Professional Documents

Culture Documents

Chemical Composition and Functional Properties of Prickly Pear

Chemical Composition and Functional Properties of Prickly Pear

Uploaded by

تونسي وراسي عاليCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Chap 2 - Sprinkler IrrigationDocument4 pagesChap 2 - Sprinkler IrrigationEng Ahmed abdilahi Ismail100% (1)

- Glenmark Pharmaceuticals Limited: Analytical Research Laboratory (Formulation), TalojaDocument5 pagesGlenmark Pharmaceuticals Limited: Analytical Research Laboratory (Formulation), Talojaरोहित जोशीNo ratings yet

- Viking PumpDocument36 pagesViking PumpSakir Zak100% (2)

- MSDS B-Kurita KF SBL-20Document1 pageMSDS B-Kurita KF SBL-20Arief SetiawanNo ratings yet

- PowerLogic PFC Capacitors - BLRCH400A480B44Document3 pagesPowerLogic PFC Capacitors - BLRCH400A480B44diditsuNo ratings yet

- SEC4 Overhead Conductors PDFDocument106 pagesSEC4 Overhead Conductors PDFKy TaNo ratings yet

- Nutanix EUC Solutions Sales Enabler For PartnersDocument2 pagesNutanix EUC Solutions Sales Enabler For PartnersKevin Karl Gabutin JornacionNo ratings yet

- Diagnosis ListDocument1 pageDiagnosis ListSenyorita KHayeNo ratings yet

- National Patients' Rights Charter: Annexure FDocument2 pagesNational Patients' Rights Charter: Annexure FK ValdesNo ratings yet

- Tsioptsias 20151Document10 pagesTsioptsias 20151Violeta GarciaNo ratings yet

- Sigma Shield 1200Document5 pagesSigma Shield 1200Ventas IMSNo ratings yet

- Vera DrakeDocument2 pagesVera DrakeDJ REYNo ratings yet

- Gujarati University, Ahmedabad Question Bank Subject: Alternate Energy Sources, B.E. Sem-Viii, MechanicalDocument2 pagesGujarati University, Ahmedabad Question Bank Subject: Alternate Energy Sources, B.E. Sem-Viii, MechanicalAnkit PatelNo ratings yet

- Employment Law in OmanDocument3 pagesEmployment Law in OmanjuliechandruNo ratings yet

- Gas Valves Interstage Pressure Between SRV and GCV high-SEP10 PDFDocument4 pagesGas Valves Interstage Pressure Between SRV and GCV high-SEP10 PDFsanjeevchhabraNo ratings yet

- IGBT Modules 1-Pack Fuji Electric AmericaDocument1 pageIGBT Modules 1-Pack Fuji Electric AmericaSergio MuriloNo ratings yet

- Floating Bodies PDFDocument8 pagesFloating Bodies PDFQSQFNo ratings yet

- Soal PAS KLS 5 Bahasa InggrisDocument2 pagesSoal PAS KLS 5 Bahasa InggrisMahpudin Al AfganiNo ratings yet

- Perbandingan Harga Apotek Vs PBFDocument3 pagesPerbandingan Harga Apotek Vs PBFRidho SaputraNo ratings yet

- Electrical Conduits & Fittings: Protect Electrical Cables and WiresDocument18 pagesElectrical Conduits & Fittings: Protect Electrical Cables and WiresA Ma RaahNo ratings yet

- Reporte Papas Fritas Holandesas AVIKODocument2 pagesReporte Papas Fritas Holandesas AVIKOginoromanNo ratings yet

- 1echocardiography and The NeonatologistDocument4 pages1echocardiography and The NeonatologistAbuAlezzAhmedNo ratings yet

- How Rfid Technology Boosts Walmart S Sup PDFDocument10 pagesHow Rfid Technology Boosts Walmart S Sup PDFKshitij ShuklaNo ratings yet

- Extra WorksDocument4 pagesExtra WorksNuwan AththanayakaNo ratings yet

- Giant PandaDocument6 pagesGiant PandaJasvinder SinghNo ratings yet

- Premature BurialDocument9 pagesPremature Burialaidee bogadoNo ratings yet

- Neurotransmitters in Schizophrenia: Dr. Adel El SheshaiDocument47 pagesNeurotransmitters in Schizophrenia: Dr. Adel El SheshaielvinegunawanNo ratings yet

- The Spirit Controlled Life Ebook PDF 1Document184 pagesThe Spirit Controlled Life Ebook PDF 1Okesola AbayomiNo ratings yet

- Seleccion & Brochure Bomba Griswold BoosterDocument19 pagesSeleccion & Brochure Bomba Griswold BoosterJonathan Mario Bolivar AldanaNo ratings yet

- Mindmap For Hands Held HighDocument1 pageMindmap For Hands Held Highapi-523333030No ratings yet

Chemical Composition and Functional Properties of Prickly Pear

Chemical Composition and Functional Properties of Prickly Pear

Uploaded by

تونسي وراسي عاليOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chemical Composition and Functional Properties of Prickly Pear

Chemical Composition and Functional Properties of Prickly Pear

Uploaded by

تونسي وراسي عاليCopyright:

Available Formats

World Journal of Dairy & Food Sciences 3 (1): 11-16, 2008 ISSN 1817-308X IDOSI Publications, 2008

Chemical Composition and Functional Properties of Prickly Pear (Opuntia ficus indica) Seeds Flour and Protein Concentrate

A.G. Nassar Food Science and Technology Department, Faculty of Agriculture, Al-Azhar University, Assuit, Egypt

Abstract: Proximate composition and functional properties of prickly pear seed flour (PPS); protein concentrate and the effect of pH on these properties were investigated. The protein content, crude fat and crude fiberof PPS flour and protein concentrate averaged 13.62 and 62.41, 10.43 and 3.57 and 9.23 and 5.31%, respectively. The minimum protein solubility was observed at pH 4.5, as 16. and 15% while maximum protein solubility was observed at pH 11 which as 85 and 92%, repectively. Measurement of emulsion and foaming properties of PPS flour and protein concentrate showed that they are greatly affected by pH levels. The minimum values of both emulsion and foam properties were obtained at pH 4.5 which was the isoelectric point of the protein. The maximum values were obtained at pH 10. PPS flour and its protein concentrate had high water and oil absorption (4.71 and 3.16g water/g flour; 2.43 and 3.26 g oil/g flour, respectively) and protein concentrate tended to have higher values than those of PPS flour. Key words: Prickly pear % Chemical composition % Amino acids % Protein % Concentrate % Functional properties INTRODUCTION About 1500 species of cactus belong to the genus Opuntia are distributed mainly in Africa, Mediterranean countries, southwestern United States, northern Mexico and other areas [1]. The main studies on the Opuntia fruits were concerned withthe chemical analysis of pulp, skin and seeds [2] and use in jam production [3]. Also the composition of prickly pear seed during the maturation period was studied [4]. Plant protein is used in foods as functional ingredient to improve stability and texture as well as nutritional quality of the product [5]. Solubility of protein under varying conditions is one of its important functional properties, because this greatly influences other properties such as emulsification, foaming and gelation; thus the protein may possess satisfactory properties, e. g. nutritional value, acceptable flavour, odour and texture [6]. Functional properties of food protein are important in food processing and product formulation. Some of these properties are water/oil binding, emulsification and foam formation. These properties are affected by the intrinsic factors of protein such as molecular structure and size and many environmental factors including the method of protein separation/production, pH, ionic strength and the

Corresponding Author:

presence of other components in the food system. The importance of these properties varies with the type of food products in which the protein concentrate is used. For example, proteins with high oil and water binding are desirable for use in meats, sausage, breads and cakes, while proteins with high emulsifying and foaming capacity are good for salad dressing, sausage, bologna, soups, confectionery, frozen dessert and cakes [7]. It is well known that there shortage in protein sources, so this study was undertaken to assess chemical composition, amino acids profile and functional properties of prickly pear seed flour and its protein concentrate. Also, the effect of pH on their functional properties was investigated, in order to these seeds in food formulations as unconventional protein source. MATERIALS AND METHODS Materials: Prickly pear fruits (Opuntia ficus indica) in the ripe stage were obtained from the local market. Methods Preparation of Prickly Pear Seeds Flour: At the laboratory, Fresh mature prickly pear fruits of Opuntia ficus-indica were washed carefully and peeled with knife

A.G. Nassar, Food Science and Technology Department, Faculty of Agriculture, Al-Azhar University, Assuit, Egypt

11

World J. Dairy & Food Sci., 3 (1): 11-16, 2008

and the pulp was mixed for a few minutes in a mixer. The seeds were recovered from the resulting pulp juice by straining and washed using distilled water for several times. After drying at room temperature (35C), they were cracked in an analytical grinder for a few minutes and their pericarps were recovered after sieving on 20 mesh sieve. Preparation of protein concentrate: protein concentrate was prepared according to [8]. Proximate Composition: Moisture, protein, fat, ash and fiber of prickly pear seeds flour and protein concentrate were determined according to [9]. Carbohydrate was determined by difference. Amino acids composition was determined according to [10]. Functional Properties: Solubility profile, Emulsion capacity (EC), foaming capacity (FC) and stability (FS) were determined according to [11]. The water and oil absorption capacity was determined as described by [12] and was expressed as the percentage of increase in the sample weight. Statistical Analysis: Triplicate samples were statistical analyzed [13]. RESULTS Proximate Composition: Table 1 shows the proximate composition of the prickly pear seed flour and protein concentrate. It was clear that PPS flour has higher contents of moisture, fat, ash, fiber and carbohydrate as compared to the protein concentrate. While, PPS protein concentrate has high protein content. Amino Acids Composition: The amino acids composition of PPS flour and its protein concentrate are presented in Table 2. Glutamic acid was the most predominant amino acid followed by aspartic acid, leucine, lycine and arginine. The values of amino acids showed that cyctine and methionine were in the lowest levels in PPS flour and protein concentrate. On the other side, essential amino acids represented 28.68 and 30.46%, while nonessential amino acids represented 43.81 and 45.88% and E/N was 0.65 and 0.66 for PPS flour and protein concentrate, respectively.

Nitrogen Solubility: The nitrogen solubility as a function of pH is shown in Fig. 1. The data show three regions of nitrogen solubility, at acidic pH, near to the isoelectric point and at alkaline pH. The minimum nitrogen solubility was observed at pH 4.5 which was 16 % for PPS flour compared to 15% for protein concentrate, indicating the isoelectric point of the protein; in the acid media (pH1). 73% of the protein was soluble compared to 79% for protein concentrate. At pH 8, 51 and 56% of protein was soluble, while 85 and 92% was soluble at pH 11. Emulsion Capacity: The effect of pH on emulsion capacity of PPS flour and protein concentrate are shown in Fig. 2. It was found that PPS flour and protein concentrate had a minimum emulsion capacity (13 and 21 ml gG1) at pH 4.5, On the other hand, maximum emulsion capacity of PPS flour and protein concentrate were 88 and 105 ml gG1 at pH 10. Foam Capacity and Stability: The foam capacity (FC) of PPS flour and protein concentrate is shown in Fig. 3. The lowest FC (30 and 27%) was obtained at pH 4.5 (isoelectric point of protein); at this point the molecules are in more compact from than other pH values. FC significantly increased, especially at pH 8 and 10 reaching 84 and 96; 97 and 103% for both PPS flour and protein concentrate. The effect of pH and time on the foam stability of the PPS flour and protein concentrate is shown in Fig. 4 and 5. Regardless of the mixture pH, foam stability gradually decreased with time. At pHs 4.5 and 6 the foam stability gradually decreased and reached to 11 and 12% when the foam stood for 90 min, while at acidic (pH 2) and alkaline (pH 8 and 10) the foam stability was increased. Water and Oil Absorption Capacity: According to Fig. 6 the WAC of protein concentrate tended to be higher (4.71 ml water/g sample) than those of PPS flour (3.16 ml water/g sample).The same trend was observed with OAC. DISCUSSION Several studies had been reported that prickly pear seeds are considered untraditional source of protein. Therefore, we have a large amount of pearkly pear fruits

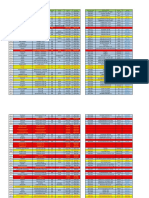

Table 1: Proximate composition of prickly pear seed flour and protein concentrate(Mean SE) Sample PPS flour PPS protein concentrate Moisture 9.030.38a 7.160.32b Protein 13.620.58b 62.411.43a Fat 10.430.63a 3.570.27b Ash 6.470.45a 5.310.40a Fiber 9.230.39a 5.290.41b Carbohydrate 51.111.25a 15.790.57b

12

World J. Dairy & Food Sci., 3 (1): 11-16, 2008

100 90 80 70 60 50 40 30 20 10 0 1 2 3 4 5 6 pH 7 8 9 10 11

Solubility%

ppS protein concentrate

Fig. 1: Effect of pH on protein solubility of prickly pear seed flour and protein concentrate

120 100 80 Emulsion capacity (ml/g) 60 40 20 0 2 4.5 6 pH 8 10 PPS flour protein concentrate

Fig. 2: Effect of pH on emulsion capacity of prickly pear seed flour and protein concentrate

120 Foaming capacity% 100 80 60 40 20 0 2 4.5 6 pH 8 10 Pricly pear seed flour Protein concentrate

Fig. 3: Effect of pH on the foam capacity of prickly pear seed flour and protein concentrate

13

World J. Dairy & Food Sci., 3 (1): 11-16, 2008

70 60 50 40 foaming Stability % 30 20 10 0 0 15 30 Time 60 90 pH2 pH4.5 pH6 PH8 pH10

Fig. 4: Effect of pH on the foam stability of prickly pear seed flour

70 60 50 40 Foaming stability% 30 20 10 0 0 15 30 Time 60 90 pH2 pH4.5 pH6 pH8 pH10

Fig. 5: Effect of pH on the foam stability of prickly pear seed flour protein concentrate

4.5 4 3.5 3 2.5 2 1.5 1 0.5 0 Water absorption Oil absorption

Prickly pear seed flour Protein concentrate

Fig. 6: Water and oil absorption capacity of prickly pear seed flour and protein concentrate

14

World J. Dairy & Food Sci., 3 (1): 11-16, 2008

Table 2: Amino acids composition of prickly pear seed flour and protein concentrate Prickly pear seed Prickly pear Amino acids Leucine Isoleucine Methionine Phenylalanine Lysine Therionine Tyrosine Valine Aspartic Glutamic Serine Glycine Alanine Histidine Arginine Cystine seed flour 7.21 4.50 0.51 3.81 4.93 1.11 2.24 4.37 7.56 15.73 6.14 3.67 3.45 2.26 4.81 0.27 Flour protein concentrate 7.82 4.76 0.47 3.96 4.98 1.46 2.38 4.63 7.79 15.58 6.77 3.89 3.71 2.87 5.09 0.18 28.68 43.81 0.65 -30.46 45.88 0.66 FAO/WHO reference protein 4.8 4.2 2.2 2.8 4.2 4.0 4.1 4.2

Total essential amino acids (E) Total non essential amino acids (N) E/ N ratio

and we wish to implementation in food technology. The current work indicated that the fat and carbohydrate of PPS flour are largely removed during protein concentrate preparation. These results are in accordance with that reported by [14]. Also, all the essential amino acid except methionine, therionine and tyrosine occurred at higher level in the PPS flour and protein concentrate than those of the FAO/ WHO reference protein [15]. Amino acids content for both PPS flour and protein concentrate are in agreement with those recorded by [16]. Protein solubility is the most important functional property because it influences other functional properties. Similar observations were reported by several workers for legumes e.g. [8] for fenugreek and [17] for African locust bean.At pH 4 and 5 there was a sharp decrease in protein solubility for both PPS and protein concentrate, but it showed good solubility in acid and alkaline pH regions which is an important characteristic in food formulations [18]. Beside, at highly acidic and alkaline pHs the protein acquires net positive and negative charges, respectively, which favors the repulsion of the molecules and thereby increase the solubility of the protein [19]. The formation and stability of emulsion is very important in food systems such as salad dressing. Protein is composed of charged amino acids, non charged polar amino acids and non polar amino acids. Emulsion capacity had low level of 15

PPS flour and protein concentrate at pH 4.5, at this pH value the protein tend to precipitate, leading to reduction in emulsion formation. However results revealed that the emulsion capacity was pH dependent and the alkaline pH improved the emulsion capacity more thane did the acidic pH. Similar results were reported by [20]. On the other hand, foam capacity of PPS flour and protein concentrate has a more compact structure, especially at acidic and neutral pH values. At the alkaline pH 8 and 10 foam capacity of the PPS products were increased, probably as a result of an increase in the negative charge density of the proteins. Increased charge density would enhance unfolding of the protein molecules into more flexible structures which form foams better than the more compact molecules that exist at pH 2,4.5 and 6 [21]. The charge effect is particularly noticeable in foam formed by PPS protein concentrate, which had low volumes at pH 2 and 6, while it was completely unstable at pH 4.5. However, at pH 8 and 10 foam capacity was increased for the protein concentrate. The increase in foam stability of PPS flour and protein concentrate under highly acidic and alkaline condition might be attributed to the increase in flexibility of the protein molecules, which diffuse more rapidly to the air water interface to encapsulate air particles, leading to enhance foaming [22]. Also, results indicated that, increase in the foam stability values of protein concentrate at acidic and alkaline condition compared with PPS flour. The high values associatedwith protein concentrate sample may be due to their high protein content and increase solubilization of these protein. The same trend was observed by [23]. Water absorption capacity (WAC) represented the ability of a substance to associate with water under a limited water condition [24] both protein and carbohydrates improved WAC in particularly protein concentrate, this may be due to smaller lipid content in its content compared with flour [25]. Oil absorption capacity (OAC) is another important functional property, since it plays an important role in enhancing the mouth feel and retaining the flavour [26]. The OAC of the protein concentrate was greater than those of the PPS flour.This could result from higher protein content of the protein concentrate leading to a greater extent of hydrophobic interaction between protein and fat. In conclusion, pearkly pear grows successfully under Egyptian condition, so it can be completely utilize to obtain unconventional protein source. Based on our results, PPS flour and protein concentrate have good functional properties and can be included in food formulation system.

World J. Dairy & Food Sci., 3 (1): 11-16, 2008

REFERENCES 1. Hegwood, D.A., 1990. Human health discoveries with Opuntia sp. (Prickly pear). J. Hort. Sci., 25: 1515-1516. 2. El-Kossori, R.L., C. Villaume, E. El-Boustani, Y. Sauvaire and L. Mejean, 1998. Compo-sition of pulp, skin and seeds of prickly pears fruit (Opuntia ficus indica sp.). Plant Foods for Human Nutrition, 52: 263-270. 3. Sawaya, W.N., H.A. Khatchadorian, W.M. Safi and H.M. Al-Mohammad, 1983. Chemical characterization of prickly pear pulp, Opuntia ficus indica and the manufacturing of prickly pear jam. J. Food Technol., 18: 183-193. 4. Coskuner,Y. and A. Tekin, 2003. Monitoring of seed composition of prickly pear (Opuntia ficus indica L.) fruits during maturation period. J. Sci. Food Agric., 83: 846-849. 5. Makri, A., E. Papalamprou and G. Doxastakis, 2005. Study of functional properties of seed storage proteins form indigenous European legume crops (lupine, pea broad bean)in admixture with polysaccharides. J. Food Hydrocolloids, 19: 583-594. 6. Kinsella, J.E., 1982. In: Food protein determination mechanism and functionality, Chery, J.P. (Ed.). Symposium series (206:301-320). Washington, DC: American Chemist Society. 7. Ahmedna, M., W. Prinyawiwatkul and R.M. Rao, 1999. Solublized wheat protein isolate: Functional properties and potential food applications. J. Agril. Food Chem., 47: 1340-1345. 8. El-Nasri, A.N. and A.H. El-Tinay, 2007. Functional properties of fenugreek (Trigonella foenum) protein concentrate. Food Chem., 103: 582-589. 9. AOAC., 1990. Official Method of Analysis. Association of Official Analytical Chemists (13th Edn.). Washnigton, DC. 10. Millipore Co-Operative, 1987. Liquid chromatographic analysis of amino acid in food was using a modification of the PICO. 11. Bera, M.B. and R.K. Mukherjee, 1989. Solubility, emulsifying and foaming properties of rice bran protein concentrates. J. Food Sci., 51: 142-145. 12. Sosulski, F.W. and A.R. McCurdy, 1987. Functionality of flour, protein fraction and isolate from field peas and faba bean. J. Food Sci., 52: 1010-1014.

13. Steel, R.G.D. and J.H. Torrie, 1980. Principles and procedures of statistics. New York: McGraw-Hill. 14. Lamghari, K., R. Kossori, C. Villaume and Y. Sauvaire, 1998. Composition of pulp,skin and seeds of prickly pear fruit. Plant Food Human Nutr., 52 (3): 263-270. 15. FAO., 1993. Food and Agriculture Organization of United Nations. Amino acid content of food and biological data on proteins. FAO Nutrition Studies No. 28. 16. Young, C.L., H.H. Keum and D.K. Sung, 1997. Composition of Opuntia ficus indica. Korean. J. Food Sci. Technol., 29: 847-853. 17. Lawal, O.S., K.O. Adebwale, B.M. Ogunsanwo, O.A, Sosanwo and S.A. Bankole, 2004. On the functional properties of globulin and albumin protein fractions and flour of African locust bean (Parkia biglobossa). J. Food Chem., 92: 681-691. 18. Idouraine, A., S.B. Yensen and C.W. Weber, 1991. Tepary bean flour albumin and globulin fractions, functional properties, compared with soy protein isolate. J. Food Sci., 56: 1316-1318. 19. Seena, S. and K.R. Sridhar, 2005. Physicochemical, functional and cooking properties of canavalia. J. Food Chem., 32: 406-412. 20. Khalid, E.K., E.E. Babiker and A.H. ELTinay, 2003. Solubility and funct-ional properties of sesame seed proteins as influenced by pH and/or salt concentration. Food Chem., 82: 361-366. 21. Aluko, E.R., T. Mcintosh and M. Reaney, 2001. Comparative study of the emulsifying and foaming properties of defatted coriander (Coriandrum sativum ) seed flour and protein concentrate. Food Res. Intl., 34: 733-738. 22. Chau, C.F. and P.C.K. Cheung, 1998. Functional properties of flours prepared from three Chinese indigenous legume seeds. Food Chem., 61: 429-433. 23. Guan, X., H. Yao, Z. Chen, L. Chan and M. Zhang, 2007. Some functional properties of oat bran protein concentrate modified by trypsin. Food Chem., 101: 163-170. 24. Singh,U., 2001. Functional properties of grain legume flours. J. Food Sci. Technol. Mysore, 38: 191-199. 25. Jitngarmkusol, S., J. Hongsuwankul and K. Tananuwong, 2008. Chemical composition, functional properties and microstructure of defatted macadamia flours. Food Chem., 110: 23-30. 26. Kinsella, J.E., 1976. Functional properties of protein in foods: A survey. Critical Reviews in Food Sci. Nutr., 7: 219-232.

16

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Chap 2 - Sprinkler IrrigationDocument4 pagesChap 2 - Sprinkler IrrigationEng Ahmed abdilahi Ismail100% (1)

- Glenmark Pharmaceuticals Limited: Analytical Research Laboratory (Formulation), TalojaDocument5 pagesGlenmark Pharmaceuticals Limited: Analytical Research Laboratory (Formulation), Talojaरोहित जोशीNo ratings yet

- Viking PumpDocument36 pagesViking PumpSakir Zak100% (2)

- MSDS B-Kurita KF SBL-20Document1 pageMSDS B-Kurita KF SBL-20Arief SetiawanNo ratings yet

- PowerLogic PFC Capacitors - BLRCH400A480B44Document3 pagesPowerLogic PFC Capacitors - BLRCH400A480B44diditsuNo ratings yet

- SEC4 Overhead Conductors PDFDocument106 pagesSEC4 Overhead Conductors PDFKy TaNo ratings yet

- Nutanix EUC Solutions Sales Enabler For PartnersDocument2 pagesNutanix EUC Solutions Sales Enabler For PartnersKevin Karl Gabutin JornacionNo ratings yet

- Diagnosis ListDocument1 pageDiagnosis ListSenyorita KHayeNo ratings yet

- National Patients' Rights Charter: Annexure FDocument2 pagesNational Patients' Rights Charter: Annexure FK ValdesNo ratings yet

- Tsioptsias 20151Document10 pagesTsioptsias 20151Violeta GarciaNo ratings yet

- Sigma Shield 1200Document5 pagesSigma Shield 1200Ventas IMSNo ratings yet

- Vera DrakeDocument2 pagesVera DrakeDJ REYNo ratings yet

- Gujarati University, Ahmedabad Question Bank Subject: Alternate Energy Sources, B.E. Sem-Viii, MechanicalDocument2 pagesGujarati University, Ahmedabad Question Bank Subject: Alternate Energy Sources, B.E. Sem-Viii, MechanicalAnkit PatelNo ratings yet

- Employment Law in OmanDocument3 pagesEmployment Law in OmanjuliechandruNo ratings yet

- Gas Valves Interstage Pressure Between SRV and GCV high-SEP10 PDFDocument4 pagesGas Valves Interstage Pressure Between SRV and GCV high-SEP10 PDFsanjeevchhabraNo ratings yet

- IGBT Modules 1-Pack Fuji Electric AmericaDocument1 pageIGBT Modules 1-Pack Fuji Electric AmericaSergio MuriloNo ratings yet

- Floating Bodies PDFDocument8 pagesFloating Bodies PDFQSQFNo ratings yet

- Soal PAS KLS 5 Bahasa InggrisDocument2 pagesSoal PAS KLS 5 Bahasa InggrisMahpudin Al AfganiNo ratings yet

- Perbandingan Harga Apotek Vs PBFDocument3 pagesPerbandingan Harga Apotek Vs PBFRidho SaputraNo ratings yet

- Electrical Conduits & Fittings: Protect Electrical Cables and WiresDocument18 pagesElectrical Conduits & Fittings: Protect Electrical Cables and WiresA Ma RaahNo ratings yet

- Reporte Papas Fritas Holandesas AVIKODocument2 pagesReporte Papas Fritas Holandesas AVIKOginoromanNo ratings yet

- 1echocardiography and The NeonatologistDocument4 pages1echocardiography and The NeonatologistAbuAlezzAhmedNo ratings yet

- How Rfid Technology Boosts Walmart S Sup PDFDocument10 pagesHow Rfid Technology Boosts Walmart S Sup PDFKshitij ShuklaNo ratings yet

- Extra WorksDocument4 pagesExtra WorksNuwan AththanayakaNo ratings yet

- Giant PandaDocument6 pagesGiant PandaJasvinder SinghNo ratings yet

- Premature BurialDocument9 pagesPremature Burialaidee bogadoNo ratings yet

- Neurotransmitters in Schizophrenia: Dr. Adel El SheshaiDocument47 pagesNeurotransmitters in Schizophrenia: Dr. Adel El SheshaielvinegunawanNo ratings yet

- The Spirit Controlled Life Ebook PDF 1Document184 pagesThe Spirit Controlled Life Ebook PDF 1Okesola AbayomiNo ratings yet

- Seleccion & Brochure Bomba Griswold BoosterDocument19 pagesSeleccion & Brochure Bomba Griswold BoosterJonathan Mario Bolivar AldanaNo ratings yet

- Mindmap For Hands Held HighDocument1 pageMindmap For Hands Held Highapi-523333030No ratings yet