Professional Documents

Culture Documents

XDRCU ALT 400kV - 2

XDRCU ALT 400kV - 2

Uploaded by

Brambilla56Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

XDRCU ALT 400kV - 2

XDRCU ALT 400kV - 2

Uploaded by

Brambilla56Copyright:

Available Formats

XLPE High Voltage Cables

Single-core Cable for 400/230 (420) kV

with Copper wire screen and Aluminum laminated sheath Cable layout Copper conductor, round stranded or segmented optionally with longitudinal water barrier Inner semiconductive layer firmly bonded to the XLPE insulation XLPE main insulation, cross-linked Outer semiconductive layer firmly bonded to the XLPE insulation Copper wire screen as short-circuit current carrying component with semi-conductive swelling tapes above and below as longitudinal water barrier Aluminum foil, overlapped as radial diffusion barrier laminated to the oversheath Thermoplastic oversheath as mechanical protection optionally with semi-conductive and/or flameretardant layer Features of metallic sheath Low weight Low losses Low cost Internationally proven design Production process The inner semiconductive layer, the XLPE main insulation and the outer semiconductive layer are extruded in a single operation applying a dry curing and a water or nitrogen cooling method. Applicable standards IEC 62067 XDRCU-ALT

Technical data

Copper conductor cross-section mm

2

Outer diameter (approx.) mm 108 109 110 112 116 116 123 131 132

Cable weight (approx.) kg/m 16 17 18 21 24 25 28 33 38

Capacitance

Impedance (90C, 50 Hz) /km 0.23 0.22 0.20 0.19 0.19 0.18 0.18 0.17 0.17

Impedance (90C, 50 Hz)

Surge impedance

Min. bending radius mm 2300 2300 2300 2400 2450 2450 2600 2700 2700

Max. pulling force kN 30 38 48 60 72 84 96 120 150

kcmil 1000 1250 1600 2000 2400 2750 3200 4000 5000

F/km 0.12 0.13 0.15 0.17 0.19 0.20 0.20 0.21 0.26

/km 0,15 0,14 0,13 0,12 0,12 0,11 0,11 0,10 0,09

56 53 48 45 43 41 40 39 35

500 630 800 1000 1200 1400 1600 2000 2500

Ampacity

Diectly buried

Diectly buried 20C 1.0 Km/W A 822 943 1064 1250 1351 1452 1553 1727 1900

In ducts

In ducts 20C 1.0 Km/W A 776 895 1014 1189 1268 1362 1456 1638 1804

In free air

In free air 35C A 1015 1199 1382 1672 1835 1996 2157 2480 2803

In ductbank 15C 0.8/1.0 Km/W A 829 951 1072 1259 1363 1465 1567 1762 1946

Directly buried

Ambient temp. Soil resistivity mm

2

20C 1.0 Km/W A 751 853 954 1120 1209 1294 1379 1513 1646

20C 1.0 Km/W A 740 843 945 1106 1192 1276 1359 1573 1725

35C A 928 1083 1237 1492 1630 1765 1899 2146 2392

40C 1.4 Km/W A 548 616 683 795 855 913 970 1054 1137

kcmil 1000 1250 1600 2000 2400 2750 3200 4000 5000

500 630 800 1000 1200 1400 1600 2000 2500

Calculation basis: Conductor temperature 90C, 50 Hz, load factor 1.0, laying depth 1200 mm, phase distance at flat formation 30 cm Earthing method: Single-Point Bonding or Cross-bonding Values apply for cables with rated voltages from 380 kV to 400 kV acc. to IEC 62067 Brugg Kabel AG 2008, Subject to modifications

You might also like

- Ultimate Guide: Wiring, 8th Updated EditionFrom EverandUltimate Guide: Wiring, 8th Updated EditionRating: 3.5 out of 5 stars3.5/5 (4)

- Bab Elektrik: Suatu PengenalanDocument82 pagesBab Elektrik: Suatu PengenalanSeindahNyaNo ratings yet

- BS7870-4.10 33kv Single Core Un ArmouredDocument3 pagesBS7870-4.10 33kv Single Core Un Armouredrudypl100% (1)

- EHV CableDocument39 pagesEHV CableSharib JalisNo ratings yet

- Bkag Xdrcu-Alt 220l127 l245l KV enDocument1 pageBkag Xdrcu-Alt 220l127 l245l KV enarisan47No ratings yet

- Xple Low Voltage Cable Hal58 Nfa2x PDFDocument1 pageXple Low Voltage Cable Hal58 Nfa2x PDFAgung Tri PamungkasNo ratings yet

- Aluminium 66 132kVDocument3 pagesAluminium 66 132kVashokkahirwarNo ratings yet

- Electrical Generator Course GEOL-TAR500L4R r2 PrintDocument40 pagesElectrical Generator Course GEOL-TAR500L4R r2 PrintPetru BurgheleaNo ratings yet

- XDRCU PBT 400kVDocument1 pageXDRCU PBT 400kVgovindarulNo ratings yet

- Deetap ® Du: Off-Circuit Tap-ChangerDocument6 pagesDeetap ® Du: Off-Circuit Tap-ChangervitalstyleNo ratings yet

- Trihal - Up To 3 150 kVA: Cast Resin TransformersDocument8 pagesTrihal - Up To 3 150 kVA: Cast Resin TransformersReyaz Basha100% (1)

- Pantografo Coelme 1Document2 pagesPantografo Coelme 1Alexander GuzmánNo ratings yet

- MCCB HavellsDocument39 pagesMCCB Havells4usangeetNo ratings yet

- Ecodesign Tricast FinalDocument8 pagesEcodesign Tricast FinalRizal IdrisNo ratings yet

- 0.6/1 KV Xlpe Insulated Single Core Cables With Copper ConductorDocument1 page0.6/1 KV Xlpe Insulated Single Core Cables With Copper Conductorgari_monsantoNo ratings yet

- Porcellana CatalogoDocument76 pagesPorcellana CatalogoIsabelleFlorNo ratings yet

- Day-5 Cable Sizing Calculation: Hyderabad Institute of Electrical EngineersDocument30 pagesDay-5 Cable Sizing Calculation: Hyderabad Institute of Electrical Engineersajayvarma026260% (1)

- Medium-Extra High Voltage Power CablesDocument56 pagesMedium-Extra High Voltage Power CablesApichartj Jusuay100% (2)

- Compact Integrated Distribution Substation CIDS CatalogDocument12 pagesCompact Integrated Distribution Substation CIDS Catalogalexns84No ratings yet

- Cable SizesDocument2 pagesCable SizesBassem MostafaNo ratings yet

- LS XLPE & AccessoriesDocument26 pagesLS XLPE & AccessoriesNavneethNo ratings yet

- Capacitors in Electric Drive ApplicationDocument38 pagesCapacitors in Electric Drive ApplicationKidus DawitNo ratings yet

- 15kv Phelps DodgeDocument4 pages15kv Phelps DodgeJuan E Torres M100% (1)

- Under Water Welding: Presented by Name Roll NODocument20 pagesUnder Water Welding: Presented by Name Roll NOPranay SudhanNo ratings yet

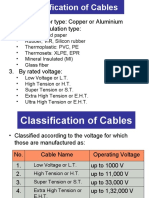

- by Conductor Type: Copper or Aluminium 2. by Basic Insulation TypeDocument27 pagesby Conductor Type: Copper or Aluminium 2. by Basic Insulation TypeRane SiddeshNo ratings yet

- En Drazni Pristroje VenkovniDocument10 pagesEn Drazni Pristroje Venkovniazulgrana77No ratings yet

- Pantogrado Coelme 2Document2 pagesPantogrado Coelme 2Alexander GuzmánNo ratings yet

- Medium Voltage Power CableDocument3 pagesMedium Voltage Power CableGuruh Panji SukardiNo ratings yet

- UPDATED AH Furutec AH Aluminium Product Catalogue-22022021 - 1657770295Document33 pagesUPDATED AH Furutec AH Aluminium Product Catalogue-22022021 - 1657770295mel perezNo ratings yet

- N2XBYDocument5 pagesN2XBYcyuenkNo ratings yet

- Flow Measurement of Liquids and Gases: OperationDocument8 pagesFlow Measurement of Liquids and Gases: Operationابزار دقیقNo ratings yet

- BobinasDocument16 pagesBobinasingmontoya704754No ratings yet

- Unishield - Uniblend 5kvDocument2 pagesUnishield - Uniblend 5kvfmillan5018No ratings yet

- PowerDocument10 pagesPowerThomas Kristianto Edhi WangkoroNo ratings yet

- K Series FansDocument2 pagesK Series FansMakarand KendreNo ratings yet

- Research On Underground CablesDocument32 pagesResearch On Underground CablesAwais IjazNo ratings yet

- 2xs (FL) H-GC-WTC 1x500rm-180 60kv Iec 60840 - Aeic Cs9-06 - Set Ingenieros - Seat Mercado Santa AnitaDocument3 pages2xs (FL) H-GC-WTC 1x500rm-180 60kv Iec 60840 - Aeic Cs9-06 - Set Ingenieros - Seat Mercado Santa AnitaedwinljbNo ratings yet

- Data Kabel HoistDocument1 pageData Kabel HoistAchmad FernandezNo ratings yet

- POLYCAB - MV Power Cable IEC 60502 2Document32 pagesPOLYCAB - MV Power Cable IEC 60502 2AmitabhaNo ratings yet

- High Frequency CoaxialDocument32 pagesHigh Frequency CoaxialMozArt FirmanNo ratings yet

- Wiring For Tomorrow Today: ApplicationDocument1 pageWiring For Tomorrow Today: Applicationgari_monsantoNo ratings yet

- Chapter 4 Cable Rating-Update - 230722 - 230401Document27 pagesChapter 4 Cable Rating-Update - 230722 - 2304012022605212No ratings yet

- High Voltage Cable PDFDocument2 pagesHigh Voltage Cable PDFDavid CharcapeNo ratings yet

- Leaflet UG ZS1 DBB Rev 2013 09 enDocument2 pagesLeaflet UG ZS1 DBB Rev 2013 09 enIvanNo ratings yet

- Leader Cable - 132kVDocument8 pagesLeader Cable - 132kVTeo Yi LinNo ratings yet

- 2060Z ITEL-L Adb Taxi EmbutidaDocument2 pages2060Z ITEL-L Adb Taxi Embutidagiant360No ratings yet

- UC ABC CatalogueDocument19 pagesUC ABC CataloguechanwfungNo ratings yet

- MFLRF114FSCTCPA002 1-14flexDocument1 pageMFLRF114FSCTCPA002 1-14flexmicroqualNo ratings yet

- MV Cable Jointing TerminationDocument27 pagesMV Cable Jointing Terminationcharleselitb92No ratings yet

- York R410ADocument2 pagesYork R410AArabiat76No ratings yet

- AMEC SPIE ERS PresentationDocument32 pagesAMEC SPIE ERS PresentationjulesjusayanNo ratings yet

- 2.4 KV GENERAL CABLE PDFDocument2 pages2.4 KV GENERAL CABLE PDFjhernandezelNo ratings yet

- Eat0n VCBDocument1 pageEat0n VCBE.ANANDANNo ratings yet

- Power CablesDocument8 pagesPower Cableslam2660% (1)

- PCV Cable-Current RatingDocument11 pagesPCV Cable-Current RatingalekyaNo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)