Professional Documents

Culture Documents

Lecture 18, Abrasives and Temporary Crowns I (Script)

Lecture 18, Abrasives and Temporary Crowns I (Script)

Uploaded by

JustDen09Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lecture 18, Abrasives and Temporary Crowns I (Script)

Lecture 18, Abrasives and Temporary Crowns I (Script)

Uploaded by

JustDen09Copyright:

Available Formats

Date: 7\12\2011

Page|1

Date: 7\12\2011

(Abrasives and temporary crowns (1 Dental Material II Lecture # 18 Slide 2,3

Why we do finishing and polishing, you want to remove any excess filling material or restoration, you want to achieve good .esthetics; A smooth fine polished surface, shiny surface We want to minimize corrosion like in amalgam, when we do finishing and polishing in amalgam we are minimizing the corrosion because we are producing a smooth surface and .minimizing stack? Accumulation which can promote corrosion So mainly smoothening, esthetics, minimize corrosion and .remove excess When you are doing that you using a series of materials starting from rough to smooth; so you always start with rough disc for example to remove gross or major excess of the filling material and then you go medium , fine, and super fine to produce a smooth shiny surface. So this is the process how .you do polishing, you should not skip one step

Slide 4

Now what affects the abrasion rate, when we are abrading surface we use different materials, we use the hand piece or sometimes manual. What affect how much you removing from :the filling, what factors affect the abrasion rate .Size, irregularity, the hardness of the particles -1

Page|2

Date: 7\12\2011

how irregular the particle are of the abrasive material; the more irregular the particle are the more abrasion it will do, the .more it will remove from the restorative material The size of the particles; larger the size of the particles, the more abrasion it will do, the more it will remove from the material. The harder the particle is, the more it will remove .from the restoration Thats why they can produce different craze of abrasive, by .controlling these factors Diamond particles are the hardest material, so they are in the top of the scale of the hardness, thats why for examples we use them for finishing and polishing for porcelain, we cant use it for amalgam because it can remove too much if you are sing the rough particle, some diamond burs coated with fine .particles, we can use these for composite The degree of the roughness or the degree of the abrasiveness will affect to which restoration you will apply to them. The more pressure you use when you are using the high speed and the higher the speed more abrasion it will do, so you need to be careful with the pressure you using and the speed of the hand piece, the speed which you are doing the .polishing and finishing More speed more pressure; more abrasion. And we won't to remove more than what we want; because there will be deficiency, and you need to apply again more material, so you .need to have good control

Slide 5

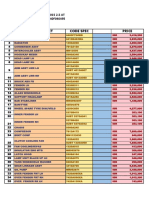

This is the hardness scale (slide 5) or MOH scale, the hardest .is diamond and the softest is gold As a rule : your abrasive material should be 1 or 2 point harder .than the surface you are abrading

Page|3

Date: 7\12\2011

Slide 6

;They can be classified according to the size of the particles .Coarse or rough: 100 micron or above .Medium: 20-100 micron .Small: 20 sub micron size The greater size of the particles the rougher it will be, so they .call it the size of the particles or grit

Slide 7

Some abrasive come in the form of paste or powder and liquid to mix with water, the more concentrated the more particles in .it, the more abrasive It will be So by controlling the water you adding you will control how much you are diluting the paste, and therefore controlling how .abrasive it is .This is another factor that affects how much abrasive it will do

Slide 8

We talked about the speed and pressure we need to be careful about speed and pressure because we dont want to remove .more than we want, and we dont want generate excess heat

Excess heat when you are finishing and polishing the restoration can harm the pulp and produce pulpitis, and even if it's too much it can cause irreversible pulpitis, which is mean we should go to root canal treatment, so the patient take off .the restoration and go to root canal treatment

Page|4

Date: 7\12\2011

Thats why we should be careful. Always use water when you do finishing and polishing, and you dont use the ??? Composite for a long period of time, you need to use it for a few seconds and use water to cool down the tooth and then you can use it again and so on, because it can cause damage .to the pulp

Slide 9

:Types of abrasives Paste abrasives, loose abrasives, coated abrasives, bonded .abrasives some of them come in a battles or containers as form of a powder or a paste, some of them in the form of abrasive strip or coated abrasive or discs; thats you need to fix on the .mandrill thats the one we use it for composite Some of the abrasives are shaped in the form of a bur (bonded .(abrasive

Slide 11

Loose abrasive; paste or powder, can be coarse or medium or fine or even super fine grit sizes, you can apply them in the surface of the restoration or the tooth by a brush so they are mixed with water or lubricants glycerin for example, then you dip the brush in the paste and then place the brush in the low speed hand piece usually, then you can use it in a rotary cycle .like on the restoration or the tooth Always start with rough end up with super fine, or you can select the type of material you will using or size of the particles you will using, according to the amount of abrasive you want to do, for example if you got stain on the surface of the tooth you can use medium or fine abrasive to remove we

Page|5

Date: 7\12\2011

wont cut it too rough, so dont start with rough you start with .medium immediately; so it depend on the clinical situation When its called prophylaxis paste, it will contain fluoride; .fluoride prevent caries, so it give the prophylaxis effect

Slide 13

Bonded abrasive they look like (slide 14); they are like discs, cones, flame shape, pointed, cups and cylinder. They are different shape so they can accommodate different surfaces of the tooth; the bur that able to use it in the labial surface you .may not able to use it on the palatal surface They are usually used in initial and intermediate finishing, and .it available in different roughness scale

Slide 15

Coated abrasive are the one we used for composite, abrasive strips or discs that we fix on the mandrill at the low hand .piece

Slide 17

We will talk about different materials Diamond : the hardest its an expensive material, so the abrasive diamond bur not disposable, you sterilize them and use it again, with time they become less efficient (wear), .because the particles loss from the bur Fine particles can be used in a form of a paste, and it use for .finishing and polishing for composite and porcelain

Slide 18

Page|6

Date: 7\12\2011

Carbide finishing bur; these burs used for finishing amalgam, they are similar to the bur we use for drilling the cavity, but it shape differently and the number of flutes (cutting end) it will determine how much finishing we will do, the higher the .number of flutes the finer the finishing These burs fixed in the hand piece, and used them for .amalgam

Slide 19,20

silicon carbide; a very hard material 9-10 on the scale come in the form of coated or bonded abrasive, can be used for .porcelain, but diamond is more common Aluminum oxide; it can be bonded abrasive, this material it .can be used for sandblasting Sandblasting: when we do a crown as the restoration, and you want to cement it on the surface of the tooth, if you make the inner surface of the crown rough this will promote more bonding, micromechanical retention, so they make the surface of the crown rough by hitting the surface with particles of aluminum oxide with pressure. They place it in a chamber, and aluminum oxide will be force to contact the metal to make it .rougher It available in paste form, and you can dib the brush, cup or wheal as we said before. The wheal we are talking about in pic .((slide 23), it can be made out of rubber (Burlew wheal

Slide 21,22,24

Silica or sand; it can be used in sandblasting, it can be used .in a form of coated discs or a strip, rate 7 on Moh scale Silica dioxide; it can be used in the form of paste or coated abrasive or bonded abrasive, the important thing you need to

Page|7

Date: 7\12\2011

go back to Moh table and see how the material hard is it, and .know to which material or restoration you can apply

Rouge; form from iron oxide, supply in red blocks; the block apply on the wheal when its turning so that the abrasive of the block will coat the wheal and then we can use the wheal for finishing and polishing; alloid or metal frame work of the .cobalt?? Partial denture Pumice; manufactured as a loose abrasive from volcanic silica .and its extremely fine

.Tin oxide; fine material can be used for polishing Calcium carbonate; used in toothpaste20-40%; toothpaste contain fluoride, coloring agent, flavor, and calcium carbonate, so tooth paste contain abrasive to remove remnants of food .debris

Slide 25,26,27

:Prophylaxis paste : made of Pumice, tin oxide, pigments, coloring agent, preservative, and .fluoride We mix it with water or glycerin, apply using a brush or a cup, usually we use it after scaling, after removing of plaque or calculus, we want to polish and smooth the surface of the teeth, remove any stains, so it can be used at the end of the .treatment They are not highly abrasive, they are used to clean dentures, to remove any debris and remove stains, but they should not be highly abrasive so they dont damage the surface of the .denture

Page|8

Date: 7\12\2011

Done by: Yazeed o. Ajlouni

Page|9

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Export + Import Process Flow - Break Bulk Cargo 27072010Document11 pagesExport + Import Process Flow - Break Bulk Cargo 27072010Ahmad Fauzi Mehat100% (1)

- Pedo 4Document59 pagesPedo 4JustDen09100% (1)

- Surgery-Past Years QsDocument10 pagesSurgery-Past Years QsGaYda'a Kana'anNo ratings yet

- Pedo 4Document59 pagesPedo 4JustDen09100% (1)

- 3 - Odontomes & Odontogenic TumorsDocument63 pages3 - Odontomes & Odontogenic TumorsAnȜ'am Abu Ȝ'leonNo ratings yet

- Infections of The Oral Mucosa 2 (Slide 12 +13)Document58 pagesInfections of The Oral Mucosa 2 (Slide 12 +13)JustDen09No ratings yet

- Diseases of The Temporomandibular JointDocument27 pagesDiseases of The Temporomandibular JointJustDen090% (1)

- Odontomes & Odontogenic Tumors II (Slide 18+19)Document39 pagesOdontomes & Odontogenic Tumors II (Slide 18+19)JustDen09No ratings yet

- BIOSTATISTICS#1Document10 pagesBIOSTATISTICS#1Sanaa QasemNo ratings yet

- Oral Ulceration and Vesiculobullous Diseases and 2Document107 pagesOral Ulceration and Vesiculobullous Diseases and 2JustDen09100% (1)

- Endodontic QuizzesDocument5 pagesEndodontic QuizzesJustDen0980% (5)

- Dia BetsDocument17 pagesDia Betsمحمد ابوالمجدNo ratings yet

- Dent 356 Midtermgrades No NamesDocument7 pagesDent 356 Midtermgrades No NamesJustDen09No ratings yet

- Dent 355 Rima Huda Lab KeratosisDocument57 pagesDent 355 Rima Huda Lab KeratosisHeba S RadaidehNo ratings yet

- Review of Cobalt Chrome Denture Design 97-2003Document44 pagesReview of Cobalt Chrome Denture Design 97-2003JustDen09100% (3)

- Major and Minor ConnectorsDocument32 pagesMajor and Minor ConnectorsJustDen09100% (1)

- Keratoses and Related Disorders of Oral Mucosa II (Slide 4 + 5 + 6)Document83 pagesKeratoses and Related Disorders of Oral Mucosa II (Slide 4 + 5 + 6)JustDen09No ratings yet

- Dent 356 Long Syllabus 2012Document6 pagesDent 356 Long Syllabus 2012JustDen09No ratings yet

- Slide 1 +2 CT Hyperplasia Slide 1 2Document115 pagesSlide 1 +2 CT Hyperplasia Slide 1 2CWT2010No ratings yet

- Lecture 1+2, Introduction Lesson (Slide)Document25 pagesLecture 1+2, Introduction Lesson (Slide)JustDen09100% (1)

- Past Year Questions For The Epidemiology CourseDocument3 pagesPast Year Questions For The Epidemiology CourseGaYda'a Kana'anNo ratings yet

- Syllabus - BiostatisticsDocument3 pagesSyllabus - BiostatisticsJustDen09No ratings yet

- Princeton 112 Plus Service ManualDocument8 pagesPrinceton 112 Plus Service ManualDavid OliveiraNo ratings yet

- Ecs2602 Tests Bank-1Document97 pagesEcs2602 Tests Bank-1corlia100% (2)

- Electromagnetic WavesDocument173 pagesElectromagnetic WavesatiqdhepNo ratings yet

- What Aspects of "Life" Are Covered by Vedic AstrologyDocument4 pagesWhat Aspects of "Life" Are Covered by Vedic AstrologyMariana SantosNo ratings yet

- Chen 2013Document16 pagesChen 2013Alexandru ArcireNo ratings yet

- DNS IodinDocument4 pagesDNS IodinKirana agist wangsa putriNo ratings yet

- Msds UreaDocument5 pagesMsds UreaHunterlan Register FilanNo ratings yet

- MODULE-4 21BE45 - PPT FinalDocument55 pagesMODULE-4 21BE45 - PPT Finalezekiel david100% (1)

- Wenco Increasing Performance and Safety 2Document12 pagesWenco Increasing Performance and Safety 2qwe qweqweNo ratings yet

- Cardiovascular Drift and Cerebral and Muscle Tissue Oxygenation During Prolonged Cycling at Different Pedalling CadencesDocument12 pagesCardiovascular Drift and Cerebral and Muscle Tissue Oxygenation During Prolonged Cycling at Different Pedalling CadencesBob UeckerleleNo ratings yet

- Substation Construction and CommissioningDocument83 pagesSubstation Construction and CommissioningShung Tak ChanNo ratings yet

- Mobil PajeroDocument2 pagesMobil Pajeroesemelekete wele2No ratings yet

- Polyurea EbookDocument39 pagesPolyurea EbookJesus De la Rosa100% (1)

- Manual Spare Parts DB540!72!07Document124 pagesManual Spare Parts DB540!72!07Gustavo CarvalhoNo ratings yet

- Johor-Answer Physics P3-Trial SPM 2007Document6 pagesJohor-Answer Physics P3-Trial SPM 2007kamalharmozaNo ratings yet

- Lesson 02 PDFDocument13 pagesLesson 02 PDFJeremy TohNo ratings yet

- Caffeine in Tea by HPLCDocument3 pagesCaffeine in Tea by HPLCanita_shar29No ratings yet

- MPD and MPK Series Midi Io Details 02Document3 pagesMPD and MPK Series Midi Io Details 02Jorge David Monroy PerezNo ratings yet

- Pharmaceutics 14 02240Document17 pagesPharmaceutics 14 02240oliverasrommelNo ratings yet

- Test Bank For Chemistry 9th Edition Zumdahl Isbn 10 1133611095 Isbn 13 9781133611097Document17 pagesTest Bank For Chemistry 9th Edition Zumdahl Isbn 10 1133611095 Isbn 13 9781133611097Lynn Higgins100% (38)

- Table MGMTDocument1 pageTable MGMTعلی احمد نعیمNo ratings yet

- Definitive Guide Robot Welding Torches v1.0Document50 pagesDefinitive Guide Robot Welding Torches v1.0AlexgriNo ratings yet

- PCI EO MEG Pemex 2013 PDFDocument38 pagesPCI EO MEG Pemex 2013 PDFepesanoNo ratings yet

- List of Coolers and HeatersDocument2 pagesList of Coolers and HeatersadityasahayNo ratings yet

- The Secrets of Ancient Rome's Buildings - History - Smithsonian Magazine PDFDocument2 pagesThe Secrets of Ancient Rome's Buildings - History - Smithsonian Magazine PDFMarlui Faith MaglambayanNo ratings yet

- Chapter 14 ForgingDocument21 pagesChapter 14 ForgingNur RokhimNo ratings yet

- ObjectivesDocument7 pagesObjectivesPeeka booNo ratings yet

- Verb Patterns: Verb + Infinitive or Verb + - Ing?: Verbs Followed by A To-InfinitiveDocument5 pagesVerb Patterns: Verb + Infinitive or Verb + - Ing?: Verbs Followed by A To-InfinitiveTeodora PluskoskaNo ratings yet

- Yangon Thanlyin Bridge 4Document50 pagesYangon Thanlyin Bridge 4ကိုနေဝင်း100% (4)