Professional Documents

Culture Documents

1 s2.0 S0040603111004680 Main

1 s2.0 S0040603111004680 Main

Uploaded by

jelke74Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 s2.0 S0040603111004680 Main

1 s2.0 S0040603111004680 Main

Uploaded by

jelke74Copyright:

Available Formats

Thermochimica Acta 526 (2011) 151156

Contents lists available at SciVerse ScienceDirect

Thermochimica Acta

journal homepage: www.elsevier.com/locate/tca

Kinetic investigation and predictive model for the isothermal degradation time in two commercial acetylsalicylic acid-based pharmaceutical tablet formulations

Luigi Campanella a , Valentina Micieli b , Mauro Tomassetti a , Stefano Vecchio b,

a b

Department of Chemistry, Sapienza University of Rome, P.le A. Moro, 5, 00185 Rome, Italy Department S.B.A.I., Sapienza University of Rome, Via del Castro Laurenziano, 7, 00161 Rome, Italy

a r t i c l e

i n f o

a b s t r a c t

Differential scanning calorimetry was used as a rapid screening technique to study the stability of acetylsalicylic acid (ASA), pure or contained in two commercially available pharmaceutical tablet formulations, denoted as PF1 and PF2, where ASA is present at a high nominal concentration, along with some of the most commonly used excipients (starch, cellulose, saccharin). The stability study was focused on the kinetic analysis of the thermal decomposition of ASA, which occurs in pure ASA as well in the two pharmaceutical tablet formulations, using two well-known multi-heating model-free kinetic methods: Kissinger and OzawaFlynnWall. A knowledge of the Arrhenius parameters related to this process (activation energy Ea , pre-exponential factor A, kinetic constant k) allows the half-life time values (extrapolated at 25 C) to be calculated at xed percentages of product degraded for pure ASA as well for both dosage forms considered. Finally, the novelty of this study is represented by the results of long-term isothermal measurements, consistent with short-term non-isothermal (accelerating) measurements, provided a reasonable predictive model to calculate the isothermal degradation times, thus demonstrating the reliability of extrapolated half-life times obtained in this study. 2011 Elsevier B.V. All rights reserved.

Article history: Received 17 June 2011 Received in revised form 2 September 2011 Accepted 17 September 2011 Available online 5 October 2011 Keywords: Acetyl salicylic acid DSC Long-term isothermal measurements Kissinger equation OzawaFlynnWall equation

1. Introduction Acetylsalicylic acid (ASA), together with sodium salicylate, was the rst non-steroidal anti-inammatory drug (NSAID) to be used in clinical practice in the early 20th century [1]. ASA in particular is considered as the prototype NSAID. Despite the introduction of new congeners, it is still the most commonly used analgesicantipyreticantinammatory drug and is considered as a paragon against which to measure the activity of other peripheral analgesics. Even though there is no lack of studies concerning ASA, there are several aspects concerning, for instance, thermal stability of pure ASA or when it is contained in pharmaceutical preparations that should be considered and studied in depth. Thermal analysis, and differential scanning calorimetry (DSC) in particular is a useful tool to solve these problems. In the last ve to ten years our group dedicated many studies to these topics. In some of our previous papers, thermal analysis and DSC in particular were used satisfactorily (i) to investigate binary mixtures [2], i.e. ASA/salicylic acid mixtures, as salicylic acid is the most important degradation product of ASA, ASA/polyethylene glycol 4000 and ASA/d-mannitol mixtures, as polyethylene glycol 4000 and dmannitol are two of the most commonly used excipients; (ii) to

Corresponding author. Tel.: +39 06 4976 6906; fax: +39 06 4976 6749. E-mail address: stefano.vecchio@uniroma1.it (S. Vecchio). 0040-6031/$ see front matter 2011 Elsevier B.V. All rights reserved. doi:10.1016/j.tca.2011.09.008

discuss the criteria of compatibility (between active component and excipients(s)) when referred to the pharmaceutical specialties considered; (iii) to determine the percentage of ASA contained in several commercial pharmaceutical tablet formulations, without using wet analysis [3]; (iv) to make a comparison of the results of the quantitative determination of ASA obtained by DSC with those recommended by European and American Pharmacopoeias (titrimetric and spectrophotometric determinations) [4,5]. In the present study, we focused our attention on the thermal stability of the active component (ASA), both as a pure compound or when contained in two commercial pharmaceutical tablet formulations by elaborating data of the corresponding DSC curves referring to the thermal decomposition from a kinetic point of view. To this end, the two tablets formulations, conventionally denoted as PF1 and PF2, were selected for their highest content of ASA. Therefore, on the basis of this fact it can expect that the DSC proles of both PF1 and PF2 should be very similar to that of pure ASA, thus suggesting that no signicant interaction should be expected between ASA and the excipients contained in the two tablets formulations tested. Lastly, the role of the excipients examined in this study for the stability determination of the dosage forms and the evaluation of degradation time values (correlated in some way with their expiration dates, which have to be set by the manufacturers) have been claried through a kinetic analysis of the thermal decomposition of pure ASA as well as of its commercial dosage forms, already

152

L. Campanella et al. / Thermochimica Acta 526 (2011) 151156

investigated by some authors in previous papers [615], as well as of ASA contained in the two dosage forms considered.

2. Material and methods 2.1. Material Pure acetylsalicylic acid was supplied by Fluka, and its purity, checked by DSC, was found to be over 99% (w/w). Each packaging of the two different pharmaceutical tablet formulations were purchased from a local drugstore and tested as is, i.e. without any pre-treatment except the careful grinding and homogenization of at least 20 tablets of each test drug. The nominal content of ASA referring to the PF1 and PF2 specialties tested in the present research, i.e. those in the widest commercial use, are 93.6 and 84.3% (w/w), respectively. According to the manufacturers declarations, the following excipients were also present: starch and cellulose in the drug PF1, and starch, cellulose, sodium saccharine, raspberry avour in the drug PF2.

2.2. Apparatuses The DSC measurements were performed using a StantonRedcroft STA 625 simultaneous TG/DSC thermoanalyzer interfaced with an IBM compatible computer running StantonRedcroft Data Acquisition System, Trace 2, software (version 4), interfaced with an IBM compatible computer running ad hoc software.

2.3. Methods About 7 mg of sample were used for each DSC experiment, operating in a stream of air (about 50 cm3 min1 ) at different heating rates (from 2.5 to 20) K min1 . DSC experiments carried out in a stream of argon, under the same operating conditions, showed that the DSC curves referring to the melting peak were practically identical to those obtained in a stream of air. This implies that the enthalpy values referring to the melting processes investigated were not appreciably affected by the surrounding atmosphere. Temperature calibration (x-axis) was achieved by exploiting the melting temperatures of known standard substances, such as indium, lead, tin, zinc, and benzoic acid [16]. Heat ow calibration was performed by recording two DSC experiments under the same experimental conditions: the rst with empty pans, while the second with a sapphire crystal placed inside the sample pan, the heat ow of which was very accurately known over a wide temperature range. The difference between the heat ow values at each temperature was used to construct a calibration curve (counts vs. mW). At the conclusion of each test performed on the various samples, taking into account the baseline of the DSC curve peak, the software was used to obtain the values corresponding to the melting temperature and the melting enthalpy. Long-term isothermal measurements were carried out in a static air atmosphere by alternately adding 910 mg of pure ASA, or PF1, or PF2 samples (weighed exactly using a Sartorius electronic balance (102 mg)) in alumina crucibles. The procedure adopted was similar to that reported in literature [17]: all the samples were placed in an oven at 70 C (1 C) and weighed accurately 25, 50, and 75 days after the samples were extracted and cooled in a desiccator for 30 min. After rapid weighing, all the samples were immediately placed in the oven.

Fig. 1. DSC curves of pure ASA (A), dosage form PF1 (B) and dosage form PF2 (C), in a stream of air at 2.5, 5, 10 and 20 K min1 (from the bottom).

3. Results and discussion The DSC curves of pure ASA and of ASA contained in the two PF1 and PF2 dosage forms, recorded at different constant heating rates (2.5, 5, 10, and 20 K min1 ) are reported in Fig. 1(AC) up to 873 K. The rst endothermic peak is ascribable to the melting of ASA with peak temperature around 405420 K. In particular, the melting temperature of ASA is close to 420 K for pure ASA and is lower in PF1 and PF2 because of the presence of excipients. The melting DSC peak is followed by two small broad endothermic peaks, observed clearly only in pure ASA, attributed to the rst and second thermal decomposition steps of ASA: the rst step occurs between 440 and 540 K and the latter between 540 and 680 K (upper curve in Fig. 1A). Different mechanisms were proposed by several authors in the past to explain how ASA (or aspirin) decomposes in its rst thermal decomposition step [6,12,14,15]. It seems an established fact [13,14] that the early stage of ASA thermal decomposition produces salicylic acid and acetic acid, as the formation of the latter is conrmed by the presence of its characteristic odour. Secondary products are also formed as a result of polymerization and condensation processes [6]. In the present study a kinetic investigation was carried out on the rst decomposition step of pure ASA as well as of ASA contained in the two PF1 and PF2 dosage forms considered. This kinetic investigation was based on the application of multi-heating rate methods like those used by Kissinger [18] and OzawaFlynnWall (OFW) [19,20]. In order to apply the Kissinger method, the DSC peak temperatures associated with the rst decomposition step

L. Campanella et al. / Thermochimica Acta 526 (2011) 151156

153

ln(/Tm2/K1 min1)

-8 -9 -10 -11 -12

A

1200

PF1 2.5% (exp) PF2 2.5% (exp) ASA 2.5% (lit)

3.3 2.7 2.2 1.6 1.1

Degradtion time (days)

900

ASA 2.5% (exp)

600

300 0.5

0

B

ln(/Tm2/K1 min1)

-8 2.1 -9 -10 -11 -12

2.2

2.3

2.4

2.5

T=303.15 K

PF1 5.0% (exp)

0.0 6.6

B

1800

Degradtion time (days)

ASA 5.0% (lit)

4.9

1200

ASA 5.0% (exp)

3.3

ln(/Tm2/K1 min1)

-82.1 -9 -10 -11 -12 2.1

2.2

2.3

2.4

2.5

600

1.6

T=303.15 K

0 297 301 305 309 313 0.0

Temperature (K)

Fig. 3. Degradation time values of pure ASA and ASA contained in dosage forms PF1 and PF2 required to achieve (A) 2.5 and (B) 5% of degradation.

2.2

2.3

2.4

2.5

1000 K/T

Fig. 2. Kissinger plot for the rst decomposition step of ASA in pure ASA (A), dosage form PF1 (B), and dosage form PF2 (C).

(Tm ) were recorded at different constant heating rates in the temperature range between 440 and 470 K. From the slope b of the 2 regression straight lines obtained by plotting ln (/Tm ) vs. (1/Tm ) (Fig. 2(AC)) (being the heating rate) the activation energies Ea (in kJ mol1 ) were calculated for the rst decomposition step of pure ASA and ASA contained in the PF1 and PF2 formulations according to the following equation [18]: ln

2 Tm

factors A (in min1 ) were also obtained for a rst-order reaction from the intercept a of the regression line derived from Eq. (1). The ln A values thus obtained have also been set out in Table 1. From the Arrhenius parameters (Ea and A) associated with the rst decomposition step a stability parameter was calculated, denoted as the half-life and dened as the degradation time tD required to reach a degradation D = 50% at a given temperature, according to the following equation: tD (298.15 K) = ln (1 D/100) A exp (Ea /RT ) (2)

=ab

1 Tm

(1)

where a = ln (AR/Ea ) and b = Ea /R (being R the gas constant). The error bars related to Fig. 2B and C are estimated to be slightly higher than that of Fig. 2A, due to a higher uncertainty in estimating the DSC peak temperatures for thermal decomposition of ASA in the case of PF1 and PF2 with respect to the case of pure ASA. The values of Arrhenius parameters thus obtained are shown in Table 1, along with the associated uncertainties, which are not so high as expected on the basis of the estimated error bars in Fig. 2 because the goodness of linear t was found to be quite good. Once the activation energy had been determined, the corresponding pre-exponential

Table 1 Arrhenius parameters obtained by Eq. (1) and half-life values for the rst decomposition step of ASA in the two dosage forms (PF1 and PF2) and for pure ASA for the sake of comparison. Material ASA ASA in PF1 ASA in PF2 Ea (kJ mol1 ) 70 1 68 2 69 2 ln (A/min1 ) 10.8 0.1 10.5 0.3 10.6 0.3 t1/2 (298.15 K) years 49 15 30 15 40 20

where T = 298.15 K is usually considered (also in the present study) as the reference temperature. Eq. (2) so proposed, is obtained rearranging the well-known integral relation g(D) = A exp (Ea /RT)t, where g(D) = ln (1 D/100) for a rst-order mechanism. The halflife values (D = 50%) calculated at 298.15 K using Eq. (2) are also given in Table 1. In addition, degradation times required to achieve given percentages of degradation (D equal to 2.5 or 5% in this study) are calculated at four xed temperatures (T = 25, 30, 35, and 40 C) using Eq. (2) for pure ASA and ASA contained in PF1 and PF2. The resulting degradation times are given in Fig. 3 and compared with those drawn from the literature [6] for pure ASA only. Experimental degradation times of pure ASA (black triangle data points in Fig. 3) are higher than those of PF1 and PF2 at 2.5 and 5% (even though deviations decrease with increasing temperature), in the following order: PF1 < PF2 < ASA. Moreover, if one considers the results of the predictive model applied only to the two PF1 and PF2 formulations (using Eq. (2)), it seems that reasonable times were obtained (see Fig. 3) regardless of the temperature tested: from 4 to 14 months to achieve 2.5% degradation and almost 2.5 years to achieve 5% degradation. Furthermore, experimental degradation times are in reasonable agreement with the values calculated from literature data [6] at D = 5% (within the corresponding standard deviations), except at 298.15 K where a signicant deviation is observed. Conversely,

Degradtion time (years)

PF2 5.0% (exp)

Degradtion time (years)

154

L. Campanella et al. / Thermochimica Acta 526 (2011) 151156

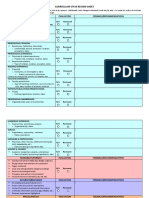

Table 2 Experimental and calculated percentages D of degraded ASA at three xed time intervals for pure ASA and ASA in PF1 and PF2. Relative standard deviations of all the values reported in this table do not exceed 6%. Material D70 C , 25 days/% Exp. Pure ASA ASA in PF1 ASA in PF2

a b

D70 C , 50 days/% Calc.a 3.8 5.7 4.4

b D%

D70 C , 75 days/% Calc.a 7.5 11.0 8.7

D% b

Exp. 7.2 11.4 8.4

Exp. 11.7 15.5 13.1

Calc.a 11.1 16.0 12.7

b D%

3.6 5.4 4.7

6.3 4.9 +5.6

4.3 +3.5 3.3

+5.5 3.5 +2.8

According to Eq. (3). D = 100(Exp. Calc.)/Exp.

experimental data at D = 2.5% show a marked deviation, and are always lower than values calculated from the literature data. The shelf-life of a drug differs slightly from its expiration date because the former is related to the drugs quality, and the latter to its safety (the date until which the manufacturer guarantees the full potency and safety of a drug). The percentage D = 10% is often selected to calculate the shelf-life, since it is often considered the reference percent of a drug degraded to estimate the shelf life value at a xed temperature, usually 25 C [21]. However, the expiration date values declared by the manufacturer for PF1 and PF2 are about 5 years, which is very close to the degradation times of 4.2 and 5.3 years required to achieve D = 10% of degradation at 25 C, calculated using Eq. (2) for PF1 and PF2, respectively. The isothermal predictive model proposed in this study seems to provide reliable values at D = 2.5, 5, and 10% of drug degraded, at least for the two pharmaceutical tablet formulations tested. On the other hand, even if half-life and degradation times seem to be reasonable, they should be viewed with caution. In fact, the validity of the halflife values thus determined should be veried, since these values were obtained by making some a priori assumptions: (i) rst-order reactions; (ii) temperature dependence of Arrhenius-type kinetic constant; (iii) the values of both Arrhenius parameters (Ea and A) must be the same at both high temperatures (in the experimental temperature range investigated) as well as at low temperatures (298.15 K)). In order to enhance result consistency (i.e., half-life values extrapolated at low temperatures) obtained from previously determined short-time measurements, long-time measurements were performed and the results expressed in terms of the percentages D of degraded pure ASA (or ASA contained in PF1 or PF2) obtained isothermally at 70 C (343.15 K) for xed t time intervals (25, 50, and 75 days). These values were compared in Table 2 with those calculated at 70 C (343.15 K) by rearranging Eq. (2), according to the following equation: D70

C,

increase linearly with increasing Ea , being ln A = c + dEa (d > 0), thus avoiding the independent determination of both Ea and ln A values. As a result, neither activation energy nor pre-exponential factor can be considered as a stability parameter. Therefore, the rate constant values k(T) of the rst decomposition step seem to be more appropriate because these values, calculated using the Arrhenius equation, take into account both the enthalpic and entropic contributions (Ea and A, respectively). The k(T) values, calculated at 298.15, 303.15, 308.15, and 313.15 K according to the Arrhenius equation using the Ea and A values listed in Table 1, were reported in Fig. 4, where the associated uncertainties were estimated taking into account mainly the error due to extrapolation outside the temperature range investigated. The k(T) values for the degradation of pure ASA are close to those of ASA contained in PF1 and PF2 at lower temperatures (25 and 30 C), while a signicant deviation is found at higher temperatures (35 and 40 C). In spite of this slight deviation between the k(T) values calculated at lower temperatures, the half-life values for the degradation of pure ASA were found to be somewhat higher than those of ASA contained in PF1 and PF2, thus demonstrating that the presence of these excipients (even though their content in the dosage forms tested is very low in both cases) has a non negligible destabilizing effect. Then, in the second part of this study the application of the isoconversional method of OzawaFlynnWall (OFW) [19,20] was considered in the temperature ranges of 427525 K for pure ASA and 417495 K for PF1 and PF2, with a view to establishing whether the activation energy associated with the rst decomposition step was dependent on the conversion degree. This method is based on the following equation: ln = ln A R E ln g() 5.3305 1.052 E R 1 T (4)

t%

= 100 1 exp A

t exp

Ea R343.15

5

(3)

Taking into account that Eq. (3) has an exponential form, percentages of relative deviation of experimental vs. calculated values ( D %) lower than 10% mean that a predictive model based on the values of Arrhenius parameters for the rst decomposition step can be considered reasonable. Actually, D % < 6.5% was found, which points to good agreement between experimental and calculated percentage values, thus demonstrating that the previously determined half-life values are reasonable as well as reliable. In previous studies performed using a kinetic approach aimed at selecting the rate determining step from among those occurring in a multistep process some contradictions sometimes emerged [22,23]. In fact, the slowest step should be characterized by the highest activation energy (lowest energy barrier) as well as by the slowest pre-exponential factor (lowest frequency of occurrence of the high-energy reaction conguration [24]). In spite of this, activation energy and pre-exponential factor of a dened single step often display a compensation effect in which the values of ln A

ASA dosage form PF1 dosage form PF2

k 107 (min1)

0 290 300 310 320 330

Temperature (K)

Fig. 4. Rate constant values as a function of temperature for the rst decomposition step of ASA in pure ASA (A), dosage form PF1 (B), and dosage form PF2 (C).

L. Campanella et al. / Thermochimica Acta 526 (2011) 151156

155

A

Ea (kJ mol1)

120 100 80 60 40 140 120 100 80 60 140 120 100 80 60 0.0 0.2 0.4

B

Ea (kJ mol-1)

especially when observed at the beginning or end of a decomposition step, were attributed to a computational artefact [25]. On the other hand, one cannot exclude that the decrease in Ea values could be also ascribable to the inuence of ASA melting at the very beginning of the rst decomposition step, since these processes occur consecutively and partly overlap. With reference to the increase at the end of the rst decomposition step, this behaviour could probably be ascribed to the presence of linear or cyclic oligomers produced by ASA thermal decomposition (even in small amounts), which exert an inhibiting effect, increasing the energy barrier to be overcome in order to change reactants into products. On the other hand, it is possible that the presence of excipients, as in the case of PF1 and PF2, could enhance or modify these processes, thus explaining the slight differences in the trends of Ea values, in particular in the early and nal stages of the plots reported in Fig. 5B and C. 4. Conclusion As far as the stability investigation is concerned, these results conrmed the expected complex nature of the thermal decomposition occurring in pure ASA or in ASA contained in the two pharmaceutical tablet formulations investigated with a slight variation of activation energy with increasing degree of transformation except for ASA contained in PF1, where signicant changes in Ea values were observed only in the ranges < 0.15 and > 0.85. As the isothermal temperature increased, the degradation of ASA contained in PF1 and PF2 was found to be faster than the degradation of pure ASA (Fig. 4). Moreover, the choice of considering the constant rate k(T) as a stability parameter (instead of Arrhenius parameters) enabled us to distinguish (albeit only partly) between the decomposition rate of pure ASA and that of the dosage forms PF1 and PF2 (even at lower temperatures). As a result, half-life values for degradation of pure ASA were found to be higher than those of ASA contained in PF1 and PF2, thus demonstrating that the presence of these excipients (even though their content in the tablet dosage forms tested is very low in both cases) has a non negligible destabilizing effect. Very reasonable degradation time values were obtained from accelerated stability experiments from pure ASA, PF1, and PF2, whose reliability was conrmed by longtime experiments carried out at constant temperature (70 C) for different time values. Finally, the good agreement between the expiration date values of PF1 and PF2 and the degradation time taken to achieve D = 10% at 25 C enabled us to conclude that the procedure adopted in this study can be considered reliable, even if for a severe validation of the method other systems and more than two formulation should be considered in the near future. Acknowledgements This work was funded by Sapienza University of Rome, Ateneo Projects. References

[1] J.H. Goodman, M.E. Gilbert (Eds.), Manual of Pharmacological Therapeutics, McGraw-Hill, 2007. [2] L. Campanella, V. Micieli, M. Tomassetti, S. Vecchio, Solidliquid phase diagrams of binary mixtures. Acetylsalicylic acid (1) + E(2) (E = salicylic acid, polyethylene glycol 4000, d-mannitol), J. Therm. Anal. Calorim. 99 (2010) 887892. [3] L. Campanella, V. Micieli, M. Tomassetti, S. Vecchio, Quantitative determination of acetyl salicylic acid in commercial drugs using differential scanning calorimetry Comparison with titration and UV spectrophotometric methods, J. Therm. Anal. Calorim. 102 (2010) 249259. [4] European Pharmacopoeia, 5th ed., 2005, p. 917. [5] United States Pharmacopoeia, USP 28 NF 23, 2005, p. 180.

C

Ea (kJ mol-1)

0.6

0.8

1.0

Fig. 5. Conversion dependency of Ea for the rst decomposition step of ASA in pure ASA (A), dosage form PF1 (B), and dosage form PF2 (C).

where is the extent of reaction. Once Doyles approximation [24]: log p(xi ) 2.315 0.4567xi , where xi = E 103 /(RT ) and 20 xi 60) is veried as valid over the entire range of , then at any selected value of , from the slope of the related regression straight line derived from the ln vs. 1/T plot, each corresponding E value is derived for each value of . The resulting Ea values are then plotted in Fig. 5 as a function of the degree of conversion for both pure ASA and for the ASA contained in the two pharmaceutical tablet formulations PF1 and PF2, where the associated uncertainties are estimated at about 8. A decreasing trend is observed in Fig. 5 A for pure ASA, in good agreement with the results obtained from the literature [6], even if with a more limited variation of Ea values. However, the mean values are always 1520% higher than those determined with the Kissinger method (Table 1). The reason for this slight discrepancy could be attributed not only to the variation of Ea values, but also to the goodness of Doyles approximation [24], which depends on both the temperature range investigated and the activation energies calculated. In fact, xi = E 103 /(RT ) values should lie in the 2060 range, while the mean value, calculated for the rst decomposition step of ASA, PF1 and PF2, is about 25, which is very close to its lower limit. A smaller variation of Ea values (within the boundaries of their uncertainties (standard deviations)) is observed in the range 0.05 < < 0.85 for the rst decomposition step of ASA in PF1 and PF2 (Fig. 5B and C). In particular, as far as the thermal decomposition of ASA contained in PF1 is concerned (Fig. 5B), the two narrow ranges < 0.15 and > 0.85 exhibit an evident decrease and increase in activation energy values (the former from 122.6 to 92.9 kJ mol1 and the latter from 90.7 to 116.0 kJ mol1 , respectively). These changes in Ea values,

156

L. Campanella et al. / Thermochimica Acta 526 (2011) 151156 [16] R. Hultgren, P.D. Desai, D.T. Hawkins, M. Gleiser, K.K. Kelley, D.D. Wagman, Selected Values of the Thermodynamic Properties of the Element, American Society for Metals: Metals Park, OH, 1973. [17] L. Abate, I. Blanco, O. Motta, A. Pollicino, A. Recca, The isothermal degradation of some polyetherketones: a comparative kinetic study between long-term and short-term experiments, Polym. Degrad. Stab. 75 (2002) 465471. [18] H.E. Kissinger, Reaction kinetics in differential thermal analysis, Anal. Chem. 29 (1972) 17021706. [19] T. Ozawa, A new method of analyzing thermogravimetry data, Bull. Chem. Soc. Jpn. 38 (1965) 18811886. [20] J.H. Flynn, L.A. Wall, A quick direct method for the determination of activation energy from thermogravimetric data, J. Polym. Sci. B: Polym. Lett. 4 (5) (1966) 323328. [21] S. Materazzi, S. Vecchio, L.W. Wo, Thermoanalytical studies of imidazole-substituted coordination compounds. Mn(II)-complexes of bis[1-methylimidazol-2-yl]ketone, J. Therm. Anal. Calorim. 103 (2011) 5964. [22] C. Papadopoulos, N. Kantiranis, S. Vecchio, M. Lalia-Kantouri, Lanthanide complexes of 3-methoxy-salicylaldehyde, J. Therm. Anal. Calorim. 99 (2010) 931938. [23] A.K. Galwey, M.E. Brown, Thermal Decomposition of Ionic Solids, 1st ed., Elsevier, Amsterdam, 1999, p. 117. [24] C.D. Doyle, Estimating isothermal life from thermogravimetric data, J. Appl. Polym. Sci. 6 (24) (1962) 639642. [25] T. Sell, S. Vyazovkin, C.A. Wight, Thermal decomposition kinetics of PBANbinder and composite solid rocket propellants, Combust. Flame 119 (1999) 174181.

[6] G.T. Long, S. Vyazovkin, N. Gamble, C.A. Wight, Hard to swallow dry: kinetics and mechanism of the anhydrous thermal decomposition of acetylsalicylic acid, J. Pharm. Sci. 91 (2002) 800809. [7] L.J. Lesson, A.M. Mattock, Decomposition of aspirin in the solid state, J. Am. Pharm. Assoc. 47 (1958) 329333. [8] J.T. Carstensen, F. Attarchi, X.-P. Hou, Decomposition of aspirin in the solid state in the presence of limited amounts of moisture, J. Pharm. Sci. 74 (1985) 741745. [9] E. Domagalina, T. Slawik, Thermal degradation of acetylsalicylic acid, Acta Pol. Pharm. 33 (1976) 623626. [10] O.M.N. Al-Gohary, R.S. Al-Kassas, Stability studies of aspirinmagaldrate double layer tablets, Pharm. Acta Helv. 74 (2000) 351360. [11] D.J. Ager, K.S. Alexander, A.S. Bhatti, J.S. Blackburn, D. Dollimore, T.S. Koogan, K.A. Mooseman, G.M. Muhvic, B. Sims, V.J. Webb, Stability of aspirin in solid mixtures, J. Pharm. Sci. 75 (1986) 97101. [12] Y. Asakura Ribeiro, A.C.F. Caires, N. Boralle, M. Ionashiro, Thermal decomposition of acetylsalicylic acid, Thermochim. Acta 279 (1996) 177181. [13] E.M.A. Silva, D.M.A. Melo, M.F.V. Moura, R.F. Farias, An investigation about the solid state thermal degradation of acetylsalicylic acid: polymer formation, Thermochim. Acta 414 (2004) 101104. [14] G. Gupchup, K. Alexander, D. Dollimore, The use of thermal analysis and mass spectrometry to study the solid state behaviour in pharmaceutical tablet mixtures, Thermochim. Acta 196 (1992) 267278. [15] S. Wissing, D.Q.M. Craig, S.A. Barker, W.D. Moore, An investigation into the use of stepwise isothermal high sensitivity DSC as a means of detecting drugexcipient incompatibility, Int. J. Pharm. 199 (2000) 141150.

You might also like

- Non Pharma Final FileDocument138 pagesNon Pharma Final FileMian. Shoaib.No ratings yet

- Approved Drug Products: Therapeutic Equivalence EvaluationsDocument1,898 pagesApproved Drug Products: Therapeutic Equivalence EvaluationsSHREE HIMANSHU KUMAR100% (1)

- Paracetamol Solubility in Pure SolventsDocument6 pagesParacetamol Solubility in Pure SolventsValentino DhiyuNo ratings yet

- J. Chem. Thermodynamics: Lianzheng Zhang, Dongmei Xu, Jun Gao, Liwen Zhao, Zhishan Zhang, Chunlu LiDocument9 pagesJ. Chem. Thermodynamics: Lianzheng Zhang, Dongmei Xu, Jun Gao, Liwen Zhao, Zhishan Zhang, Chunlu LiFrank ElizaldeNo ratings yet

- A Laboratory Manual of Physical PharmaceuticsFrom EverandA Laboratory Manual of Physical PharmaceuticsRating: 2.5 out of 5 stars2.5/5 (2)

- Perth Zoo Excursion Parent Letter Permission Form 25Document2 pagesPerth Zoo Excursion Parent Letter Permission Form 25api-451237803No ratings yet

- ROLE OF HPLC IN PREFORMULATION (Irina Kazakevich)Document6 pagesROLE OF HPLC IN PREFORMULATION (Irina Kazakevich)livevilfrNo ratings yet

- Vapor-Liquid Equilibrium Measurements For The BinaDocument9 pagesVapor-Liquid Equilibrium Measurements For The BinaMariaFernandaHernandezZuñigaNo ratings yet

- YttreDocument8 pagesYttreImad AghilaNo ratings yet

- Differential Scanning Calorimetry in Food Research A ReviewDocument27 pagesDifferential Scanning Calorimetry in Food Research A ReviewMarius MihaiNo ratings yet

- Talanta: Ayd In Yiğit, Yavuz Yard Im, Metin Çelebi, Abdulkadir Levent, Zühre ŞentürkDocument9 pagesTalanta: Ayd In Yiğit, Yavuz Yard Im, Metin Çelebi, Abdulkadir Levent, Zühre ŞentürkYoselin GomezNo ratings yet

- Equilibrio Co2Document8 pagesEquilibrio Co2baslitaNo ratings yet

- Stability of PH, Blood Gas Partial Pressure, Hemoglobin Oxygen Saturation Fraction, and Lactate ConcentrationDocument9 pagesStability of PH, Blood Gas Partial Pressure, Hemoglobin Oxygen Saturation Fraction, and Lactate ConcentrationJavier DeinecaNo ratings yet

- Rojek-Wesolowski2019 Article DSCSupportedByFactorAnalysisAsDocument9 pagesRojek-Wesolowski2019 Article DSCSupportedByFactorAnalysisAsBojan PavlovićNo ratings yet

- Air Drying by Pressure Swing Adsorption - Chihara-SuzukiDocument7 pagesAir Drying by Pressure Swing Adsorption - Chihara-SuzukiAndri SaputraNo ratings yet

- Thermal Stability of Surfactants For Steam FloodDocument10 pagesThermal Stability of Surfactants For Steam FloodFIRA AULIASARINo ratings yet

- ASA StabilityDocument11 pagesASA StabilitySarathchandran Chandrashekar ShenoyNo ratings yet

- Fluid Phase Equilibria: Chong Sun, Wei Cao, Jia Wu, Xiaoping HuDocument5 pagesFluid Phase Equilibria: Chong Sun, Wei Cao, Jia Wu, Xiaoping HuBrianDiazNo ratings yet

- VL Critical Prop Elements Compounds Unsat Aliphatic HCsDocument12 pagesVL Critical Prop Elements Compounds Unsat Aliphatic HCstutuncucananNo ratings yet

- Accepted Manuscript: Thermochimica ActaDocument29 pagesAccepted Manuscript: Thermochimica ActayascheNo ratings yet

- Vapor Pressure Measurements For Metal Chloride Systems by The Knudsen Effusion MethodDocument6 pagesVapor Pressure Measurements For Metal Chloride Systems by The Knudsen Effusion MethodHerdiana KristiNo ratings yet

- Isothermal Microcalorimetry: An Analytical Technique For Assessing The Dynamic Chemical Stability of UHMWPEDocument6 pagesIsothermal Microcalorimetry: An Analytical Technique For Assessing The Dynamic Chemical Stability of UHMWPEmurugandevaNo ratings yet

- Determining Oxidation Induction Time of Hydrocarbons by Differential Scanning CalorimetryDocument6 pagesDetermining Oxidation Induction Time of Hydrocarbons by Differential Scanning CalorimetryEric GozzerNo ratings yet

- Chemical Engineering Science: Ardi Hartono, Muhammad Saeed, Arlinda F. Ciftja, Hallvard F. SvendsenDocument11 pagesChemical Engineering Science: Ardi Hartono, Muhammad Saeed, Arlinda F. Ciftja, Hallvard F. SvendsenrahulNo ratings yet

- 1 s2.0 S1876610217314078 MainDocument10 pages1 s2.0 S1876610217314078 Maingen.elang.0505No ratings yet

- Determination of Olive Oil 2-Thiobarbituric Acid Reactive Substances by Parallel Flow InjectionDocument6 pagesDetermination of Olive Oil 2-Thiobarbituric Acid Reactive Substances by Parallel Flow InjectionzvzvzvdgNo ratings yet

- Ultrasound Assisted Pressurized SolventDocument6 pagesUltrasound Assisted Pressurized SolventKhalil OukebdaneNo ratings yet

- J. Soujanya, Ch. Anvesh Reddy, B. Satyavathi, T. SankarshanaDocument7 pagesJ. Soujanya, Ch. Anvesh Reddy, B. Satyavathi, T. Sankarshanareyna ocampoNo ratings yet

- 078a PDFDocument6 pages078a PDFPrashant RobbieNo ratings yet

- Activated Carbon and MethanolDocument5 pagesActivated Carbon and MethanolSibnath KayalNo ratings yet

- SPE-164128-MS James JohnstoneDocument20 pagesSPE-164128-MS James JohnstoneOilfieldJimNo ratings yet

- Himeno JChemEngData 2005 PDFDocument8 pagesHimeno JChemEngData 2005 PDFEduardo Enrique Choto AguirreNo ratings yet

- Antecedentes 2Document26 pagesAntecedentes 2Carlos Mario Ortiz MuñozNo ratings yet

- Enantioseparation of 1-Phenyl-1-Propanol On Chiralcel OD by Supercritical Fluid Chromatography I. Linear IsothermDocument6 pagesEnantioseparation of 1-Phenyl-1-Propanol On Chiralcel OD by Supercritical Fluid Chromatography I. Linear Isothermconstantine234No ratings yet

- Creep of PolyurethaneDocument33 pagesCreep of PolyurethaneubdubNo ratings yet

- An Investigation Into The Degradation of Ascorbic Acid in Solutions PDFDocument7 pagesAn Investigation Into The Degradation of Ascorbic Acid in Solutions PDFnonameNo ratings yet

- 1 s2.0 S0140700712001405 MainDocument14 pages1 s2.0 S0140700712001405 MainPatrice PariNo ratings yet

- Final Report On The Key Comparison Ccm.P-K4.2012 in Absolute Pressure From 1 Pa To 10 KpaDocument37 pagesFinal Report On The Key Comparison Ccm.P-K4.2012 in Absolute Pressure From 1 Pa To 10 KpaMaria Isabel LadinoNo ratings yet

- PhysicalchemistryresearchDocument11 pagesPhysicalchemistryresearchMrittika MarketingNo ratings yet

- Heat Capacities of L-Histidine L-Phenylalanine L-PDocument13 pagesHeat Capacities of L-Histidine L-Phenylalanine L-Paniket singhNo ratings yet

- Zúñiga Moreno Galicia Luna2007 Article CompressedLiquidDensitiesOf1 PDocument17 pagesZúñiga Moreno Galicia Luna2007 Article CompressedLiquidDensitiesOf1 Pjasontodd22031995No ratings yet

- Kinetics of Carotenoid Degradation in SPDocument10 pagesKinetics of Carotenoid Degradation in SPJobin GeorgeNo ratings yet

- Sun 2003Document9 pagesSun 2003adolfo olmosNo ratings yet

- E 1899 - 97 Rte4otktukveDocument7 pagesE 1899 - 97 Rte4otktukveGaraje ToysNo ratings yet

- Alkaline PhosphatasesDocument6 pagesAlkaline PhosphatasesMohammed AlMujainiNo ratings yet

- Solubility of Antibiotics in Different Solvents. Part II. Non-Hydrochloride Forms of Tetracycline and CiprofloxacinDocument8 pagesSolubility of Antibiotics in Different Solvents. Part II. Non-Hydrochloride Forms of Tetracycline and CiprofloxacinfmtaNo ratings yet

- Phase Equilibrium (Solid-Liquid-Gas) in Polyethyleneglycol-Carbon Dioxide SystemsDocument9 pagesPhase Equilibrium (Solid-Liquid-Gas) in Polyethyleneglycol-Carbon Dioxide SystemsCu ExNo ratings yet

- Chickos 519 Vap2003Document360 pagesChickos 519 Vap2003pmolyneuxNo ratings yet

- Trache 2012Document9 pagesTrache 2012patilsahyadri2181No ratings yet

- Blackpool TableDocument64 pagesBlackpool TableLuxna SureshNo ratings yet

- Determination of The Melting Temperature, Heat of Fusion, and Purity Analysis of Different Samples of Zidovudine (AZT) Using DSCDocument8 pagesDetermination of The Melting Temperature, Heat of Fusion, and Purity Analysis of Different Samples of Zidovudine (AZT) Using DSCSaurav BhattacharjeeNo ratings yet

- N-Methyldiethanolamine, Diethanolamine, and 2-Amino-2-Methyl-1-Propanol inDocument6 pagesN-Methyldiethanolamine, Diethanolamine, and 2-Amino-2-Methyl-1-Propanol indeshaka11No ratings yet

- Determination and Calculation of Solubility of Bisphenol A in Supercritical Carbon DioxideDocument7 pagesDetermination and Calculation of Solubility of Bisphenol A in Supercritical Carbon DioxideAndrés F. CáceresNo ratings yet

- 7-A Neural Network Approach For Thermal and Pressure Food ProcessingDocument7 pages7-A Neural Network Approach For Thermal and Pressure Food ProcessingKathya C. PerezNo ratings yet

- (J. C. Yannopoulos (Auth.) ) The Extractive MetallDocument8 pages(J. C. Yannopoulos (Auth.) ) The Extractive MetallmirafrmNo ratings yet

- Vent Sizing Applications For Reactive SystemsDocument10 pagesVent Sizing Applications For Reactive SystemsAritraDalalNo ratings yet

- Paracetamol DegradationDocument9 pagesParacetamol DegradationTruyền Phạm MinhNo ratings yet

- Acp 2020 940Document22 pagesAcp 2020 940MicciNo ratings yet

- DSCasparticDocument5 pagesDSCasparticaniket singhNo ratings yet

- Physico-Chemistry of Solid-Gas Interfaces: Concepts and Methodology for Gas Sensor DevelopmentFrom EverandPhysico-Chemistry of Solid-Gas Interfaces: Concepts and Methodology for Gas Sensor DevelopmentNo ratings yet

- Dynamics of Leaf Photosynthesis: Rapid Response Measurements and Their InterpretationsFrom EverandDynamics of Leaf Photosynthesis: Rapid Response Measurements and Their InterpretationsNo ratings yet

- Veolia Water Tech AUS PharmaDocument7 pagesVeolia Water Tech AUS Pharmamanojdhamne5802No ratings yet

- Pharmacy Resume Review Rubric PDFDocument3 pagesPharmacy Resume Review Rubric PDFsara elalfyNo ratings yet

- Senarai Produk Yang Diluluskan Dalam PBKD368 6 JANUARI 2022 WebsiteDocument15 pagesSenarai Produk Yang Diluluskan Dalam PBKD368 6 JANUARI 2022 WebsitematloboNo ratings yet

- Pharmacy Management SystemDocument4 pagesPharmacy Management SystemTaniya FernandoNo ratings yet

- Biotechnology Analytical Development Director in CT Resume Shirish DhumeDocument5 pagesBiotechnology Analytical Development Director in CT Resume Shirish DhumeSharishDhumeNo ratings yet

- BAIN REPORT Global Healthcare Private Equity 2016 PDFDocument40 pagesBAIN REPORT Global Healthcare Private Equity 2016 PDFkaramNo ratings yet

- Amoxicillin and Clavulanate PotassiumDocument6 pagesAmoxicillin and Clavulanate PotassiumPascalis AyukNo ratings yet

- MicroencapsulationDocument5 pagesMicroencapsulationDéépákNo ratings yet

- Annual Report 1Document535 pagesAnnual Report 1Suraj ApexNo ratings yet

- Sensodyne Market AnalysisDocument27 pagesSensodyne Market AnalysisJacky FaragNo ratings yet

- Cleanroom ClassificationDocument59 pagesCleanroom Classificationabbas aliNo ratings yet

- Aromatherpy - The Power of Scent - A ReviewDocument16 pagesAromatherpy - The Power of Scent - A ReviewWilliam ChandraNo ratings yet

- Therapeutic Interchange ListDocument29 pagesTherapeutic Interchange ListНазарій ЛавровськийNo ratings yet

- Herbal ResearchDocument25 pagesHerbal ResearchDaniel BartoloNo ratings yet

- Batuk - Pilek Harga Jumlah Barang: Satuan Masuk Terjual SisaDocument7 pagesBatuk - Pilek Harga Jumlah Barang: Satuan Masuk Terjual Sisadoni januarindraNo ratings yet

- MPharm Course StructureDocument6 pagesMPharm Course Structurepmano2014No ratings yet

- Medication Therapy Management Current ChallengesDocument11 pagesMedication Therapy Management Current ChallengesDzaky UlayyaNo ratings yet

- APDS TobramycinDocument35 pagesAPDS TobramycinintanlisnaNo ratings yet

- DAFTAR ATC DDD ANTIBIOTIK WHO 2018 AbcDocument12 pagesDAFTAR ATC DDD ANTIBIOTIK WHO 2018 AbcMahezha DhewaNo ratings yet

- Mefloquine Hydrochloride, Brain Damage: Military Service and Toxic DrugsDocument3 pagesMefloquine Hydrochloride, Brain Damage: Military Service and Toxic DrugsByron Harding100% (1)

- Beximco PharmaDocument8 pagesBeximco PharmaShakilfunkyNo ratings yet

- GIVING DirectionsDocument1 pageGIVING DirectionsLita OktaviantariNo ratings yet

- Mission Statements and Stakeholders: A, B, C, D, or FDocument2 pagesMission Statements and Stakeholders: A, B, C, D, or FNavarro CarlojohnNo ratings yet

- Journal Reflection in Immersion Pharmacy LaboratoryDocument4 pagesJournal Reflection in Immersion Pharmacy LaboratoryCiel GevenNo ratings yet

- Assays For Controlling Host-Cell Impurities in BiopharmaceuticalsDocument5 pagesAssays For Controlling Host-Cell Impurities in BiopharmaceuticalsBabbooNo ratings yet