 0.1mm,

.

A shorter wavelength was examined, but 400 nm was Iinally selected because a shorter

wavelength causes a durability problem in the plastics oI the Substrate Incident.

Fig. (a)

As shown in Fig. (a) many plastics Ior optical discs or optical devices suddenly show a

poor transmission Iactor when under 400 nm. Furthermore, some are deteriorated by a

phenomenon similar to sunburn.

The wavelength Iluctuation during production must be considered. The tolerance is set so

that the wavelength does not Iall below 400 nm. In conventional cases, the wavelength is

temperature dependent (Ior 80 nm the dependency ca. 0. nm /deg.; Ior 50 nm ca.

0.5 nm/deg.). In particular, when recorded on a Iilm with a pigment series recording

sensitivity dependent on wavelength, a number oI developments were needed. However, a

400 nm GaN laser seems to have a wavelength with a very small temperature dependency

compared with 80 nm and 50 nm lasers.

The diameter oI the concentrated beam is deIined by the NA value oI the objective lens

and the wavelength, as in the Iollowing expression:

Beam Diameter u x /NA

wavelength, u a constant

As seen in the above expression, the larger NA is, the smaller the beam diameter,

although NA does not exceed 1.0 in the atmosphere. The largest NA values oI CDs and

DVDs obtainable during mass production were 0.45 and 0., respectively. For Blu-ray

Disc , an objective lens with an NA value oI 0.85 was Iirst made by laying two lenses,

which can be manuIactured with the technique Ior the 0. class NA, one on top oI

another. The working distance oI this lens can be guaranteed at 0.14 mm at most, and it

was oIten said that the lens would hit the disc, unlike CDs or DVDs. However, it was

only in the early stages oI the CD that using a lens with a diameter as large as 4.5 mm

was possible and that the lens never physically hit the disc considering its moving

distance. Because oI the present compact designs, the lens can sometimes hit the disc both

Ior CDs and DVDs. ThereIore, we can`t ignore the Iact that the smaller the working

distance, the higher the probability oI a hit. However, some preventive measures can be

taken by the hardware to sense danger and activate a protection circuit to prevent a hit, or

a damper can be attached in case. In addition, JVC and other manuIactures have recently

started to design and prototype a stemma lens that can secure a working distance oI

approximately 0.5 mm. In all practicality, this distance will not cause any problem.

As described later, due to this large value oI NA, the margin in the Iocus direction, which

is aIIected by the square oI NA, and the margin in the normal direction oI the Cover

Layer, which is aIIected by NA to the Iourth power, must be considered. For optical

recording, a large NA value is an advantage. Because oI smaller spot size, it can be

plainly said that the power necessary Ior recording by a Bluray system with a 400 nm

wavelength and 0.85 NA is only 1/4 oI a DVD system with a 50 nm wavelength and 0.

NA.

Fig. (b)

A comparison oI diameter and intensity distribution oI a concentrated beam on a disc

between a CD and a DVD is shown in Fig. (b). The diameter used in the comparison is

the Iirst ring diameter when the Rim condition is satisIied at 100. Since the integral oI

this waveIorm is the recording energy on an optical media, the energy is supposed to be

input to the objective lens. Assuming the recording on the media begins with the same

energy, the smaller the diameter (that is, the higher the density), the less the necessary

laser power. This is one oI reasons why Blu-ray requires only 5 mW Ior recording while

CDs and DVDs require several tens oI mW Ior a similar recording speed.

This will make room Ior recording power when Multi Layer recording or high-speed

recording is developed in the Iuture. As described beIore, one oI the Blu-ray Disc Iormat

Ieatures is its applicability to Multi Layer discs.

Fig. (c)

4

In this case, L1 is deIined by the L0 plane sandwiched a 5 m thick Space Layer, and

the thickness oI the Cover Layer L1 is 5 m. L0 Ior all Multi Layer discs is always at the

position oI 100 m depth. ReIer to the later chapter as 1.4 Multi Layer disc in detail.

Since Blu-ray Disc Iormat employs diIIerent wavelengths, NA values, and Cover Layer

thicknesses Irom CDs and DVDs, it is necessary to design and develop a compatible

pickup Ior a system interchangeable with CDs and DVDs Ior recording and playing back.

This is the same problem encountered Ior reading and writing CDs when a

recording/playing back device Ior DVDs was planned. Some successIul studies have

already been released.

Groove Format

Physical structure oI a Blu-ray disc is a Groove recording as shown the Iollowing Iigure.

Fig. (d)

There were many opinions and study results concerning this, and it would be one oI

reasons why several recording Iormats were deIined Ior DVDs. Fortunately, companies

which dealt with the three DVD recording systems have joined the Blu-ray Disc Iormat

development group; all the studies have been reexamined and one physical Iormat has

been established. Furthermore, it was quite helpIul that the most comprehensive erasable

system was introduced Iirst, unlike the cases Ior the CD and DVD in which the ROM

came Iirst and the other systems had to be adapted to it. It was natural that the master

design oI Blu-ray was made compatible Ior both home-use devices and computer

peripheral devices. ThereIore, the structure oI the Data Unit arrangement was made,

5

leaving a gap between blocks as with DVD-RAM. In addition, as in the past, to include

ROM and R media into the vision, the Groove recording system was employed instead oI

Land/Groove recording in order to respond to these three kinds oI recording media. This

idea had also been adopted Ior CD-R, RW, DVD-RW, and RW systems. One oI reasons

why discs oI diIIerent Track Pitch coexist in the Iamily is to prevent losing the Ireedom oI

the optical pickup design. At Iirst, the mastering seemed to be extremely diIIicult Ior a

0. m Track Pitch; the Groove itselI must be Iormed with about a halI the precision oI

0. m. Besides, since it would be necessary in the Iuture to make a ROM type disc

whose Pit must be Iormed by embossing, intensive developments have been carried out.

As a result, mastering by Electron Beam (EB) was enabled Iirst, and subsequently

mastering by deep UV was enabled in the 5 GB class oI Blu-ray Disc. Furthermore, the

mastering technology Ior Blu-ray using a beam with a wavelength oI 400 nm was even

developed, removing all obstacles against Groove recording. A stamping technology Ior

this density has already been established.

Furthermore Ior BD-RE and BD-R H to L Type media, taking a high NA value such as

0.85 into account, the On-Groove method was selected instead oI In-Groove. Although it

is not easy to explain this in a scalar Iield, On-Groove was selected based on simulation

results shown in the Iigure and actual experiments.

Fig. (e)

As seen in the In-Groove Iigure Ior these parameters, the power oI the recording beam

runs oII in a radial direction. A narrow Track Pitch will make the Land/Groove recording

system, which records both On-Groove and In-Groove, diIIicult.

At Iirst, there were doubts whether or not the R media could respond to an On-Groove

system. However an H to L Type R media that could respond to such a structure has

already been developed and an On-Groove system can be applied to derivative Iormats

such as CD and DVD.

Later the L to H Type R media was developed as the Iamily oI BD-R. This Type media

adopted organic dye Ior the recording material. The dye Recording Layer is made by

using the spin coating technology and In-Groove is suitable considering the

manuIacturing process. Among the dye media there are materials that irradiate heat or

explode and induce the physical change around the recorded Mark during the recording.

The Mark made by this kind oI recording mechanism tends to extend in the radial

direction and needs the In-Groove wall that can stop the Mark expansion in the radial

direction. ThereIore In-Groove recording was adopted Ior the L to H Type BD-R.

Addressing Method

Blank addressing, when Groove recording is adopted, is Iormed only by the Wobble

method. This concept is close to that employed Ior RW. Although addressing with a Pit

was Iirst examined, an addressing system without a Pit was Iinally chosen considering

that the recording density must be increased to make room Ior the header with the Pit and

that in a Multi Layer disc, the Pit address has a great inIluence on the recording in other

layers. The modulation technique Wobbling in the radial direction is based on MSK

(Minimum ShiIt Keying) and Iormatted in blocks oI 4 kB. The basic Wobble Irequency

is around 5 m, and 0 and 1 are expressed as the position where the sinusoidal wave is

modulated by the MSK rule. Although the modulation energy oI MSK is large, it is easily

inIluenced by deIects because inIormation is localized. For that, a signal called STW

(Saw Tooth Wobble) is used in Iorm oI multiplying to MSK. The STW adds secondary

harmonics to all sinusoidal waves oI Wobble, and 0 and 1 oI the address data correspond

to the polarity oI added secondary harmonics. Since the energy oI the STW signal is

distributed in space unlike that oI MSK, and detected by integration, it is robust against

partial deIects. The detection oI an address in the Blu-ray system is robust because oI the

use oI both MSK and STW.

Error Correction Method

An Error Correction method must be designed in accordance with the error distribution oI

a Cover Layer thickness oI 100 m. This operation started by statistically treating the

error distribution when the actual disc structure was subjected to a dust test and played

back, and by modeling the distribution. As a result, what came out were short bursting

errors by dust or scratches, and so-called picket codes with a structure matching long

bursting errors that sometimes occur. This is made by combining a deep interleave to a

long distance code, a kind oI Reed-Solomon Code with a size oI 4 kB, and then adding a

burst indicator called BIS.

Modulation Technique

The modulation technique oI the main channel recorded along a track is called 1PP ((1,

) RLL Parity-Preserve, Prohibit Repeated Minimum Transition Runlength code). This is

a so-called d1 code. As the examination results show, assuming that a Rewritable disc is

taken Iirst, the d1 code was employed this time around because the wide detection

window is advantageous as compared with the d code used Ior CDs and DVDs (see the

Iigure below). Further, a low Channel clock can be used when recording at high speed.

Fig. (I)

8

This data was obtained Irom a past experiment using a wavelength oI 50 nm. Although

the horizontal axis must be transIormed to the density oI Blu-ray, this tendency was

obtained when recorded and played back on a Phase Chang media. The use oI d 1 means

that non-linear Equalizer and PRML detection represented by Limit-Equalizer act more

eIIectively, and this type oI signal processing is more important in Blu-ray Disc compared

with CD and DVD. Although the mastering and embossing ROM Pit seemed diIIicult at

Iirst because the minimum Pit is shorter than that oI d, those processes were eventually

successIul thanks to the progress oI the mastering technology when the capacity is around

5 GB. The Parity preserve means that DC balance oI signals aIter modulation can be

evaluated without looking at the 0-1 series, and it is eIIective in reducing the hardware

load. Prohibit RMTR (Repeated Minimum Transition Runlength) is limited not to run

seven or more in 1PP by preventing long run oI minimum length (what represented by

101 aIter modulation).

|ReIerence|

'Optical Disc System Ior Digital Video Recording, T. Narahara et.al., Jpn. J. Appl. Phys.

9 (000)

Recording Medium and Writing Strategy

Blu-ray Disc uses Phase Change Iilm as a recording media. Phase Change Iilm is

classiIied into two types: a Iamiliar example is what`s called the GST (GeSbTe

stoichiometrical composition) type used Ior DVD-RAM and the other is the eutectic type

used Ior CD-RW, DVD-RW, and RW. Each type has its advantages in repeat recording

characteristics and high-speed recording. For Blu-ray Disc, the recording pattern was

devised to allow the application oI both types oI Phase Change Iilms. Both media were

also improved so that a recording pattern oI the same type can be used with a

predetermined density and a range oI almost the same power. An example oI recorded

pattern Ior RE v1.0 is shown in Fig. (g). It`s a waveIorm Ior recording a Pit including

two pulses oI the Channel clock, which is the smallest Pit length, and a waveIorm Ior

recording a longer Pit including Iive pulses.

9

Fig. (g)

In BD-RE V1.0, the largest recording power at Mbps is 5. mW (10.4 mW Ior dual

layers). This was explained previously where a high NA value suppressed the power at

this level, even Ior Mbps.

33 Outline of the File System Application format

The BD-RE standard consists oI three parts: Part 1 (Physical Iormat), Part (File System

Iormat), and Part (Application Iormat). Abstracts are explained here on the Application

Iormat Ior R and RE and the File system Iormat.

331 Application format for RE and R

First, the Iunction oI the Application Iormat is described.

Digital roadcasting Direct Recording Function

This recording Iunction enables the recording oI not only digital broadcast image data

without destroying the image quality, but also oI data broadcast data and multi-channel

sound data altogether.

To this end, this Iormat employs the MPEG-TS (Transport Stream), used by digital

broadcasts, as a stream type Ior recording.

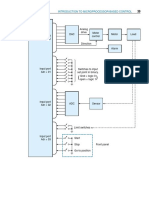

Received MPEG-TS data is recorded on a disc as a Clip AV stream Iile (Fig. (h)).

0

Fig. (h)

Random Access High-speed Playback Function

To achieve a Iunction that enables random access to a desired scene in MPEG-TS and

high speed playback, tables to obtain the record position oI data corresponding to a

playback time requested by the user are provided Ior each Clip AV stream Iile. The tables

are stored in the Clip InIormation File shown in Fig. (i).

Editing and Marking Function

The PlayList Iile is provided Ior removing unnecessary scenes without copying or

transIerring recorded data like tape media, and editing material recorded on the disc

without processing the original image (Fig. (i)).

Fig. (i)

The PlayList Iile also holds bookmark inIormation to enable direct access to a Iavorite

scene.

1

Contents Search Function

In each thumbnail related Iile shown in Fig. (i), thumbnails (representing a scaled-down

version oI picture) oI the PlayList Iile and bookmarked scenes are stored. This enables the

search Ior recorded contents and bookmarks by viewing thumbnail images.

332 File System format

Main Iunctions oI the File system Iormat are described next.

High-speed Response

To shorten the response as much as possible Irom the time the disc is inserted until

recording/playing back becomes ready, Iiles other than Clip AV stream Iiles are stored

closely in certain area on the disc.

High Reliability

Even iI stored data becomes impossible to read due to scratches or dust, cases oI lost

recorded contents should be avoided as much as possible.

ThereIore, the File system Iormat has a mechanism that always copies the PlayList Iiles,

part oI the thumbnail related Iiles, Clip InIormation Iiles, etc. to another recording area

Ior backup.

Multi Layer disc Chapter-4

41 Dual Layer disc

Dual layer system is deIined Ior rewritable or recordable type oI Blu-ray discs. To

achieve the Dual Layer, many new techniques such as super-thin recording Iilms and

assembly processes are needed. It can be said that continuous developments since 1994

produced results, i.e. the Dual Layer BD 1) ). BD provides large recording capacities

such as 50GB (5GB per layer). More than 4 hours oI HDTV and more than 0 hours oI

SDTV can be recorded respectively. In addition, since recording and playback can be

done Irom one side, user does not have to turn the disc over in the drive.

Fig.4 (a)

Fig.4 (a) shows a schematic drawing oI the Dual Layer BD disc. In Blu-ray Disc Iormat,

an inIormation recording layer 100 m away Irom the laser incident plane is deIined as

the L0 Layer, and another inIormation recording layer 5 m away is called as the L1

Layer. A Phase Change material is used as the recording media because oI prior

experience with DVD-RAM, DVD-RW, etc. Fig.4 (a) Dual Layer disc

Fig.4 (b) is a comparison oI the structures oI the DVD (ROM) and BD Dual Layer discs.

With the DVD, the Rear and the Front Layers are Iormed separately on two Substrates

and then, the Substrates are attached one on top oI another with a UV-hardening resin

adhesive. Because each Substrate is 0. mm thick, a guide Groove Ior tracking can be

Iormed independently. On the other hand, in BD, the Rear Layer consisting oI Multi

Layered Iilms is Iormed on a 1.1 mm thick polycarbonate Substrate with a guide Groove

Ior tracking, and then the 5 m thickness oI Space Layer made oI resin is Iormed. The

Front Layer is Iormed on it, and Iinally the 5 m thick Cover Layer is Iormed. The

Cover Layer is too thin to Iorm a guide Groove. The Iirst technological hurdle Ior BD is

how to Iorm this guide Groove. A suggested Iorming method speciIies that a guide

Groove Ior the Front Layer is transcribed on the Space Layer side like a stamping process

).

Fig.4 (b)

The second technological hurdle Ior the Dual Layer BD disc is the Front Recording

Layer. The Iollowing conditions are speciIied Ior the Front Layer (See Fig.4 (c)).

Fig.4 (c)

(1) Transmittance

Because in the Dual Layer disc the Rear Layer is recorded through the Front Layer, it is

important that the Front Layer has a suIIiciently large transmittance. It is natural that the

Front Layer itselI should be recorded and read with certain light power; thereIore the

target value oI its transmittance is 50 to share light between both layers.

(2) The transmittance should not change before and after recording

4

Since BD assumes random access recording, sometimes the Rear Layer is recorded or

read while there are Recorded Areas and Unrecorded Areas mixed on the Front Layer. II

the transmittances change depending on whether or not the area is recorded, the intensity

oI passed beams Iluctuates and negatively inIluences the recording/reading oI the Rear

Layer. It is thereIore desirable that the transmittance does not change between recorded

and unrecorded states. Selection oI the recording Iilm material and the design oI the

Multi-Layer Iilm are important.

(3) alance of the cooling speed and crystallization speed

Phase Change material becomes amorphous aIter high-power laser heating during

recording Iollowed by quick cooling and crystallizes with middle-power heating when

being erased. To make the Front Layer semi-transparent, the reIlection Iilm and recording

Iilm tend to be thinner compared with conventional discs. However, there are problems

with the Iormer, where the cooling speed decreases aIter melting, and Ior the latter, the

crystallization speed decreases.

In addition, it is desirable Ior the Rear Layer to be the same as a Single Layer considering

the eIIiciency oI development and production. In consideration oI the above-mentioned

points, the development oI the Dual Layer disc and the BD standardization were

promoted. Fig.4 (d) shows the played-back signal (aIter Limit-Equalizer) oI the

developed 50 GB disc. The signal characteristics are comparable to a Single Layer BD

disc. The development oI the Dual Layer disc will be the key Ior Iurther enhancements oI

BD's charm as a large volume recording media.

Fig.4 (d)

5

42 Triple Layer disc and Quadruple Layer disc (DXL)

One oI Blu-ray Disc Iormat Ieatures is to be able to pile up layers as Multi Layer disc.

BDA successIully speciIied Triple Layer disc Iormat 100GB Ior R and RE and Quadruple

Layer disc Iormat 18GB Ior R in June 010. Either Iormat is named as BDXL.

BDA created BDXL SpeciIications on three basic design concepts as Iollows.

1 Used the same core parameters as SL/DL

BDXL SpeciIications use the same core parameters such as L0 Layer thickness, laser

wave length, lens NA, Track Pitch, ECC, modulation codec and Wobble address Iormat

(STW/MSK). It means a new device supporting BDXL discs can use almost the same

technologies on the optical pickup and LSI as those used in a legacy device. It helps to

realize the interoperability among Single Layer disc, Dual Layer disc, Triple Layer disc

and Quadruple Layer disc.

2 Minimized the changes to achieve high capacity

In order to achieve higher capacity, BDA (i) deIine the appropriate thickness oI each

Layer except L0 Layer Ior either the Triple Layer disc or the Quadruple Layer disc, (ii)

increase the linear density (capacity/layer) and (iii) update some data alignments oI disc

management inIormation.

3 Optimized Specifications for RE and R to reflect physical property differences of

Multi Layer Recording Stacks

Physical parameters such as reIlectivity, write power, read power etc were optimized to

reIlect its own physical property Ior either R or RE. ReIer to White Paper oI BD-RE and

BD-R in detail.

Table 4(a) shows brieI physical speciIications oI all BD Discs

Table 4(a) shows brieI parameters oI pickup and disc structure. Since the optical

parameters oI a pickup such as NA (Numerical Aperture) and wave length oI the laser

diode are common, the pick up to read the Triple Layer disc and/or the Quadruple Layer

disc can read either the Single Layer disc or the Dual Layer disc easily. All types oI BD

discs have L0 Layer at the position oI 100m depth. At the start up timing, a pick up can

seek L0 Layer oI any disc with the compensation Ior 100m spherical aberration and can

Iind the disc type which it is reading. The thickness oI the Space Layer is designed to

avoid the cross talk Irom other layers. ReIer to the White Paper R and RE in detail.

Fig.4 (e)

Fig.4 (e) shows compatibility between legacy and BDXL. A legacy device to support

5/50GB only cannot read nor write a BDXL disc. BDA has prepared a new logo as

shown to clearly distinguish BDXL discs Irom 5/50GB discs and devices Irom the

legacy ones. A device having this BDXL logo can handle a disc having the BDXL logo. It

is not mandatory, but the new device supporting BDXL disc can be easily designed to

support 5GB/50GB discs since BDXL speciIications have been developed with small

impact on pickup and LSI Ior 5/50GB discs.

Fig.4 (I)

BDXL disc can be used Ior proIessional use. Fig.4 (I) shows some application images Ior

BDXL disc. Data such as broad cast program, media data and internet data become bigger

and bigger day by day. The archiving market is rapidly growing along with this data

explosion. It is expected that BDXL disc would be useIul Ior this market.

Fig.4 (g)

Fig.4 (g) shows another example. Since the capacity oI the Ilash memory becomes bigger

and bigger, it is necessary to increase the disc capacity in order to backup this data. And

also there is a strong requirement Irom proIessional industry to have large capacity

storage devices Ior proIessional video camera and proIessional server to store huge data.

8

BDXL disc is expected to meet these requirements. In addition BDXL disc can be used

Ior the consumer market like a recorder which can record longer TV programs.

Fig.4 (h)

43 Requirements for signal quality

Table 4(b) shows requirements Ior signal quality speciIied in the Format Books.

i-MLSE*: integrated Maximum Likelihood Sequence error Estimation

The signal quality oI SL disc or DL disc is measured by Limit-Equalizer. On the other

hand, since the liner density becomes higher, the new signal quality evaluation index as i-

MLSE, which stands Ior integrated Maximum Likelihood Sequence error Estimation

using PR (1,,,,1) is applied Ior TL disc or QL disc. The speciIication required Ior each

layer oI a disc is described in Table 4(b). The values are measured by a Tester in the

Testing Center. The speciIication value oI a closer layer to the pickup

is more relaxed, because a shorter optical path has larger tolerance Ior the disc tilt.

9

There are two types oI R-SER (Random-Symbol Error Rate). R-SER speciIied in Part1

Book is required Ior a disc. When a Tester in Testing Center writes and measures a disc,

the disc has to satisIy less than .0E-4 oI R-SER. R-SER speciIied in the Drive Test

SpeciIications is required Ior a drive. When a drive writes a Test disc, the Test disc has to

satisIy less than 1.0E- oI R-SER by a Tester. The Tester mentioned above means a tester

which satisIies the test conditions speciIied in the Format Book and the Test disc is a disc

authorized by BDA Ior testing purpose.

itter measurement using the Limit-Equalizer

Generally, a playback signal reading system uses a Linear Equalizer to improve the

Signal to Noise Ratio (SNR) around minimum-length Pits and to suppress Inter-Symbol

InterIerence. Disc noise exists mainly in a low-Irequency region as shown in Fig.4 (i).

When high Irequency around minimum length Pits is selectively boosted using the Linear

Equalizer, the minimum-Pit-length signal level can be markedly enhanced with only a

small increase in the total amount oI noise. That is, it is possible to improve the SNR by

using a Linear Equalizer that boosts high Irequencies. However, since an excessive

boosting oI high Irequencies causes an increase in Inter-Symbol InterIerence, the

Conventional Linear Equalizer has a limit to SNR improvement.

Fig.4 (i)

A Limit-Equalizer is capable oI boosting high Irequencies without increasing Inter-

Symbol InterIerence. Fig.4 (j) shows the conIiguration oI the Limit-Equalizer system

used in 1PP modulation. In this system, a Pre-Equalizer Iirst minimizes Inter-Symbol

InterIerence.

40

A Conventional Linear Equalizer is used as the Pre-Equalizer. The Limit-Equalizer is

located next to the Pre-Equalizer. The Limit-Equalizer has almost the same construction

as a Finite-Impulse- Response (FIR) Linear Equalizer, except that the Limiter restricts the

amplitude oI part oI playback signal. The FIR Iilter acts as a high-Irequency-boosting

Equalizer, and its gain is determined by coeIIicient 'k. The gain oI the FIR Iilter

increases with the value oI k.

Fig.4 (j)

Sample values oI the playback signal are indicated at the small-circle points in Fig.4 (k)

To understand the operation oI the Limit-Equalizer, we pay attention to the zero-cross

point and the sample values at points close to the zero-cross point. The operation oI the

Equalizer without a Limiter is as Iollows.

ReIerring to the leIt-side chart oI Fig.4 (k), iI the playback signal waveIorm is

symmetrical as indicated by the solid line, the data summed up by the Equalizer becomes

0 as expressed in Equation (1), and the zero-cross point does not move.

(-k)x(-a) (k)x(-a) (k)x(a) (-k)x(a) 0 --- (1)

However, iI the playback signal waveIorm is asymmetrical as shown in the dotted line,

the data summed up by the Equalizer does not become 0 as indicated by Equation (),

resulting in the Inter- Symbol InterIerence.

(-k)x(b) (k)x(c) (k)x(d) (-k)x(e) = 0 --- ()

41

Fig.4 (k)

II a Limiter is used to restrict the signal amplitude to around the peak amplitude level oI

the shortest wavelength signal, the waveIorm becomes symmetrical as shown by the

dotted line in the right-side chart oI Fig.4 (l). In that case, the data summed up by the

Equalizer is constantly 0, as expressed in Equation ().

(-k)x(-I) (k)x(-I) (k)x(I) (-k)x(I) 0 --- ()

The Limiter does not act on a signal with minimum-length Mark, and the Equalizer

ampliIies the signal amplitude. For a low-Irequency signal with high amplitude, the

Limiter restricts the amplitude around the center tap, which is to be added to the sum. The

Iilter gain is eIIectively decreased. Thus, the Limit-Equalizer can boost high Irequencies

without increasing Inter-Symbol InterIerence, and SNR is improved.

Since the Blu-ray Disc Iormat adopts high-density recording and 1PP modulation, the

minimum Mark length is shorter than Ior a conventional optical disc, and its SNR is

lower. Viterbi decoding in the disc drive can compensate Ior the lower SNR to achieve

good playback perIormance. However, since Viterbi decoding output is the result aIter

1/0 determination and is poor in sensitivity, it is not suitable Ior use in evaluating optical

discs in general. The jitter oI signals processed by a Linear Equalizer is dominated by the

component attributed to the noise oI disc itselI rather than the component attributed to the

quality oI Recording Marks, making it diIIicult to determine whether or not the recording

state is optimal. In this regard, a Linear Equalizer is not suitable Ior use in disc

evaluation.

4

The Blu-ray Disc system employs a Limit-Equalizer to improve the SNR and to measure

jitter Ior disc evaluation. With the Limit-Equalizer, it is possible to determine the quality

oI Recorded Marks with high sensitivity. Fig.4 (m) shows the relation oI jitter to the error

rate. Though the Limit-Equalizer has a non linear operation block inside, the relationship

oI input to output is linear and suitable Ior the measurement system.

Fig.4 (l)

In BDXL Iormats the capacity per layer is raised up to .4GB or .0GB only by

increasing the linear density. As a result, in BDXL, the Inter-Symbol-InterIerence (ISI) oI

the readout signal becomes much stronger compared to the prior Iormat that allows just

5GB per layer. ThereIore the readout signal processing needs to be improved. Also, the

prior signal quality evaluation method using the Limit-Equalizer technology has turned

out to be no longer applicable. Integrated-Maximum- Likelihood -Sequence-Error-

Estimation (i-MLSE), which is an alternative signal quality evaluation

method Ior BDXL, was newly developed and retains the stability and the precision in

such a severe ISI condition oI BDXL. The evaluation method oI i-MLSE stands on the

detection principle oI the Viterbi-Algorithm (VA) in the Partial-Response-Maximum-

Likelihood (PRML) readout signal processing. ReIer to R or RE White Paper in detail.

4

Fig.4 (m)

Random Symbol Error Rate (RSER)

ECC is designed to recover the correct data Irom the data damaged by deIects. But ECC

ability Ior correcting data in a disc is used not only Ior deIects but also Ior the random

error in a disc. In order to guarantee the ECC power Ior the user oriented deIects such as

Iingerprints and scratches, both the Random Symbol Error Rate (RSER) oI a disc and

deIects should be speciIied. Roughly more than halI oI the ECC power is reserved Ior the

user oriented deIects.

The RSER Ior judging the system margin is 4. X 10 . This value is derived Irom the

worst condition that all degradations oI a disc and a drive occur simultaneously. Thus

such a value is too high Ior the RSER value in which ECC works. The RSER oI 1.0 X 10-

was used Ior DVD. The value corresponds to a boundary condition some degradation

such as the worst radial tilt with some tangential tilt and some deIocus in a rather bad

drive. In the BD system a Viterbi decoder is located between the retrieved HF signal and

an ECC circuit. The Viterbi decoder has the ability oI the SNR improvement and it can

reduce the RSER value below 1/10. The measurement circuit Limit-Equalizer also can

improve SNR as same as the Viterbi decoder and it also can reduce the RSER value

below 1/10. For the RSER value oI a disc measured aIter the Limit-Equalizer a value oI

.0 x 10 4 is speciIied, which is 1/5 oI 1.0 x 10 . In order to measure RSER the

degradation due to the deIects should be taken out. At the development stage the

averaging in a large ECC Blocks was used Ior removing the eIIects oI deIects. But the

averaging method was not enough Ior measuring such the low RSER value. In the inner

radius there are .11 ECC Blocks within one rotation. II there is a large deIects as shown

44

in Fig.4 (n) then some 100 bytes errors are counted in every .11 ECC Blocks. That is the

reason why the measured RSER jumped up around a deIect.

Then it was decided to separate the deIects and the RSER in the measurement method.

Considering the ECC ability the allowed deIects in an ECC Block (In the speciIication the

block is called LDC Block.) is speciIied as 00 bytes in total and the maximum number

oI deIects is speciIied as . From the measured RSER the consecutive errors longer than

or equal 40 bytes are excluded. 40 bytes is the length oI the BIS (Burst Indicating Sub

code) data between BIS (8 bytes) and it corresponds to the minimum burst error length

BIS can detect. In order to detect the burst error correctly the ECC method measurement

as shown in Fig.4 (n) is used. The correct data can be obtained aIter an ECC. By using

additional circuit Ior the measurement the correct data aIter ECC is interleaved in order to

get the correct data allocation on a disc. It is compared with the data on a disc and the

erroneous symbols are identiIied.

Fig.4 (n)

There are many cases that some correct bytes exist between the erroneous bytes. Fig.4 (o)

shows an example oI an error pattern. In order to judge the 40 bytes burst error length the

Iollowing procedure was speciIied. The burst starts aIter the correct bytes longer than or

equal bytes. The error length count continues iI the correct bytes length between error

bytes is less than or equal . The error length count stops iI there appear correct bytes

longer than or equal bytes. Though the error length includes the correct bytes less than

45

or equal bytes, those correct bytes are excluded Irom the number oI the erroneous bytes.

The errors longer than or equal 40 bytes are excluded Irom both the numerator and the

denominator oI the RSER calculation. But the burst errors below 40 bytes are still

included in the erroneous bytes. Although RSER is averaged over 10000 ECC Blocks, Ior

the measurement 1000 Blocks averaging is allowed iI the disc shows good RSER.

Fig.4(o)

|ReIerences|

1) K.A. Rubin et al: Proc. SPIE 8 (1994) 4.

) K. Nagata et al: Jpn. J. Appl. Phys. 8 (1999) 19.

) S. Hayashi et al: Technical Digest oI ISOM001, Taipei, Pd- (001) 10.

4

Contents Protection System and Interface Chapter-5

Since BD assumes that the HD contents oI digital broadcasts are being recorded,

capabilities to protect such content, iI desired, are more important than with conventional

DVDs, on which only SD contents are recorded. Thus a new contents protection system

(Advanced Access Content System Blu-ray Disc Recordable Book) optimized Ior MPEG-

TS recordings oI digital broadcasts has been adopted.

Fig.5 (a) shows the outline oI the contents protection system when digital broadcast

contents are recorded. BeIore the start oI recording, copy control inIormation within the

digital broadcast signal is detected. When copying is allowed as per the copy control

inIormation, the contents and copy control inIormation are protected and recorded on the

disc. During playback, recorded contents are decoded and outputted Irom a device on

which contents protection technology is installed, based on a copy control inIormation.

Fig.5 (a)

In the BD contents protection system, AES (Advanced Encryption Standard) with a key

length oI 18 bits has been adopted. In addition, Ior the exclusion oI illegal devices

(System Renewability) and Ior the prevention oI illegal copying, MKB (Media Key

Block) inIormation and a Disc ID which is unique to the disc are written in the disc. Each

recorder (player) has device keys, which diIIer depending on the manuIacturer or the

machine. An encryption key is generated by combining the device key and MKB.

4

ThereIore, illegal devices can be excluded by updating the MKB inIormation.

Furthermore, illegal copying is also prevented by using a Disc ID which is unique to the

disc.

In addition to such highly-secure coding during recording, by implementing the contents

protection technology in the interIace to output played-back contents, illegal copying and

retransmission to the general public through Internet can be prevented. BeIore being

outputted, contents are protected by DTCP *1) Ior MPEG-TS stream output and by

HDCP *) Ior baseband digital output. In addition, CGMS-A and Macrovision copy

control signal *) are added to the analog image signal.

48

Hard-Coating Ior Bare Disc Chapter-

BD is much more sensitive to scratches and Iingerprints compared with DVD. Slight

scratch or Iingerprints will cause deterioration oI error rates and/or loss oI a tracking

servo control. To avoid such problems, the Iirst generation BD-RE (ver1.0) is protected

with a Cartridge case. A Bare disc, however, is desired in order to downsize a disc drive.

In addition, it is preIerred to reduce the media manuIacturing cost by making them

Cartridge-Iree.

Thus the Hard-coat technology Ior the Bare discs has been explored, aiming mainly at

scratchand Iingerprint-resistances. Hard-coatings have already been applied to some

conventional optical media such as DVD-RW. UV-curable acrylic resin has been used as

the Hard-coat in such cases. Although they have a moderate scratch-resistance, higher

hardness will be necessary Ior some BD applications. Moreover, a problem oI Iingerprint

has not been considered. ThereIore many kinds oI materials have been investigated Ior

alternative Hard-coat. As a result, it was concluded that colloidal

silica-dispersed UV-curable resin is one oI the most promising candidates, in which

scratch-resistance, optical property, and productivity are compatible

1)

.

Fig. (a)

The disc structure is shown in Fig. (a). A light-transmitting layer consists oI a 98 m

thick Cover Layer and a m thick Hard-coat. For example, both layers can be spin-

coated successively). In that case, a conventional UV-curable resin without colloidal

silica can be used as the Cover Layer.

49

Typical properties oI the Hard-coat are outlined below. In Fig. (b) jitter values oI BD-

REs are shown with (a) polycarbonate sheet, (b) conventional UV-curable Hard-coat and

(c) the new Hard-coat, whose surIaces were worn away by rubbing with steel wool. In the

disc (c), over 00 times oI abrasion did not give rise to deterioration oI the jitter value.

For general use, you will be able to obtain a secure Ieeling comparable to that oI DVDs

by the conventional Hard-coat (b), Irom a viewpoint oI scratchresistance. The new Hard-

coat (c) will be required, however, to enhance reliability oI BD systems, and will open up

wide variety oI applications (eg. long-term data archiving, use Ior camcorder, etc.).

Regarding the problem oI Iingerprints, you may accidentally put your Iingerprints on a

blank disc beIore setting it on a recorder. Generally data signals recorded over

Iingerprints contain much more errors than ROM data signals read through Iingerprints.

This is the reason that Iingerprint-resistance is viewed as more crucial property in BD-RE

or BD-R, compared to BD-ROM.

Against such a background, BD-RE requires some kind oI Protective Coating to reduce

an impact oI Iingerprint. Additionally, we should establish the way to evaluate an eIIect

oI Iingerprints to the BD system, iI BD-RE mandatory requires such a Protective Coating.

In BD-RE Iormat, anti-Iingerprint eIIect is to be quantiIied as Iollows (Fig. (c)).

Fig. (b)

50

In the evaluation method, originally prepared artiIicial Iingerprint (AFP) reagent is

necessary). AFP reagent is a suspension which mainly consists oI triolein (viscous Iatty

oil) and inorganic particle. Inorganic particles simulate insoluble ingredients and/or

waxes included in actual Iingerprint. It also has a Iunction to enhance repeatability oI

AFP test. A procedure to put AFP onto the disc surIace is based on that prescribed in JIS

K4:1994 with some modiIications. In BD-RE Iormat, SER shall be less than 4. x 10-

, which is measured Ior the data signal recorded through AFP oI prescribed level. This

AFP level was determined with reIerence to the impact oI Iingerprint to DVD-RW/RW/-

RAM. In other words, BD-RE speciIication Ior bare disc guarantees Iingerprint-

resistance, which is comparable or superior to that oI recordable DVDs.

Fig. (c)

Fig. (c) Procedure to put AFP onto BD-RE. Firstly AFP reagent is prepared by mixing

triolein, #11 oI JIS test powder 1, and methoxy propanol (5//0 in weight). Then next,

(1) AFP reagent-applied plastic (polycarbonate) Substrate is prepared by spin-coating

method (eg, 100rpm Ior 1sec, then 5000rpm Ior 1sec), and cylindrical silicone rubber is

pressed on the Substrate, thus () AFP reagent is put on an end Iace oI the silicone rubber.

The silicone rubber shall be preliminarily ground with sand paper as prescribed in JIS

K4, prior to the procedure (1). And then () the silicone rubber is pressed onto the

surIace oI the disc to be evaluated, thus (4) AFP-applied BD-RE is prepared. A bare BD-

RE speciIication requires that SER oI above AFP-applied BD shall be less than 4. x 10-

, which is measured Ior the data signal recorded through AFP.

Actually, above-mentioned new Hard-coat is easily endowed with an anti-Iingerprint

property. It is possible to upgrade Iingerprint-resistance while maintaining the original

hardness oI the silicadispersed hard-coat.

51

In Fig. (d) anti-Iingerprint properties measured Ior diIIerent Hard-coatings are shown.

AFPs were put onto the light-incident surIaces oI (a) and (c), then bERs were measured

(symbols Ior each sample are same as in Fig. (b)). It must be noted that AFP level (i.e.,

amount oI AFP) applied to this evaluation is diIIerent Irom that in BD-RE speciIication,

Ior experimental purpose.

Fig. (d)

As shown in Fig. (d), the impact oI the Iingerprint was severe in the disc (a), and

tracking was not controllable in some cases. On the other hand, the disc (c) exhibited the

bER oI around 1.0 x 10-5, which was measured Ior the data signal recorded prior to

adhesion oI AFP. In the disc (c`), antiIingerprint property was improved while

maintaining abrasion-resistance (see Fig. (d)). It exhibited adequate Iingerprint-

resistance Ior the signals recorded both beIore and aIter the Iingerprint adhesion.

Next, playability oI AFP-applied BD-RE and DVDs was veriIied on commercial disc

drives. As indicated in Tab. 1..1, BD with Hard-coat (c) shows good Iingerprint-

resistance which is equal or superior to that oI DVDs. From the aspect oI recording

motion picture, the disc (c) will allow rough handling comparable to that oI DVDs.

For all the playability results, the disc (c) may be still sensitive to Iingerprint in terms oI

error rate, which is measured Ior the data signal recorded through Iingerprints. However,

playability could be Iurther improved by using the anti-Iingerprint hard-coating oI type

(c') due to the reduced bER especially Ior writing through FP.

5

Table (a)

Ior DVD-R/-RW, and DMRE50 (Panasonic) Ior DVD-RAM.

*Respective criteria were as Iollows: OK both recording and playback normally

completed; Read NG recording operation completed (precise recording may not be

done), but not playable; R/W NG neither recording nor playback completed.

As shown in Fig. (e), the amount oI AFP decreased drastically in discs (a), (c) and (c`),

in this order. It implies a clear correlation between the amount oI AFP and resulting

bERs. In Fig. (I), shown is bER dependency on the area ratio oI AFP. As can be seen

Irom the Iigure, error rate depends almost entirely upon AFP area ratio, and is

independent oI the nature oI the disk surIace. In Figure (d) bERs measured aIter AFP

adhesion. Blue bars represent bERs oI the signals written beIore AFP adhesion, and red

ones indicate bERs Ior the signals recorded aIter AFP adhesion. other words, the disks (c)

and (c`) are endowed with the property to aIIord lower Iingerprint area ratio compared to

the disc (a), when you apply Iingerprints oI the same level.

Fig. (e)

5

Fig. (I)

Although only 'Iingerprint repellency was described in this article, the discs (c) and (c`)

are superior to the disc (a) also in terms oI 'Iingerprint removability. It should be noted

that the new Hard-coat (c`) combined with the spin-coated Cover Layer has good

production ability and will achieve the production cost comparable to that oI recordable

DVDs.

54

REFERENCES:

1) N. Hayashida, H. Hirata, T. Komaki, M. Usami, T. Ushida, H. Itoh, K. Yoneyama,

and H. Utsunomiya, Jpn. J. Appl. Phys., 4, 50-5 (00).

) T. Komaki, H. Hirata, M. Usami, T. Ushida, N. Hayashida, H. Inoue, T. Kato, H.

Shingai, and H. Utsunomiya, Jpn. J. Appl. Phys., 41, 9-9 (00).

) N. Hayashida, H. Itoh, K. Yoneyama, T. Kato, K. Tanaka, and H. Utsunomiya,

Proc. oI SPIE Vol. 509, 1-8 (00).

4) Digital Transmission Content Protection: A content protection technology

developed by Iive companies: Hitachi, Intel, Panasonic, Sony, and Toshiba. The

speciIication is proprietary, and implementing DTCP requires a license.

5) High-bandwidth Digital Content Protection: A content protection technology

developed by Intel. The speciIication is proprietary, and implementing HDCP requires a

license.

) Macrovision is a content protection technology developed by Rovi Corporation.

The speciIication is proprietary, and utilizing Macrovision requires a license.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Products 2019: Division MarineDocument33 pagesProducts 2019: Division MarineValerian GheorgheNo ratings yet