Professional Documents

Culture Documents

Cathelco Seawater Pipework Anti-Fouling

Cathelco Seawater Pipework Anti-Fouling

Uploaded by

Michael CorderoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cathelco Seawater Pipework Anti-Fouling

Cathelco Seawater Pipework Anti-Fouling

Uploaded by

Michael CorderoCopyright:

Available Formats

Seawater Pipework Anti-fouling Systems

Cathelco world leaders in seawater pipework anti-fouling systems

Cathelco is the worlds largest designer and manufacturer of marine pipework anti-fouling systems. With a record of 20,000 installations over a period of more than 50 years, the company has amassed considerable experience in the problems associated with marine pipework bio-fouling and developed the expertise to solve them effectively. Our customers include some of the largest cruise and commercial vessel operators in the world and our systems are used on the ships of over 40 navies. As the result of continued expansion, Cathelco recently moved into new, purpose built premises in Chesterfield, United Kingdom. This has enabled production facilities to be streamlined and additional space to be devoted to the companys research and development facilities. As a result, we are able to provide a faster response to customers needs. Cathelcos major strength is its international network of agents/installers based in ports throughout the world. In response to increasing demand, Cathelco have established strategic stocks of equipment in Brazil, Canada, China, Dubai, Germany, Iceland, Korea, Singapore and South Africa. By continuously developing the product range, Cathelco can provide an exceptionally wide choice of anodes and control panels spanning the requirements of large vessels and the needs of smaller craft such as fishing vessels, workboats and luxury yachts. Quality is at the forefront of all of our activities and is maintained through our in-house monitoring systems and adherence to Lloyds Register Quality Assurance ISO 9001. All of these factors contribute to providing customers with cost effective pipework anti-fouling systems, specifically designed for their application and combined with the highest levels of customer support.

The problem of bio-fouling in pipework

The purpose of the Cathelco system is to prevent blockages in seawater cooling systems caused by various forms of marine growth, primarily barnacles and mussels. Blockages are expensive and time consuming to remove, particularly when whole sections of pipework need to be cleaned or replaced. There is also the risk that seawater valves and other important items of equipment are affected jeopardising the operational capability and safety of the vessel. Even partial blockages can have serious consequences, making engines run at abnormally high temperatures and significantly increasing fuel usage. This has a direct bearing on the cost of vessel operation and profitability.

Key benefits of the Cathelco system

With its long record of effectiveness and reliability, the Cathelco system has become the most widely used seawater pipework antifouling system in the world. This success is the result of a combination of factors.

Based on the electrolytic principle, providing

continuous and reliable protection without the use of chemicals.

A dual system combining pipework anti-fouling

and corrosion suppression.

A range of control panels and anodes to suit

vessels of every size.

Every system custom designed for its particular

application ensuring greater effectiveness.

Automatic operation requires minimal attention

and makes very little demands on crew time.

Easy installation anodes can be installed in

seachests or strainers at newbuilding or retrofit.

Environmentally benign does not involve

the use of chlorine based chemicals or other biocides.

Approved by classification societies. Saves maintenance costs by eliminating

pipework cleaning.

Does not interfere with the production of fresh

water using reverse osmosis desalination systems.

How the Cathelco system operates

The Cathelco system has proved to be an extremely effective and versatile system for eliminating blockages in seawater pipework caused by biofouling. The system is based on the electrolytic principle and usually consists of pairs of copper and aluminium anodes which are mounted in seachests or strainers and wired to a control panel. In the case of cupro-nickel pipework, a ferrous anode is used instead of the aluminium anode. In operation, the copper anode produces ions which are carried by the flow of seawater, creating an environment in which barnacles and mussels will not settle or multiply. Alternatively, if systems need to be installed prior to scheduled drydocking, the anodes can be mounted in the seawater strainers. This also simplifies replacement when anode renewal becomes necessary. In special cases, where the Cathelco system supersedes existing chemical based anti-fouling equipment, the anodes can be mounted in treatment (electrolysis) tanks in order to economise on the installation costs by utilising existing pipework.

A range of control panels

Modular control panels (RS/DD)

A new range of control panels offering significant savings in size and weight. This is because the cabinet size can be varied to suit the number of modules which are required.

Modular design for easy installation and

replacement

Compact and lightweight Up to 16 anode outputs Clear digital output displays Individual alarm LEDS Alarm relays to control deck Strongly constructed IP66 Rating

Steel pipework protected by copper and

aluminium anodes.

Cupro-nickel pipework protected by copper and

ferrous anodes.

Seachest mounted anodes generally installed at

newbuilding and are replaced at drydocking.

Strainer mounted anodes can be replaced at any

time when the vessel is alongside.

Electrolysis tanks can be used to replace

chemical systems or in specialised applications.

Mini Control Panels (EB/CC)

These control panels have been designed for smaller craft such as fishing vessels and workboats where space is at a premium. Although compact, they have clear digital displays and alarm features.

Preventing settlement

During the settlement period, which lasts up to 8 hours, barnacle and mussel larvae are particularly sensitive to the presence of copper. By introducing copper ions in very small concentrations, around 2 parts per billion, the Cathelco system interrupts the settlement sequence. Instead of adhering to the surface of seachests, strainers and pipework, the larvae pass harmlessly through the cooling water system to the point of discharge. Without anti-fouling protection, pipes become encrusted with organisms leading to partial or total blockages which reduce the efficiency of the seawater cooling system.

Environmentally friendly does not use chemicals.

Operates with copper concentrations of just 2 parts per billion.

Dimensions: 2 anode outputs 200 x 300 x 120mm

(5kg)

Dimensions: 4 anode outputs 300 x 300 x 120mm

Power in

(8kg)

Output 2 amps maximum per anode

To Heat Exchangers, Oil Coolers, Evaporators, Fire Pumps and Ancillary Systems

Alarm relays to control deck

Seawater Cooling Line

Strongly constructed IP65 Rating

Nano Control Panels (EB/NS)

Valve Cathelco Anodes Strainer

A dual action system

The action of the copper ions is assisted by aluminium hydroxide created by aluminium anodes which flocculate the released copper ions. This highly gelatinous copper-aluminium hydroxide floc is carried throughout the system and tends to spread out into the slow moving areas closer to the pipe surfaces where marine larvae are most likely to settle. As a result, marine growth larvae do not settle, instead passing direct to discharge. At the same time, a cupro-aluminium film is built up on the internal surfaces of pipes to suppress corrosion. In this way, the system has a dual action protecting seawater pipework against bio-fouling and corrosion.

Ultra compact for small craft and luxury yachts, these panels will fit comfortably in confined spaces, whilst offering advanced features and excellent reliability.

Dimensions: 2 anode outputs 200 x 200 x 80mm

(2.5kg)

Dimensions: 4 anode outputs 200 x 300 x 80mm

(3kg)

Input 12/24v DC Output 0.5amp maximum Robust design IP65 Rating

Seachest or strainer mounted anodes

When systems are installed at newbuilding, anodes are generally fitted in the seachests using special sleeves or flange mountings.

Types of anodes and mounting arrangements

Cathelco has developed a range of anodes with mountings which enable them to be installed in the seachests or strainers of almost any type of vessel. The size of the anodes is determined by the flow rates and their anticipated design life, taking into consideration the scheduled dry docking period. Detailed drawings are supplied for every ship to assist in installation and ensure that the anodes are positioned for maximum effectiveness in the seawater flow. The anodes can be installed using a number of mounting arrangements including steel flanges, steel sleeves, nylon mountings, cofferdams and pipe upstands.

Anti-fouling systems for box coolers

Seachest mounted system

Cathelco have formed an alliance with Blokland Non-Ferro, Europes leading manufacturer of box cooler systems, to develop a range of anti-fouling systems which are specifically designed to provide the maximum level of effectiveness. In operation, copper ions are delivered directly beneath the cooling tubes where they prevent mussel larvae from settling and growing. Seachest mounted systems. A steel cathode plate, running parallel to the anode, ensures an even distribution of current flow, producing a uniform wear pattern along the length of the anode. This is an important advance on original box cooler installations where the anode was inserted through the seachest plate. The new system means fewer seachest penetrations and less installation work, whilst ensuring effective and reliable protection against bio-fouling.

Copper anodes

These are used in the majority of installations to protect steel pipework against bio-fouling through the creation of copper ions. Standard sizes range from 60mm to 120mm in diameter and 100mm to over 1,000mm in length and miniaturised anodes are available for smaller vessels. The photograph shows the anode fitted with a flange mounting arrangement.

Aluminium anodes

The purpose of aluminium anodes is to assist in anti-fouling process through the production of aluminium hydroxides when protecting steel pipework. They also produce a cuproaluminium film which acts as an anti-corrosive layer on the internal surfaces of pipes. The anode is shown with a weld-in mounting sleeve.

Frame mounted system

One of the advantages of the collaboration with Blokland has been the design of special mounting arrangements which simplify the installation process. Frame mounted systems. In the case of frame mounted anode arrangements, the anti-fouling anode is attached to the base of the box cooler on a framework. This enables the box cooler and anti-fouling system to be fitted as a complete unit, resulting in faster, easier installation involving less time for the yard. Alternatively, the anode can be mounted on the side of the seachest, directly below the cooling tubes. Anode replacement intervals can be designed to coincide with the vessels drydocking schedule or the service period of the box coolers up to a maximum duration of 5 years.

Dual purpose anodes

In cases where there is a requirement for anti-fouling and corrosion suppression, but only space to fit one anode in a strainer, this dual purpose design provides an effective solution. Dual purpose anodes can be produced with either copper/ aluminium or copper/ferrous elements in a single assembly. It is shown here with a nylon mounting which simplifies installation.

Ferrous anodes

These are used to protect cupro-nickel pipework which is commonly found on naval vessels. By producing ferrous ions, the soft iron anode helps to maintain a protective oxide layer on the internal surfaces of pipes to suppress corrosion. The anode is shown with a cofferdam arrangement.

Even distribution of copper ions

along the length of the box cooler for greater effectiveness.

Cathode plate ensures a uniform

wear pattern along the length of the anode.

Omni anodes

Small and versatile, Omni anodes have been developed for fitting in the smaller types of strainers found on workboats and luxury yachts. Designed with integral cathodes, they can be installed in plastic strainers, pipes and areas where a cathode does not exist.

Can be supplied as complete unit

involving less installation work.

Systems designed around dry docking schedule or box

cooler service intervals.

Cathelco can adapt anti-fouling systems to suit any size or

shape of box cooler from any manufacturer.

Dedicated Cathode Arrangement

+

Cathodes

In some cases, when using standard anodes, it may be beneficial to have a dedicated cathode to avoid any problems resulting from stray current corrosion. This particularly applies where strainer bodies are internally lined and the strainer basket is isolated. It is also advisable in situations where seachests are well painted and do not contain sacrificial anodes or where there is the need to avoid any interference with impressed current cathodic protection systems (ICCP). The cathode can be either isolated (dedicated) or connected to the ships earth.

Seachest Top

Copper Anode

Aluminium Anode

Stainless Steel Cathode

The anode and the cathode are isolated from the hull

Systems for commercial and cruise vessels

Commercial vessels

Cathelcos reputation has been built on providing seawater pipework anti-fouling systems for some of the largest fleets of commercial vessels in the world. With the ability to treat high volumes of sea water, the system is ideally suited to the requirements of the VLCCs, container ships, LNG carriers and numerous other types of ocean going vessels. For this reason, it continues to be chosen by major operators, reflecting both the effectiveness of the system and the on-going support which is provided to customers. In operation, the system is automatic and makes very little demands on crew time apart from periodically monitoring the anode outputs. A log sheet monitoring service provided by Cathelco ensures that systems continue to perform effectively.

Systems for naval vessels

Cathelco seawater pipework anti-fouling systems are installed on the ships of more than 40 navies around the world. With their durable construction, Cathelco control panels are ideally suited to rigorous demands of the naval sector. This is combined with a range of anodes to serve the needs of both surface craft and submarines.

Fast patrol craft

Cathelco have considerable experience in the design of pipework anti-fouling systems for fast patrol craft where space is at a premium. These vessels generally have a number of small inlets which can be protected with compact dual purpose anodes, consisting of copper/aluminium or ferrous elements in a single assembly. Alternatively, miniaturised Nano anodes can be fitted in strainers. The Cathelco Mini and Nano control panels ensure that systems can be installed in the tightest areas within engine rooms.

Cruise ships

Cruise ships use very high volumes of seawater with flow rates often exceeding 10,000 cubic metres per hour. The Cathelco system has the ability to treat these volumes effectively, whilst providing a number of other benefits. Systems are generally designed with multiple anode installations to protect high and low sea chests serving the engines and ancillary systems. These may include air conditioning systems, refrigeration systems and fire fighting pumps all essential to the safe and efficient operation of the vessel. Operating with copper concentrations of just 2 parts per billion, the system can be used to protect the inlets for desalination plants, coming well within the safe requirement of 100 parts per billion. As no chemicals are involved, the system is also environmentally friendly and helps to meet the green standards of modern cruise vessels. Reflecting the trend of longer intervals between drydocking for cruise ships, anode replacement can be timed at 5 years.

Frigates

Systems on frigates usually involve a combination of seachest and strainer mounted anodes. As with most military vessels, the pipework is predominantly cupronickel and therefore pairs of copper and ferrous anodes are used to provide effective anti-fouling and corrosion suppression. Standard Cathelco control panels can be used as they meet the levels of shock and vibration resistance required by naval authorities. Recent contracts for frigates and warships include equipment for the BAM project in Spain, PVO and BVL projects in Venezuela and the FREMM project involving the Italian and French Navy.

Multiple anode installations can be used to treat

large flow rates effectively.

Complete protection for engine cooling systems

and ancillary services.

Dual action pipework anti-fouling and corrosion

suppression.

Automatic system makes little demand on crew

time.

Submarines

The Cathelco system was originally designed for use on submarines and the company regularly supplies anti-fouling equipment for some of the worlds leading builders of submarines including Kockums, HDW, TNSW and the Australian Submarine Corporation. Because of space restrictions within strainers, installations are usually based on compact dual purpose anodes. Systems are often specially designed to meet the exact requirements of particular classes of submarines.

Safe - no chemicals are involved for better crew

and passenger safety.

Environmentally friendly.

Aircraft carriers

These installations involve the treatment of large volumes of seawater using multi-anode installations serving numerous inlets covering the requirements of engine cooling water systems, refrigeration, air conditioning and fire fighting systems. Cathelco have supplied equipment for the HMS Queen Elizabeth and HMS Prince of Wales, the Royal Navys two new 65,000 tonne aircraft carriers.

Systems for smaller vessels

By miniaturising control panels and anodes, Cathelco have brought the benefits of pipework anti-fouling technology to a wide variety of smaller craft including offshore supply vessels, workboats, small ferries and tugs. Many of these vessels operate continuously within in-shore waters where there is a much higher risk of bio-fouling. By fitting a Cathelco system and eliminating problems of blockages in seawater lines serving engine cooling systems, considerable savings can be made in fuel usage and maintenance costs.

Nano Systems

This system represents the ultimate in miniaturisation with a control panel designed to fit into the tightest areas on patrol craft, workboats and luxury yachts. Now fitted to hundreds of small craft, Nano systems provide effective and reliable protection using a range of very compact anodes which can be fitted in strainers or small seachests. In addition to small copper and ferrous anodes to protect steel or cupro-nickel pipework, special anodes with integral cathodes are available which can be fitted within plastic strainers.

Ultra-compact system to protect seawater lines

and ancillary equipment.

Anodes available with integral cathodes for use

with plastic strainers and any type of pipework.

Can be powered from the crafts battery supply. Control panel for anodes in 1 or 2 strainers

measures 200mm (height) x 200 (width) x 80mm depth. Weight 2.5 kgs.

Control panel for anodes in 3 or 4 strainers

Mini systems

These systems are ideal for the protection of small to medium sized vessels where space is limited. The units can be fitted solely to provide anti-fouling protection or as dual purpose systems offering the advantages of corrosion suppression in pipework. Although the control panels are only a fraction of the size and weight of standard models, they incorporate many features including digital displays and built in alarms. A complete range of seachest and strainer mounted anode types is available to protect steel and cupronickel pipework. There are also special dual purpose anodes copper/aluminium or copper/ferrous which can be fitted directly within pipework.

measures 300mm (height) x 200 (width) x 80mm (depth). Weight 3kgs.

Anode sizes from 25mm diameter to 75mm length

Omni Anodes

Small and versatile, Omni anodes are proving their value in applications where space is limited and other factors may prohibit the use of standard anodes. They are designed with integral cathodes providing a dedicated earth return and avoiding the risk of stray current corrosion. Suitable for applications on work boats, fishing vessels and luxury yachts they combine a number of advantages.

Can be fitted within plastic strainers. Can be fitted within pipe upstands. Overcomes space restrictions in numerous small

craft applications.

Compact, lightweight control panels for ease of

installation.

Anodes are available for use with plastic strainers. Control panel to protect 1 seachest or strainer

300mm (height) x 200mm (width) x 120mm (depth). Weight 5 kgs.

Control panel to protect 2 seachests or strainers

300mm (height) x 300mm (width) x 120mm (depth). Weight 8kgs.

Anodes with minimum dimensions of 62mm

diameter x 108mm length.

ICCP hull corrosion protection systems

Worldwide Service Network

Our worldwide network of sales and service centres can provide immediate advice and assistance on the complete range of Cathelco products. Agents contact details are available on our website: www.cathelco.com

Algeria Argentina Australia Belgium Brazil Canada

(East & West Coast)

Holland Iceland India Indonesia Iran Ireland Israel Italy Japan Korea Malaysia Malta Mexico Monaco New Zealand Norway Peru Philippines Poland Portugal

Romania Russia

(St Petersburg, Murmansk, Vladivostok)

Saudi Arabia Scotland Singapore South Africa Spain Sweden Switzerland Taiwan Thailand Turkey United Arab Emirates United Kingdom USA

(East, West and Gulf Coasts)

Cathelco are maintaining their position as technological leaders in the design and production of impressed current cathodic protection (ICCP) systems for ships. A new generation of anodes and control panels ensures that the optimum level of corrosion protection is achieved on vessels ranging from VLCCs and container ships to ferries and cruise ships. This also includes the supply of sophisticated ICCP systems for warships and other naval vessels. A range of hull mounted anodes are available to suit all hull configurations and customers have the choice of thyristor or modular control panels incorporating the latest information systems.

Chile China

(Dalian, Guangzhou, Shanghai, Hong Kong)

Croatia Cyprus Denmark Dubai Egypt Finland France

(Atlantic & Mediterranean Coasts)

Cathelco Seafresh reverse osmosis desalinators

Cathelco has recently acquired Seafresh Desalinators, a company with over 30 years of experience in the design and manufacture of desalination systems for commercial vessels, naval vessels and luxury yachts. With a reputation for quality, durability and ease of installation, the company has installed systems on over 1,800 craft around the world. Their success combines engineering expertise with the use of high quality components. Now a division of Cathelco, Seafresh benefits from an international sales and service network putting the advice and experience of fully trained personnel at your disposal for installation and servicing.

Germany Greece

Venezuela Vietnam

Cathelco Ltd, Marine House, Dunston Road Chesterfield S41 8NY United Kingdom Telephone: +44 (0) 1246 457900 Fax: +44 (0) 1246 457901 Email: sales@cathelco.com Web: www.cathelco.com

You might also like

- Mooring System Engineering for Offshore StructuresFrom EverandMooring System Engineering for Offshore StructuresRating: 5 out of 5 stars5/5 (1)

- Delta Marin Report - Study of Hydraulic and Electric Driven Deepwell Cargo Pump Options 190407Document36 pagesDelta Marin Report - Study of Hydraulic and Electric Driven Deepwell Cargo Pump Options 190407Sorin-Adrian LearschiNo ratings yet

- Manual de Servico EMD 645 E7C F7B PDFDocument381 pagesManual de Servico EMD 645 E7C F7B PDFMichael Cordero100% (7)

- Tank Cleaning Machine - PolarmarineDocument77 pagesTank Cleaning Machine - Polarmarineibnuhary100% (1)

- Ship and Boat Building and Repair-5Document5 pagesShip and Boat Building and Repair-5navalmamunNo ratings yet

- 2017 06 07 Experiences With Methanol in Dual Fuel Operation On Stena Germanica LewenhauptDocument19 pages2017 06 07 Experiences With Methanol in Dual Fuel Operation On Stena Germanica LewenhauptAkram FaisalNo ratings yet

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- Design of Marine Risers with Functionally Graded MaterialsFrom EverandDesign of Marine Risers with Functionally Graded MaterialsNo ratings yet

- Detroit Diesel s60 Catalog LR CarbDocument48 pagesDetroit Diesel s60 Catalog LR CarbRicardo Ramirez EstrelloNo ratings yet

- Chasis NC95KDocument3 pagesChasis NC95KOctavio RamirezNo ratings yet

- Solar Car Wheel Motor Information SheetDocument2 pagesSolar Car Wheel Motor Information SheetHamzaHariateNo ratings yet

- FRAMECAD Comparison Chart 0815Document3 pagesFRAMECAD Comparison Chart 0815Gurjit SidhuNo ratings yet

- 000 5Document185 pages000 5fahad jamilNo ratings yet

- Cathelco ElectrochlorinationDocument8 pagesCathelco ElectrochlorinationmohammadazraiNo ratings yet

- Cathodic Protection OffshoreDocument8 pagesCathodic Protection OffshoreSubramanian Saravanan100% (1)

- Hydrostatics & Stability ReportDocument63 pagesHydrostatics & Stability ReportnyaungzinNo ratings yet

- Wartsila Exhaust Gas Cleaning Presentation 2013Document30 pagesWartsila Exhaust Gas Cleaning Presentation 2013pavlo_7903176970% (1)

- IACS Req Pipes Pressure VesselDocument69 pagesIACS Req Pipes Pressure VesselFrancesco CauzNo ratings yet

- Bilge Oily Water SeparatorDocument25 pagesBilge Oily Water Separatornguyenvanhai19031981100% (2)

- Alfa Laval Fuel Conditioning Module For Methanol (Meoh) : Low-Flashpoint Fuel Supply System For Me-Lgi EnginesDocument2 pagesAlfa Laval Fuel Conditioning Module For Methanol (Meoh) : Low-Flashpoint Fuel Supply System For Me-Lgi EnginesSamo SpontanostNo ratings yet

- Retrofit - Propulsion ImprovementDocument4 pagesRetrofit - Propulsion ImprovementRamon Velasco StollNo ratings yet

- Exhaust Gas Cleaning Systems Selection Guide - US Dept. of Transport - 2011Document155 pagesExhaust Gas Cleaning Systems Selection Guide - US Dept. of Transport - 2011Yao WeiNo ratings yet

- S50MC-C8 2 PDFDocument345 pagesS50MC-C8 2 PDFodinshippingNo ratings yet

- Hull Coatings For Vessel PerformanceDocument94 pagesHull Coatings For Vessel Performancescribdtaker12345100% (4)

- Approval Ballast eDocument7 pagesApproval Ballast eAbd ZouhierNo ratings yet

- Wartsila o Gs LNG LiquefactionDocument8 pagesWartsila o Gs LNG LiquefactionEli Boscan100% (1)

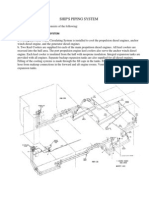

- SHIP Piping SystemDocument5 pagesSHIP Piping Systemsurnaik100% (1)

- Exhaust Gas Scrubber Systems AdvisoryDocument52 pagesExhaust Gas Scrubber Systems Advisoryfredy2212No ratings yet

- Deep Water Mooring Systems Using Fiber RopesDocument10 pagesDeep Water Mooring Systems Using Fiber RopesSaeed JabbariNo ratings yet

- Marine Coating For ShipsDocument3 pagesMarine Coating For ShipsShahbaz Ahmed Khan100% (1)

- Shuttle Tanker Propulsion 19993762Document9 pagesShuttle Tanker Propulsion 19993762hpss77No ratings yet

- Seeking Answers in Shipwreck in ItalyDocument3 pagesSeeking Answers in Shipwreck in ItalyBlue Dancing100% (1)

- Lloyds Register Concise Guide To The Green PassportDocument44 pagesLloyds Register Concise Guide To The Green PassportHashem Gam100% (2)

- DeaeratorDocument3 pagesDeaeratorpawangwlNo ratings yet

- Conn BrocDocument3 pagesConn BrocbenhealyNo ratings yet

- Cargo Plant GuidelinesDocument93 pagesCargo Plant GuidelinesPhani PrahladNo ratings yet

- Sea-Struct Groutbag PDFDocument2 pagesSea-Struct Groutbag PDFErica MartinNo ratings yet

- Ship Corrosion - Cathodic Protection and Sacrificial AnodesDocument17 pagesShip Corrosion - Cathodic Protection and Sacrificial Anodese. barajas100% (1)

- What Are Ship Bottom Plugs or Dock PlugsDocument11 pagesWhat Are Ship Bottom Plugs or Dock PlugsstamatisNo ratings yet

- Dry Dock TermsDocument15 pagesDry Dock TermswaleedyehiaNo ratings yet

- Allborg BoilersDocument2 pagesAllborg BoilersHIPAP100% (1)

- M26 Anti FoulingDocument33 pagesM26 Anti FoulingVinay Kumar NeelamNo ratings yet

- Marine TerminologyDocument109 pagesMarine Terminologyadam1950No ratings yet

- DieselFacts 2008-1 PDFDocument16 pagesDieselFacts 2008-1 PDFAsh Kai100% (1)

- Naval Sea Systems Command Anti Fouling ProgramDocument36 pagesNaval Sea Systems Command Anti Fouling Programtambok100% (1)

- 09 EffShip HandoutDocument24 pages09 EffShip HandoutVassileios TsarsitalidisNo ratings yet

- Ships Lay Up and Reactivation Normal Procedures For Ships Lay UpDocument23 pagesShips Lay Up and Reactivation Normal Procedures For Ships Lay UpRiteshNo ratings yet

- Man Ae DFDocument19 pagesMan Ae DFpavlo_790317697No ratings yet

- Offshore Support VesselsDocument7 pagesOffshore Support VesselsCriss MadNo ratings yet

- Nox Technical Code Mepc.291Document15 pagesNox Technical Code Mepc.291Arvind Agarwal (Faculty)No ratings yet

- Ship SizesDocument5 pagesShip SizesJeesonAntonyNo ratings yet

- ABS Guide For BWT (August 2016)Document71 pagesABS Guide For BWT (August 2016)LelosPinelos123No ratings yet

- Question:-Piping QuestionsDocument4 pagesQuestion:-Piping Questionsaimri_cochinNo ratings yet

- Marine Pumps: Grundfos Industrial Solutions MarineDocument7 pagesMarine Pumps: Grundfos Industrial Solutions MarineGrundfosEgypt100% (1)

- Container Vessel: Reefers/ContainersDocument5 pagesContainer Vessel: Reefers/ContainersErmanda Mesquita SoaresNo ratings yet

- Technical Matters 1Document12 pagesTechnical Matters 1Şansal DikmenerNo ratings yet

- Floating LNG FLNG Technical Challenges and Future TrendsDocument12 pagesFloating LNG FLNG Technical Challenges and Future TrendsIsioma1100% (2)

- ABB Optimization of Engine Performance 2009Document40 pagesABB Optimization of Engine Performance 2009Napoleon MpNo ratings yet

- Ship Energy Saving DeviceDocument43 pagesShip Energy Saving DeviceMax VerardiNo ratings yet

- Devlopment of The Rêvo Wasp 743 PDFDocument14 pagesDevlopment of The Rêvo Wasp 743 PDFrobertoNo ratings yet

- Subsea 7 FleetDocument34 pagesSubsea 7 FleetTord MartinsenNo ratings yet

- Marine and Offshore Corrosion: Marine Engineering SeriesFrom EverandMarine and Offshore Corrosion: Marine Engineering SeriesNo ratings yet

- Toyota 2TR-FE (2.7 L, DOHC) Engine - Review and Specs, Service DataDocument10 pagesToyota 2TR-FE (2.7 L, DOHC) Engine - Review and Specs, Service DataMichael CorderoNo ratings yet

- Maxlumina® Marine Signal Lantern: FeaturesDocument2 pagesMaxlumina® Marine Signal Lantern: FeaturesMichael Cordero100% (1)

- Mvh-85ub Operating Manual Ing - Esp - PorDocument48 pagesMvh-85ub Operating Manual Ing - Esp - PorMichael CorderoNo ratings yet

- CH 1Document40 pagesCH 1Mintesinot KasaNo ratings yet

- Stock Ageing Report (7) RECDocument19 pagesStock Ageing Report (7) RECDulanka DamithNo ratings yet

- Daikin 7 8 Ton Uatq90c Roof Top Air ConditionerDocument24 pagesDaikin 7 8 Ton Uatq90c Roof Top Air Conditionermiyaintaj400No ratings yet

- Catalog BondstrandDocument6 pagesCatalog Bondstrandgigiphi1No ratings yet

- Electromagnetic WavesDocument54 pagesElectromagnetic WavesPortia A. EgkenNo ratings yet

- Aristotig 400: Instruction ManualDocument22 pagesAristotig 400: Instruction ManualGurkan ÇetinkayaNo ratings yet

- A Textbook of Electrical Technology Vol. 2 - Theraja-P1Document29 pagesA Textbook of Electrical Technology Vol. 2 - Theraja-P1Muhammad TaimoorNo ratings yet

- Ammonia Refrigeration 1904Document200 pagesAmmonia Refrigeration 1904DonT_RN100% (7)

- Large Submersible Propeller PumpsDocument16 pagesLarge Submersible Propeller PumpsVincent Mutambirwa100% (2)

- EM & SOMDocument8 pagesEM & SOMVikram RaoNo ratings yet

- Tohatsu 60 - 70 - 90 - 120 - 140 Owner's Manual (ENG)Document111 pagesTohatsu 60 - 70 - 90 - 120 - 140 Owner's Manual (ENG)kamilNo ratings yet

- Electrical Measurements: 1 ComponentsDocument15 pagesElectrical Measurements: 1 Componentsmishraanwesh7380No ratings yet

- Well PlanningDocument26 pagesWell PlanningMyat Yadanar HtunNo ratings yet

- Work Power Energy JEE TestDocument6 pagesWork Power Energy JEE TestAman RolandNo ratings yet

- MTU 12V4000 Diesel EngineDocument2 pagesMTU 12V4000 Diesel Enginenastyn-1No ratings yet

- Man Elconv Tune En.Document5 pagesMan Elconv Tune En.Carlos Brayan CandeloNo ratings yet

- Catalog Yellow JacketDocument28 pagesCatalog Yellow JacketJohn SuarezNo ratings yet

- Servo Mr-E-A-Ag PDFDocument310 pagesServo Mr-E-A-Ag PDFkashinath0% (1)

- BCG Matrix For Thermax GroupDocument10 pagesBCG Matrix For Thermax GroupMayura Vijay PathakNo ratings yet

- UL Rolls-Royce UL 305Document2 pagesUL Rolls-Royce UL 305hellixNo ratings yet

- Calnev Pipeline Rupture Leads To Deaths, Injuries and DamagesDocument2 pagesCalnev Pipeline Rupture Leads To Deaths, Injuries and DamagesArielle DukofskyNo ratings yet

- Understanding Power MOSFET Data Sheet ParametersDocument28 pagesUnderstanding Power MOSFET Data Sheet Parametersgui9871No ratings yet

- Relays and TimersDocument133 pagesRelays and Timerskarstegg100% (1)

- CHEM1901/3 Worksheet 6: Molecular Geometry Model 1: Oxidation NumbersDocument4 pagesCHEM1901/3 Worksheet 6: Molecular Geometry Model 1: Oxidation Numbersdeckbyte865No ratings yet

- Towards Efficient Energy Management in Smart Grids Considering Microgrids With Day-Ahead Energy ForecastingDocument11 pagesTowards Efficient Energy Management in Smart Grids Considering Microgrids With Day-Ahead Energy ForecastingYahaya FatawuNo ratings yet

- User's Manual: Gq-5200 SMD Rework Soldering StationDocument9 pagesUser's Manual: Gq-5200 SMD Rework Soldering StationJose ViquezNo ratings yet

- NXAIR Design CatalogueDocument146 pagesNXAIR Design Cataloguegerardo.aquinoNo ratings yet