Professional Documents

Culture Documents

TiO2 Titanium White Trim Board Installation Tips

TiO2 Titanium White Trim Board Installation Tips

Uploaded by

PrestigeDeckingCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TiO2 Titanium White Trim Board Installation Tips

TiO2 Titanium White Trim Board Installation Tips

Uploaded by

PrestigeDeckingCopyright:

Available Formats

Facts Single source FSC-certified mill

All 100% defect-free plantation grown Radiata Pine kiln dried to 10 to 12% moisture content

Water never touches the raw

TiO2 Titanium White Trim Boards

Important Facts about TiO2 Titanium White

Sustainable Source Of Substrate Blocks and Cutstock S.A., SA-COC-002109, which is the single source substrate supplier for TiO2 Titanium White, has attained chain of custody status under the Forest Stewardship Council (FSC), Sustainable Forest Management Certification for its operation in San Pedro de la Paz, Conception, Chile. Consistent source of supply with back-up raw material available.

SCS-COC-001671 What are the advantages to this Substrate? All 100% defect-free Chilean Radiata Pine dried to 10% to 12% moisture content. Clear finger-jointed and edge-glued Radiata Pine for dimensional stability. Emulsion polymer isocyanate (EPI) adhesive, provides superior bonding than typical poly-vinyl acrylics. All 16 lengths... no trim-backs.

wood no grain raising or grain swelling means better long-term coating adhesion

No VOC 100% acrylic topcoat

Durable enough for exterior use, beautiful enough to feature on the interior

Available in 100% 16' lengths, 4/4" and 5/4"thickness Carefully packaged and protected to ensure clean, dry material

How is it Coated? Water never touches the wood - oil primer to seal. High quality alkyd primer is the first application, followed by a no VOC 100% acrylic topcoat. TiO2 Titanium White trim boards uses one of the most durable exterior coatings designed for wood substrate available. A topcoat, while recommended, is not required for one year. Why is an oil primer and latex top coat system better than two coats of latex or two coats of oil? Water never touches the raw wood - no grain raising or grain swelling, better long-term adhesion. The TiO2 coating system provides genuine long-term protection for the substrate - oil primers by themselves, do not. Why is TiO2 better than other trim products? Longer lasting - true exterior topcoat versus multiple coats of primer. Product is durable enough to be used on the exterior and beautiful enough to use on the interior. FSC certified substrate coated in an FSC approved outsource coating facility. No plastic slip sheets between board layers to dispose of. What are the packaging specifications? 750 board foot units...smaller than competitors 1,000 to 1,500bf units. All boards are individually end-tagged for easy identification. Units have top and bottom cardboard protection prior to application of a fitted TiO2 lumber bag. Three stickers and three straps minimize potential shifting in units.

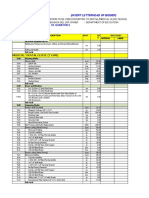

Unit Specifics H 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.25 1.25 1.25 1.25 1.25 1.25 W x 3 x x 4 x x 5 x x 6 x x 8 x x 10 x x 12 x x 4 x x 5 x x 6 x x 8 x x 10 x x 12 x L 16 16 16 16 16 16 16 16 16 16 16 16 16 Pieces 204 156 120 96 72 60 48 117 90 72 54 45 36 BF 816 832 800 768 768 800 768 780 750 720 720 750 720

Quick Facts TiO2 Titanium White should always be kept in a dry location and allowed to reach equalibrium prior to installation

Install product over a WeatherResistant Barrier such as TYPAR

TiO2 Titanium White Trim Boards

Tio2 Titanium White Handling and Installation Tips

Product must be kept dry at all times prior to installation. Keep TiO2 Titanium White elevated at least 6 off the ground with a vapor barrier underneath the product and a loose waterproof cover over the finish boards that allows adequate air circulation. Avoid storage in direct sun. TiO2 Titanium White Installation Tips 1. Product must be installed over a Weather-Resistant Barrier such as TYPAR. Dry (15% moisture or less) framing and sheathing is essential prior to installation of the WRB. 2. All end cuts and rip cuts must be immediately primed with a high quality white exterior oil-alkyd primer while avoiding overlap on the finished face of the TiO2 Titanium White. 3. Product should be fastened using stainless steel or or hot-dipped galvanized nails driven flush to the substrate surface. Avoid sinking the fastener head beyond the board surface. Coat fastener device heads immediately after installation with a white exterior oil-alkyd stain-blocking primer. Coat the immediate area around the fastener head only. 4. Product should be installed at least 6 inches off the ground. Avoid direct contact against cement, brick or asphalt and provide enough space for future landscaping below. 5. Proper window and door flashing is necessary. 6. All avenues for exterior water intrusion should be immediately caulked with a high performance acrylic exterior caulk. Moisture: Limiting changes in moisture content will improve the overall performace of the TiO2 Titanium White product. Moisture infiltration is not a paint or wood defect and is not covered by any warranty, expressed or implied. To control moisture and help prevent possible problems, take the following steps: Proper building design that includes adequate roof overhang, flashing at roof edges, gutters and downspouts aid in reducing potential moisture infiltration. Always allow several days for product to reach elqualibrium before job site installation Completely seal all cut ends and rip cuts to minimize moisture infiltration Interior vapor barriers will help reduce condensation within the wall Properly ventilate bathrooms and laundries to control indoor humidity Ventilate attics, dehumidify damp basements and carefully control humidification systems Field Applied Topcoats TiO2 Titanium White should be installed according to above instructions. It is highly advisable to topcoat as soon as possible however; TiO2 Titanium White may be left uncoated for up to one year. Always follow paint manufacturers suggested application guidelines when selecting a field applied topcoat.

For best results when installing TiO2 Titanium White, use stainless steel or hot dipped galvanized nails

Nails should be driven an 1-1/2" or more through dry sheathing and framing lumber

Re-coat exposed butt scarf joint ends and rip cuts with oil-alkyd stain-blocking primer to reduce moisture penetration

For best results, brush apply two coats of a high quality, exterior 100% acrylic color paint as soon as possible

You might also like

- EASE Material Base Sorted by ClassificationDocument3 pagesEASE Material Base Sorted by ClassificationOscar Pacheco100% (2)

- Australian StandardDocument2 pagesAustralian Standardlauren_connors9172100% (4)

- RedGard Installation InstructionsDocument5 pagesRedGard Installation InstructionsAlex LongNo ratings yet

- Nitoseal 220 PDFDocument4 pagesNitoseal 220 PDFmilanbrasinaNo ratings yet

- Data SheetDocument8 pagesData SheettomychalilNo ratings yet

- Idrostop MasticDocument2 pagesIdrostop MasticPrateek JainNo ratings yet

- Aerocon Planks and Boards (HIL LTD)Document33 pagesAerocon Planks and Boards (HIL LTD)Venkat BadaralaNo ratings yet

- Nitoseal 220Document4 pagesNitoseal 220Venkata RaoNo ratings yet

- SikaTack Panel System - DatasheetDocument10 pagesSikaTack Panel System - DatasheetBojan BogdanovicNo ratings yet

- DELTIO81XDocument6 pagesDELTIO81XkishanptlNo ratings yet

- 7080 SiliconBrochure FINALDocument6 pages7080 SiliconBrochure FINALRudolph TJ GVNo ratings yet

- RT/duroid 5870/5880 High Frequency Laminates Fabrication GuidelinesDocument8 pagesRT/duroid 5870/5880 High Frequency Laminates Fabrication GuidelinesmaamriaNo ratings yet

- ShaliTex Sealing CompoundDocument2 pagesShaliTex Sealing CompoundHimagiriNo ratings yet

- Timber Weatherboard InstallationDocument6 pagesTimber Weatherboard InstallationAndrew LeeNo ratings yet

- Pliastic PDFDocument4 pagesPliastic PDFmilanbrasinaNo ratings yet

- Hardwood Tile Application: Installation & PrecautionsDocument2 pagesHardwood Tile Application: Installation & PrecautionsPedroNo ratings yet

- ESD High Temp Polymide Tape: Used in Applications Masking PCB Gold Features For Wave Soldering and IR Reflow OvensDocument1 pageESD High Temp Polymide Tape: Used in Applications Masking PCB Gold Features For Wave Soldering and IR Reflow OvensChristopher RiceNo ratings yet

- WaterproofingReckoner PDFDocument40 pagesWaterproofingReckoner PDFhelloitskalaiNo ratings yet

- Henkel Loctite AdesiveDocument60 pagesHenkel Loctite Adesive69x4No ratings yet

- Loctite Solution Guide Issue 6Document56 pagesLoctite Solution Guide Issue 6José María GarcíaNo ratings yet

- Roof Concrete Brochure Zephyr Vent PDFDocument4 pagesRoof Concrete Brochure Zephyr Vent PDFHRroofingNo ratings yet

- Loctite Product SelectionDocument158 pagesLoctite Product SelectionRiki Nurzaman100% (1)

- Nitoseal 777 PDFDocument4 pagesNitoseal 777 PDFmilanbrasinaNo ratings yet

- 21-5 PDS AiDocument3 pages21-5 PDS Aiuocmogiandi_aNo ratings yet

- Interzone 101Document0 pagesInterzone 101hennawijayaNo ratings yet

- Semigloss 90 - 1210 PDSDocument6 pagesSemigloss 90 - 1210 PDSPablo PuebloNo ratings yet

- DR Fixit Waterproofing ReckonerDocument40 pagesDR Fixit Waterproofing ReckonerSusheel TalrejaNo ratings yet

- Nitoflor FC550Document4 pagesNitoflor FC550Venkata Raju KalidindiNo ratings yet

- Wetsuit Roofing and Waterproofing WV1Document29 pagesWetsuit Roofing and Waterproofing WV1waterproofing_bestNo ratings yet

- RTV Is800 SeriesDocument4 pagesRTV Is800 SeriesFaraan KhanNo ratings yet

- Nitoproof 100 PDFDocument2 pagesNitoproof 100 PDFmilanbrasinaNo ratings yet

- TDS - Resist 86Document4 pagesTDS - Resist 86EricNo ratings yet

- 04 TD Dichtol GBDocument2 pages04 TD Dichtol GBsusu222000No ratings yet

- Loctite Catalogue 6023 AamDocument30 pagesLoctite Catalogue 6023 AamAndre FaccinNo ratings yet

- WIP Field GuideDocument28 pagesWIP Field GuideVictor PadillaNo ratings yet

- Stopaq Subsea CompoundDocument2 pagesStopaq Subsea CompoundDAGOBERTO MORANo ratings yet

- Nitocote HT120Document4 pagesNitocote HT120Venkata Raju KalidindiNo ratings yet

- SikaflexPRO TdsDocument6 pagesSikaflexPRO TdsidontlikeebooksNo ratings yet

- Nitoflor FC150Document4 pagesNitoflor FC150Venkata Raju KalidindiNo ratings yet

- Thioflex 600: Two-Part Polysulphide SealantDocument4 pagesThioflex 600: Two-Part Polysulphide SealantVenkata Raju KalidindiNo ratings yet

- Build: Builders Silicone SealantsDocument3 pagesBuild: Builders Silicone SealantsAhmed KhameisNo ratings yet

- SikaTop Seal 107 PDS (CE) PDFDocument4 pagesSikaTop Seal 107 PDS (CE) PDFSed BeelzeNo ratings yet

- QTs EcoSeriesDocument22 pagesQTs EcoSeriesasrihamidNo ratings yet

- Nitoseal 125Document2 pagesNitoseal 125Hantu TuahNo ratings yet

- Acid Resistant Rubber Lining & Liquid CoatingsDocument81 pagesAcid Resistant Rubber Lining & Liquid CoatingsSikander AleemNo ratings yet

- Silicona Gris Permatex 599 Ultra-GreyDocument2 pagesSilicona Gris Permatex 599 Ultra-GreyjotapinzonNo ratings yet

- Aliphatic Acrylic Polyurethane Finish CoatDocument4 pagesAliphatic Acrylic Polyurethane Finish CoatDexter R. RoqueNo ratings yet

- Blasteel ZiliplateDocument2 pagesBlasteel ZiliplateKarthimeena MeenaNo ratings yet

- OlyBond 500 Green Data SheetDocument3 pagesOlyBond 500 Green Data SheetsajuhereNo ratings yet

- Tritosil W70-TDSDocument4 pagesTritosil W70-TDSRANo ratings yet

- Atmatec - Fibreglass Products For Drainage Systems PDFDocument44 pagesAtmatec - Fibreglass Products For Drainage Systems PDFHafiz KamalNo ratings yet

- Plexus Selector GuideDocument8 pagesPlexus Selector GuideLodewykbronnNo ratings yet

- Sikaflex TS Plus PDSDocument4 pagesSikaflex TS Plus PDSMark CousinsNo ratings yet

- FF1021 Acoutstical Smoke Sealant SheetDocument2 pagesFF1021 Acoutstical Smoke Sealant SheetChinith012No ratings yet

- Silicone RTV Boss 310Document2 pagesSilicone RTV Boss 310Vinaya Almane DattathreyaNo ratings yet

- Loctite Solution GuideDocument26 pagesLoctite Solution GuideAhmed Emad AhmedNo ratings yet

- SikaTop Seal 107 PDS (CE)Document5 pagesSikaTop Seal 107 PDS (CE)Vladimir StojanovicNo ratings yet

- Family Handyman HacksFrom EverandFamily Handyman HacksFamily HandymanNo ratings yet

- Family Handyman Do-It-Yourself Basics Volume 2From EverandFamily Handyman Do-It-Yourself Basics Volume 2Family HandymanRating: 5 out of 5 stars5/5 (2)

- Family Handyman Quick & Easy ProjectsFrom EverandFamily Handyman Quick & Easy ProjectsFamily HandymanNo ratings yet

- Family Handyman Whole House Repair Guide Vol. 2: 300+ Step-by-Step Repairs, Hints and Tips for Today's HomeownersFrom EverandFamily Handyman Whole House Repair Guide Vol. 2: 300+ Step-by-Step Repairs, Hints and Tips for Today's HomeownersFamily HandymanNo ratings yet

- Family Handyman Handy Hints, Volume 2From EverandFamily Handyman Handy Hints, Volume 2Family HandymanNo ratings yet

- DC Valuation Gujranwala With Kahsra NumberDocument27 pagesDC Valuation Gujranwala With Kahsra NumberJavaid Ashraf0% (1)

- Permanent Wood Foundations CWCDocument6 pagesPermanent Wood Foundations CWCsantiagoNo ratings yet

- Pros and Cons of Radiant Cooling in Humid Climates - Uponor BlogDocument8 pagesPros and Cons of Radiant Cooling in Humid Climates - Uponor BlogMian RubbaniNo ratings yet

- Lightning Protection Calculation For Various Buildings (AS PER IS:2309-1989) Project: Plant AreaDocument3 pagesLightning Protection Calculation For Various Buildings (AS PER IS:2309-1989) Project: Plant AreaAmit GuptaNo ratings yet

- Return Air WallsDocument5 pagesReturn Air WallsMina Maher MikhailNo ratings yet

- BTCVE506A Materials, Testing & Evaluation Syllabus Dbatu UniversityDocument2 pagesBTCVE506A Materials, Testing & Evaluation Syllabus Dbatu Universityrameshwar911983020% (3)

- Estimate - Quatation For 1700Document5 pagesEstimate - Quatation For 1700QUAD CONSTRUCTIONNo ratings yet

- Msu NaawanDocument7 pagesMsu NaawanGerry Jr BaldomeroNo ratings yet

- Review #3 Building TechnologyDocument181 pagesReview #3 Building TechnologyCharisse Bernadette Dela CruzNo ratings yet

- ASCE7 SeismicProvisionsForNonStructuralComponents PDFDocument10 pagesASCE7 SeismicProvisionsForNonStructuralComponents PDFsrikanth.iitkgpNo ratings yet

- Retaining Wall DesignDocument6 pagesRetaining Wall DesignpkNo ratings yet

- Wirecrete System PresentationDocument17 pagesWirecrete System PresentationFaith Joy BonadorNo ratings yet

- Fundamental of Building PhysicsDocument52 pagesFundamental of Building PhysicssyafixNo ratings yet

- 8351 - L&T Arch CommentsDocument1 page8351 - L&T Arch CommentsVarunn VelNo ratings yet

- IBPDDocument42 pagesIBPDwilson604No ratings yet

- BP - Res U2 Elect Symbols Outlets Note PDFDocument23 pagesBP - Res U2 Elect Symbols Outlets Note PDFyeng botzNo ratings yet

- Taurus Ducted SplitDocument4 pagesTaurus Ducted SplitSrinivasan ThyagarajanNo ratings yet

- Master Budget PembangunanDocument3 pagesMaster Budget Pembangunanvalens dharmairenanNo ratings yet

- Design Analysis VRVDocument47 pagesDesign Analysis VRVAnonymous YVUsY9JG0% (1)

- Prefabrication and Modular ConstructionDocument28 pagesPrefabrication and Modular ConstructionAmmaar RayedNo ratings yet

- JeevanDocument15 pagesJeevanb.r.thanujNo ratings yet

- WorkingDocument4 pagesWorkingUsman ZafarNo ratings yet

- General Construction NotesDocument5 pagesGeneral Construction NotesPatricia Nicole ElediaNo ratings yet

- Masdar Institute Location: Architect:: Design and InnovationDocument3 pagesMasdar Institute Location: Architect:: Design and InnovationBachelor of ArchitectureNo ratings yet

- Detailed Bill of QuantitiesDocument8 pagesDetailed Bill of QuantitiesInsorPiNo ratings yet

- Bigboy ConstructionDocument8 pagesBigboy Constructionmaria cristina santosNo ratings yet

- CS Sensity - Brochure - WoodDocument6 pagesCS Sensity - Brochure - WoodArtache AlexandruNo ratings yet

- SG Load Types and CombinationsDocument5 pagesSG Load Types and CombinationsRsjBugtongNo ratings yet