Professional Documents

Culture Documents

Common Fabric Defects

Common Fabric Defects

Uploaded by

Suhail Ahmed0 ratings0% found this document useful (0 votes)

13 views3 pagesWeft streaks are faint or sometimes prominant lines along the lenght of the fabric. Use of good quality reeds will largly reduce streaks due to uneven end spacing. Phurkies are small weft loops protruding from the fabric surface.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWeft streaks are faint or sometimes prominant lines along the lenght of the fabric. Use of good quality reeds will largly reduce streaks due to uneven end spacing. Phurkies are small weft loops protruding from the fabric surface.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

13 views3 pagesCommon Fabric Defects

Common Fabric Defects

Uploaded by

Suhail AhmedWeft streaks are faint or sometimes prominant lines along the lenght of the fabric. Use of good quality reeds will largly reduce streaks due to uneven end spacing. Phurkies are small weft loops protruding from the fabric surface.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 3

Common Fabric Defects-1

Common Fabric Defects

1. Weft Streaks

These are faint or sometimes prominant lines along the lenght of the fabric. Use of good quality reeds will

largly reduce streaks due to uneven end spacing. Streaks can also be avoided through careful

housekeeping and ensuring that different batches of yarns do not get mixed up.

2. Reediness

This defect is characterised by a general grouping of warp ends drawn through individual dents of the

reed with a fine crack showing up in between such groups. This is caused by

- insufficient tension difference between the shed lnes during beat up.

- excessive warp tension

- late shedding

3. rregular reppiness

t is characterised by the prominance of alternate picks over small areas on one face of the fabric. The

following precautions can help to minimise the occurrence of reppiness.

a. Worn out tappets and tradle bowls should be replaced

b The back rest should be raised by about 4 cm with respect to the fell line.

c. The emery rolles should be in good condition.

d. An increase in warp tension within workable limits helps to reduce this defects.

4. Small weft loops ( phurkies)

A phurki is a weft loom protruding from the cloth surface. Generally, the length of the yarn in the loop is

not sufficient to permit snarling. These loops may protrude from both faces of the fabric. Early shedding,

incresing warp tension within workable limits, use of good temples and adequate size pick of about 12%

or higher - these measures can be used to prevent the occurrence of phurkies.

5. Curled and folded selvedges

This defect is characterised by the appearance of curls and folds in the fabric selvedges. The following

points merit attention:

a. Denting order- the number of ends per reed dent in the selvedge should be 50 to 100% more than that

in the body.

b. Warp Tension- An increase in warp tension results in a tighter selvedge.

c. Selvedge construction- The selvedge yarns should be preferably two ply and should be drawn one end

per heald eye.

6.Missing nterlacement of weft at selvedges

n this defect, a group of extreme warp ends in the selvedges do not interlace with the weft over a fabric

length of 1 to 4 cm. The main cause of this defect is excessive tension in the weft yarn.

7. Weft snarls

A weft snarl in a fabric is caused by a short length of three fold weft yarn of which two folds are

intertwisted.

The incidence of such snarls can be reduced by ensuring the process setting of twist and by minimising

the possibility of severe rubbing of yarn between the shuttle and the box front plate.

8. Weft Bar

A weft bar is dark or light band across the width of the fabric which shows up prominantly particularly in

dyed fabrics.

Medium to long term periodic irregularity in yarn will produce regular weft bars in the fabric.

The remedial measures can be:

a. Better process control such as:

i. uniformity of count on groups of ring frames spinning the same count.

ii. Prevention of periodic irregularity in the yarn.

iii. Control of winding and pirning tension.

iv. Proper maintenance of let off and take up motion

v. Control over blend proportion.

vi. Better housekeeping to prevent mixing up of yarn from frames.

9. Broken Picks

n plain woven fabrics, this defect materialises by the presence of two picks in the same shed for a part of

the width of the fabric.

The main cause of weft breaks are rough surfaces of shuttle, shuttle box, rough or incorrect placement of

shuttle eye, loose fitting of pirn in the shuttle, incorrect alignment of pirn with shuttle eye and low yarn

strength.

10. Lashing-in

Lashing in is the term used to describe bits of extra weft yarn found tucked into the selvedge of the

fabric.

Remedial measures are:

a. Proper maintenance of accessories and loom parts.

b. Adjusting the pattern of changes of the boxes.

c. The use on drop-box looms of a suitable brush fixed at the end of the temple rod.

11. Missing End (Chira)

A defect where one or more warp ends are missing in the fabric is called a chira. This is the most

frequently occurring defect in ndian fabrics and constitutes 40-50% of the total defects. Most chiras are

caused by broken that are not mended immediately.

t can be prevented by minimising missing ends in the beam and efficient maninteance of the warp stop

motion.

Effective supervision to ensure that a broken end is not left unmended for long can also minimise the

occurrence of chira.

Common Weaving Defects-2

FIoat (JaIa)

A float or Jala is formed when there is no proper interlacement of the warp and weft yarns over a certain

area. The remedial measures are the use of overall high warp tension and keeping the lease rods close

to the heald shafts.

$tarting Marks

Weft Crack (Jerki)

A srip in the fabric where the pick density is lower than normal is calld a weft crack or jerki

Crammed Pick (Patti)

A strip in the fabric where the pick density is more than normal is called a patti. The defect is caused by

improper setting of the anti crack motion.

$:ttIe $mas

The defect is caused when many ends break consequent to a shuttle trap. The important causes of

shuttle trap are : wrong timing of shedding, soft picking, insufficient checking of shuttle in the boxes,

severe slough off, and damaged or broken picking accessories.

Weft $Io:g

A weft slough of one or two coils. the main causes of slough are softly wound pirn, overfilled pirns, high

density of coils, short chase length etc.

Improper Weft Treading ($ingIe Moti)

The defect is characterised by a loose and uneven selvedge consisting of weft and warp protroduing

loosly beyong the true selvedge line.

Go:t

Hardened fluff, as well as foreign matter such as piece of leather accessories or wood chips, woven into

the texture of the fabric is called a gout.

TempIe Marks

n this defect, the yarns are distorted from their true paths and fine holes are caused near the selvedges.

Unsuitable choice of temples and poor mechanical condition of temples are the main causes of this

defect.

Hard $ize

The defect is characterised by uneven and distorted appearance of the fabric, because of hard gummed

spots in the warp. Use of cold size or keeping the immesion roller dipped in size during a long machine

stop causes such spots.

$tains (Dagi)

Stains are caused by lubricants and rust. Most of the stains can be traced back to poor manintenance

and material handling.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Chapter 8 Training and Developing EmployeesDocument14 pagesChapter 8 Training and Developing EmployeesSuhail Ahmed50% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

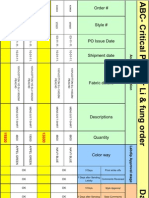

- Li&Fung Order Critical Path DT 13-12-11Document1 pageLi&Fung Order Critical Path DT 13-12-11Suhail AhmedNo ratings yet

- Conflict Management SkillsDocument25 pagesConflict Management SkillsFaris HasanNo ratings yet

- Order System ChartDocument5 pagesOrder System ChartSuhail AhmedNo ratings yet