Professional Documents

Culture Documents

Helical Pile Datasheet

Helical Pile Datasheet

Uploaded by

Avi ShonbergOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Helical Pile Datasheet

Helical Pile Datasheet

Uploaded by

Avi ShonbergCopyright:

Available Formats

HelicalPile TechnicalDataSheet

March2011

Unit714SmallfordWorks,SmallfordLane, St.Albans,Hertfordshire,UK,AL40SA. Tel:+44(0)1727821282.Fax:+44(0)1727828098.

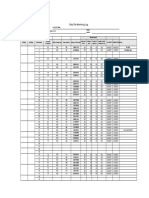

1.0 Introduction ScrewFastFoundationsLtdarethelargestandlongestestablishedoperatinghelicalpiledesigner, supplierandinstallationcompanyintheUK.In2005wewereawardedthehighlycovetedQueens Award for Enterprise in the category of Innovation. As a founding member of the international InstitutionofHelicalPileEngineering(IHPEng),ScrewFastFoundationsareattheforefrontofthe global helical piling industry and lead the way with regard to best practice, quality, health and safety, research & development, pile testing, experience & technical knowhow, standards and specification. The company is led by a team of competent, experienced design engineers, project and procurement managers, and technicians. The design team consists of highly qualified and chartered civil, geotechnical and structural engineers and is backed up by a technical team of specialistmechanicalengineersandexperiencedtechnicians. 2.0 DesignRequirements Anelasticanalysismodelcanbeusedtoevaluatedeformationunderload.ScrewFastFoundations LtduseOasysGSA. 5.1 Shaft ShaftsectionsareformedfromstandardstructuralhollowsectionsinGradeS355tothenecessary impact property using BS EN 10210 with longitudinal weld seam or seamless, or BS EN 10219 material with longitudinal weld seam. Outside Diameters (OD) used are generally defined by standardSCIBluebooktablesorsimilar.Thewallthicknessisgenerally8or10mm,butothersizes andspecificationsareavailableforusedependingonapplication. OD 60.3 76.1 88.9 114.3 139.7 168.3 193.7 219.1 244.5 Table1Commonshaftoutsidediameters(mm) 273.0 323.9 4.2 LateralLoading LateralloadingrestraintonverticalpilesisanalysedusingmethodssuggestedbyBroms(1964)or Brinch Hansen (1961). These depend on pile length and stiffness, ground stiffness, and the stiffnessoftheconnectionattheheadofthepile.Restraintcanalsobeachievedbyrakingpiles (individually or within a group), or enhanced by the use of Angel wings on vertical piles to increasetheprojectedsurfaceareaactingagainstthesoil. Thesummationoftheindividuallateralcapacitiesprovidestheultimatelateralresistanceofapile groupwherepilesareconsideredaswidelyspacedinaccordancewithCIRIAReport103Designof LaterallyLoadedPiles. 5.0 StructuralDesign

Pleaserefertothewebsiteatwww.screwfast.com ortheIHPEngwebsitewww.ihpeng.com formoreinformation,casestudiesandphotos.

They may include anallowance for sacrificial cross sectional loss, galvanizing to BS ENISO 1461, cathodicprotectionbyprovisionofsacrificialanodes,ortheuseofacoatingsystem. 7.0 Fabrication&Quality

FabricationofhelicalpilesistoBSEN10902.PleaserefertoSFFQR054HelicalPileSpecification formoreinformation. ScrewFastFoundationsmaintainsanISO9001(UKAS)accreditedQualityManagementSystemand alsocomplieswithotherqualityauditsystemsasindicatedbelow.Thisincludesfulltraceabilityof allmaterials,itemsandworkmanship(weldsandinspections). 8.0 Installation,Torque&Equipment

Structural design is undertaken to BS EN 19935 and BS EN 199311. Please refer to SFFQR054 HelicalPileSpecificationformoreinformation.

For information on ScrewFast Foundations requirements for pile design, including site investigation,loadingandotherrequirements,pleaserefertotheseparateScrewFastFoundations document SFFQR057 Guidance on General Requirements for Pile Design which can be found on theScrewFastwebsite. 3.0 Specification

ScrewFastFoundationsoperateandmaintainthelargestandbroadestrangeoftorquedriveheads for helical pile use in the UK, from 5kNm up to 250kNm capacity. What is believed to be the worlds largest dynamometer for torque head calibration has been developed to operate and maintain a stringent calibration, inspection and maintenance procedure for all drive heads. ScrewFastsmethodsaretraceabletoUKAScertifiedinstrumentsincompliancewithScrewFasts ISO 9001 (UKAS) accreditation. The dynamometer is backed up by torque transducers, which accuratelymeasuretorquebasedonelectronicsensorsbuiltintodoubleflangedcouplingswhich are fitted between the pile driving heads and the piles. Electronic data logging options showing date,time,locationandtorqueareavailable. Afeatureofhelicalpilingtechnologywhichcanprovideassuranceofpilecompetenceisderived frommonitoringtheinstallationtorquewhilescrewingthepileintotheground.However,thishas to be assessed with due regard given the possible inaccuracies in both the measurement of the installationtorque(onethatreliesonpressureonly),aswellasinpredictingtherequiredtorque. Installation torque predictions can vary considerably depending on soil types and pile configuration. Torque measurements during installation can reveal useful information about the competence of the pile and may also indicate whether soil reports are compatible with the evidencefromtorquereadings.Itisthereforeimportanttogetaccuratereadings,especiallyover the final phases of installation. Countrywide installation experience has led to a large torque databaseforvarioussoilconditions. Torqueheadsarepoweredfromthehydraulicsofstandardexcavators(5tonneto45tonne)and powervariesdependingonpressureoutput.Pleasecontactthetechnicaldepartmentforadvice. 9.0 PileTesting

PleaserefertotheseparateScrewFastFoundationsdocumentSFFQR054HelicalPileSpecification writteninlinewiththeICESpecificationforPilingandEmbeddedRetainingWalls(2007)whichcan befoundontheScrewFastwebsite. 4.0 GeotechnicalDesign

AFEMelasticanalysismodelcanbeusedtoevaluatedeformationandsettlement,translationand rotationofthepile(group)underaxialandlateralload.ScrewFastFoundationsLtduseOasysGSA andOasysALPforthispurpose. 4.1 AxialLoading Axial (tension and compression) capacity is calculated from the sum of the individual helix plate capacities using effective stress bearing theories in coarse grained materials and the Brinch Hanson (1961, 1968, 1978) & Meyerhof (1963) methods in fine grained materials. Various other possiblefailuremechanisms(includingcylindricalpulloutfailure)arealsoanalysed. Helices are strategically positioned for best performance and are spaced such that their zone of influence does not overlap (or suitable reduction factors are applied). ScrewFast Foundations conservativelyignoreskinfrictionandendbearingontheshaft. Installedaxialpilecapacitiesofuptoapproximately3000kNULSincompressionand1800kNULS in tension are currently achievable, and with future developments its likely that 5000kN ULS compressionand3000kNULStensionwillbepossible. Practicalguidanceonhelicalpiles(designandinstallation)canbefoundinH.PerkosHelicalPiles (2009)andothersources. ScrewfastProductsareProtectedbyCopyright,PatentsFiledandPending,UK&Foreign,No.s: GB2360809,GB2390128,GB2412686,GB2413164,GB2426777,GB2418949,GB2420581,GB2431938, 816230.7,903579.1,908684.4,1002308.3,1002310.9,1005971.5.

Thechoiceofshaftsectionisbasedprimarilyonitstorsionalcapacity,butbendingcapacity,axial crosssectionresistanceanddurabilityarealltakenintoconsideration. 5.2 Helices HelixplatesarepressedfromstandardstructuralrolledproductsinGradeS275,S355orS450.The thicknessoftheplatecanbefrom10to35mmthicknessdependingonthenecessarystructural capacityrequired.Theoutsidediameterofthehelixplatecanvaryfrom250upto1200mmand canbepressedtovariouspitchesdependingontheapplicationandgroundconditions. In order to provide accurate calculated working capacity and torsional output, ScrewFast ensure that the helix is true, i.e. of constant gradient, with the lead and trailing edges parallel, and radiallyperpendiculartothepileshaft. 5.3 Connections WeldedandboltedconnectionsarealldesignedtoBSEN19935andBSEN199311. 6.0 DurabilityDesign

ScrewFastFoundationshaveundertakenasubstantialnumberofpiletestsonhelicalpiles(often at our own instigation) over a wide range of applications and soil types. This includes cyclical testingattheTransportResearchLaboratory,maintainedworkingloadandultimateloadtestson workingandpreliminarypiles.Alltestdataisstoredinourelectronicdatabaseforongoinganalysis toaiddesigndevelopmentfordifferentpileconfigurations,soiltypes,andloadapplications. 10.0 Records

Forsteelhelicalpiles,adurabledesigncanbeachievedbyanumberofdifferentmeansdepending ontherequireddesignlifeandtheenvironmentalconditionsintowhichthepileisinstalled.These protectionsystemswillgenerallybeeither: 1. 2. 3. Electrolytic(includingcathodicandsacrificial)systems Barriersystems;or AcombinationofElectrolyticandBarriersystems

Arecordismadeofeverypileinstallationonsiteandeachischeckedandsignedoffbyamember of the project design team. Any onsite design variation requests are referred back to the design teamforinstructionandapprovalduringinstallation.ScrewFastFoundationsoperatea24/7help deskforallourprojects.

Member of

CompanyRegistrationNo:3902417 VatNo:741032576

No. 510514

No. 77558

No. GB 9498

You might also like

- AKKE2211-SDO-MOS-02 - Hydraulic Drop Hammer PilingDocument6 pagesAKKE2211-SDO-MOS-02 - Hydraulic Drop Hammer PilingMuhammad Hamidy KamarulZamanNo ratings yet

- National Productivity and Quality Specifications (NPQS) : C4-30 Pile TestingDocument36 pagesNational Productivity and Quality Specifications (NPQS) : C4-30 Pile TestingJacky TiongNo ratings yet

- Corelight Bro Cheatsheets 2.6Document6 pagesCorelight Bro Cheatsheets 2.6AlecNo ratings yet

- Civil Engineering ExaminationDocument4 pagesCivil Engineering Examinationshardultagalpallewar100% (2)

- Single Free-Body ProceduresDocument3 pagesSingle Free-Body Proceduresa_mohamedenNo ratings yet

- Ruukki Splicing of Steel Piles by WeldingDocument8 pagesRuukki Splicing of Steel Piles by Weldingyanickdouce1206100% (1)

- (Livro) Helical Pile Engineering Handbook PDFDocument51 pages(Livro) Helical Pile Engineering Handbook PDFTimoteo RochaNo ratings yet

- GEOTECHNIC 2 - Site InvestigationDocument14 pagesGEOTECHNIC 2 - Site InvestigationMohd Farhan Syazwan100% (1)

- Raymond Pile BrochureDocument16 pagesRaymond Pile Brochuremoyarek100% (4)

- Macro & Mini PilesDocument1 pageMacro & Mini PilesAnonymous JZFSB3D0% (1)

- Specifying Bolt Length For High-Strength Bolts: Manual of Steel ConstructionDocument12 pagesSpecifying Bolt Length For High-Strength Bolts: Manual of Steel ConstructionalbertoxinaNo ratings yet

- S21-CnS Roads and DrainsDocument39 pagesS21-CnS Roads and DrainsLukeNo ratings yet

- QCS 2014 - Section 2, Part 14 Appendix ADocument1 pageQCS 2014 - Section 2, Part 14 Appendix AJenna Mortel-DoligolNo ratings yet

- Design Checklist Interconnection Diagram: Document No.: Originated BY: DateDocument4 pagesDesign Checklist Interconnection Diagram: Document No.: Originated BY: DatefreijNo ratings yet

- Building TolerencesDocument9 pagesBuilding TolerencesmasteriragaNo ratings yet

- Hardwood 1999Document43 pagesHardwood 1999Salvador Ramos GomezNo ratings yet

- Checklist For 33kV DP Structure Design & DrawingDocument4 pagesChecklist For 33kV DP Structure Design & DrawingRupesh KhandekarNo ratings yet

- MOS Pile DrivingDocument6 pagesMOS Pile DrivingstephonNo ratings yet

- Estimate Pile Capacity PDFDocument307 pagesEstimate Pile Capacity PDFkhun_kaeNo ratings yet

- J105 Cube Testing FormDocument1 pageJ105 Cube Testing Formkoh whNo ratings yet

- Screw Pile Checklist September 2012Document2 pagesScrew Pile Checklist September 2012Abdul WazedNo ratings yet

- Aggregate Sub Base - Road Base Report SummaryDocument1 pageAggregate Sub Base - Road Base Report SummaryAbdul100% (1)

- Sikagrout Test MethodDocument3 pagesSikagrout Test MethodDä-niel Ballesteros-LeónNo ratings yet

- ASCE 7.10 - Wind Loads PDFDocument60 pagesASCE 7.10 - Wind Loads PDFOsama TamariNo ratings yet

- Profis Anchor 2.5.0 HILTIDocument6 pagesProfis Anchor 2.5.0 HILTIALONSO GOMEZNo ratings yet

- Pullout TestDocument3 pagesPullout TestAvinash Lal100% (1)

- Are They Pour Lines or Cold Joints - tcm45-348413Document4 pagesAre They Pour Lines or Cold Joints - tcm45-348413محمد كاشف جاويدNo ratings yet

- Grade SlabDocument9 pagesGrade SlabDagur PavanNo ratings yet

- Daily Pile Monitoring Log: Pile Grid ID '' ReinforcementDocument2 pagesDaily Pile Monitoring Log: Pile Grid ID '' ReinforcementKarl ToddNo ratings yet

- Driven Cast in Situ PilesDocument17 pagesDriven Cast in Situ PilesSonu KumawatNo ratings yet

- Issues in Evaluating Capacity of Rock Socket FoundationsDocument11 pagesIssues in Evaluating Capacity of Rock Socket FoundationspaducoNo ratings yet

- Methods of Piles InstallationDocument5 pagesMethods of Piles InstallationAsif KhanNo ratings yet

- Lighting SystemDocument10 pagesLighting SystemJyoti ShekharNo ratings yet

- Cold Weather ConcretingDocument2 pagesCold Weather ConcretingBoris DikovNo ratings yet

- Measurement and Prediction of Construction Vibration Affecting Sensitive LaboratoriesDocument7 pagesMeasurement and Prediction of Construction Vibration Affecting Sensitive Laboratoriesfandy sipataNo ratings yet

- Base Isolated Building Design Based On ASCE 7-16/10 Design CriteriaDocument3 pagesBase Isolated Building Design Based On ASCE 7-16/10 Design CriteriaBudi AgungNo ratings yet

- Post Tension SpecificationDocument7 pagesPost Tension SpecificationsweetlaicheeNo ratings yet

- Field Inspection of PCCDocument55 pagesField Inspection of PCCGilbert chuksNo ratings yet

- PreviewpdfDocument90 pagesPreviewpdfSheeraz AhmedNo ratings yet

- Sampling Frequency of Concrete CubeDocument2 pagesSampling Frequency of Concrete CubeRAJESH KUMAR SRIVASTAVA100% (1)

- Lateral Load PileDocument21 pagesLateral Load PileCarlos FilipusNo ratings yet

- ACI 318-14 ColumnaDocument4 pagesACI 318-14 ColumnaMoy ReapNo ratings yet

- Basics of Post Installed Rebar Connections: 1 ApplicationsDocument33 pagesBasics of Post Installed Rebar Connections: 1 ApplicationsHaitham KayyaliNo ratings yet

- Correlation of Soil Parameters and Bearing CapacityDocument62 pagesCorrelation of Soil Parameters and Bearing CapacityArham SheikhNo ratings yet

- Checklist-Structural Concrete Post PouringDocument1 pageChecklist-Structural Concrete Post Pouringajit karandikarNo ratings yet

- Determination of Radial Coefficient of Consolidation Using Log I T I MethodDocument10 pagesDetermination of Radial Coefficient of Consolidation Using Log I T I MethodKlaus HenriqueNo ratings yet

- Final RerortDocument14 pagesFinal Rerortsrigirisetty208No ratings yet

- CapwapDocument2 pagesCapwapjilofeNo ratings yet

- Method Statement For Core CuttingDocument5 pagesMethod Statement For Core Cuttingahmedshah512No ratings yet

- Pile Load TestDocument10 pagesPile Load TestAlhaz Uddin100% (1)

- Pile Analysis in Accordance With EN 1997-1:2004 Incorporating Corrigendum Dated February 2009 and The Recommended ValuesDocument4 pagesPile Analysis in Accordance With EN 1997-1:2004 Incorporating Corrigendum Dated February 2009 and The Recommended ValuesRuemu Godwin InikoriNo ratings yet

- Specification For Testing of Bored PileDocument22 pagesSpecification For Testing of Bored PileAlly KhooNo ratings yet

- EDO-PLN-QAC-GNR-INT-XXX-013-110-111-Rev-A.SAMPLE PROJECT QUALITY MANAGEMENT FOR STORAGE TANK PDFDocument31 pagesEDO-PLN-QAC-GNR-INT-XXX-013-110-111-Rev-A.SAMPLE PROJECT QUALITY MANAGEMENT FOR STORAGE TANK PDFErol DAĞNo ratings yet

- Plastic Bending of SteelDocument12 pagesPlastic Bending of SteelJohn Diete-Koki100% (1)

- QCS 2010 Part 6.03 EarthworksDocument21 pagesQCS 2010 Part 6.03 EarthworksRotsapNayrb100% (2)

- Stone Pitching DetailDocument1 pageStone Pitching DetailTwahirwa JoelsonNo ratings yet

- Syed Mazhar PHD Qualifying Exam PaperDocument3 pagesSyed Mazhar PHD Qualifying Exam PaperVinayaka RamNo ratings yet

- @method Statement For Static Load TestDocument76 pages@method Statement For Static Load TestTrương Văn ĐồngNo ratings yet

- SikaTack Panel System - Sheet 1 Cert 05 - 4218Document10 pagesSikaTack Panel System - Sheet 1 Cert 05 - 4218Peter DudasNo ratings yet

- Numerical Methods and Implementation in Geotechnical Engineering – Part 1From EverandNumerical Methods and Implementation in Geotechnical Engineering – Part 1No ratings yet

- Australian STDRD For ScaffDocument1 pageAustralian STDRD For ScaffjaweriaNo ratings yet

- 275HDV High Voltage DetectorDocument5 pages275HDV High Voltage DetectorByron PanchiNo ratings yet

- Career Mentor NotesDocument8 pagesCareer Mentor NotesQueen MakerNo ratings yet

- Handbook 2020-21 FinalDocument216 pagesHandbook 2020-21 FinalwebiisNo ratings yet

- Final Review QuestionsDocument5 pagesFinal Review QuestionsJeremy PearsonNo ratings yet

- Typical Values of Soil Friction Angle For Different Soils According To USCSDocument5 pagesTypical Values of Soil Friction Angle For Different Soils According To USCSCHIKARANo ratings yet

- Pagcor v. Rilloroza (Digest)Document5 pagesPagcor v. Rilloroza (Digest)Eumir SongcuyaNo ratings yet

- Nail Care w1 Sample DLLDocument2 pagesNail Care w1 Sample DLLWella Formento100% (2)

- Graphic Design Basics: The Elements and Principles of Graphic Design Used in Desktop PublishingDocument64 pagesGraphic Design Basics: The Elements and Principles of Graphic Design Used in Desktop PublishingKris AdiwijayaNo ratings yet

- BT Lifter - LHM230Document26 pagesBT Lifter - LHM230Efrain AvilaNo ratings yet

- Ultra Cam Eagle, Understanding The New SensorDocument6 pagesUltra Cam Eagle, Understanding The New Sensorraintree1980No ratings yet

- K-Pipe 50 - 01-20130710Document23 pagesK-Pipe 50 - 01-20130710MateuszNo ratings yet

- OMAE2011-50201 Fatigue Assessment of Aluminum Ship Details by Hot-Spot Stress ApproachDocument10 pagesOMAE2011-50201 Fatigue Assessment of Aluminum Ship Details by Hot-Spot Stress ApproachLiu YangtzeNo ratings yet

- Avolan IsDocument3 pagesAvolan IsIván Cuevas100% (1)

- 02 Video 1 The Corporation As GovernmentDocument2 pages02 Video 1 The Corporation As GovernmentAbegail MaupoyNo ratings yet

- Advert For 50 Posts - Electrical Technicians DraftDocument7 pagesAdvert For 50 Posts - Electrical Technicians DraftEM NemiNo ratings yet

- Webnotice Swoa 2021-22-Phase 2Document64 pagesWebnotice Swoa 2021-22-Phase 2Ramesh SahuNo ratings yet

- SE Chapter04 Software Requirement AnalysisDocument11 pagesSE Chapter04 Software Requirement AnalysisYóshíí Éú BëëlNo ratings yet

- March 2021 INTERNAL AUDITDocument5 pagesMarch 2021 INTERNAL AUDITMUHAMMAD NABIL BIN MOHD NAZRI MoeNo ratings yet

- Espiritu vs. Cipriano and CA, G.R. No. L-32743 February 15, 1974Document4 pagesEspiritu vs. Cipriano and CA, G.R. No. L-32743 February 15, 1974Anasor Go100% (1)

- Ford Engine Troubleshooter Reference ManualDocument42 pagesFord Engine Troubleshooter Reference Manualleeroyhill100% (4)

- Corporatre ValuationDocument46 pagesCorporatre ValuationVipin MehtaNo ratings yet

- Handayani (2021)Document13 pagesHandayani (2021)ArthaNo ratings yet

- Valve II Valve II Valve II: Dome Dome DomeDocument2 pagesValve II Valve II Valve II: Dome Dome DomeShukla SuyashNo ratings yet

- Hopcraft Et Al-2008-Australian Dental Journal PDFDocument7 pagesHopcraft Et Al-2008-Australian Dental Journal PDFtea metaNo ratings yet

- B. Tech. CSE Course Structure MLSU 2021-22 and 2022-23 (3rd and 4th Sem)Document3 pagesB. Tech. CSE Course Structure MLSU 2021-22 and 2022-23 (3rd and 4th Sem)HimanshuNo ratings yet

- 1550 TractorDocument277 pages1550 TractorLouis TaftaNo ratings yet

- CDI NORSOK Testing Elastomers Tech Report WebDocument2 pagesCDI NORSOK Testing Elastomers Tech Report WebwholenumberNo ratings yet

- Guia - SkyrimDocument5 pagesGuia - SkyrimQualidadeSidertecnicNo ratings yet

- An Essay On Farming in IndiaDocument3 pagesAn Essay On Farming in Indiajagpreet100% (1)