Professional Documents

Culture Documents

Siemens MV Drives

Siemens MV Drives

Uploaded by

Jilla Baskar SathishOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Siemens MV Drives

Siemens MV Drives

Uploaded by

Jilla Baskar SathishCopyright:

Available Formats

Trends in MV Drive systems

a presentation by

SIMOVERT

DRIVE SYSTEMS PRODUCT OVERVIEW

MASTERMASTERDRIVES

45 - 1500 kW (4000 kW)

MV

550 - 3400 kW (7200 kW)

S

2500 - 100000 kW

D

1500 - 100000 kW

Low voltage inverters 230 - 690 V

Air/water cooled

Medium voltage inverters 2.3 kV / 3.3 kV / 4.16 kV / 6 kV / 6.6 kV Air/water cooled

Medium voltage inverters 1.0 - 23.0 kV

Medium voltage inverters 1.35 - 23.0 kV Air/water cooled

Air /water cooled

Drive Systems - Basic Principles

Voltage Source Inverter (VSI)

Product Overview Drive Systems 1 Drive Systems 2 The Driving Force Examples The Drive System Components The Power Section The Control System The Excitation System The Cooling System Conclusion Details / Drive Components

SIMOVERT MasterDrives SIMOVERT MV SIMOVERT S

SYM ASM

IG

Load Commutated Inverter (LCI)

ASM

SYM

Drive system components voltage source

2.3...36 kV 3~ 50/60 Hz

Circuit-breaker

Inverter transformer

Line-side rectifier DC link with capacitors

We take care of all drive components

Motor-side inverter

Combined motor-side CT / PT Sinusoidal EMC output filter (option) Squirrel-cage induction motor with medium-voltage winding

IM

Drive Systems Components Current source

or

Product Overview Drive Systems 1 Drive Systems 2

Examples The Drive System Components The Power Section The Control System The Excitation System The Cooling System

SM

We take care of all drive components

Conclusion Details / Drive Components

Development Of The Power Components

HVIGBT

MOS Tran FET sisto r

LVIGBT

IG C T

sym GTO .

asym . GTO

Thyris tor

fasthing switc iode D

Diode

Bipola r Trans istor

Transistor

Mercuryvapor rectifier

Fit for the future:

HV-IGBTs

Progress of Power Semi-Conductors

Index Drive System Design Principle of the 3-Level Inverter Comparison 2-Level and 3-Level Inverter SIMOVERT MV for 6 / 6.6 kV HV-IGBT Comparison of Power Semiconductors

technology and its propagation

HV-IGBT

bipolar transistors

LV-IGBT

GTO thyristor

IGCT SGCT fast switching diode

mercury arc rectifier

60s

silicon diode

70s 80s

90s

00s

time

HV-IGBT Fit For The Future And Reliable

! ! ! ! ! !

No snubber circuitry compact modular service-friendly Intrinsically current limiting no output filter high reliability short-circuit proof inverter

IGBT

Can be simply gated ! few power components ! high reliability HV-IGBTs - -the optimum power semiconductor - -the component HV-IGBTs the optimum power semiconductor the component for the future for the future We are technological pacemaker and market leader worldwide in the We are technological pacemaker and market leader worldwide in the development development and production of HV IGBTs (SIEMENS / /EUPEC) and production of HV IGBTs (SIEMENS EUPEC)

Comparison Of Power Semiconductors

HV-IGBT Low gating power Can be simply gated, few power components

GTO High gating power Complex gating, many power components

Hard-switching GTO (IGCT) High gating power Complex gating, many power components

Current-limiting Short-circuit proof inverter without any additional circuitry

Not current-limiting Short-circuit proof inverter only with additional circuit (an output filter is required)

Not current-limiting Short-circuit proof inverter only with additional circuitry (an output filter is required)

Absolutely no snubber circuitry required

Snubber circuitry required

di/dt snubber circuitry required

Leading-edge HV-IGBT - tested and well-proven

Control Characteristics of HV-IGBT and IGCT

approx. 800 A

approx. 1000A/"s

IGCT

gate current

low turn-on and turn-off current no on-state current in the respective condition simple and reliable control!

approx.5A approx.5A

IDG 4A

HV-IGBT t ("s)

approx. 6000A/"s

Iload

3-Level Medium-Voltage Inverter

Line-side rectifier

DC link

3-level inverter

+

3-ph. 2.3 - 36 kV AC 50/60 Hz

1 Hz

50/60 Hz DC

M 3~

100 Hz

Comparison, 2-Level / 3-Level Voltage-Source DC Link Converter

Phase-phase voltage U1

+

Ud

2-level inverter

A 3-level inverter B C D E

load current

Ud

(+) (0) () (+) (0)

+

0

Load current

0 5 10 time[msec] 15 20

3-Level Output Inverter

DC link

3-level inverter

V1

+

L1 L2 L3

V2

0

V5

V6

t1

U1 L1 L2 L3

Air or Water Cooling for all Ratings

Index Customer Benefits Requirements Product Overview The Standard All Branches All Applications Air or Water Cooling Power Range Supply Voltage For all Motors Basic Technical Figures

HV-IGBT Power Cards

air cooling

water cooling

Voltage 2.3 kV 3.3 kV 4.16 kV 6.0 kV 6.6 kV

Range in kW 640 to 2040 810 to 2560 1070 to 7500 550 to 1640 550 to 1640

Simovert S Current source Converter

Conclusion Details / Drive Components

Drive Systems Components Current source

or

Product Overview Drive Systems 1 Drive Systems 2

Examples The Drive System Components The Power Section The Control System The Excitation System The Cooling System

SM

We take care of all drive components

Conclusion Details / Drive Components

SIMOVERT S Current source

Basic Power Circuitry

Product Overview

simple design only few components extremely reliable and robust maintenance-free, fuseless

The Driving Force

isolated (ungrounded)

Examples The Drive System Components

short-circuit proof integrated dc link reactor water or air-cooled compact, complete inherent 4-quadrant operation

SM

The Control System

The Excitation System

world-wide tele-service via modem

The Cooling System Conclusion Details / Drive Components

Comparison SIMOVERT S - DC Drive

Product Overview Drive Systems 1 Drive Systems 2 The Driving Force Examples The Drive System Components

SIMOVERT S SIMOVERT S

DC Drive DC Drive

transformer transformer

transformer transformer

rectifier rectifier electronic electronic commutator commutator

rectifier rectifier mechanical mechanical commutator commutator

The Control System The Excitation System The Cooling System Conclusion Details / Drive Components

Simovert S : Main Characteristics

Examples Components The Control System The Excitation System

The Cooling System Conclusion Details / Drive Components

lowest number of components most robust switching elements (thyristors) highest efficiency simple power section circuitry fault tolerant (due to special dc link reactor arrangement) unlimited output power can be realized (above 100 MW) easy to handle no dV/dt stress on motor windings inherent 4quadrant operation inherent ride-through capability of up to 3 sec blackouts inherent immediate restart after power failure safe and simple synchronization of large synchronous motors (starting converter) last but not least: longest experience - proven technique

Starting Sequence of a Starting Converter

SIMOVERT S STARTING CONVERTER

SE

Simadyn D for soft-starter SD AUR

Simadyn D for process control communication SD AK

paralleling unit PSG

SA

SN

SA

SN

SM 1

SM 2

SErr

SErr

SIMOVERT S STARTING CONVERTER - Starting Sequence

START command from PCS START command to soft starter CLOSE command to breaker n

Simadyn D D for soft-starter soft-starter SD AUR AUR

Simadyn D D for process process control control communicommunication SD AK AK

Drive Systems 1

paralleling unit PSG

t CLOSE command to motor line breaker OPEN command to breaker

excitation controller SM 1 SM

motor is on line

SIMOVERT S HighSpeed Gas Compressor Drive 65 MW

Drive Systems 1 Product Overview Drive Systems 2 The Driving Force Examples The Drive System Components

The Control System The Excitation System The Cooling System Conclusion Details / Drive Components

8m

Application Areas In waterworks and water treatment plants. - Pumps for drinking water recovery and water distribution plants Slurry Pumps. In Oil and natural gas Industry. - Pumps and compressors. In Foodstuff Industry. - Centrifugal drives, Pumps, mixers, mills, Extruders. In Marine engineering. - Propeller drives, bow thrusters. In cement Industry. - Conveyor belt systems, blowers and crushers. In open pit mining - Conveyor belt systems, Vibrators, excavators, crushers In Power Utilities: - Pumps, blowers, coal crushers

Applications for Major Industry Sectors

Petrochemicals/ Fertilizers

Power Generation

Cement

Steel

Induced Draft / Forced Draft Fan, Primary Air Fan Boiler Feed Pump Circulating Water Pump Condensate Extraction Pump Air Compressors Coal Handling Plant Ash Handling Plant

Raw Mill Fan Raw Electrostatic Precipitator Fan Preheater Fan Calcinar Fan Cement Mill Fan Coal Mill Fan

Descaling Pump Waste Gas Fan Ladle Furnace Fan Induced Draft Fan at LD Furnace Crusher

Pumps, Compressors for Cooling Tower, Heat Exchanger Induced Draft / Forced Draft Fan used in Distillation and Furnace area Pumps for pipelines

Captive Power plants (CPP) for core sectors (mainly for CPPs >30MW )

An optimum solution for low rating MV motors (<1 MW)

Need for HLH Soultion

# There exists large installed base of motors of ratings 200KW & above in MV range in major industries # Majority of these motors are utilised for fan & pump applications having good energy savings potential # Big requirement of retrofitting these applications with VFD to achieve energy savings # Offering MV drives for such low ratings is very uneconomical

H-L-H is ideal cost effective solution for such retrofit cases

Schematic for HLH configuration

Step-Down Transformer kV/V

12-Pulse Rectifier

Inverter Output Sine Filter Step-Up Transformer V/kV MV/HV Motor

Single Line Schematic of Installed System

3 Phase, 11kV, 50Hz

VCB0 (Existing)

VCB1 Step-Down Transformer 11kV/1.7kV-1.7KV

Incoming Rectifier DFE Diode Front End 3-Level Inverter with HV-IGBTs 3.3kV SIMOVERT MV Drive System

VCB3 (Bypass Breaker)

Step-Up Transformer 3.3kV/11kV

VCB2

M

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Acer Predator Helios 300 N17C3 Compal LA-F991P DH53F Rev 1.C СхемаDocument73 pagesAcer Predator Helios 300 N17C3 Compal LA-F991P DH53F Rev 1.C СхемаMykola BasovychNo ratings yet

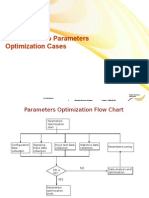

- (Huawei) WCDMA Radio Parameters Optimization CasesDocument88 pages(Huawei) WCDMA Radio Parameters Optimization CasesAbDalla Yabarow100% (13)

- SD Servo Driver Detail ManualDocument67 pagesSD Servo Driver Detail ManualAmaury OrtegaNo ratings yet

- CHE 702 ControlDocument13 pagesCHE 702 ControlSaswata PradhanNo ratings yet

- Silicon CapacitorDocument5 pagesSilicon Capacitorbsnl_cellone47No ratings yet

- Huawei 2G Alarm ListDocument5 pagesHuawei 2G Alarm ListAntariksha SinghNo ratings yet

- Pioneer DV 2022 Owners ManualDocument2 pagesPioneer DV 2022 Owners Manualricardo4roNo ratings yet

- MATLAB Crash CourseDocument11 pagesMATLAB Crash CourseMohsen salimyNo ratings yet

- Mtr10ii SeriesDocument290 pagesMtr10ii SeriesJavier MuñozNo ratings yet

- Assignment 1Document2 pagesAssignment 1Shivendra KeshariNo ratings yet

- Scopus IRD 2600 - 2800Document134 pagesScopus IRD 2600 - 2800Utkarsh SaxenaNo ratings yet

- Amp Boards SettingsDocument75 pagesAmp Boards SettingsJorge100% (1)

- Pendo Power Router User ManualDocument2 pagesPendo Power Router User ManuallunwenNo ratings yet

- MIL DTL 17 Cable DescriptionsDocument1 pageMIL DTL 17 Cable DescriptionsvkmsNo ratings yet

- Wireless Remote Controls: PS:price Based On The Quantity, Negotiable Price Here Is For One of Its Type Just For ReferenceDocument21 pagesWireless Remote Controls: PS:price Based On The Quantity, Negotiable Price Here Is For One of Its Type Just For ReferenceashfaqNo ratings yet

- Module 1 Question BankDocument1 pageModule 1 Question BankAbcNo ratings yet

- Antenna Theory & DesignDocument19 pagesAntenna Theory & DesignNabeel A K JadoonNo ratings yet

- MDR 3 Pressure SwitchDocument7 pagesMDR 3 Pressure SwitchFranci RamosNo ratings yet

- Sony Sa Wmsp85Document12 pagesSony Sa Wmsp85Joseni Figueiredo100% (1)

- Ezmax Electronic Limited Ez8898b500 4974Document1 pageEzmax Electronic Limited Ez8898b500 4974Farhan MubarokNo ratings yet

- CKP Notes Vol 2 VERSION 2Document116 pagesCKP Notes Vol 2 VERSION 2Sivasankar AkcNo ratings yet

- ECE 121B: Homework 4 SolutionsDocument6 pagesECE 121B: Homework 4 Solutionscourse her o daNo ratings yet

- ElectricalDocument27 pagesElectricaleunica_dolojan100% (1)

- Cel MicroprojectDocument17 pagesCel MicroprojectNeha AnkushraoNo ratings yet

- Input & OutputDocument65 pagesInput & Outputmas akhbaruddinNo ratings yet

- DS2430Document16 pagesDS2430giulian2009No ratings yet

- NAD C521i Service ManualDocument33 pagesNAD C521i Service ManualAttila KissNo ratings yet

- Taiwan Kolin Vs Kolin Electronics FactsDocument1 pageTaiwan Kolin Vs Kolin Electronics FactsHarold Estacio100% (1)

- Measurement of Voltage Standing Wave RatioDocument12 pagesMeasurement of Voltage Standing Wave RatioDan MwaiNo ratings yet

- Impedance and Admittance of A Parallel RLC CircuitDocument13 pagesImpedance and Admittance of A Parallel RLC Circuit2XWinNo ratings yet