Professional Documents

Culture Documents

Mechanisms Notes 2012

Mechanisms Notes 2012

Uploaded by

kookwfCopyright:

Available Formats

You might also like

- 1 1 4 A PulleydrivessprocketsDocument4 pages1 1 4 A Pulleydrivessprocketsapi-30839565067% (3)

- Siemens Win TDCDocument32 pagesSiemens Win TDCBilal Aslam100% (1)

- Eric Priest - Magnetohydrodynamics of The Sun-Cambridge University Press (2014) PDFDocument580 pagesEric Priest - Magnetohydrodynamics of The Sun-Cambridge University Press (2014) PDFLaura Mora100% (1)

- 3 MechanismsDocument35 pages3 Mechanismsesham2100% (1)

- 10 Mechanical Design HL ExtensionDocument38 pages10 Mechanical Design HL ExtensionSyeda Fariya Nisar AliNo ratings yet

- Pulleys 1 Rotary Cams 1 Gears 2: Pulleys Are Used To Transfer Rotating Motion, Via A BeltDocument17 pagesPulleys 1 Rotary Cams 1 Gears 2: Pulleys Are Used To Transfer Rotating Motion, Via A BeltRentu PhiliposeNo ratings yet

- What Are Cermets PDFDocument5 pagesWhat Are Cermets PDFAnonymous Inwmu7iEvM100% (1)

- MACHINING-lathe and Milling)Document29 pagesMACHINING-lathe and Milling)YosephNo ratings yet

- Drilling SRM UniviersityDocument27 pagesDrilling SRM UniviersityBhavin Desai100% (2)

- Bda20303 Chapter 1-Gear SystemDocument27 pagesBda20303 Chapter 1-Gear SystemWan SamiraNo ratings yet

- Simple Machine Component of Rube GoldbergDocument7 pagesSimple Machine Component of Rube GoldbergThomas Adam Johnson100% (1)

- Lathe Machine and Its OperationsDocument16 pagesLathe Machine and Its OperationsLokesh PatilNo ratings yet

- 65e0233c88677 Submission Template Varroc Eureka Challenge 2.0 NewDocument15 pages65e0233c88677 Submission Template Varroc Eureka Challenge 2.0 Newmr.tommy12143No ratings yet

- Machine Tools and Machining1Document62 pagesMachine Tools and Machining1Faisal MaqsoodNo ratings yet

- Mechanical SickelDocument42 pagesMechanical SickelPaul AntoNo ratings yet

- ShaperDocument20 pagesShaperMilan SainiNo ratings yet

- Simple Machines and Gears and Their Mechanical AdvantageDocument11 pagesSimple Machines and Gears and Their Mechanical AdvantageSanthosh Kumar VempatiNo ratings yet

- Lathe and Drilling MachinesDocument48 pagesLathe and Drilling MachinesMisga BekeleNo ratings yet

- Chapter 2 - Metal Cutting LatheDocument165 pagesChapter 2 - Metal Cutting LathebmdbmdbmdNo ratings yet

- Report Screw Jack (1) TDocument47 pagesReport Screw Jack (1) TAshish Sharma80% (5)

- Design of Single Point Cutting ToolDocument11 pagesDesign of Single Point Cutting ToolSiddharth DubeyNo ratings yet

- Introduction To Design of Machine ElementsDocument11 pagesIntroduction To Design of Machine Elementssakali aliNo ratings yet

- Non Chip FormingDocument33 pagesNon Chip FormingNur AmirahNo ratings yet

- BoltsDocument18 pagesBoltsSatyaKrishna Palla100% (1)

- Sheet Metal WorkingDocument10 pagesSheet Metal WorkingBhupendhar HarshawardanNo ratings yet

- Smithy & Forging ShopDocument24 pagesSmithy & Forging Shopashok junapudiNo ratings yet

- MMAM (21ME54), Assignment-2., 2023-24Document1 pageMMAM (21ME54), Assignment-2., 2023-24pranamnathanielrajNo ratings yet

- Dsa 5500Document12 pagesDsa 5500Nguyen Van ToanNo ratings yet

- ME I - Experiment No 2 Spinning ProcessDocument3 pagesME I - Experiment No 2 Spinning Processmansukh0% (1)

- Dies and Its TypesDocument2 pagesDies and Its TypesRajat AhujaNo ratings yet

- Name Harshal Bhatt Department Mechanical 2 YearDocument30 pagesName Harshal Bhatt Department Mechanical 2 YearRahul KhatriNo ratings yet

- BME Unit IV Machine ToolsDocument41 pagesBME Unit IV Machine ToolsArvind BhosaleNo ratings yet

- Lecture 4 - Mechanical Advantage, Transmission AngleDocument3 pagesLecture 4 - Mechanical Advantage, Transmission AngleMohankumarNo ratings yet

- An Introduction To 6S: Tim Mcmahon August, 2008Document43 pagesAn Introduction To 6S: Tim Mcmahon August, 2008Ester Hope HuraNo ratings yet

- Lathe and Capstan & TurretDocument13 pagesLathe and Capstan & TurretNishit Parmar100% (1)

- Machine Elements, Power Transmission Devices-pages-BY MBOKEHDocument93 pagesMachine Elements, Power Transmission Devices-pages-BY MBOKEHAvopaul ZeNo ratings yet

- 6-2 Machining Processes IDocument44 pages6-2 Machining Processes IOmar Ahmed100% (1)

- Gear and Gear TrainDocument21 pagesGear and Gear Trainm_er100No ratings yet

- Design and Analysis of PROTECTED FLANGE COUPLING Solidworks 2016 and ANSYS WorkbenchDocument27 pagesDesign and Analysis of PROTECTED FLANGE COUPLING Solidworks 2016 and ANSYS Workbenchamu100% (1)

- Machining ProcessDocument51 pagesMachining ProcessSudeepNo ratings yet

- Chisel NewDocument4 pagesChisel NewCornelius BillyNo ratings yet

- BearingsDocument63 pagesBearingsYeabsraNo ratings yet

- Gear TrainsDocument24 pagesGear Trainsjacob ellyNo ratings yet

- Contact Stress TheoriesDocument33 pagesContact Stress TheoriesTibebu Meride100% (1)

- MD-18 Power Screws PDFDocument4 pagesMD-18 Power Screws PDFjmartinezmoNo ratings yet

- Lecture 1 - Intro To Single Point Cutting Tool GeometryDocument16 pagesLecture 1 - Intro To Single Point Cutting Tool GeometryMuhammad Umar IqtidarNo ratings yet

- Patterns For Mould MakingDocument21 pagesPatterns For Mould MakingokicirdarNo ratings yet

- Drilling Operations l3 NotesDocument21 pagesDrilling Operations l3 Notesishimwe kwizera willyNo ratings yet

- Machine ShopDocument6 pagesMachine ShopZain MirzaNo ratings yet

- Power Transmission: Belt Drives, Rope Drives, Chain Drives, Gear DrivesDocument27 pagesPower Transmission: Belt Drives, Rope Drives, Chain Drives, Gear DrivesAshwin AdithyaNo ratings yet

- Unit I - Theory of Metal CuttingDocument111 pagesUnit I - Theory of Metal CuttingSaravana KumarNo ratings yet

- Metal Cutting and Machine ToolsDocument70 pagesMetal Cutting and Machine ToolsKirankumar Koduru100% (1)

- Mechanics of Metal CuttingDocument24 pagesMechanics of Metal CuttingSreehari ViswanathanNo ratings yet

- Type of Gears Trains and The Methods To Find Train ValueDocument14 pagesType of Gears Trains and The Methods To Find Train Valueabbas bilalNo ratings yet

- Gearbox 210509074427Document59 pagesGearbox 210509074427mussietilahungessesseNo ratings yet

- Tutorial 3 Josephine Bakewa IDDocument10 pagesTutorial 3 Josephine Bakewa IDJosephine BakewaNo ratings yet

- 881 Final T2Document22 pages881 Final T2Ankit BurnwalNo ratings yet

- Experiment No: 06 Name of The Experiment: Study of Gear ChangingDocument5 pagesExperiment No: 06 Name of The Experiment: Study of Gear ChangingTalat FarhanNo ratings yet

- Ars (AutoRecovered) 5Document11 pagesArs (AutoRecovered) 5christinachikafaNo ratings yet

- Gears and PulleysDocument33 pagesGears and Pulleyskim haroldNo ratings yet

- Lab 1Document8 pagesLab 1Mansoob BukhariNo ratings yet

- S1 Structures WK 3 2012Document2 pagesS1 Structures WK 3 2012kookwfNo ratings yet

- Name: - Class: - StructuresDocument7 pagesName: - Class: - StructuresKoo WFNo ratings yet

- Marks: Commonwealth Secondary School Design and Technology Structures Worksheet 2Document2 pagesMarks: Commonwealth Secondary School Design and Technology Structures Worksheet 2kookwfNo ratings yet

- Safety 2012Document1 pageSafety 2012kookwfNo ratings yet

- Content PageDocument2 pagesContent PagekookwfNo ratings yet

- TADANO Gr300ex3Document157 pagesTADANO Gr300ex3Abi Jith100% (1)

- Math 1 Lessson PlanDocument4 pagesMath 1 Lessson Planapi-235237171No ratings yet

- Hw1 2 SolutionsDocument7 pagesHw1 2 SolutionsFrancisco AlvesNo ratings yet

- Chapter 3 Practice TestDocument3 pagesChapter 3 Practice TestteachopensourceNo ratings yet

- Noise Control in BuildingDocument52 pagesNoise Control in BuildingarnabgogoiNo ratings yet

- PB 86130689Document328 pagesPB 86130689xattaNo ratings yet

- Data LabDocument6 pagesData LabAnonymous Kmmc9rNo ratings yet

- DPWH Specifications For WaterstopsDocument6 pagesDPWH Specifications For WaterstopsFrancis DomingoNo ratings yet

- NX Open: Training StructureDocument6 pagesNX Open: Training StructureRahul PatilNo ratings yet

- CUCET Question PaperDocument17 pagesCUCET Question PaperTapan SharmaNo ratings yet

- DDB094R2 and DDB099 Demo BoardsDocument7 pagesDDB094R2 and DDB099 Demo BoardscharlesNo ratings yet

- BGAS Question AnswerDocument14 pagesBGAS Question Answerراجہ شہزاد انور100% (1)

- Pythagorean Theorem DLPDocument7 pagesPythagorean Theorem DLPRodel CaliniahanNo ratings yet

- Chapter 2Document37 pagesChapter 2Abdullah Ibn MasudNo ratings yet

- Comptia A+ 220-601 Practice Test QuestionsDocument32 pagesComptia A+ 220-601 Practice Test Questionsmidnight sun fanNo ratings yet

- Weidmuller SAI PIDocument32 pagesWeidmuller SAI PIHrvoje HorvatNo ratings yet

- Gibson - 1954 - The Visual Perception of Objective Motion and Subjective MovementDocument11 pagesGibson - 1954 - The Visual Perception of Objective Motion and Subjective MovementcentralparkersNo ratings yet

- 100 Interview Questions On Hadoop - Hadoop Online TutorialsDocument22 pages100 Interview Questions On Hadoop - Hadoop Online Tutorialsamarbhai100% (1)

- Chapter 16: Semiconductor Devices: Maharashtra State BoardDocument18 pagesChapter 16: Semiconductor Devices: Maharashtra State BoardAmish ShahNo ratings yet

- Distribution of Experiments (RU-23)Document2 pagesDistribution of Experiments (RU-23)alifarafatbiplobyNo ratings yet

- FWP GR 10467-10x38 CylindricalfuselinksDocument4 pagesFWP GR 10467-10x38 Cylindricalfuselinkskhairalla mohamedNo ratings yet

- Aashto M 252-09 (2012)Document11 pagesAashto M 252-09 (2012)HongHaiDuong100% (1)

- 02 FrictionDocument45 pages02 FrictiondarshanNo ratings yet

- Data Base Management System: 1. Design and Model of Data in DatabaseDocument2 pagesData Base Management System: 1. Design and Model of Data in DatabaseVunnam HarishNo ratings yet

- 17 A02 PHExDocument6 pages17 A02 PHExPeter LeaderNo ratings yet

- Solucion Ejercicios Impares Ed NagleDocument748 pagesSolucion Ejercicios Impares Ed NagleDavid García100% (1)

- PHP Unit 3Document20 pagesPHP Unit 3bedkesachin1No ratings yet

- TNT PH 2 PLDT ROSARIO - As-Built PlanDocument3 pagesTNT PH 2 PLDT ROSARIO - As-Built PlanDebussy PanganibanNo ratings yet

Mechanisms Notes 2012

Mechanisms Notes 2012

Uploaded by

kookwfOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mechanisms Notes 2012

Mechanisms Notes 2012

Uploaded by

kookwfCopyright:

Available Formats

COMMONWEALTH SECONDARY SCHOOL

DESIGN AND TECHNOLOGY2012

Name: ________________ (

) MECHANISMS

Class: _______

Content Outline 1. Introduction 2. Movement 3. Gears 4. Pulleys 5. Cams and followers 6. Levers 7. Screw Threads 8. Linkages

1.

Mechanisms are used today, as they have been for thousands of years, as a mean of controlling movement & force. Our lives depend on mechanisms for making things work at home and at school, in shopping & leisure centres and in factories & offices. Just imagine how inconvenient it would be if you we had to walk to CSS from home everyday by foot.

Transport

Communication

Leisure

Koo WF

Mechanical devices are designed to produce necessary movements that help to facilitate our lives and enable us to work more efficiently. The four types of movements are: Linear straight line motion

Rotary

circular motion

Reciprocating

forward and backward motion along a straight line

Oscillating

forward and backward motion along an arc

Can you think of mechanical devices that incorporate the movements listed above?

A mechanism is usually considered as a SYSTEM, which produces an OUTPUT movement or force, from a given INPUT movement or force.

Mechanical systems are used to convert one type of movement at the input to a different type of movement at the output.

A glue stick, for example, uses a screw thread to convert the rotary movement of the knob into the linear movement of the glue.

COMMONWEALTH SECONDARY SCHOOL

DESIGN AND TECHNOLOGY2012

2.

Mechanical Components

2.1

Gears The gear wheel is a basic mechanical component. Its purpose is to transmit rotary motion and force. Gears are generally used for one of four different reasons: 1. 2. 3. 4. To reverse the direction of rotation To increase or decrease the speed of rotation To move rotational motion to a different axis To keep the rotation of two axis synchronized

A gear wheel has teeth around its edges. These teeth can lock into the teeth of another gear wheel. When one wheel rotates, it makes the other wheel turn as well.

Gear teeth

2.1.1 Types of Gears

a)

Bevel Gears These are designed in such a way that two of them come in contact rotate at 90 to each other. Examples are hand drill and food mixers.

bevel gear

Koo WF

b)

Spur Gears (most common industrial gears) Two gears are placed edge-to-edge turn in opposite directions; If the gears are of different diameters, different speeds can be generated; For example, if a driver gear with 10 teeth and a driven gear with 20 teeth are meshed, the driven gear will rotate at half the speed of the driver.

c)

Worm and Gear Wheels They are used to change the direction of motion by 90. The gear wheel cannot be used to rotate the worm wheel.

Examples: Found in mechanisms for opening and closing Venetian blinds.

Worm

Gear Wheel

d)

Rack and Pinion Gear The pinion is fixed on a shaft. When the pinion turns it makes the rack move in a straight line. Pulling or pushing the rack makes the pinion turn.

Can you identify the rack and pinion?

COMMONWEALTH SECONDARY SCHOOL

DESIGN AND TECHNOLOGY2012

e)

Other Gears There exist more other types of gears, each designed for different uses and applications. These include the helical gears, planetary gears and more. Discover more on their uses and functions.

2.1.2 Driver, Driven and Idler Gears A gear system consists of two or more gears which are meshed together. A driver gear is one that receives energy from a power source, such as an electric motor. A driven gear is one that receives motion from the driver gear.

I am driven by you!

I am the driver. I move first!

2.1.3 Gear Ratio Calculations To calculate gear ratio, all we need to know is the number of teeth in each gear.

Koo WF

In the figure above, the diameter of the gear on the left is twice that of the gear on the right. The gear ratio is therefore 2:1 (pronounced "two to one"). Every time the larger gear goes around once, the smaller gear goes around twice. You can see that if both gears had the same diameter, they would rotate at the same speed but in opposite directions.

If two gears are in mesh, the following is established:

Speed of Gear A no. of teeth in Gear A = Speed of Gear B no. of teeth in Gear B For example, Gear A has 60 teeth and rotates and has rotational speed of 10 rpm. Gear B has 30 teeth. What is Gear Bs rotational speed? Answer: Speed of Gear A no. of teeth in Gear A = Speed of Gear B no. of teeth in Gear B 10 60 = Speed of Gear B 30 Therefore, what is the speed of Gear B?

2.2

Pulleys A pulley is a wheel that is used with a belt or cable for transmitting movement or force. It is used to increase or decrease the speed of rotation. Pulleys are used in lifts & cranes for converting rotary motion into linear motion. In a tape measure or retractable washing line, pulleys convert linear motion into rotary motion.

COMMONWEALTH SECONDARY SCHOOL

DESIGN AND TECHNOLOGY2012

2.2.1 Types of Pulleys The two common types of pulleys are the flat and vee pulleys.

Two common belt arrangements: open drive and crossed drive

Flat belt

vee belt

Two pulleys rotate in the same direction

Two pulleys rotate in the opposite direction

2.2.2 Compound Pulley Systems Pulleys can be combined in a compound pulley system to help lift heavy weights. The more pulleys in a compound system, the easier it is to lift the weight.

Koo WF

2.2.3 Pulley Systems: Velocity Ratio (Transmission Ratio) The calculation of the velocity ratio of pulleys is similar to that used to calculate gear ratios. Take a look at the following example:

Velocity Ratio =

Output movement Input movement

How many degrees will the driven pulley rotate through for a single revolution of the driver pulley? Answer:

Diameter of driver pulley angular movement of driven pulley = Diameter of driven pulley angular movement of driver pulley

= Velocity Ratio = = Output movement Input movement

1800 3600

200 3600 400

2.3

Cams A cam is a specially shaped piece of material fixed to a shaft. It is normally used with a follower to create a cam and lever or cam and slider mechanism. The edge, or profile, of the cam guides the motion of a follower. It converts this input motion into a reciprocating output motion of the follower. The cam normally rotates with constant velocity of rotation.

COMMONWEALTH SECONDARY SCHOOL

DESIGN AND TECHNOLOGY2012

2.3.1 Types of Cams There are 3 common types of cam shapes: the pear, snail, and eccentric. Most cams are designed to have a smooth curved shape so that the motion transmitted to the follower is smooth and without sudden jerk.

2.3.2 Types of followers A follower can slide or roll on the edge or surface of a cam. The common types of followers are the flat, knife-edged and roller followers.

Can you identify which is which?

2.3.3 Toy Cam Examples Can you figure out how the following examples work?

Koo WF

2.4

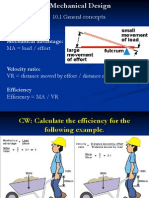

Levers

2.4.1 First Class Lever A first class lever with its various parts is labeled as shown below. A downward force on the effort arm will cause an upward force to be applied to the load. Objects like hand carts, scissors, pliers and nail extravagators are all examples of first class levers.

2.4.2 Second Class Lever The load in a second class lever lies between the fulcrum and the applied effort. Examples of this class are wheelbarrows, and bottle openers.

2.4.3 Third Class Lever The third class lever is characterized by having the applied effort between the fulcrum and the load. This class of levers is used as movement amplifiers. Examples are hammers, tweezers and fishing rods.

10

COMMONWEALTH SECONDARY SCHOOL

DESIGN AND TECHNOLOGY2012

2.5

Linkages A linkage is a mechanism made by connecting levers together. To connect the levers together you can use any type of fastening which allows free movement, for example screws, pins, paper fasteners, pop rivets etc.

It is also defined as a system of links used in machines and equipment to transform and transmit motion from one direction into another direction.

2.5.1 Reverse Motion Linkage Reverse motion linkages are used to change the direction of motion. A single lever with a pivot at its centre reverses and input motion without affecting the input force. The input force and the length of transmitted movement can be increased or decreased by altering the position of the pivot.

2.5.2 Parallel Motion Linkage

Parallel motion linkages are used to make 2 or more parts of a mechanism move and stay parallel to each other as the linkage move.

Koo WF

11

link

link link link

crank

brake pedal

leg pedal of a sewing machine

Examples of linkages

Useful Links: http://technologystudent.com http://www.flying-pig.co.uk/mechanisms/ http://www.howstuffworks.com/gears.htm http://www.howstuffworks.com/pulley.htm

12

You might also like

- 1 1 4 A PulleydrivessprocketsDocument4 pages1 1 4 A Pulleydrivessprocketsapi-30839565067% (3)

- Siemens Win TDCDocument32 pagesSiemens Win TDCBilal Aslam100% (1)

- Eric Priest - Magnetohydrodynamics of The Sun-Cambridge University Press (2014) PDFDocument580 pagesEric Priest - Magnetohydrodynamics of The Sun-Cambridge University Press (2014) PDFLaura Mora100% (1)

- 3 MechanismsDocument35 pages3 Mechanismsesham2100% (1)

- 10 Mechanical Design HL ExtensionDocument38 pages10 Mechanical Design HL ExtensionSyeda Fariya Nisar AliNo ratings yet

- Pulleys 1 Rotary Cams 1 Gears 2: Pulleys Are Used To Transfer Rotating Motion, Via A BeltDocument17 pagesPulleys 1 Rotary Cams 1 Gears 2: Pulleys Are Used To Transfer Rotating Motion, Via A BeltRentu PhiliposeNo ratings yet

- What Are Cermets PDFDocument5 pagesWhat Are Cermets PDFAnonymous Inwmu7iEvM100% (1)

- MACHINING-lathe and Milling)Document29 pagesMACHINING-lathe and Milling)YosephNo ratings yet

- Drilling SRM UniviersityDocument27 pagesDrilling SRM UniviersityBhavin Desai100% (2)

- Bda20303 Chapter 1-Gear SystemDocument27 pagesBda20303 Chapter 1-Gear SystemWan SamiraNo ratings yet

- Simple Machine Component of Rube GoldbergDocument7 pagesSimple Machine Component of Rube GoldbergThomas Adam Johnson100% (1)

- Lathe Machine and Its OperationsDocument16 pagesLathe Machine and Its OperationsLokesh PatilNo ratings yet

- 65e0233c88677 Submission Template Varroc Eureka Challenge 2.0 NewDocument15 pages65e0233c88677 Submission Template Varroc Eureka Challenge 2.0 Newmr.tommy12143No ratings yet

- Machine Tools and Machining1Document62 pagesMachine Tools and Machining1Faisal MaqsoodNo ratings yet

- Mechanical SickelDocument42 pagesMechanical SickelPaul AntoNo ratings yet

- ShaperDocument20 pagesShaperMilan SainiNo ratings yet

- Simple Machines and Gears and Their Mechanical AdvantageDocument11 pagesSimple Machines and Gears and Their Mechanical AdvantageSanthosh Kumar VempatiNo ratings yet

- Lathe and Drilling MachinesDocument48 pagesLathe and Drilling MachinesMisga BekeleNo ratings yet

- Chapter 2 - Metal Cutting LatheDocument165 pagesChapter 2 - Metal Cutting LathebmdbmdbmdNo ratings yet

- Report Screw Jack (1) TDocument47 pagesReport Screw Jack (1) TAshish Sharma80% (5)

- Design of Single Point Cutting ToolDocument11 pagesDesign of Single Point Cutting ToolSiddharth DubeyNo ratings yet

- Introduction To Design of Machine ElementsDocument11 pagesIntroduction To Design of Machine Elementssakali aliNo ratings yet

- Non Chip FormingDocument33 pagesNon Chip FormingNur AmirahNo ratings yet

- BoltsDocument18 pagesBoltsSatyaKrishna Palla100% (1)

- Sheet Metal WorkingDocument10 pagesSheet Metal WorkingBhupendhar HarshawardanNo ratings yet

- Smithy & Forging ShopDocument24 pagesSmithy & Forging Shopashok junapudiNo ratings yet

- MMAM (21ME54), Assignment-2., 2023-24Document1 pageMMAM (21ME54), Assignment-2., 2023-24pranamnathanielrajNo ratings yet

- Dsa 5500Document12 pagesDsa 5500Nguyen Van ToanNo ratings yet

- ME I - Experiment No 2 Spinning ProcessDocument3 pagesME I - Experiment No 2 Spinning Processmansukh0% (1)

- Dies and Its TypesDocument2 pagesDies and Its TypesRajat AhujaNo ratings yet

- Name Harshal Bhatt Department Mechanical 2 YearDocument30 pagesName Harshal Bhatt Department Mechanical 2 YearRahul KhatriNo ratings yet

- BME Unit IV Machine ToolsDocument41 pagesBME Unit IV Machine ToolsArvind BhosaleNo ratings yet

- Lecture 4 - Mechanical Advantage, Transmission AngleDocument3 pagesLecture 4 - Mechanical Advantage, Transmission AngleMohankumarNo ratings yet

- An Introduction To 6S: Tim Mcmahon August, 2008Document43 pagesAn Introduction To 6S: Tim Mcmahon August, 2008Ester Hope HuraNo ratings yet

- Lathe and Capstan & TurretDocument13 pagesLathe and Capstan & TurretNishit Parmar100% (1)

- Machine Elements, Power Transmission Devices-pages-BY MBOKEHDocument93 pagesMachine Elements, Power Transmission Devices-pages-BY MBOKEHAvopaul ZeNo ratings yet

- 6-2 Machining Processes IDocument44 pages6-2 Machining Processes IOmar Ahmed100% (1)

- Gear and Gear TrainDocument21 pagesGear and Gear Trainm_er100No ratings yet

- Design and Analysis of PROTECTED FLANGE COUPLING Solidworks 2016 and ANSYS WorkbenchDocument27 pagesDesign and Analysis of PROTECTED FLANGE COUPLING Solidworks 2016 and ANSYS Workbenchamu100% (1)

- Machining ProcessDocument51 pagesMachining ProcessSudeepNo ratings yet

- Chisel NewDocument4 pagesChisel NewCornelius BillyNo ratings yet

- BearingsDocument63 pagesBearingsYeabsraNo ratings yet

- Gear TrainsDocument24 pagesGear Trainsjacob ellyNo ratings yet

- Contact Stress TheoriesDocument33 pagesContact Stress TheoriesTibebu Meride100% (1)

- MD-18 Power Screws PDFDocument4 pagesMD-18 Power Screws PDFjmartinezmoNo ratings yet

- Lecture 1 - Intro To Single Point Cutting Tool GeometryDocument16 pagesLecture 1 - Intro To Single Point Cutting Tool GeometryMuhammad Umar IqtidarNo ratings yet

- Patterns For Mould MakingDocument21 pagesPatterns For Mould MakingokicirdarNo ratings yet

- Drilling Operations l3 NotesDocument21 pagesDrilling Operations l3 Notesishimwe kwizera willyNo ratings yet

- Machine ShopDocument6 pagesMachine ShopZain MirzaNo ratings yet

- Power Transmission: Belt Drives, Rope Drives, Chain Drives, Gear DrivesDocument27 pagesPower Transmission: Belt Drives, Rope Drives, Chain Drives, Gear DrivesAshwin AdithyaNo ratings yet

- Unit I - Theory of Metal CuttingDocument111 pagesUnit I - Theory of Metal CuttingSaravana KumarNo ratings yet

- Metal Cutting and Machine ToolsDocument70 pagesMetal Cutting and Machine ToolsKirankumar Koduru100% (1)

- Mechanics of Metal CuttingDocument24 pagesMechanics of Metal CuttingSreehari ViswanathanNo ratings yet

- Type of Gears Trains and The Methods To Find Train ValueDocument14 pagesType of Gears Trains and The Methods To Find Train Valueabbas bilalNo ratings yet

- Gearbox 210509074427Document59 pagesGearbox 210509074427mussietilahungessesseNo ratings yet

- Tutorial 3 Josephine Bakewa IDDocument10 pagesTutorial 3 Josephine Bakewa IDJosephine BakewaNo ratings yet

- 881 Final T2Document22 pages881 Final T2Ankit BurnwalNo ratings yet

- Experiment No: 06 Name of The Experiment: Study of Gear ChangingDocument5 pagesExperiment No: 06 Name of The Experiment: Study of Gear ChangingTalat FarhanNo ratings yet

- Ars (AutoRecovered) 5Document11 pagesArs (AutoRecovered) 5christinachikafaNo ratings yet

- Gears and PulleysDocument33 pagesGears and Pulleyskim haroldNo ratings yet

- Lab 1Document8 pagesLab 1Mansoob BukhariNo ratings yet

- S1 Structures WK 3 2012Document2 pagesS1 Structures WK 3 2012kookwfNo ratings yet

- Name: - Class: - StructuresDocument7 pagesName: - Class: - StructuresKoo WFNo ratings yet

- Marks: Commonwealth Secondary School Design and Technology Structures Worksheet 2Document2 pagesMarks: Commonwealth Secondary School Design and Technology Structures Worksheet 2kookwfNo ratings yet

- Safety 2012Document1 pageSafety 2012kookwfNo ratings yet

- Content PageDocument2 pagesContent PagekookwfNo ratings yet

- TADANO Gr300ex3Document157 pagesTADANO Gr300ex3Abi Jith100% (1)

- Math 1 Lessson PlanDocument4 pagesMath 1 Lessson Planapi-235237171No ratings yet

- Hw1 2 SolutionsDocument7 pagesHw1 2 SolutionsFrancisco AlvesNo ratings yet

- Chapter 3 Practice TestDocument3 pagesChapter 3 Practice TestteachopensourceNo ratings yet

- Noise Control in BuildingDocument52 pagesNoise Control in BuildingarnabgogoiNo ratings yet

- PB 86130689Document328 pagesPB 86130689xattaNo ratings yet

- Data LabDocument6 pagesData LabAnonymous Kmmc9rNo ratings yet

- DPWH Specifications For WaterstopsDocument6 pagesDPWH Specifications For WaterstopsFrancis DomingoNo ratings yet

- NX Open: Training StructureDocument6 pagesNX Open: Training StructureRahul PatilNo ratings yet

- CUCET Question PaperDocument17 pagesCUCET Question PaperTapan SharmaNo ratings yet

- DDB094R2 and DDB099 Demo BoardsDocument7 pagesDDB094R2 and DDB099 Demo BoardscharlesNo ratings yet

- BGAS Question AnswerDocument14 pagesBGAS Question Answerراجہ شہزاد انور100% (1)

- Pythagorean Theorem DLPDocument7 pagesPythagorean Theorem DLPRodel CaliniahanNo ratings yet

- Chapter 2Document37 pagesChapter 2Abdullah Ibn MasudNo ratings yet

- Comptia A+ 220-601 Practice Test QuestionsDocument32 pagesComptia A+ 220-601 Practice Test Questionsmidnight sun fanNo ratings yet

- Weidmuller SAI PIDocument32 pagesWeidmuller SAI PIHrvoje HorvatNo ratings yet

- Gibson - 1954 - The Visual Perception of Objective Motion and Subjective MovementDocument11 pagesGibson - 1954 - The Visual Perception of Objective Motion and Subjective MovementcentralparkersNo ratings yet

- 100 Interview Questions On Hadoop - Hadoop Online TutorialsDocument22 pages100 Interview Questions On Hadoop - Hadoop Online Tutorialsamarbhai100% (1)

- Chapter 16: Semiconductor Devices: Maharashtra State BoardDocument18 pagesChapter 16: Semiconductor Devices: Maharashtra State BoardAmish ShahNo ratings yet

- Distribution of Experiments (RU-23)Document2 pagesDistribution of Experiments (RU-23)alifarafatbiplobyNo ratings yet

- FWP GR 10467-10x38 CylindricalfuselinksDocument4 pagesFWP GR 10467-10x38 Cylindricalfuselinkskhairalla mohamedNo ratings yet

- Aashto M 252-09 (2012)Document11 pagesAashto M 252-09 (2012)HongHaiDuong100% (1)

- 02 FrictionDocument45 pages02 FrictiondarshanNo ratings yet

- Data Base Management System: 1. Design and Model of Data in DatabaseDocument2 pagesData Base Management System: 1. Design and Model of Data in DatabaseVunnam HarishNo ratings yet

- 17 A02 PHExDocument6 pages17 A02 PHExPeter LeaderNo ratings yet

- Solucion Ejercicios Impares Ed NagleDocument748 pagesSolucion Ejercicios Impares Ed NagleDavid García100% (1)

- PHP Unit 3Document20 pagesPHP Unit 3bedkesachin1No ratings yet

- TNT PH 2 PLDT ROSARIO - As-Built PlanDocument3 pagesTNT PH 2 PLDT ROSARIO - As-Built PlanDebussy PanganibanNo ratings yet