Professional Documents

Culture Documents

Experimental Determination of Thermal Conductivity of

Experimental Determination of Thermal Conductivity of

Uploaded by

Pedro Casanova TretoCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Phy 106 DiscussionDocument10 pagesPhy 106 DiscussionKenny GildmanNo ratings yet

- Zaclon Galvanizing HandbookDocument127 pagesZaclon Galvanizing HandbookMohammed Abdallah100% (2)

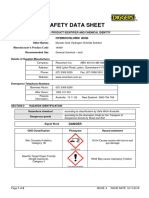

- Safety Data Sheet Recochem AustraliaDocument6 pagesSafety Data Sheet Recochem AustraliaJohn SmitgNo ratings yet

- Dr. Seema Sharma: Book PublishedDocument5 pagesDr. Seema Sharma: Book PublishedMajid_Darrodi_366No ratings yet

- Basic Petroleum EngineeringDocument2 pagesBasic Petroleum EngineeringNovandri KusumaNo ratings yet

- Organic Chemistry OpticalDocument14 pagesOrganic Chemistry OpticalPadirikuppam PavithraNo ratings yet

- Assoc - Prof.Dr. Aytaç GÜVEN Spring 2015-2016Document76 pagesAssoc - Prof.Dr. Aytaç GÜVEN Spring 2015-2016Bünyamin NergizNo ratings yet

- Soldier Pile WallDocument15 pagesSoldier Pile WallYousif Mohammed Yousif100% (1)

- Midterm Review SolutionsDocument16 pagesMidterm Review SolutionsKate SongNo ratings yet

- Bitumen Emulsion NouryonDocument20 pagesBitumen Emulsion Nouryonahm21e1001No ratings yet

- Danfoss Application HandbookDocument112 pagesDanfoss Application Handbookniantons100% (1)

- Concure AbDocument2 pagesConcure AbtalatzahoorNo ratings yet

- Table 1. Summary of Holding Times and Preservation For Liquid and Soil PHDocument3 pagesTable 1. Summary of Holding Times and Preservation For Liquid and Soil PHBenoitNo ratings yet

- Mokka Tips: Create A Unique Tactile Experience With Sappi's Touch Collection Release PapersDocument2 pagesMokka Tips: Create A Unique Tactile Experience With Sappi's Touch Collection Release Papersmanish singhalNo ratings yet

- Capillary ElectrophoresisDocument16 pagesCapillary ElectrophoresisSaksham Sanwaria100% (1)

- Variation of Conductivity With ConcentrationDocument15 pagesVariation of Conductivity With Concentrationbisman0% (1)

- Te Cgpa Nov 14 Jalgaon DisDocument2,014 pagesTe Cgpa Nov 14 Jalgaon Disapi-276920450No ratings yet

- Cromarod Duplex B-1Document1 pageCromarod Duplex B-1Matija BušićNo ratings yet

- Cummins Prem Blue 15w40 1-18 L Sing Ssv3028m18 Asia-Pacific Purple Book (GHS) - EnglishDocument14 pagesCummins Prem Blue 15w40 1-18 L Sing Ssv3028m18 Asia-Pacific Purple Book (GHS) - EnglishjosephvanbacNo ratings yet

- Thermal Measurements The Foundation of Fire Standards, ASTM, 2003Document199 pagesThermal Measurements The Foundation of Fire Standards, ASTM, 2003JheimyMarazNo ratings yet

- TT140Document4 pagesTT140Irvan YudhistiraNo ratings yet

- 5B18 Final PPT Minor ProjectDocument32 pages5B18 Final PPT Minor ProjectShikhar KumarNo ratings yet

- Caf31 EngDocument40 pagesCaf31 EngCopperConceptNo ratings yet

- Ceramics: Classification and Properties of Ceramic MaterialsDocument36 pagesCeramics: Classification and Properties of Ceramic MaterialsMadhumita KumarNo ratings yet

- Formulae Stoichiometry and The Mole ConceptDocument6 pagesFormulae Stoichiometry and The Mole ConceptFaiza RizwanNo ratings yet

- Introduction To Column Buckling: ©teaching Resource in Design of Steel StructuresDocument35 pagesIntroduction To Column Buckling: ©teaching Resource in Design of Steel Structureshemant_durgawaleNo ratings yet

- The Hand Forged Knife PDFDocument75 pagesThe Hand Forged Knife PDFtobertoNo ratings yet

- SS06 Latest 1Document5 pagesSS06 Latest 1Hydro_Spa_FitnessNo ratings yet

- Silicone Rubber Compounds, Curing Agent Dicumyl Peroxide, 40-75 Shore A, Q, Peroxide Cure (M 608 - 5 DCP)Document2 pagesSilicone Rubber Compounds, Curing Agent Dicumyl Peroxide, 40-75 Shore A, Q, Peroxide Cure (M 608 - 5 DCP)sunitaNo ratings yet

- A Serie MouvexDocument3 pagesA Serie Mouvexrasotto100% (1)

Experimental Determination of Thermal Conductivity of

Experimental Determination of Thermal Conductivity of

Uploaded by

Pedro Casanova TretoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experimental Determination of Thermal Conductivity of

Experimental Determination of Thermal Conductivity of

Uploaded by

Pedro Casanova TretoCopyright:

Available Formats

Prir&i~n

Great

Britain. All right\ rcsewcd 02hO-X773M $15,(111 +l).llo

Experimental Determination of Thermal Conductivity of Apple and Potato at Different Moisture Contents

G. Donsi, G. Ferrari & R. Nigro

Universitri di Salerno, Dipartimcnto di lngegneria Chimica e Alimentarc, Via Ponte Don

Melillo. 84084 Fisciano, Italy (Received Y January 1996; revised 2Y February IYYh:accepted 1 June IYY6)

ABSTRACT Thermal conductivity of apple and potato samples was measured by means of a specificully designed apparatus based on Fitchs method. The thermal conductivity was determined at various moisture contents at the sample mean temperature of 30C. As expected the conductivity decreases with the decrease in moisture content. Thermal conductivity data were correlated with moisture content using a straight line. Copyright 0 1996 Elselier Science Limited

NOMENCLATURE

A

c,, KH I> 111,

1 ,1 I

I(;,

Sample area, m2 Specific heat of copper plug (J/kgC) Effective thermal conductivity (W/m.(Z) Sample thickness, m Mass of copper plug (g) Time (s) Temperature (C) Water mass fraction (g/g initial water content) INTRODUCTION

The achievement of a high and constant quality of products is the challenge for the food industry at the end of the 1990s. Apart from the supply of raw materials of high quality, this aim requires that the operation of food processing plants is reliable and fully controlled. This, in turn, requires new design criteria for the relevant apparatus, based on a complete model description of the process. So far, design procedures of food processing plants are mostly dependent on practice and on scalcmathematical modelling is limited to very few up criteria, while complete 263

G. Donsi et al.

applications. This is also related, and it is not clear whether as an effect or as a cause, to the lack of systematic physical data, which are the input variables of any model. Some data of basic physical properties are reported in the literature, but almost all of them refer to measurements in specific conditions and for specific foods (Miles, 1991; Mohsenin, 1980). As a consequence, predictive wide range correlations are almost non-existent. Among the physical properties relevant to process modelling, thermal conductivity is one of the most critical, being the controlling parameter of almost all thermal processes, like drying, sterilization, freezing and thawing. In particular, the performance of mild preservation technologies, like vacuum and freeze drying, is strictly dependent on the thermal conductivity of the product. This property is very sensitive to moisture content, but also to structure modifications occurring during processes (Lozano, 1983). In spite of its influence on process design, no systematic evaluation of thermal conductivity data of foods has been performed, and the few existing predictive models are very complicated, requiring as input parameters data more difficult to measure than thermal conductivity itself (Mattea, 1986, 1989). The aim of this work is to determine thermal conductivity of foodstuffs as a function of moisture content by means of an apparatus based on Fitchs unsteady method and to obtain a simple equation to correlate experimental data.

EXPERIMENTAL Test materials were Stark Delicious apples and Bintjie potatoes. Chemical analyses were carried out on fresh samples, according to standard methods, to determine the mass fractions of main components relevant to heat transfer phenomena, i.e. water, cellulose, sugar and starch. The amounts of the components are shown in Table 1. Samples at different moisture content were prepared by partial dehydration of fresh materials in a freeze dryer, in order to minimize structure deformations. A uniform profile of residual moisture was obtained by keeping the sample wrapped in a polyethilene film for at least 30 min at ambient conditions. The determination of

Chemical Constituent

Composition

of Stark Delicious

TABLE 1 Apple and Bintjie Wet Basis

Potato Evaluated

on Dry and

Apple Sk (dty basis) gig (wet basis) 0.844 0.156 0.1218 0.0342 &!k (dry basis) 3.35 1 0.848 0.096 0.0560

Potato gk (wet basis) 0.77 0.23 0.195 0.022 0.013

Initial water content Dry matter Starch Soluble sugar Cell matter

5.41 1 0.781 0.219

thermal conductivity was carried out by means of a quasi-steady technique, derived from the original work of Fitch (Mohsenin, 1980; Zuritz, 1989). The sketch of the apparatus is shown in Fig. 1. It consists of a water tank, at controlled temperature. acting as thermal ballast, fitted with a heat sink that includes the sample holder. The heat sink is a copper plug containing the sample to be tested. Samples are cylinders having a maximum diameter of 43 mm and thickness between 2 and 6 mm. Heat flow is established between the hot water reservoir and the copper plug, the conductivity of which is much higher than the walls, if the apparatus is properly insulated. The transient temperature rise of the copper plug is measured by a thermocouple, fitted to the plug axis. As the only thermal resistance due to the sample, whose conductivity is one order of magnitude lower than that of copper. the thermal balance of the plug can be written as: A.k.(T-T,) L and integrated in the form: In with the initial conditions: T = T,, at t = 0. A.k L~m;C,,, .t (3 = m,..C,,; dT dt (1)

Fig. 1. Fitch-type

apparatus

used for thermal conductivity regime.

measurements

in 21quasi-steady

266

G. Donsi et al.

Equation (2) implies that a plot of the log of the temperature ratio vs time is a straight line. Thermal conductivity can be determined from the slope (A-k/ L .m;C,,). An example of such plots is shown in Fig. 2. The best fitting of the linear part of the temperature-time history was chosen optimizing the 2 correlation coefficient, disregarding the initial and the final points, corresponding to an initial transient heat transfer and a steady heat transfer respectively. The temperaturetime relationship was considered linear when the correlation coefficient was equal or greater than 0.996. The original design of this apparatus has been modified and optimized in order to: minimize the contact thermal resistance between sample and plug; reduce heat accumulation in the plug; minimize heat dispersion; minimize the temperature difference between hot and cold sources; lower measuring time, to avoid moisture changes during tests; keep a high value of the ratio between thermal resistance of the insulating material and sample. The last requirement is very critical for measurements performed at low moisture contents. In this range, in fact, thermal conductivity is very low and radial thermal losses cannot be disregarded. In these extreme situations, a steady-state method is to be preferred. The apparatus has been calibrated with a sample of known conductivity. The calibration factor, defined as the ratio between measured and true conductivity, is 0.97 for a calibration conductivity of 0.15 W m-C .

I -1

10

--I-20 30

Fig. 2. Example

time, min of a plot of In (temperature ratio) vs time from a thermal measurement of a potato sample (r? = 0.9978).

conductivity

I . l . . . . 8. . . l . f .

l*

1

I~\ 1

7

0.4 06 08 IO

02 Fig. 3. Thermal conductivity

Xw, water mass fraction

of tested materials

as a function

of water mass fraction.

RESULTS In Fig. 3 thermal conductivity of apple and potato, measured at a mean sample temperature of 3OC, is shown as a function of water mass fraction of the sample. Each point represents an average of at least three measurements. Thermal conductivity decreases as moisture content decreases. For water mass fraction up to 0.4, data of both materials have a similar value, while for higher values of moisture content, thermal conductivity of potato is 20% higher than that of apple. Thermal conductivity of fresh product is 052 and 0.43 W m C for potato and apple respectively. These data are in good agreement with those found in the literature (Miles, 1991; Lozano, 1979; Lamberg, 1986; Wang, 1992). Experimental data were correlated using a linear regression as shown in Fig. 3, whose constants, calculated within a 95% confidence interval, are given in Table 2. Thermal conductivity data follow the linear correlation suggested by Sweat (1074) in the range of moisture content considered.

Estimated Sumpk Potato Apple

Values of the Constants u 0.389 0.322

TABLE 2 of the Linear Correlation

Analysis with Yi% Confidcncc ,. 11 (I.970 (1.071

0.1445 0. I263

268

G. Donsi et al.

CONCLUSIONS The present study presents an unsteady-state measurement technique for thermal conductivity which allows reliable determination at high and medium moisture contents in short times. This avoids consistent moisture evaporation during the test. The technique is applied to apple and potato. The decrease of thermal conductivity with moisture content is confirmed. The correlation of experimental data with a simple linear relationship gives a tool for the prediction with high accuracy of the thermal conductivity of these vegetables in the entire range of moisture content.

REFERENCES

of potatoes and a computer simulation model of a blanching process. J. Food Techno!., 21, 577. Lozano, J. E., Urbicain, M. J. 6i Rotstein, E. (1979). Thermal conductivity of apples as a function of moisture content. .I. Food Sk., 44, 1198. Lozano, J. E., Rotstein, E. & Urbicain, M. J. (1983). Shrinkage, porosity and bulk density of foodstuffs at changing moisure content. J. Food Sci., 48, 1497. Mattea, M., Urbicain, M. J. & Rotstein, E. (1986). Prediction of thermal conductivity of vegetable foods by the effective medium theory. .I. Food Sci., 51(l), 113. Mattea, M., Urbicain, M. J. & Rotstein, E. (1989). Effective thermal conductivity of cellular tissue during drying: prediction by a computer assisted model. .I. Food Sci., 54(l), 194. Miles, C. A., van Beek, G. & Vcerkamp, C. H. (1991). Calculation of thermophisical properties of foods. In Physical Properties of Foods, ed. R. Jowitt. Applied Science Publisher, UK. Mohsenin, N. N. (1980). Thermal Properties of Foods and Agricultural Materials. Gordon and

Lamberg, I. & Hallstrom, B. (1986). Thermal properties

Breach, New York.

Sweat, V. E. (1974). Experimental values of thermal conductivity of selected fruits and vegetables. J. Food Sci., 39, 1080. Wang, N. & Brennan, J. G. (1992). Thermal conductivity of potato as a function of moisture content. .I. Food Etzgng, 17, 153-160. Zuritz, C. A., Sastry, S. K., McCoy, S. C., Murakami, E. G. & Blaisdell, J. L. (1989). A modified Fitch device for measuring the thermal conductivity of small food particles.

A.S.A.E., 32(2), 711.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Phy 106 DiscussionDocument10 pagesPhy 106 DiscussionKenny GildmanNo ratings yet

- Zaclon Galvanizing HandbookDocument127 pagesZaclon Galvanizing HandbookMohammed Abdallah100% (2)

- Safety Data Sheet Recochem AustraliaDocument6 pagesSafety Data Sheet Recochem AustraliaJohn SmitgNo ratings yet

- Dr. Seema Sharma: Book PublishedDocument5 pagesDr. Seema Sharma: Book PublishedMajid_Darrodi_366No ratings yet

- Basic Petroleum EngineeringDocument2 pagesBasic Petroleum EngineeringNovandri KusumaNo ratings yet

- Organic Chemistry OpticalDocument14 pagesOrganic Chemistry OpticalPadirikuppam PavithraNo ratings yet

- Assoc - Prof.Dr. Aytaç GÜVEN Spring 2015-2016Document76 pagesAssoc - Prof.Dr. Aytaç GÜVEN Spring 2015-2016Bünyamin NergizNo ratings yet

- Soldier Pile WallDocument15 pagesSoldier Pile WallYousif Mohammed Yousif100% (1)

- Midterm Review SolutionsDocument16 pagesMidterm Review SolutionsKate SongNo ratings yet

- Bitumen Emulsion NouryonDocument20 pagesBitumen Emulsion Nouryonahm21e1001No ratings yet

- Danfoss Application HandbookDocument112 pagesDanfoss Application Handbookniantons100% (1)

- Concure AbDocument2 pagesConcure AbtalatzahoorNo ratings yet

- Table 1. Summary of Holding Times and Preservation For Liquid and Soil PHDocument3 pagesTable 1. Summary of Holding Times and Preservation For Liquid and Soil PHBenoitNo ratings yet

- Mokka Tips: Create A Unique Tactile Experience With Sappi's Touch Collection Release PapersDocument2 pagesMokka Tips: Create A Unique Tactile Experience With Sappi's Touch Collection Release Papersmanish singhalNo ratings yet

- Capillary ElectrophoresisDocument16 pagesCapillary ElectrophoresisSaksham Sanwaria100% (1)

- Variation of Conductivity With ConcentrationDocument15 pagesVariation of Conductivity With Concentrationbisman0% (1)

- Te Cgpa Nov 14 Jalgaon DisDocument2,014 pagesTe Cgpa Nov 14 Jalgaon Disapi-276920450No ratings yet

- Cromarod Duplex B-1Document1 pageCromarod Duplex B-1Matija BušićNo ratings yet

- Cummins Prem Blue 15w40 1-18 L Sing Ssv3028m18 Asia-Pacific Purple Book (GHS) - EnglishDocument14 pagesCummins Prem Blue 15w40 1-18 L Sing Ssv3028m18 Asia-Pacific Purple Book (GHS) - EnglishjosephvanbacNo ratings yet

- Thermal Measurements The Foundation of Fire Standards, ASTM, 2003Document199 pagesThermal Measurements The Foundation of Fire Standards, ASTM, 2003JheimyMarazNo ratings yet

- TT140Document4 pagesTT140Irvan YudhistiraNo ratings yet

- 5B18 Final PPT Minor ProjectDocument32 pages5B18 Final PPT Minor ProjectShikhar KumarNo ratings yet

- Caf31 EngDocument40 pagesCaf31 EngCopperConceptNo ratings yet

- Ceramics: Classification and Properties of Ceramic MaterialsDocument36 pagesCeramics: Classification and Properties of Ceramic MaterialsMadhumita KumarNo ratings yet

- Formulae Stoichiometry and The Mole ConceptDocument6 pagesFormulae Stoichiometry and The Mole ConceptFaiza RizwanNo ratings yet

- Introduction To Column Buckling: ©teaching Resource in Design of Steel StructuresDocument35 pagesIntroduction To Column Buckling: ©teaching Resource in Design of Steel Structureshemant_durgawaleNo ratings yet

- The Hand Forged Knife PDFDocument75 pagesThe Hand Forged Knife PDFtobertoNo ratings yet

- SS06 Latest 1Document5 pagesSS06 Latest 1Hydro_Spa_FitnessNo ratings yet

- Silicone Rubber Compounds, Curing Agent Dicumyl Peroxide, 40-75 Shore A, Q, Peroxide Cure (M 608 - 5 DCP)Document2 pagesSilicone Rubber Compounds, Curing Agent Dicumyl Peroxide, 40-75 Shore A, Q, Peroxide Cure (M 608 - 5 DCP)sunitaNo ratings yet

- A Serie MouvexDocument3 pagesA Serie Mouvexrasotto100% (1)