Professional Documents

Culture Documents

Architecture of A Fault Diagnosis Expert System For Power Plants Protection

Architecture of A Fault Diagnosis Expert System For Power Plants Protection

Uploaded by

serg6007Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Architecture of A Fault Diagnosis Expert System For Power Plants Protection

Architecture of A Fault Diagnosis Expert System For Power Plants Protection

Uploaded by

serg6007Copyright:

Available Formats

Architecture of a Fault Diagnosis Expert System for Power Plants Protection

C.C. Kontogiannis Ph.D. student A.N.Safacas Professor Dr.Ing. Electromechanical Energy Conversion Laboratory Dept. of Electrical & Computer Engineering University of Patras Tel:+302610997351 Fax:+ 302610997362 Ckontogiannis@patras.atmel.com a.n.safacas@ee.upatras.gr Abstract This paper outlines the basic architecture of

"HELMOS", a knowledge based expert system implemented for the fault diagnosis and the detailed monitoring of generators and distribution substations in power plants. Every circuit breaker and switch operation is recorded in the Digital Fault Recorder (DFR) of the plant. All current and voltage value are measured by the installed current and voltage transformers respectively. These signals are acquired by the presented computational system and are subsequently used for the generator and the substation state estimation. The estimated state is compared to the measured state in order to detect any conflict that could intimate an abnormal situation. An intelligent algorithm is executed during a program scan cycle incorporating the stored knowledge of the expert operator. A thoughtfully designed monitoring system displays selected information in the control room that helps even not well trained personnel to recognize and face emergency signals whenever they appear.

1.INTRODUCTION

Artificial Intelligence (AI) programs are developed and used in computer science since the early days of digital computers. Only during the last two decades though industry has taken advantage of those special features that make AI so unique in modeling and representing knowledge, as well as imitating the common sense reasoning. The continuous augmentation of available computational strength and low cost of modern microprocessors on one hand, and the software tools recently developed on the other, leaded in the remarkable expansion of AI applications in the domain of electrical power systems and power electronics. Expert Systems among others is a very popular AI technique in industry. According to the working group D10 of the line protection subcommittee [1], an Expert System (ES) is a computer program that uses knowledge and inference procedures to solve problems that are ordinarily solved through human expertise. The main components of an ES are: a) inference engine, b) database, c) userinterface. ES incorporate rule kind of programming. They are currently being used in many applications in the area of power systems and power electronics. Several systems for the short or long term load forecasting have been already introduced based on ES technology [2][3]. Intelligent SCADA and offline training systems for non-expert operators is another application where ES are often used [4][5]. All these offline applications are nevertheless not critical for the power system robustness and stability. More and more applications are currently using ES in real time monitoring and/or control, and AI turns to be a common practice in industrial automation. Regarding the category of real time monitoring and control, many applications have already been proposed, focusing mainly on topology

estimation and fault diagnosis in distribution substations [6][7][8], and on the fault diagnosis and restoration strategies for transmission networks [9][10][11] [12][13]. Expert Systems basically mimic the problem solving behavior of experts using domain knowledge acquired through interviews during the knowledge acquisition phase. Knowledge based ES as mentioned go beyond in a sense that they enrich problem-solving strategy with methods that are not ordinarily employed by human experts [1]. The proposed system is designed for the generators and distribution substations protection in power plants. Especially in weak interconnected power systems, operation of plants with high installed power can be of great importance for the stability and efficiency of the whole system. An unhandled fault can have a significant impact on power availability for an expanded area of the transmission network. Besides, a damage on a generator would add a very high financial overhead. Such unhandled faults have though been reported in the past and can lead even to human casualties. The system is designed to instantly recognize and report abnormalities that can be related to a mechanical equipment failure or to an electrical, or electronic equipment malfunction, or even to a mistaken human operator control command.

2. SYSTEM DESCRIPTION

Distribution substations are the interlocking connection points of power plants to the electrical power grid. The state of all substation components (circuit breakers, disconnectors, protection relays etc.) is monitored and recorded to Digital Fault Recorders (DFR) while the electrical values of every circuit breaker, bus, transformer and generator terminal are measured by ad hoc installed current and voltage transformers. From the operator perspective an alarm situation arises when a monitored value exceeds a predefined upper or lower limit, activating a sound or light alert on control panel. An expert operator would handle this situation by first checking the control panel indications, trying then to locate the faulted area, according to the theoretical state of the switching equipment and the current values of the measurement points. This procedure may take some time especially when operators act under stress conditions. On the other hand inference process can be a very complicated task when some input data or measurements are faulted. For example, a very difficult fault to diagnose has been reported in the past, when after a voltage transformer explosion a bypass switch broke and caused a short-circuit, supplying the generator with an unbalanced load. In this case the switch position was mistakenly reported and the operator could not easily detect the real current flow path.

The time between the fault appearance and its recognition and restoration inference can be critical for the equipment and personnel safety.

Digital Fault Recorder

Inference Engine Comparison module Fault location Fault inference Restoration module

Monitoring System

Data Base Knowledge History

Figure 1. Basic system architecture diagram

A sophisticated fault diagnosis and monitoring system can detect similar contradictions and point out the optimal restoration sequence. The proposed expert system uses a dedicated module for the topology and state estimation of the generator and the distribution substation. This module considers as known inputs the voltages and currents measured on the arriving from the network transmission lines, as well as the generator and transformer current and voltage. Also known is considered the state of the circuit breakers, disconnectors, protection relays etc. Based on the above values the system composes an estimated state regarding the voltage and current flow at all measuring points. Another module composes the same state based on the performed measurements at the same points. The estimated and measured states are being compared till a conflict arises between the estimated and measured values of a certain measurement point. Then the fault-locating module locates the faulted area, and the fault scenario module inferences the fault hypothesis. The system then activates the restoration module in order to propose the restoration sequence bringing the process back to its normal operation.

main sub modules running simultaneously and using three different threads: Data acquisition and monitoring System. This program is responsible for the data acquisition, interfacing the external acquisition hardware. It passes all acquired information to the inference engine and displays some defined data to the system monitor. It also displays some selected by the operator data, implementing thus the system GUI input and output. Selected data are sent to the system data base for history logging. Data Base. The system data base is consisted mainly by two modules. The knowledge data base part keeps all the knowledge acquired during the system design phase, via exhausting interviews with the station expert operators. This data base is designed in such a way that allows knowledge modification and update, offering to the system flexibility and upgrade capability. The history recording and logging data base is used for the store of selected values that can be used by the inference engine in real time, or even can be recalled by the user offline for further processing and evaluation. Inference Engine. This program is the heart of the whole system. It is an intelligent function based on rule-base programming. Using the current data values of the data acquisition module and the knowledge stored in the knowledge base, it inferences knowledge imitating the expert operator reasoning. In the same time it performs advanced checks that an operator cannot do in real time, using special rules that offer a quality process monitoring and analysis.

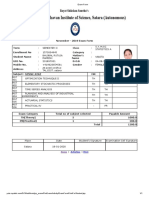

Table 1. System inputs & measurements summary

Generator Analog: - machine speed -neutral currents & voltages -output currents & voltages -excitation currents & voltasges Digital: -differential relay -trip relay -excitation field loss -control switches -other protection relays

Substation&Transformer Analog: -Transmission lines currents & voltages -High voltage buses currents & voltages -circuit breakers currents & voltages -main transformer primary& secondary currents & voltages

3. SYSTEM ARCHITECTURE

The proposed knowledge based expert system runs on a dedicated workstation PC. Extra data acquisition and digitization hardware is not required as the data acquired from the Digital Fault Recorder are transferred to the host computer via a standard RS-232 connection supplied directly from the DFR. The core of the system is the software running on the PC. It is consisted of three

Digital: -circuit breakers state -switches state

No Measurements acquisition Start of Algorithm System input values and states acquisition Estimated state acquisition Measured state calculation Is there any conflict?

No Check if fault remains Yes

Yes

Restoration operations rules activated

Fault inference rules activated

Fault locating rules activation

Figure 2. Fault recognition and analysis algorithm

When a fault is diagnosed the engine inferences the fault scenario and proposes to the operator the necessary restoration actions. Alternatively, after the exhausting test of the system, the inference engine can produce not only messages output but control signals as well.

4. SOFTWARE IMPLEMENTATION

The various system modules presented above are implemented in independent software units in Visual C++, see figure 4. Each module runs in a dedicated thread on a Win2000 based workstation platform. Three main threads are active and run simultaneously for the graphical user interface, the inference engine and the data acquisition service. There is another thread used for testing purposes only, substituting the hardware module with selected test data for use in the laboratory during the development phase or after. This is very useful when the physical system is absent or when some specific scenarios must be tested. The system initially used mainly a rule-based style of programming. All advanced checks and operations where performed from the inference engine restoring the acquired knowledge stored in the knowledge base, in combination with measurements acquired by the Digital Fault Recorder. A conventional expert system built this way was proved to be not convenient in describing an extended and complex industrial process without problems and conflicts arising between the rules and the real objects properties. Another problem that can be mentioned here is that knowledge engineers experienced significant problems with the expert engineers of the plant, as they approached the system description from a different point of view. The

knowledge engineers attempted to describe the plant entities with a set of rules containing all the entitys properties while the expert operators described the objects in natural language giving each object some properties and operations. The gap between the two approaches closes when the knowledge engineer translated the object with a set of rules that is not always easy to produce and check. Translating objects properties into rules though increases the complexity of the system and slows down the development process significantly, especially when the same objects are used by the system many times. On the other hand, rule based kind of programming can give a very good representation of the human reasoning. The reasons mentioned above helped in realizing that a hybrid programming style should be incorporated in order to accelerate the development and to increase the efficiency of the system offering same time a simple and easily expandable architecture. - Power Plant Entities Implementation. This part of the system is developed using Object Oriented Programming (OOP). Every object is implemented by an independent Active-X control holding a number of properties and methods that enable it to imitate precisely the real objects behavior. Let us consider the Line and the Line Breakers as two different objects. The classes for these Active-X objects would schematically appeared as following: Class Breaker(n){ Properties: double current; double voltage_left; double voltage_right; integer line_left;

integer line_right; boolean state Methods: void operate_open(); void operate_close();

Transformer

grid Switch1 Breaker2 Switch2 Line2 grid

Breaker3

Line1

~

} Generator Class Line(n){ Properties: double current; double voltage; integer line_left; integer line_right; boolean state integer element_left_Num integer element_left_Type integer element_Right_Num integer element_Right_Type } A change of a property of one object will automatically mean a number of chaining changes to the neighboring objects properties with no action of the main expert system to be needed as all necessary calculations are performed by every single Active-x unit. -? uman Reasoning Representation. This part of the expert system is implemented using rule based programming as the conditional reasoning of the humans by nature is closely related to this style of knowledge representation. Using a combination of both Rule Based programming and Object Oriented programming the system can efficiently detect a conflict when it arises, and inferences scenarios for the cause of the problem as well as the optimal restoration procedure.

Figure 3. Case study

Breaker1

6.CONCLUSIONS

This work introduces a knowledge based expert system for the generator and substation monitoring and fault diagnosis in power plants. The fault detection is based on a comparison algorithm polling for specific measurement values, comparing them to the corresponding estimated values, according to the system current inputs, and then checking for possible conflicts . Whenever a conflict arises the system uses rule-based reasoning to inference the fault scenario and the optimal restoration sequence, which is fed back to the control room operator for further action. The knowledge based expert system efficiency is based on, but not limited to, the expert operators reasoning. It can report and analyze faults, even having received partially mistaken input data, something that for a human operator is very difficult or impossible in real time, especially under emergency situation stress. The knowledge base can be continuously updated with rules, offering thus a learning capability that enriches the system with new, recent experience. Based on some more advanced rules the system can offer fault scenario inference performing multiple input calculations, with strictly restrictive complexity for the human operator real time processing. This can lead to a detailed diagnosis of faults, even when the cause is indirect. For example, a failure of power semiconductor elements of the generator field excitation rectifier, that consists of power electronics, can be recognized and classified indireclty, according to its effects combination on the measured and estimated parameters.

5.EXAMPLE

Let us consider the following simple example as a case study (figure 3). Line1 is connected to the power grid (Breaker(2).state = TRUE ), while Line2 is not connected (Breaker(3).state = FALSE). Due to a short circuit of the Switch2 the voltage transformer between the switch and the Breaker1 will measure the grid voltage although the system calculates Switch2.voltage_left to be zero. The system that in every scan cycle compares the estimated with the measured values will instantly recognize the conflict and will inference a scenario for the cause of the problem. The calculations are automatically performed by the Active-x elements while the fault location and scenario inference are based on the rules stored in the knowledge data base.

5. REFERENCES

[1] Working Group D10 of the line Protection Subcommittee, Power System Relaying Committee:, Potential applications of expert systems to power system protection, IEEE Transactions on Power Delivery, vol9, No2 April 1994 [2] M.S Kandil-N.E.Hasanien, Long-Term Load Forecasting for fast Developing utility using a knowledge based expert system, IEEE Transactions on Power Systems, vol7, No2, May 2002

HELMOS SYSTEM SOFTWARE ARCHITECTURE User Interface GUI_Thread.c GUI.dll Display.dll Data Base Monitoring System Main_Thread.c Compare.dll faultLocate.dll faultInfer.dll Restore.dll SQL DBMS

Data Acquisition DAcq_Thread.c DataAcq.dll

sqldb.dll

Test_Thread.c Signaling.dll

USBData.sys

Hardware I/O Module

Figure 4. Software architecture

[3] D.J.Sobaj, J.H.Douglas, A system engineering based approach for power market operations and monitoring, ISAP03 vol2,29-33, Lemnos August 2003 [4] S.Islam-N.Chowdhury, A case based windows graphic package for the education and training of power system restoration, IEEE Transactions on Power Systems, vol16, No2, May 2001 [5] M.Negnevitsky A knowledge based tutoring system for teaching fault analysis, IEEE Transactions on Power Systems, vol13, No1, May 1998 [6] M.Kezunovic, Z.Ren-D.R.Sevcik, J.Lucey An expert system for automated analysis of circuit breaker operation", ISAP03, Lemnos August 2003 [7] H.Lee, B.AhnY.Park A fault diagnosis expert system for distribution substations, IEEE Transactions on Power Systems, vol15, No1,January 2000 [8] H.Lee, D.Park, B.shin, Y.Park, J.Park, S.Venkata A fuzzy expert system for the integrated fault diagnosis IEEE Transactions on Power Delivery, vol5, No2 April 2000 [9] E.Styvaktakis, M.Bollen, I.Gu Expert system for classification and analysis of power system events, IEEE Transactions on Power Delivery, vol7, No2 April 2002

[10] Y.Liu, N.Schulz, Knowledge based system for distribution system outage locating using comprehensive information, IEEE Transactions on Power Systems, vol17, No2,May 2002 [11] J.Tan, P.Crossley, D.Kirschen, J.Goody-J.Downes: An expert system for the backup protection of a transmission network, IEEE Transactions on Power Delivery, vol5, No2 April 2000 [12] J.Tan, P.Crossley, P.McLaren, I.hall, J.Farrell, P.Gale:Sequential tripping strategy for a transmission network backup protection expert system, IEEE Transactions on Power Delivery, vol17, No1 Jan 2002 [13] J.Tan, P.Crossley, P.McLaren, I.hal, -J.Farrell, P.Gale, Application of a wide area backup protection expert system to prevent cascading outages , IEEE Transactions on Power Delivery, vol17, No1 Jan 2002 [14] CKontogiannis, A.Safacas, A knowledge Based Fault Diagnosis and Supervisory Expert System for Generators and Distribution Substations in Power Plants, EUROPES conference , vol1, July 2004

You might also like

- Script Jungle CruiseDocument24 pagesScript Jungle CruiseronnyNo ratings yet

- Ultrasonic Testing Report Format Based On IACSDocument1 pageUltrasonic Testing Report Format Based On IACSDeepak100% (6)

- Postural Assessment SheetsDocument2 pagesPostural Assessment SheetsFebryLasantiNo ratings yet

- PSA Chapter 07Document95 pagesPSA Chapter 07anggit100% (1)

- An Expert System For Power Plants: Department of Elctrical & Electronics EngineeringDocument10 pagesAn Expert System For Power Plants: Department of Elctrical & Electronics EngineeringPVV RAMA RAONo ratings yet

- An Expert System For Power Plants Paper Presentation 100115092532 Phpapp02Document10 pagesAn Expert System For Power Plants Paper Presentation 100115092532 Phpapp02Vasundhara SrinivasNo ratings yet

- Lecture 6 - Power System AutomationDocument15 pagesLecture 6 - Power System AutomationAweSome, ST,MTNo ratings yet

- Psoc Notes PDFDocument61 pagesPsoc Notes PDFanon_613151744100% (1)

- Tesla 96Document8 pagesTesla 96Oμάδα 5No ratings yet

- Substation Automation Basics - The Next Generation: By: By: John Mcdonald, P.EDocument5 pagesSubstation Automation Basics - The Next Generation: By: By: John Mcdonald, P.ELaxman VeerepalliNo ratings yet

- Power System Automation ReportDocument11 pagesPower System Automation ReportSahana P MNo ratings yet

- ETAP RT vs. Power SCADADocument7 pagesETAP RT vs. Power SCADANghĩa HữuNo ratings yet

- Substation Automation Basics - The Next GenerationDocument8 pagesSubstation Automation Basics - The Next GenerationAlly RaxaNo ratings yet

- Power System Automation ReportDocument11 pagesPower System Automation ReportSahana P MNo ratings yet

- Unit - VDocument20 pagesUnit - VhavejsnjNo ratings yet

- Kezunovic Cigre2005Document11 pagesKezunovic Cigre2005pvenky_kkdNo ratings yet

- Contingency Alysis BaselineDocument44 pagesContingency Alysis BaselinevaseemalikhanNo ratings yet

- Metode Monitoring Trafo DistributionDocument5 pagesMetode Monitoring Trafo DistributionSiswoyo SuwidjiNo ratings yet

- Road To The Integrated Protective Relaying Fault Information SystemDocument4 pagesRoad To The Integrated Protective Relaying Fault Information SystemproteccionesNo ratings yet

- Supervisory SystemsDocument23 pagesSupervisory Systemspotugaadu1No ratings yet

- AbstractDocument4 pagesAbstractamkrishnakumarNo ratings yet

- SeminarDocument23 pagesSeminaraartitomar47_8332176No ratings yet

- Backplane Health Rests On Fault FindingDocument20 pagesBackplane Health Rests On Fault FindingAhmed HamoudaNo ratings yet

- Advances in Power System ManagementDocument15 pagesAdvances in Power System ManagementKalyan RanjanNo ratings yet

- Unit 4 - Power System Operation and ControlDocument25 pagesUnit 4 - Power System Operation and ControlSilas StephenNo ratings yet

- Operation Indices For Smart Power Dispatch Center Design: Jianing Liu, Puming Li, Jin Zhong, Liang LiangDocument6 pagesOperation Indices For Smart Power Dispatch Center Design: Jianing Liu, Puming Li, Jin Zhong, Liang LiangalfiraNo ratings yet

- The Essentials of Automation Applied To Distribution Systems Via PLCs SCADA IEDs and RTUsDocument17 pagesThe Essentials of Automation Applied To Distribution Systems Via PLCs SCADA IEDs and RTUsBruno SamosNo ratings yet

- White Paper: What Your Smart Grid Needs From A Power Management SystemDocument8 pagesWhite Paper: What Your Smart Grid Needs From A Power Management Systema_damrongNo ratings yet

- Application of Artificial Intelligence Methods in DiagnosticsDocument6 pagesApplication of Artificial Intelligence Methods in DiagnosticsYULEIMY YASMIN LUCAS ZASIGANo ratings yet

- Definition of Fundamental TermsDocument2 pagesDefinition of Fundamental TermsShid JullNo ratings yet

- Econv Trans 97 - Continuous On-Line Partial Discharge Monitoring of Generator Stator WindingsDocument6 pagesEconv Trans 97 - Continuous On-Line Partial Discharge Monitoring of Generator Stator Windingsreza515heiNo ratings yet

- Energy Control Center Functions For Power SystemDocument9 pagesEnergy Control Center Functions For Power SystemtejaNo ratings yet

- Robotic Monitoring of Power SystemsDocument14 pagesRobotic Monitoring of Power SystemsHOD EEENo ratings yet

- Document 1 (Proposal)Document13 pagesDocument 1 (Proposal)RahulNo ratings yet

- Advanced Automated Fault Location System For Primary Distribution NetworkDocument13 pagesAdvanced Automated Fault Location System For Primary Distribution NetworkSateesh IamNo ratings yet

- Scada in Power Distribution SystemsDocument10 pagesScada in Power Distribution SystemsMike AjayiNo ratings yet

- Industrial ADocument23 pagesIndustrial Aalijiha23No ratings yet

- IAS 2009 Vfinal2Document7 pagesIAS 2009 Vfinal2Cinthya BorgesNo ratings yet

- General Notions About The Introduction of Technical Diagnosis For Machine ToolsDocument23 pagesGeneral Notions About The Introduction of Technical Diagnosis For Machine ToolsNikhil ThakurNo ratings yet

- Monu PDFDocument6 pagesMonu PDFMonurajanNo ratings yet

- Artificial Speech SynthesisDocument22 pagesArtificial Speech SynthesisGururaj RevankarNo ratings yet

- Smart DevicesDocument16 pagesSmart DevicesmanojchandrasekharanNo ratings yet

- 1 - Introduction To Power System AutomationDocument6 pages1 - Introduction To Power System AutomationLeonardo CamposNo ratings yet

- Distribution Management SystemDocument7 pagesDistribution Management Systemg tsNo ratings yet

- PSOC Unit 5Document23 pagesPSOC Unit 5jagabeeee100% (1)

- An Application of Protection Management SystemDocument1 pageAn Application of Protection Management SystemEli RiezaNo ratings yet

- Wireless ARM-Based Automatic Meter Reading & Control System (WAMRCS)Document6 pagesWireless ARM-Based Automatic Meter Reading & Control System (WAMRCS)Muthu KumaranNo ratings yet

- Automation of Conventional Transmission PDFDocument9 pagesAutomation of Conventional Transmission PDFScada UcvNo ratings yet

- PSOC Unit 5 PDFDocument23 pagesPSOC Unit 5 PDFNarsingam GurramNo ratings yet

- Ee1401 Power System Operation and Control Energy Control Center SafetyDocument3 pagesEe1401 Power System Operation and Control Energy Control Center Safetysrmce100% (1)

- Power System Studies - AbstractDocument5 pagesPower System Studies - AbstractK.RamachandranNo ratings yet

- Energy Control Center Functions For Power SystemDocument9 pagesEnergy Control Center Functions For Power SystemsachinNo ratings yet

- Use of SCADA Systems in Power System AutomationDocument10 pagesUse of SCADA Systems in Power System AutomationKamlesh KumarNo ratings yet

- Various Operating States in Power System and Their Control StrategiesDocument25 pagesVarious Operating States in Power System and Their Control Strategiesmanu_ram1No ratings yet

- Wide Area ProtectionDocument27 pagesWide Area ProtectionRamesh KannanNo ratings yet

- Unit V Computer Control of Power Systems: 5.3 Data Acquisition and Control (DAS)Document25 pagesUnit V Computer Control of Power Systems: 5.3 Data Acquisition and Control (DAS)BALAKRISHNANNo ratings yet

- ERJM Volume 42 Issue 2 Pages 93-98Document6 pagesERJM Volume 42 Issue 2 Pages 93-98ahmed.hossamelden91No ratings yet

- Lect 1 PDFDocument14 pagesLect 1 PDFFikaduNo ratings yet

- Circuit Breaker System Using Iot Based Smart Load ControlDocument29 pagesCircuit Breaker System Using Iot Based Smart Load Controlkalemula sahithiNo ratings yet

- Protection CoordinationSiemensIncDocument3 pagesProtection CoordinationSiemensIncMarcWorldNo ratings yet

- Design Distributed Control System Power Supply of The TelecommunicationDocument4 pagesDesign Distributed Control System Power Supply of The TelecommunicationJorge MongesNo ratings yet

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsFrom EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsNo ratings yet

- Ripple Effect by Paul McCusker, Chapter 1Document8 pagesRipple Effect by Paul McCusker, Chapter 1ZondervanNo ratings yet

- 6.5 - Pie ChartDocument7 pages6.5 - Pie ChartKhánh An VũNo ratings yet

- Chapter 1 Challenges of Nation Building Class 12 Political Science NotesDocument9 pagesChapter 1 Challenges of Nation Building Class 12 Political Science Notesshreya 917No ratings yet

- DDocument28 pagesDkle3nexNo ratings yet

- Communication and GlobalizationDocument14 pagesCommunication and GlobalizationJOHN LEE VALDEZNo ratings yet

- Anthro Quotes Midterm+Final (FML) Flashcards - QuizletDocument51 pagesAnthro Quotes Midterm+Final (FML) Flashcards - QuizletLhamokyi GNo ratings yet

- Masonic SymbolismDocument19 pagesMasonic SymbolismOscar Cortez100% (7)

- English Final Exam Sixth GradeDocument2 pagesEnglish Final Exam Sixth GradeCLAUDIA PAREJANo ratings yet

- Exam FormDocument1 pageExam FormRutuja BhujbalNo ratings yet

- Different Types of RelationsDocument3 pagesDifferent Types of RelationsCatherine DancelNo ratings yet

- Lab 4: Self-Balancing Robot: Learning ObjectivesDocument4 pagesLab 4: Self-Balancing Robot: Learning ObjectivesAtikah AbdallaNo ratings yet

- Paging AlgorithmsDocument21 pagesPaging AlgorithmsAnonimusNo ratings yet

- FeedbackDocument11 pagesFeedbackVibhor AggarwalNo ratings yet

- Task CardDocument2 pagesTask CardEam OsarNo ratings yet

- Android Application To Read and Record Data From Multiple SensorsDocument8 pagesAndroid Application To Read and Record Data From Multiple SensorsRanjitha RNo ratings yet

- Soldier Pile Wall Analyzed With Limit-Equilibrium and Non-Linear Analysis Methods PDFDocument15 pagesSoldier Pile Wall Analyzed With Limit-Equilibrium and Non-Linear Analysis Methods PDFRobert Junior KoumetioNo ratings yet

- Contributed by Sumit Roy, Faculty, Seed Infotech LTD, Pune, IndiaDocument21 pagesContributed by Sumit Roy, Faculty, Seed Infotech LTD, Pune, IndiaAnkit JainNo ratings yet

- Forensic 4Document47 pagesForensic 4Apple Del RosarioNo ratings yet

- Lesson Plan WorksheetDocument4 pagesLesson Plan WorksheetMichael UrrutiaNo ratings yet

- Aced SNFDocument12 pagesAced SNF김성곤No ratings yet

- Syntax LING 315 Handout 1 1 Linguistics and GrammarDocument4 pagesSyntax LING 315 Handout 1 1 Linguistics and GrammarChristopher DiamantopoulosNo ratings yet

- Apac2014 PDFDocument64 pagesApac2014 PDFDe El Eurey ShineNo ratings yet

- UN Global Compact Annual Review 2010Document60 pagesUN Global Compact Annual Review 2010Europak OnlineNo ratings yet

- Newton's Law of Cooling EquationDocument4 pagesNewton's Law of Cooling EquationnishagoyalNo ratings yet

- Ogl 360 Final Project-CompressedDocument19 pagesOgl 360 Final Project-Compressedapi-538770249No ratings yet

- Cognitive Dissonance TheoryDocument3 pagesCognitive Dissonance TheoryJelena RodicNo ratings yet

- D A V Public Schools: Jharkhand Zone-HDocument3 pagesD A V Public Schools: Jharkhand Zone-H3617 'B' Akshay KumarNo ratings yet