Professional Documents

Culture Documents

0718-P - Pro Series - LR

0718-P - Pro Series - LR

Uploaded by

Siddharth RaoCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Adva 825 CLI HandbookDocument672 pagesAdva 825 CLI HandbookWill Beach100% (1)

- SOP 001 Dust MoppingDocument2 pagesSOP 001 Dust MoppingMade GileeNo ratings yet

- Utm MastersDocument20 pagesUtm MastersLeslie WilliamsNo ratings yet

- Design of Continuous RC BeamsDocument14 pagesDesign of Continuous RC Beamsengineer khanNo ratings yet

- 13 - Flexistrut Ducting Tech Data v1.1 WebsiteDocument14 pages13 - Flexistrut Ducting Tech Data v1.1 WebsiteThái Trần VănNo ratings yet

- Building Survey Report SampleDocument91 pagesBuilding Survey Report SampleabcNo ratings yet

- Sychronous Type Overview 4 Pole Models: Basic - TypesDocument2 pagesSychronous Type Overview 4 Pole Models: Basic - TypesRichard Leo MoroniNo ratings yet

- Urcea Bioc0mposite Wood Adhesive Artocarpus BlancoiDocument16 pagesUrcea Bioc0mposite Wood Adhesive Artocarpus BlancoiVincent Ronin SerratoNo ratings yet

- Astm PDFDocument8 pagesAstm PDFDaniel Camilo CanoNo ratings yet

- Fig. 910 - Swivel Sway Brace FittingDocument1 pageFig. 910 - Swivel Sway Brace FittingANTONIO GUTIERREZ MIRANDANo ratings yet

- GRCA 2015 Congress - The International Glassfibre Reinforced Concrete Association (GRCA) For All Your GRC - GFRC InformationDocument2 pagesGRCA 2015 Congress - The International Glassfibre Reinforced Concrete Association (GRCA) For All Your GRC - GFRC InformationselcuksivaciNo ratings yet

- SG 248055Document566 pagesSG 248055Sofiane HamidNo ratings yet

- Foot Step Power Generation SynopsisDocument14 pagesFoot Step Power Generation SynopsisTARUN SINGH0% (1)

- Configuring A Zone-Based Policy Firewall (ZPF)Document13 pagesConfiguring A Zone-Based Policy Firewall (ZPF)JahazielCruzMonzon100% (1)

- S4m-En Part ManualDocument8 pagesS4m-En Part ManualGustavo Andrés Mardones NovaNo ratings yet

- Shipment API en v2Document35 pagesShipment API en v2matejkahuNo ratings yet

- 84876283Document4 pages84876283homaNo ratings yet

- Penawaran Harga COLDSTORAGEDocument1 pagePenawaran Harga COLDSTORAGEChannel Arif0% (1)

- ZF DKKFDocument6 pagesZF DKKFSugiyatno GiantoNo ratings yet

- Guide Specification PowerWave 33-1Document11 pagesGuide Specification PowerWave 33-1ZIPDASHNo ratings yet

- Calculo de Consumos Electricos de Equipos en AmbulanciasDocument4 pagesCalculo de Consumos Electricos de Equipos en AmbulanciasCarlos CastilloNo ratings yet

- NS2 Evalvid DocumentationDocument7 pagesNS2 Evalvid DocumentationShesha Vishnu Prasad100% (1)

- Basic EE PrelimDocument3 pagesBasic EE PrelimJohnCris B. FornilosNo ratings yet

- (Design, Strength, and Construction TechnologyDocument239 pages(Design, Strength, and Construction Technologyali trrafNo ratings yet

- Manual StackerDocument4 pagesManual StackerLevente BiroNo ratings yet

- FOGT - Subsea Flanges, Comparison Between Conventional API 6A & SPO CF DesignsDocument14 pagesFOGT - Subsea Flanges, Comparison Between Conventional API 6A & SPO CF DesignsEDWIN M.PNo ratings yet

- Silos Design With Different Aspect RatiosDocument9 pagesSilos Design With Different Aspect Ratiosmrnaeem100% (1)

- Concrete Is Listed As One of The Most Widely Used Building MaterialsDocument2 pagesConcrete Is Listed As One of The Most Widely Used Building Materialslorraine atienzaNo ratings yet

- Alternating Current GeneratorsDocument28 pagesAlternating Current GeneratorsLouise UmaliNo ratings yet

- Sri Lanka Standard 1247-2003Document34 pagesSri Lanka Standard 1247-2003piyalaravinnaNo ratings yet

0718-P - Pro Series - LR

0718-P - Pro Series - LR

Uploaded by

Siddharth RaoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

0718-P - Pro Series - LR

0718-P - Pro Series - LR

Uploaded by

Siddharth RaoCopyright:

Available Formats

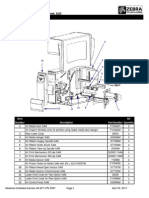

Pro Series Diaphragm Pumps

With a product and design legacy that goes back almost as far as the diaphragm pump itself, ARO diaphragm pumps have the proven proprietary designs and performance features that fluid handling professionals demand. And what is the diaphragm pump that is at the front of this famous offering? ARO Pro Series. ARO Pro Series are the pumps that deliver trouble-free, stall-free and ice-free fluid handling. Featuring a broad selection of wetted and body materials; including stainless steel and cast iron 2" and 3" ported models, ARO Pro Series pumps have the internal and external features that continue to drive a reputation that is both legendary and unrivaled. Do you want optimum fluid handling productivity with minimal maintenance? Go Pro...ARO Pro Series Diaphragm Pumps.

Progress in Motion Pro Series Diaphragm Pumps

1/4" - 3" Ports, Metallic and Non-metallic Construction

For more than 100 years, weve helped drive innovation with revolutionary technology creating new standards for how the world gets work done. Weve done it by producing best-in-class Ingersoll Rand / ARO pumps and dispensing technologies, and by knowing our customers industries and the demands placed on productivity and quality.

Pro Body Construction

Pro Air Motor Technology

Pro Performance Cost Savings

Get Connected! fluids.ingersollrand.com

Easy Access to Operators Manuals and Product Data Users can now search with complete or partial model numbers, gaining access to documents in multiple languages Pump Selection Software Allows you to identify the best pump for your application Competitive Model Crossover Visitors can easily and quickly crossover competitive units to ARO models Productivity Park An interactive 3D tour of markets and industries where Ingersoll Rand Fluid Technologies products are utilized

ARO Pump Selection Guide

Wide selection of body materials, A positive O-ring seals air flow and Increased poductivity, deliveries up including stainless steel and cast to 237 GPM (897 LPM). prevents costly air blow-by. iron. Wide selection of model 1/2 and 3/8 ported models configurations to perfectly match Thick walled castings for increased feature a simul-shift valve design your production delivery durability. that provides both stall-free operation as well as faster trip-over requirements. Bolted construction for leak-tight integrity and environmental safety. with less pulsation. Ultra-efficient air motor design utilizes less compressed air - thereby reducing operation costs.

For more information: See your local distributor Call (800) 495-0276 Visit fluids.ingersollrand.com

Ingersoll Rand Industrial Technologies provides products, services and solutions that enhance our customers' energy efficiency, productivity and operations. Our diverse and innovative products range from complete compressed air systems, tools and pumps to material and fluid handling systems and environmentally friendly microturbines. We also enhance productivity through solutions created by Club Car, the global leader in golf and utility vehicles for businesses and individuals.

FORM 0718-P 15290109

2007 Ingersoll Rand Company

Pro Series Diaphragm Pumps

Compact series models 1/4-3/4 ports

Plant Maintenance

Plant Maintenance applications aren't pretty, but Pro Series pumps are tough enough for even the most demanding jobs. Stall-free air motor for on-demand operation Performs well in high back-pressure applications Non-bonded backer diaphragm enhances performance and service life of primary PTFE diaphragm

Pro series models 1-3 ports

Model

Maximum Flow GPM (LPM) Maximum Discharge Pressure PSI (BAR) Maximum Solids Inches (mm) Fluid Ports Inlet/Outlet (BSP Available) Materials of Construction

1/4"

4.6 (17.4) 100 (6.9)

3/8"

10.6 (40.1) 100 (6.9)

1/2"

14.4 (54.5) 100 (6.9)

1/2"

12 (45.4) 100 (6.9)

3/4"

13.6 (51.5) 100 (6.9)

3/4"

14.8 (56) 100 (6.9)

1"

47 (177.9) 120 (8.3)

1-1/2"

100 (378.5) 120 (8.3)

2"

145 (548.8) 120 (8.3)

1"

35 (133) 120 (8.3)

1-1/2"

90 (340.7) 120 (8.3)

2"

172 (651) 120 (8.3)

3"

237 (897) 120 (8.3)

Original Equipment

Pro Series can adapt to the varied requirements of Original Equipment Manufacturers. Materials of construction include aluminum, polypropylene, stainless steel, cast iron and PVDF Multiple diaphragm options let you maximize fluid compatibility Pro Series is energy efficient, resulting in more gpm for less cfm Comprehensive selection of OEMideal compact diaphragm pumps

Clean Fluids Only 3/8" (F) - In 1/4" (F) - Out (No BSP) Polypropylene Groundable Acetal PVDF Groundable Acetal Polypropylene PVDF

1/16 (1.6) 3/8" (F) - In/Out Rp 3/8 (3/8-19BSP, parallel) Polypropylene Groundable Acetal PVDF Acetal PVDF Polypropylene Stainless Steel

3/32 (2.4) 1/2" (F) - In/Out Rp 1/2 (1/2-14BSP) Polypropylene Groundable Acetal PVDF Acetal PVDF Polypropylene Stainless Steel

3/32 (2.4) 1/2" (F) - In/Out Rp 1/2 (1/2-14BSP) Aluminum Stainless Steel

3/32 (2.4) 3/4 - 14 N.P.T.F.-2 Rp 3/4 (3/4-14BSP, parallel) Aluminum

3/32 (2.4) 3/4 - 14 N.P.T.F.-1 Rp 3/4 (3/4-14 BSP, parallel) Polypropylene

1/8 (3.2) 1" ANSI/DIN Flange 1 (F) Threaded Rp 1 (1-11BSP) Polypropylene PVDF

1/4 (6.4) 1-1/2" ANSI/DIN Flange Polypropylene PVDF

1/4 (6.4) 2" ANSI/DIN Flange Polypropylene PVDF

1/8 (3.2) 1" (F) - In/Out Rp 1 (1-11BSP) Aluminum Stainless Steel Cast Iron Aluminum 316 Stainless Steel Polypropylene PVDF Carbon Steel Hard 440 Stainless Steel

1/4 (6.4) 1-1/2" (F) In/Out Rp 1-1/2 (1-1/2-11BSP) Aluminum Stainless Steel Cast Iron Aluminum 316 Stainless Steel Polypropylene PVDF Carbon Steel 440 Stainless Steel

1/4 (6.4) 2" (F) In/ Out Rp 2 (2-11BSP) Aluminum Stainless Steel Cast Iron Aluminum Hytrel Santoprene 316 Stainless Steel PVDF Carbon Steel Hard 440 Stainless Steel Nitrile PTFE (Teflon) Hytrel Santoprene Nitrile 316 Stainless Steel

3/8 (9.5) 3" (F) In/ Out Rp 3 (3-11BSP) Aluminum Stainless Steel Cast Iron Aluminum Hytrel Santoprene 316 Stainless Steel PVDF Carbon Steel Hard 440 Stainless Steel Nitrile PTFE (Teflon) Hytrel Santoprene Nitrile

Primary and Secondary Production

Pro Series pumps cut their teeth in numerous Primary and Secondary production applications, with advantages that have made them a stalwart throughout industry. Air motor features a positive O-ring seal, eliminating expensive blow-by of compressed air Unbalanced air valve for reliable stall-free operation Bolted construction replaces band clamps that fatigue and then leak

Seat Material

Aluminum Polypropylene Stainless Steel

Aluminum Polypropylene

Polypropylene

316 Stainless Steel Polypropylene PVDF Hard 440 Stainless Steel

316 Stainless Steel Polypropylene PVDF Hard 440 Stainless Steel

316 Stainless Steel Polypropylene PVDF 440 Stainless Steel

Ball Material

PTFE

Bulk Transfer

Pro Series pumps have the performance to handle bulk transfer applications Excellent Flow: With flow rates up to 237-gpm (897-lpm), Pro Series can complete bulk transfer jobs quickly and efficiently Across the Line Performance: With Pro Series, using PTFE diaphragms doesn't mean production gets cut in half

Santoprene Hytrel Stainless Steel PTFE (Teflon) Viton

Santoprene Hytrel Nitrile Stainless Steel PTFE (Teflon) Polyurethane Viton

Santoprene Hytrel Nitrile Stainless Steel PTFE (Teflon) Polyurethane Viton

Santoprene Hytrel PTFE (Teflon)

Santoprene Hytrel PTFE (Teflon)

Viton PTFE (Teflon) Polyurethane 316 Stainless Steel Hytrel Santoprene Nitrile Neoprene EPR Medical Grade Santoprene Viton PTFE (Teflon)/Santoprene Hytrel Santoprene Nitrile Neoprene EPR & Medical Grade Santoprene

Viton PTFE (Teflon) Polyurethane Hytrel Santoprene Nitrile Neoprene EPR

Viton PTFE (Teflon) Polyurethane Hytrel Santoprene Nitrile Neoprene EPR

Viton PTFE (Teflon) Polyurethane Stainless Steel Hytrel Santoprene Nitrile Neoprene EPR Acetal Viton PTFE (Teflon)/Santoprene Hytrel Santoprene Nitrile Neoprene EPR

Viton PTFE (Teflon) Polyurethane Stainless Steel Hytrel Santoprene Nitrile Neoprene EPR Acetal Viton PTFE (Teflon)/Santoprene Hytrel Santoprene Nitrile Neoprene EPR

Diaphragm Material

Santoprene Nitrile PTFE (Teflon)

Santoprene Hytrel PTFE (Teflon)/Santoprene Viton

Santoprene Hytrel Nitrile PTFE (Teflon)/Santoprene Viton Polyurethane

Santoprene Hytrel Nitrile PTFE (Teflon)/Santoprene Viton Polyurethane

Santoprene Hytrel PTFE (Teflon)/Santoprene

Santoprene Hytrel PTFE (Teflon)/Santoprene

Viton PTFE (Teflon)/Santoprene Hytrel Santoprene Nitrile Neoprene EPR

Viton PTFE (Teflon)/Santoprene Hytrel Santoprene Nitrile Neoprene EPR

PTFE (Teflon)/Santoprene Hytrel Santoprene Nitrile

PTFE (Teflon)/Santoprene Hytrel Santoprene Nitrile

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Adva 825 CLI HandbookDocument672 pagesAdva 825 CLI HandbookWill Beach100% (1)

- SOP 001 Dust MoppingDocument2 pagesSOP 001 Dust MoppingMade GileeNo ratings yet

- Utm MastersDocument20 pagesUtm MastersLeslie WilliamsNo ratings yet

- Design of Continuous RC BeamsDocument14 pagesDesign of Continuous RC Beamsengineer khanNo ratings yet

- 13 - Flexistrut Ducting Tech Data v1.1 WebsiteDocument14 pages13 - Flexistrut Ducting Tech Data v1.1 WebsiteThái Trần VănNo ratings yet

- Building Survey Report SampleDocument91 pagesBuilding Survey Report SampleabcNo ratings yet

- Sychronous Type Overview 4 Pole Models: Basic - TypesDocument2 pagesSychronous Type Overview 4 Pole Models: Basic - TypesRichard Leo MoroniNo ratings yet

- Urcea Bioc0mposite Wood Adhesive Artocarpus BlancoiDocument16 pagesUrcea Bioc0mposite Wood Adhesive Artocarpus BlancoiVincent Ronin SerratoNo ratings yet

- Astm PDFDocument8 pagesAstm PDFDaniel Camilo CanoNo ratings yet

- Fig. 910 - Swivel Sway Brace FittingDocument1 pageFig. 910 - Swivel Sway Brace FittingANTONIO GUTIERREZ MIRANDANo ratings yet

- GRCA 2015 Congress - The International Glassfibre Reinforced Concrete Association (GRCA) For All Your GRC - GFRC InformationDocument2 pagesGRCA 2015 Congress - The International Glassfibre Reinforced Concrete Association (GRCA) For All Your GRC - GFRC InformationselcuksivaciNo ratings yet

- SG 248055Document566 pagesSG 248055Sofiane HamidNo ratings yet

- Foot Step Power Generation SynopsisDocument14 pagesFoot Step Power Generation SynopsisTARUN SINGH0% (1)

- Configuring A Zone-Based Policy Firewall (ZPF)Document13 pagesConfiguring A Zone-Based Policy Firewall (ZPF)JahazielCruzMonzon100% (1)

- S4m-En Part ManualDocument8 pagesS4m-En Part ManualGustavo Andrés Mardones NovaNo ratings yet

- Shipment API en v2Document35 pagesShipment API en v2matejkahuNo ratings yet

- 84876283Document4 pages84876283homaNo ratings yet

- Penawaran Harga COLDSTORAGEDocument1 pagePenawaran Harga COLDSTORAGEChannel Arif0% (1)

- ZF DKKFDocument6 pagesZF DKKFSugiyatno GiantoNo ratings yet

- Guide Specification PowerWave 33-1Document11 pagesGuide Specification PowerWave 33-1ZIPDASHNo ratings yet

- Calculo de Consumos Electricos de Equipos en AmbulanciasDocument4 pagesCalculo de Consumos Electricos de Equipos en AmbulanciasCarlos CastilloNo ratings yet

- NS2 Evalvid DocumentationDocument7 pagesNS2 Evalvid DocumentationShesha Vishnu Prasad100% (1)

- Basic EE PrelimDocument3 pagesBasic EE PrelimJohnCris B. FornilosNo ratings yet

- (Design, Strength, and Construction TechnologyDocument239 pages(Design, Strength, and Construction Technologyali trrafNo ratings yet

- Manual StackerDocument4 pagesManual StackerLevente BiroNo ratings yet

- FOGT - Subsea Flanges, Comparison Between Conventional API 6A & SPO CF DesignsDocument14 pagesFOGT - Subsea Flanges, Comparison Between Conventional API 6A & SPO CF DesignsEDWIN M.PNo ratings yet

- Silos Design With Different Aspect RatiosDocument9 pagesSilos Design With Different Aspect Ratiosmrnaeem100% (1)

- Concrete Is Listed As One of The Most Widely Used Building MaterialsDocument2 pagesConcrete Is Listed As One of The Most Widely Used Building Materialslorraine atienzaNo ratings yet

- Alternating Current GeneratorsDocument28 pagesAlternating Current GeneratorsLouise UmaliNo ratings yet

- Sri Lanka Standard 1247-2003Document34 pagesSri Lanka Standard 1247-2003piyalaravinnaNo ratings yet