Professional Documents

Culture Documents

The Pakistan Steel Mills

The Pakistan Steel Mills

Uploaded by

Talha MehmoodOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Pakistan Steel Mills

The Pakistan Steel Mills

Uploaded by

Talha MehmoodCopyright:

Available Formats

The Pakistan Steel Mills, PSM, is the state-owned producer of long rolled steel and heavy iron products

in Karachi, Sindh Province of Pakistan. The Pakistan Steel Mill is the country's largest industrial undertaking having a production capacity of 1.1 million tonnes of steel. The enormous dimensions of the project can be visualised from the construction inputs which involved the use of 1.29 million cubic meters of concrete, 5.70 million cubic meters of earth work (second to Tarbela Dam), 330,000 tonnes of machinery, steel structures and electrical equipment. Its unloading and conveyor system at Port Qasim is the third largest in the world and its industrial water reservoir with a capacity of 110 million imperial gallons (500,000 m3) per day is the largest in Asia. A 2.5 km-long sea water channel connects the sea water circulation system to the plant site with a consumption of 216 million imperial gallons (980,000 m3) of sea water per day. However only 18 percent of this capacity is actually in use and the chairman of the mills has requested a government bailout of Rs12 billion to prevent their closure.[1]

History of Pakistan Steel Mills

Main article: Pakistan Council of Scientific and Industrial Research After independence in 1947, it did not take long for Pakistan to come to the realization that progressive industrial and economical development would be impossible without the possession of a self reliant iron and steel making plant. The dependence on imports would cause serious setbacks to the country along with an extortionately high import bill which would be impossible to support. In 1968, the Government of Pakistan decided that the Karachi Steel Project should be sponsored in the public sector, for which a separate Corporation, under the Companies Act, be formed. In pursuance of this decision, Pakistan Steel Mills Corporation Limited was incorporated as a private limited company to establish and run steel mills at Karachi. Pakistan Steel Mills Corporation concluded an agreement with V/o Tyaz Promexport of the USSR in January, 1969 for the preparation of a feasibility report for the establishment of a coastal-based integrated steel mill at Karachi.

[edit] Background

In 1956, M/S Krupp of Germany offered to set up a steel mill based on Kalabagh iron ore, coal and most other minerals available within about 11 miles (18 km). The project was shelved (Mr Z.A Bhutto former Pakistan PM is said to have wanted to take up Pak Steel project for Sindh, based on 100% imported iron ore instead of the local ore at Kalabagh), the Chairman of PIDC, Mr. Ghulam Farooq, resigned. In June 1966, another German company M/S Salzgitter produced in Germany 5,000 tonnes of quality steel from 15,000 tonnes of Kalabagh iron ore in the presence of some international experts, and sold it to Volkswagen. The company offered in August 1967 to set up Kalabagh Steel Mill of over 0.8 million tonnes per year (mtpy) capacity based on Kalabagh iron ore and imported coal at an estimated cost of Rs. 1.542 billion (including foreign exchange cost of Rs. 878 million). Some European banks offered loans for this project,

which confirms technical and financial viability of the project. PIDC selected a site with about 80% raw materials available within 11 miles (18 km). This offer was also shelved.Visits of Chinese and Korean companies' experts to Pakistan (March, 2011) with interest for setting up steel mill at Kalabagh is a proof of its viability.In 1972, Chinese experts found a substantial quantity of iron ore in Nokkundi area of Balochistan. Steel experts from America and Japan confirmed its suitability for steel production and recommended to set up a mini-steel mill in Balochistan. Later on, this ore was found suitable for Pak Steel Mill after upgradation. The News of January 31, 1999 confirmed that offers from China and Iran for a mini-steel mill in Balochistan were under consideration of the government.In April 1968,President General M. Ayub Khan accepted the Russian offer for Kalabagh Steel Mill project, and the next President General Yahya Khan signed the project agreement with Russia. Subsequently, it transpired that Russia did not have the technology to produce steel from the Kalabagh iron ore. Instead of reviving the German offers based on local raw materials, site of the steel mill project was shifted to Karachi and Pak Steel Mill was established with a comparatively inferior machinery, based on 'imported' iron ore and coal.Construction of Pak Steel Mill was commenced at an estimated cost of Rs. 14.287 billion and commissioned at a cost of Rs. 24.7 billion in 1985, with an installed production capacity of 1.1 million tonnes per year (mtpy).On the average, about 70% to 80% of installed production capacity of 1.1 mtpy has been utilized during the last 17 years. The installed machinery is generally blamed for this inefficiency. For comparison, a Brazilian Steel Mill set up in 1956 with Japanese machinery and technology was producing 4.3 million tonnes steel annually with 13,000 employees (Newsweek, November 4, 1991), whereas the Pak Steel Mill commissioned in 1985 produced about 0.75 million tonnes steel in 1991 with 28,000 employees including 4,000 temporary.

[edit] Soviet Contribution to Steel Mill

In January 1971 Pakistan and the USSR signed an agreement under which the latter agreed to provide techno-financial assistance for the construction of a coastal-based integrated steel mill at Karachi. The foundation stone of this vital and gigantic project was laid on 30 December 1973 by the Prime Minister of Pakistan Zulfikar Ali Bhutto. The mammoth construction and erection work of an integrated steel mill, never experienced before in the country, was carried out by a consortium of Pakistani construction companies under the overall supervision of Soviet experts.

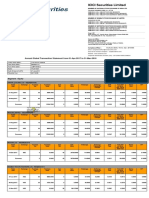

[edit] Corporate Business and Net worth

Pakistan Steel not only had to construct the main production units, but also a host of infrastructure facilities involving unprecedented volumes of work and expertise. Component units of the steel mills numbering over twenty, and each a big enough factory in its own right, were commissioned as they were completed between 1981 to 1985, with the Coke Oven and Byproduct Plant coming on stream first and the Galvanizing Unit last. Commissioning of Blast Furnace No.1 on 14 August 1981 marked Pakistan's entry into the elite club of iron and steel producing nations. The project was completed at a capital cost of Rs.24,700 million. The completion of the steel mill was formally launched by the then-President of Pakistan General Muhammad Zia-ul-Haq on 15 January 1985. Pakistan Steel today is the country's largest industrial undertaking, having a production capacity of 1.1 million tonnes of steel.

[edit] Founders of Pakistan Steel Mills

The real founders of Pakistan Steel Mills are Prof. Dr. Niaz Muhammad, Wahab siddiqui and Russian scientist Mikhail Koltokof. It was the hard work of Niaz Muhammad that thousands of scientists and technical staff got trained by him. His inspirations and innovations got him the highest award from President of Pakistan, and also from Government of USSR. The Government of Pakistan has given him Pride of Performance. He was also nominatd for Nobel prize.

[edit] Location and site

Pakistan Steel is located at a distance of 40 km Southeast of Karachi at Bin Qasim near Port Muhammad Bin Qasim. It was found to be an ecologically preferable location, alongside a tidal creek and having a wind direction away from the city of Karachi. Pakistan Steel is spread out over an area of 18,660 acres (75.5 km2) (about 29 square miles (75 km2)) including 10,390 acres (42 km2) for the main plant, 8,070 acres (33 km2) for the township and 200 acres (0.8 km2) for the 110 MG water reservoir. In addition it has leasehold rights over an area of {convert|7520|acre|km2|0} for the quarries of limestone and dolomite in the Makli and Jhimpir areas of Thatta district.

[edit] Social obligations

Pakistan Steel Mills, besides its core activities, has done a lot in making the environment in and around Pakistan Steel green and beautiful through the addition of three unique projects: the Quaid-I-Azam Park, The Quaid-I-Azam Cricket Park and the Quaid-I-Azam Beach. The QuaidI-Azam Park, which spreads out over an area of 45 acres (0.18 km2), consists of a series of six interconnected lakes, lush green lawns and grassy terraces, colourful flower beds, fountains, lifesize steel-made models of wild and marine animals, a jogging track, a bird sanctuary and minizoo, as well as a children's play and recreational ground and boating facilities. The other unique project, known as the Quaid-I-Azam Cricket Park, has been established amidst the picturesque surroundings of Steel Town, featuring sloping grassy terraces all around for spectators and four diagonally-located hillocks with seating arrangements to provide a panoramic view of the game. This is spread over an area of 32000 sq. meters and is equipped with all the necessary facilities, conforming to international standards. The third project, Quaid-I-Azam Beach, is being developed with the aim to provide a seaside recreational spot to the employees of Pakistan Steel, especially those residing at Steel Town and Gulshan-e-Hadeed. Mohammad Mushaffay Ahmed is majority times elected president of Pakistan steel mills union. Pakistan Steel is also on its way to establish Quaid-I-Azam National Park over a vast area of 400 acres (1.6 km2) adjacent to Steel Town which shall be a tremendous contribution in the development of the environment.[citation needed]. The organisation also has a football team Pakistan Steel FC that currently competes in the Pakistan Premier League.

[edit] Privatisation of Steel Mills

In May 2006,[2] the government of General Musharraf privatised Pakistan Steel Mills. The consortium involving Saudi Arabia-based Al Tuwairqi Group of Companies submitted a winning bid of $362 million for a 75 per cent stake in Pakistan Steel Mills Corporation (PSMC) at an open auction held in Islamabad. the consortium of Saudi Arabia-based Al Tuwairqi Group of Companies, Russia's Magnitogorsk Iron & Steel Works and local firm Arif Habib Securities paid a total Rs21.6 billion ($362 million), or Rs16.8 per share, to take control of Pakistan's largest steel manufacturing plant. [1] Tuwairqi Group of Companies, one of the Ieading business concerns in Saudi Arabia, also launched a $300 million steel mills project at Bin Qasim. The group will set up Tuwairqi Steel Mills (TSM), a state-of-the-art steel-making plant in the southern port city of Gawadar, Pakistan.

[edit] Steel Mills Supreme Case

In order to stop the privatisation which was, in fact, a 'day light robbery' peoples' worker's union of Pakistan Steel filed a petition in the Supreme Court of Pakistan against the privatisation citing irregularities in the process which was accepted by Chief Justice of Pakistan. The verdict was delivered on 8 August 2006.[3] The Supreme Court on 8 August 2006 held that the entire disinvestment process of the Pakistan Steel Mills reflected a haste, ignoring profitability aspect and assets of the mills by the financial adviser before its evaluation. The transaction was the outcome of a process reflecting procedural irregularities, said the 80-page judgement in the PSM case. On 23 June, a nine-member bench of the Supreme Court had annulled the sale of the countrys largest industrial unit to a three-party consortium and had directed the government to refer the matter to the Council of Common Interests within six weeks. It had declared the $362 million transaction with the Russian-Saudi-Pakistan investors as null and void. Authored by Chief Justice of Pakistan Justice Iftikhar Mohammad Chaudhry, the judgement said the entire exercise reflected a haste by the Privatisation Commission (PC) and the Cabinet Committee on Privatisation (CCOP). The PC had processed the 30 March final report of the financial adviser the same day and a meeting of the PC board and a summary had also been prepared the same day when a six week time was mandatory to examine and fix a fair reference price for approval by the CCOP. This unexplained haste casts reasonable doubt on the transparency of the whole exercise and reflects CCOPs disregard towards mandatory rules and materials, essential for arriving at a fair reference price, it maintained. The board had proposed to value the share of the mill at Rs17.43 but it was reduced to Rs16.18 without assigning any reason, the verdict said. The verdict said that keeping in view the annual

net profit of the mill, its shares value should have been ascertained by offering 10 per cent equity of the mills on the stock exchange. A constitutional court would be failing in its duty if it does not interfere to rectify the wrong, more so when valuable assets of the nation are at stake, the judgment said.

You might also like

- List of FMCG Companies in Karachi, Lahore PakistanDocument8 pagesList of FMCG Companies in Karachi, Lahore PakistanNida Mohammad50% (2)

- Multinational Corporations in PKDocument40 pagesMultinational Corporations in PKNadeem75% (51)

- GPA by Seller FormatDocument2 pagesGPA by Seller FormatSaud AnsariNo ratings yet

- 40 Industrial Biggest Groups in PakistanDocument20 pages40 Industrial Biggest Groups in PakistanObaid Rehman50% (2)

- 1 DaewooDocument77 pages1 DaewooAbdullah Afzal100% (1)

- Muntazir OGDCL Internship ReportDocument61 pagesMuntazir OGDCL Internship Reportsyed Muntazir naqvi83% (6)

- Pak Steel MillDocument31 pagesPak Steel Millwasiq Ahmed0% (1)

- Pakistan Steel Mills Annual Report From Superior UniversityDocument8 pagesPakistan Steel Mills Annual Report From Superior UniversityShahbaz Ahmad100% (1)

- Steel Mill Case Study PDFDocument11 pagesSteel Mill Case Study PDFshiz100% (1)

- Pakistan Steel Mills - An IntroductionDocument6 pagesPakistan Steel Mills - An IntroductionVijay Kumar Dodai100% (1)

- Sail ProjectDocument69 pagesSail ProjectBhoomika SrivastavaNo ratings yet

- 2013 Pakistanis Rich List PDFDocument37 pages2013 Pakistanis Rich List PDFSaeed AhmedNo ratings yet

- Pakistan Steel MillDocument8 pagesPakistan Steel MillNadiraHameedNo ratings yet

- List of ACCA Employers: Serial # Company Address-1 Address-2 Address-3 Town Website Approval LevelDocument6 pagesList of ACCA Employers: Serial # Company Address-1 Address-2 Address-3 Town Website Approval LevelchintengoNo ratings yet

- Pharmaceutical Sector of PakistanDocument15 pagesPharmaceutical Sector of PakistanMuhammad Aqeel Ashraf100% (1)

- My Contact List GrowingDocument35 pagesMy Contact List GrowingAli RazaNo ratings yet

- The Following Is The List of Banks in PakistanDocument3 pagesThe Following Is The List of Banks in PakistanSidra AdilNo ratings yet

- Muhammad Aleem Khan: Core CompetenciesDocument4 pagesMuhammad Aleem Khan: Core Competenciesanon_880022946No ratings yet

- Accord Textiles LimitedDocument41 pagesAccord Textiles LimitedSyed Ilyas Raza Shah100% (1)

- Obiz Pakistan (PVT.) LTD.: OgdclDocument3 pagesObiz Pakistan (PVT.) LTD.: OgdclMasood KhanNo ratings yet

- Assistant Director Wildlife 37 K 2019Document1 pageAssistant Director Wildlife 37 K 2019Kamran HashmiNo ratings yet

- Super Asia ProjectDocument18 pagesSuper Asia ProjecthifzamubeenNo ratings yet

- List of Valuators August 30, 2018 Pakistan Banks Association PBA by Asif Sahu 03324346150Document19 pagesList of Valuators August 30, 2018 Pakistan Banks Association PBA by Asif Sahu 03324346150asif sahuNo ratings yet

- Mcdonald Final ProjectDocument36 pagesMcdonald Final ProjectMuhammad FarooqNo ratings yet

- List of Labels Woven in PakistanDocument31 pagesList of Labels Woven in PakistanSayed Aasim JawaidNo ratings yet

- Fatima Fertilizer Company Limited IpoDocument5 pagesFatima Fertilizer Company Limited IpoQasim AliNo ratings yet

- List of NGOs in PakistanDocument34 pagesList of NGOs in PakistanBanaras KhanNo ratings yet

- Supplies of Paper in PakistanDocument9 pagesSupplies of Paper in PakistanHafeez SabirNo ratings yet

- SECP Internship ReportDocument53 pagesSECP Internship ReportKomal Shujaat33% (3)

- PakistanDocument45 pagesPakistanbilalakramkashmiriNo ratings yet

- Karachi HospitalDocument9 pagesKarachi HospitalQaisar NaveedNo ratings yet

- Report On OGDCLDocument47 pagesReport On OGDCLsyed Muntazir naqvi100% (7)

- 500+ CompaniesDocument13 pages500+ CompaniesOsama RizwanNo ratings yet

- List of Companies in PakistanDocument57 pagesList of Companies in PakistanaabdulNo ratings yet

- PAKPLAS Magazine 2018 (Low Res)Document172 pagesPAKPLAS Magazine 2018 (Low Res)Yq GillNo ratings yet

- Pakistan Stock ExchangeDocument41 pagesPakistan Stock ExchangeAdanNo ratings yet

- IT Industry of PakistanDocument54 pagesIT Industry of PakistanAyaz Bhatti100% (1)

- Steel Mils in PakistanDocument9 pagesSteel Mils in Pakistanbestniaz100% (3)

- Pakistan Steel MillsDocument13 pagesPakistan Steel MillsFatiima Tuz ZahraNo ratings yet

- LCCI 2019 (Arrnaged Final Data)Document210 pagesLCCI 2019 (Arrnaged Final Data)Zeeshan Ahmed100% (1)

- EcsDocument4 pagesEcsFraz AhmedNo ratings yet

- HR Managers in PakistanDocument96 pagesHR Managers in Pakistanmurad habibNo ratings yet

- List of Pharmaceutical Industries in Karachi, Pakistan - MediMoonDocument4 pagesList of Pharmaceutical Industries in Karachi, Pakistan - MediMoonowaisNo ratings yet

- List of Hospital ListDocument11 pagesList of Hospital ListNedian Sarfaraz Ahmed ShaikhNo ratings yet

- Pso HRMDocument96 pagesPso HRMraomuhammadkamranNo ratings yet

- Hascol Ipo2016Document46 pagesHascol Ipo2016Rebekah SchmidtNo ratings yet

- Chemical Manufacture and Industries Lahore Sheikhupura RoadDocument6 pagesChemical Manufacture and Industries Lahore Sheikhupura RoadEngr Muhammad Haider AliNo ratings yet

- Pharma CompaniesDocument3 pagesPharma CompaniesKashif AliNo ratings yet

- Audit Firms in FSDDocument3 pagesAudit Firms in FSDUsmän MïrżäNo ratings yet

- My Dawlance Report PDFDocument18 pagesMy Dawlance Report PDFShahzainAkramNo ratings yet

- Pakistan Steel Mills: "An Introduction"Document7 pagesPakistan Steel Mills: "An Introduction"Kamran MalikNo ratings yet

- PSM DraftDocument7 pagesPSM DraftNumairNo ratings yet

- Pakistan Steel Complex Case StudyDocument2 pagesPakistan Steel Complex Case StudyHiya RarhiNo ratings yet

- Pakistan Steel IndustryDocument3 pagesPakistan Steel IndustrySee_star99100% (1)

- Development of Steel Industry of PakistanDocument19 pagesDevelopment of Steel Industry of PakistanAlexander RaoNo ratings yet

- Pakistan Steel Mill The UNITY......Document8 pagesPakistan Steel Mill The UNITY......Fizza DollNo ratings yet

- 12 - Chapter 3 PDFDocument20 pages12 - Chapter 3 PDFkathirNo ratings yet

- Internship Report Pakistan Steel MillDocument57 pagesInternship Report Pakistan Steel MillJahanzaib Awan67% (3)

- Pakistan Steel Mills Corporation (PVT.) LimitedDocument2 pagesPakistan Steel Mills Corporation (PVT.) LimitedKhan ShahNo ratings yet

- Steel Industry After Pakistan IndependenceDocument13 pagesSteel Industry After Pakistan IndependenceHarris LodhiNo ratings yet

- Wikipedia OrgDocument6 pagesWikipedia OrgPrasadNo ratings yet

- ICICI Securities Limited: Annual Global Transaction Statement From 01-Apr-2017 To 31-Mar-2018Document5 pagesICICI Securities Limited: Annual Global Transaction Statement From 01-Apr-2017 To 31-Mar-2018Vijaykumar D SNo ratings yet

- 6-5 WebSphere MQ Adapter Install and Users GuideDocument218 pages6-5 WebSphere MQ Adapter Install and Users GuideAnubha AgarwalNo ratings yet

- Chapter 11 Sources of CapitalDocument32 pagesChapter 11 Sources of Capitalmkahnum12No ratings yet

- Online Store Using E-Commerce and Database Design and ImplementationDocument21 pagesOnline Store Using E-Commerce and Database Design and ImplementationParth PawarNo ratings yet

- Gary Mcbride: Hello Everyone. My Name'S Gary McbrideDocument2 pagesGary Mcbride: Hello Everyone. My Name'S Gary McbrideThúy ViNo ratings yet

- Managing The Urban EnvironmentDocument10 pagesManaging The Urban EnvironmentM Navneeth RoyNo ratings yet

- 6 Sales Pitch ExamplesDocument13 pages6 Sales Pitch ExamplesEmmanuel AkoloNo ratings yet

- Q Part 4Document10 pagesQ Part 4kajkargroupNo ratings yet

- Safety Pre-Construction Meeting GKS .Document66 pagesSafety Pre-Construction Meeting GKS .ce.rashed12No ratings yet

- Division 1 - Duties of Owners, Tenants, Occupants and Visitors 1. Payment of Strata FeesDocument17 pagesDivision 1 - Duties of Owners, Tenants, Occupants and Visitors 1. Payment of Strata FeesPritish TandonNo ratings yet

- Endole Company Report - 09519832Document31 pagesEndole Company Report - 09519832lchenhan94No ratings yet

- The Main Focuses of The Chapter Are:: by Bereket SDocument33 pagesThe Main Focuses of The Chapter Are:: by Bereket SGetnete degemuNo ratings yet

- BMA 3201 - Strategic Tax Management - EditedDocument10 pagesBMA 3201 - Strategic Tax Management - EditedMark Dave YuNo ratings yet

- Defining A Product and Differentiating Product, Services, and ExperiencesDocument4 pagesDefining A Product and Differentiating Product, Services, and ExperiencesYvearyyNo ratings yet

- Investor Perspective On The CMO Industry - v8 (No POBOS)Document26 pagesInvestor Perspective On The CMO Industry - v8 (No POBOS)chandel08No ratings yet

- B737NGWBT1T2L1Document9 pagesB737NGWBT1T2L1MedaNo ratings yet

- Esd Module PDFDocument100 pagesEsd Module PDFkeith Nkala0% (1)

- GC Return PolicyDocument3 pagesGC Return PolicyAli AnbaaNo ratings yet

- Glossary of Abbreviations of Report No 5 of 2017 - Public Sector Undertakings Government of Tamil NaduDocument4 pagesGlossary of Abbreviations of Report No 5 of 2017 - Public Sector Undertakings Government of Tamil Nadumohamedali tharvesh maideenNo ratings yet

- Prepaway TestDocument40 pagesPrepaway TestmamoudNo ratings yet

- Driving The Global Cannabis Industry: February 2019Document22 pagesDriving The Global Cannabis Industry: February 2019Sameer MahomedNo ratings yet

- FinMan Assign. No. 6 - IndividualDocument5 pagesFinMan Assign. No. 6 - IndividualKristine Nitzkie SalazarNo ratings yet

- Nikhil KanthDocument76 pagesNikhil Kanthharpreet singh100% (1)

- ASM2-Security-Nguyen Huu LoiDocument28 pagesASM2-Security-Nguyen Huu LoiNguyễn Hữu LợiNo ratings yet

- DIGESTDocument9 pagesDIGESTNhaz PasandalanNo ratings yet

- Roadrunner CaseDocument7 pagesRoadrunner CasephuongvietngoNo ratings yet

- Chapter 4 - Marketing Organization For EggsDocument4 pagesChapter 4 - Marketing Organization For EggsTest OneNo ratings yet

- BPCL2Document44 pagesBPCL2pgpm2024.asafNo ratings yet

- Economics AssignmentDocument18 pagesEconomics AssignmentmanjarisirohiNo ratings yet