Professional Documents

Culture Documents

05080739

05080739

Uploaded by

Saqib Ali KhanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

05080739

05080739

Uploaded by

Saqib Ali KhanCopyright:

Available Formats

CORROSION SCIENCE SECTION

Discussion: Electrochemical Techniques for Studying Corrosion of Reinforcing Steel: Limitations and Advantages

F. Mansfeld*

ABSTRACT

F. Mansfeld* discusses Electrochemical Techniques for Studying Corrosion of Reinforcing Steel: Limitations and Advantages, by J.A. Gonzlez,** J.M. Miranda,*** N. Birbilis,**** and S. Feliu,** which was published in CORROSION 61, 1 (2005), p. 37-50. A reply from J.A. Gonzlez, J.M. Miranda, N. Birbilis, and S. Feliu follows. KEY WORDS: comparison, concrete, electrochemical methods, polarization, steel

DISCUSSION

The authors repeat a common error by referring to the simple parallel RTC circuit in their Figure 1 as the Randles circuit. In fact, the equivalent circuit (EC) in Figure 1 has no name. The Randles circuit is the circuit that is shown in their Figure 4, where the Warburg impedance W is shown in series with RT.1-2 In our experience, very few corrosion systems show impedance spectra that agree with the Randles circuit, in which the Warburg impedance Zw is given by: Z w = (1 j) 1/2 (1)

where is the Warburg coefcient and = 2f is the frequency f of the applied alternating current (AC) signal in rad/s. The Randles circuit applies for cases with an innite diffusion length. The EC in Figure 1(a) becomes the Randles circuit for Xi = Zw. In the complex plant plot (Figure 1[b]), which is often erroneously called the Nyquist plot,3 the real part of the impedance Z and the imaginary part Z reach innite values as f 0. The impedance modulus |Z| in the Bode plot of Figure 1(c) shows similar behavior. Better agreement with experimental impedance spectra has been found for the EC containing the open boundary nite length diffusion (OFLD) element that models the diffusion impedance when the diffusion layer has nite dimensions.4-5 In the EC shown in Figure 1(a) for Xi = ZOFLD, the OFLD impedance is in series with the polarization resistance Rp and in parallel with the capacitance C. Using Boukamps notation,6 the impedance of the OFLD element is given by: Z OFLD = {tanh[Bd ( j )1/2 ]} / Yo ( j )1/2 (2)

* Corrosion and Environmental Effects Laboratory (CEEL), Department of Materials Science and Engineering, University of Southern California, Los Angeles, CA 90089-0241. ** Centro Nacional de Investigaciones Metalrgicas, Av. Gregorio del Amo, No. 8, 28040, Madrid, Spain. *** Instituto de Metalurgia de la U.A.S.L.P., Av. Sierra Leona, No. 550, 78210, San Luis Potos, Mexico. **** S.P.M.E., Monash University, Wellington Road, Clayton, 3800, Australia. Present address: Fontana Corrosion Center, The Ohio State University, Columbus, OH 43210.

where Bd = l/(D)1/2 is the diffusion parameter, l is the diffusion length, D is the diffusion coefcient, and Yo = [ (2)1/2]1. For the OFLD model, Z reaches zero ohms (Figure 1[b]) and |Z| reaches a direct current (DC) limit equal to Rs + Rp + Bd/Yo at very low frequencies (Figure 1[c]). For the phase angle ||, a second maximum is observed at very low frequencies, and, contrary to the case of the Randles circuit, reaches zero degree as f 0. This EC has been applied successfully to the analysis of impedance spectra for various polymer coating systems for which l has been found

CORROSIONVol. 61, No. 8

0010-9312/05/000149/$5.00+$0.50/0 2005, NACE International

739

CORROSION SCIENCE SECTION

(a)

(b)

where the EC in Figure 1 apply. For cases where the Randles circuit applies, Rp(ap) contains contributions from Zw, the magnitude of which depends on the potential scan rate used for the measurement. For cases where the OFLD model applies, Rp(ap) = Rs + Rp + Bd/Yo. Only analysis of electrochemical impedance spectroscopy (EIS) data with these models allows the separation of the contributions of charge-transfer (Rp) and mass-transport (, Bd) processes. The other electrochemical methods discussed by Gonzlez, et al., suffer from the same problems as those discussed here. Finally, the statement that the use of EIS requires measurement times much longer than those required for LPR, and, thus, it turns out more convenient to resort to LPR techniques is surprising, since the authors discuss the effects of scan rates that are too fast on Rp(ap) values earlier.14 It should also be noted that Gonzlez, et al., state that the interpretation of the impedance data for clean and precorroded steel electrodes shown in their Figure 13 is difcult, if not impossible. Not everybody might agree with the authors conclusions that the inadequate use of electrochemical techniques is often the cause for great discrepancies of Rp values determined with different methods. All electrochemical methods are based on very simple models that might not apply for all corrosion systems, including steel in concrete, which is a very complex system. As discussed by Gonzlez, et al., and noted elsewhere,15 it is not possible to speed up electrochemical measurements.

REFERENCES

1. C.M.A. Brett, A.M. Oliveira Brett, Electrochemistry: Principles, Methods, and Applications (Oxford, U.K.: Oxford University Press, 1993). 2. P.A. Christensen, A. Hammett, Techniques and Mechanisms in Electrochemistry (Condon, U.K.: Blackie Academic and Professional, 1994). 3. J.R. Macdonald, Impedance Spectroscopy (West Sussex, U.K.: Wiley-Interscience, 1987). 4. F.M. Geenen, J.H.W. deWit, E.P.M. Westing, Prog. Org. Coat. 18 (1990): p. 299. 5. F. Mansfeld, L.T. Han, C.C. Lee, G. Zhang, Electrochim. Acta 43 (1998): p. 2,933. 6. B.A. Boukamp, Equivalent Circuit (Equivcrt.Pas) Users Manual (Enschede, The Netherlands: University of Twente, 1989). 7. E. Kus, M.A. Grunlan, W.P. Weber, F. Mansfeld, Evaluation of Non-Toxic Polymer Coatings with Potential Biofoul Release Properties Using EIS, J. Electrochem. Soc. (in press). 8. Y.K. Song, F. Mansfeld, Evaluation of the Corrosion Resistance of Different Galvanized Steels Treated in a Cerium Salt Solution, Mater. Corros. (in press). 9. Y.-K. Song, F. Mansfeld, Development of a Molybdate-Phosphate-Silane-Silicate (MPSS) Coating Process for Galvanized Steel, Corros. Sci. (in press). 10. A. Nagiub, F. Mansfeld, Corros. Sci. 43 (2001): p. 2,147. 11. F. Mansfeld, The Polarization Resistance Technique for Measuring Corrosion Currents, in Advances in Corrosion Science and Technology, eds. M.G. Fontana, R.W. Staehle, vol. 7 (New York, NY: Plenum Press, 1976), p. 163. 12. K.B. Oldham, F. Mansfeld, Corrosion 27 (1971): p. 434. 13. F. Mansfeld, Corrosion 30 (1974): p. 92. 14. F. Mansfeld, M. Kendig, Corrosion 37 (1981): p. 545. 15. E. Kus, F. Mansfeld, An Evaluation of the Electrochemical Frequency Modulation (EFM) Technique, Corros. Sci. (in press).

(c)

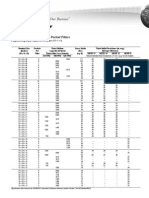

FIGURE 1. (a) Equivalent circuit, (b) complex plane plot, and (c) Bode plot for two different impedance elements Xi.

to be similar to the coating thickness,5,7 cerium-based conversion coatings on galvanized steel,8-9 as well as the corrosion inhibition of brass in chloride media.10 It will be noted that in linear polarization resistance (LPR) measurements, which is a misnomer when the term LPR is applied to polarization curves obtained in the vicinity of the corrosion potential,11-13 the apparent polarization resistance value Rp(ap) contains contributions from the diffusion terms for cases

740

CORROSIONAUGUST 2005

CORROSION SCIENCE SECTION

REPLY

We thank F. Mansfeld for his comments on our paper, which we feel deserve a response on a pointby-point basis to help the reader better interpret some questions raised throughout the paper. To begin, we refer to the Randles circuit as the circuit given as Figure 1 in our paper.1 Although Mansfeld suggests that a Randles circuit must contain a Warburg impedance, this is not exclusively in line with what is stated by Randles,2 while any precedent for containing a Warburg element is very diluted. In fact, there are many famous examples where the circuit we portray in Figure 1 is termed a Randles circuit, such as the review by Scully in this journal3 and in common software packages;4 as a result of these precedents, rather than simply naming a circuit, we also included the circuit schematic to avoid confusion (most likely a necessary precaution given the present state of confusion). We agree that in certain situations, electrochemical impedance data may be best interpreted with an element that includes an open boundary nite length diffusion (OFLD) element. Experimentally, there is no evidence that |Z| for the steel in a concrete system reaches a direct current (DC) limit at what Mansfeld describes as very low frequencies. Examples are evident in our previous paper;1 this lack of steady-state behavior is the predominant reason why the steel-concrete system is unique. Prior to suggesting the use of the OFLD, its suitability needs to be experimentally proven, which is not possible unless 0. Impedance data collected on real systems bear little resemblance to the Bode plot shown by Mansfeld in Figure 1(c) in this discussion.5 In fact, the information regarding the phase angle collected on real samples does not approach zero, nor is there any useful phase angle information revealed at low frequencies as seen in Figure 1 shown here. There presently is no (experimental) precedent that the steel in a concrete system has a diffusion layer of nite dimensions. Consequently, for steel in concrete, not only is it difcult to prescribe the use of an OFLD, but (based on what we observe in Figure 1) it is difcult to unequivocally prescribe the use of any specic equivalent circuit.6-7 This is because prior to the completion of (transient) charge-transfer processes under an applied polarization, the system is under the control of mass-transport phenomena (owing to the torturous diffusion path through concrete).6-10 As also noted by Glass, et al.,7 specically for steel experiencing low corrosion rates in concrete, no reported impedance spectra that exhibit evidence of a characteristic frequency associated with the peak in the Nyquist diagram were uncovered in the literature.7,11-12 Steel in concrete may represent an archetypal case where traditional (incremental sinusoidal) impedance techniques are of limited applicability. As

FIGURE 1. Bode plot for active steel in concrete (Ecorr = 500 mV vs. silver/silver chloride [Ag/AgCl]).6

a result of this, there has recently been a signicant drift toward nonstationary methods based on transient techniques for studying the electrochemical properties of steel in concrete.10,13-15 These techniques allow for minimal system perturbation (compared to traditional impedance), while facilitating the collection of impedance information through the transformation of time domain data to the frequency domain,7 or through time domain (transient) analysis.13-14 Furthermore, drawing parallels between the electrochemical response of steel in concrete with the prior results of Mansfeld on polymer-coated systems, conversion coatings, and inhibited brass may not be considered appropriate, owing to the vastly different physicochemical properties of the concrete cover. The inuence of diffusion effects on electrochemical data for steel in concrete has been known since at least 19869 and has also recently been modeled, highlighting the ease at which the system may come under diffusion control (over a range of applied current densities).8 At any rate, these latter points could be, and are, the object of other papers. As noted by Mansfeld, we agree and are well aware that the linear polarization resistance (LPR) method is only valid in the absence of diffusion effects. We suggested that in terms of practical monitoring (aimed at those executing testing on-site) that LPR may be more convenient than the impedance technique known as electrochemical impedance spectroscopy (EIS). This is not surprising as suggested by Mansfeld, as LPR is effectively equivalent to an EIS measurement at one particular frequency. As a result, LPR is naturally more rapid (while obviously not providing direct information across a range of frequencies). In addition, the cumulative charge passed through the system being investigated is necessarily much greater in an EIS measurement than for LPR, leading to the onset of mass-transport-related phenomena (viz. diffusion overpotential) over a wide range of frequencies.

CORROSIONVol. 61, No. 8

741

CORROSION SCIENCE SECTION

Furthermore, the time taken to measure lowfrequency impedance data will nominally correspond to a period where a drift in the natural corrosion potential of steel in concrete will be realized (especially for environmentally exposed infrastructures), creating a nonstationary situation and likely violating the impedance method per se. The nonstationary nature of electrodes has recently formed the basis of several papers across several metal-electrolyte systems.16-20 Finally, we cannot comment on the last point made by Mansfeld, since the paper that he referred to is not yet published and not available in the scientic domain. In spite of this, we do not suggest that it is possible to speed up electrochemical measurements. However, it is well known that it is possible to extract detailed electrochemical information without the need for a steady-state response during an applied polarizing signal. Exhibitions of this are largely based on the work of Macdonald and McKubre,21 whereby transformation between the time and frequency domains is possible, as well as the application of white noise signals,22 or when the relaxation transient is investigated (in open circuit following a rapid polarization).7,13-14 Such methods have the advantage of not invoking excessive diffusion effects and are, again, the object of other papers. The specic goal of our paper1 was to present a very general empirical account of the possible sources and the magnitude of errors that may arise when the corrosion of steel in concrete is monitored; this is of relevance to those involved in the day-to-day monitoring of infrastructures using one or more of the techniques mentioned. For more specic details, readers are referred to the reference list and, naturally, to papers that have been submitted following our paper. Again, we thank F. Mansfeld for bringing to light and emphasizing some of the more important points that the paper was attempting to communicate.

REFERENCES

1. J.A. Gonzlez, J.M. Miranda, N. Birbilis, S. Feliu, Corrosion 61, 1 (2005): p. 37-50. 2. J.E.B. Randles, Disc. Faraday Soc. 1 (1947): p. 11. 3. J.R. Scully, Corrosion 56 (2000): p. 199. 4. B. Yuem, ZSimpWin, Echem Software (2002). 5. F. Mansfeld, Corrosion 61, 8 (2005): p. 739. 6. V. Feliu, J.A. Gonzlez, C. Andrade, S. Feliu, Corros. Sci. 40 (1998): p. 975. 7. G.K. Glass, A.M. Hassanein, N.R. Buenfeld, Electrochim. Acta 43 (1998): p. 1,863. 8. N. Birbilis, Monitoring the Corrosion and Protection of Concrete Reinforcement (Ph.D. thesis, Monash University, Australia, 2004). 9. B.B. Hope, J.A. Page, A.K.C. Ip, Cem. Conc. Res. 16 (1986): p. 771. 10. G.K. Glass, A.M. Hassanein, N.R. Buenfeld, Corrosion 54 (1998): p. 887. 11. D.D. Macdonald, Y.A. El-Tantawy, R.C. Rocha-Filho, M. UrquidiMacdonald, Evaluation of Electrochemical Techniques for Detecting Corrosion of Rebar in Reinforced Concrete, Strategic Highway Research Program Report no. SHRP-ID/UFR-91-524, vol. 1, Washington, DC, 1991. 12. M.I. Jafar, J.L. Dawson, D.G. John, Electrochemical Impedance: Analysis and Interpretation, eds. J.R. Scully, D.C. Silverman, M.W. Kendig, ASTM STP 1188 (West Conshohocken, PA: ASTM International, 1993), p. 348. 13. V. Feliu, J.A. Gonzlez, S. Feliu, J. Electrochem. Soc. 151 (2004): p. B134. 14. N. Birbilis, K.M. Nairn, M. Forsyth, Corros. Sci. 45 (2003): p. 1,895. 15. N. Birbilis, K.M. Nairn, M. Forsyth, Electrochim. Acta 49 (2004): p. 4,331. 16. J.E. Garland, C.M. Pettit, D. Roy, Electrochim. Acta 49 (2004): p. 2,623. 17. S.J.M. Rosvall, M.J. Honeychurch, D.M. Elton, A.M. Bond, J. Electroanal. Chem. 515 (2001), p. 8. 18. K. Darowicki, J. Orlikowski, A. Arutunow, Corros. Eng., Sci. Technol. 39 (2004): p. 255. 19. K. Darowicki, S. Krakowiak, P. Slepski, Electrochim. Acta 49 (2004): p. 2,909. 20. N. Birbilis, R.G. Buchheit, Electrochim. Acta 50, 16-17 (2005): p. 3,536-3,544. 21. D.D. Macdonald, M.C.H. McKubre, Impedance Measurements in Electrochemical Systems, in Modern Aspects of Electrochemistry, eds. J.OM. Bockris, B.E. Conway, R.E. White, no. 14 (New York, NY: Plenum Press, 1982), p. 61. 22. E. Van Gheem, J. Vereecken, J. Schoukens, R. Pintelon, P. Guillaume, P. Verboven, L. Pauwels, Electrochim. Acta 49 (2004): p. 2,919.

742

CORROSIONAUGUST 2005

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Soft Errors in Modern Electronic SystemsDocument335 pagesSoft Errors in Modern Electronic SystemsSaqib Ali KhanNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Breakup CureDocument168 pagesThe Breakup CureMladen Muskinja100% (2)

- Nsrec05 SC Buchner PDFDocument80 pagesNsrec05 SC Buchner PDFSaqib Ali KhanNo ratings yet

- The Single-Event Effect Evaluation Technology For Nano Integrated CircuitsDocument6 pagesThe Single-Event Effect Evaluation Technology For Nano Integrated CircuitsSaqib Ali KhanNo ratings yet

- Radiation Handbook For ElectronicsDocument118 pagesRadiation Handbook For ElectronicsSaqib Ali KhanNo ratings yet

- Modeling and Simulation of Single-Event Effect in CMOS CircuitDocument11 pagesModeling and Simulation of Single-Event Effect in CMOS CircuitSaqib Ali KhanNo ratings yet

- Malaysia MapDocument1 pageMalaysia MapSaqib Ali KhanNo ratings yet

- Microbial Production of Scleroglucan and DSPDocument19 pagesMicrobial Production of Scleroglucan and DSPgandurikNo ratings yet

- Huawei MA5600TDocument48 pagesHuawei MA5600TChangDong SunNo ratings yet

- Power Plant Engineering NotesDocument3 pagesPower Plant Engineering NotesNeelesh PandeyNo ratings yet

- The Adventurer's Guide To Abusing Monsters PDFDocument41 pagesThe Adventurer's Guide To Abusing Monsters PDFAnonymous 9lC4ZLNo ratings yet

- 1 Basic Concept of Disaster and Disaster RiskDocument68 pages1 Basic Concept of Disaster and Disaster RiskBarbie CoronelNo ratings yet

- Post Assesment Question 1Document7 pagesPost Assesment Question 1Ganesh GuptaNo ratings yet

- Alamine 304 052523Document7 pagesAlamine 304 052523Loisse GrimaldoNo ratings yet

- The Future of Renewable Energy: Solar, Wind, and BeyondDocument1 pageThe Future of Renewable Energy: Solar, Wind, and Beyondtiticelestin98No ratings yet

- Working Load To Break Load: Safety Factors in Composite Yacht StructuresDocument8 pagesWorking Load To Break Load: Safety Factors in Composite Yacht Structurescarlos ivan carvajal ortizNo ratings yet

- Douglas SBD DauntlessDocument27 pagesDouglas SBD Dauntlessseafire47100% (3)

- Phoenix - Transducers Product Catalogue 2016Document56 pagesPhoenix - Transducers Product Catalogue 2016pjhollowNo ratings yet

- 20-Cow Module Buffalo Milk Production: Profi Tability AnalysisDocument45 pages20-Cow Module Buffalo Milk Production: Profi Tability AnalysisNobodyNo ratings yet

- Basic Electrical Engineering SyllabusDocument5 pagesBasic Electrical Engineering SyllabusCatherine Salvador0% (1)

- Corrections ZorichDocument3 pagesCorrections ZorichxelnxNo ratings yet

- UnconsciousnessDocument6 pagesUnconsciousnessSeema RahulNo ratings yet

- Multiple CorrelationDocument8 pagesMultiple Correlationabu nayam muhammad SalimNo ratings yet

- N05 - Compared Values 3 Vs 2Document44 pagesN05 - Compared Values 3 Vs 2Carlos MartinezNo ratings yet

- Mass Transfer Performance in Pulsed Disc and Doughnut Extraction ColumnsDocument10 pagesMass Transfer Performance in Pulsed Disc and Doughnut Extraction ColumnsSatria PNo ratings yet

- Mud Valve Rupture Pin Mud Pumps PDFDocument4 pagesMud Valve Rupture Pin Mud Pumps PDFFranklin Jose Almera AcostaNo ratings yet

- Presostato Danfoss KP 15Document10 pagesPresostato Danfoss KP 15RolandoNo ratings yet

- TD-CV2 Vacuum TypeDocument30 pagesTD-CV2 Vacuum TypeabidNo ratings yet

- Concrete Road Surface With The Use of Cement Concrete - Selected ResultsDocument8 pagesConcrete Road Surface With The Use of Cement Concrete - Selected ResultsElber Cuya PillacaNo ratings yet

- Panchatantra Stories - 2Document3 pagesPanchatantra Stories - 2DeepikaNo ratings yet

- The Quicksilver Court 1St Edition Melissa Caruso Online Ebook Texxtbook Full Chapter PDFDocument69 pagesThe Quicksilver Court 1St Edition Melissa Caruso Online Ebook Texxtbook Full Chapter PDFlouise.cornett103100% (5)

- VBP Catalog Solenoids Vers4 2 PDFDocument137 pagesVBP Catalog Solenoids Vers4 2 PDFDennis Baumann100% (1)

- Panel Dual Polarization Half-Power Beam WidthDocument2 pagesPanel Dual Polarization Half-Power Beam WidthjohnnybravoNo ratings yet

- Amedee by Eugene IonescoDocument9 pagesAmedee by Eugene Ionescozaid aliNo ratings yet

- DriPak 2000 Engr Data AFP 7 114 PDFDocument0 pagesDriPak 2000 Engr Data AFP 7 114 PDFdin_thorpe3248No ratings yet

- Fesc 107Document14 pagesFesc 107P.MohanaveluNo ratings yet